connecting tft lcd to arduino manufacturer

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

In this Arduino touch screen tutorial we will learn how to use TFT LCD Touch Screen with Arduino. You can watch the following video or read the written tutorial below.

For this tutorial I composed three examples. The first example is distance measurement using ultrasonic sensor. The output from the sensor, or the distance is printed on the screen and using the touch screen we can select the units, either centimeters or inches.

The next example is controlling an RGB LED using these three RGB sliders. For example if we start to slide the blue slider, the LED will light up in blue and increase the light as we would go to the maximum value. So the sliders can move from 0 to 255 and with their combination we can set any color to the RGB LED, but just keep in mind that the LED cannot represent the colors that much accurate.

The third example is a game. Actually it’s a replica of the popular Flappy Bird game for smartphones. We can play the game using the push button or even using the touch screen itself.

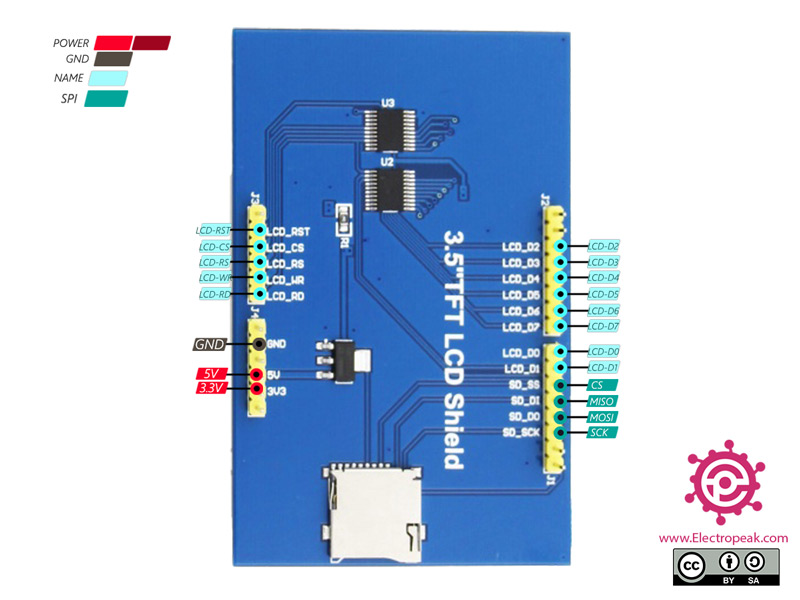

As an example I am using a 3.2” TFT Touch Screen in a combination with a TFT LCD Arduino Mega Shield. We need a shield because the TFT Touch screen works at 3.3V and the Arduino Mega outputs are 5 V. For the first example I have the HC-SR04 ultrasonic sensor, then for the second example an RGB LED with three resistors and a push button for the game example. Also I had to make a custom made pin header like this, by soldering pin headers and bend on of them so I could insert them in between the Arduino Board and the TFT Shield.

Here’s the circuit schematic. We will use the GND pin, the digital pins from 8 to 13, as well as the pin number 14. As the 5V pins are already used by the TFT Screen I will use the pin number 13 as VCC, by setting it right away high in the setup section of code.

I will use the UTFT and URTouch libraries made by Henning Karlsen. Here I would like to say thanks to him for the incredible work he has done. The libraries enable really easy use of the TFT Screens, and they work with many different TFT screens sizes, shields and controllers. You can download these libraries from his website, RinkyDinkElectronics.com and also find a lot of demo examples and detailed documentation of how to use them.

After we include the libraries we need to create UTFT and URTouch objects. The parameters of these objects depends on the model of the TFT Screen and Shield and these details can be also found in the documentation of the libraries.

Next we need to define the fonts that are coming with the libraries and also define some variables needed for the program. In the setup section we need to initiate the screen and the touch, define the pin modes for the connected sensor, the led and the button, and initially call the drawHomeSreen() custom function, which will draw the home screen of the program.

So now I will explain how we can make the home screen of the program. With the setBackColor() function we need to set the background color of the text, black one in our case. Then we need to set the color to white, set the big font and using the print() function, we will print the string “Arduino TFT Tutorial” at the center of the screen and 10 pixels down the Y – Axis of the screen. Next we will set the color to red and draw the red line below the text. After that we need to set the color back to white, and print the two other strings, “by HowToMechatronics.com” using the small font and “Select Example” using the big font.

Next is the distance sensor button. First we need to set the color and then using the fillRoundRect() function we will draw the rounded rectangle. Then we will set the color back to white and using the drawRoundRect() function we will draw another rounded rectangle on top of the previous one, but this one will be without a fill so the overall appearance of the button looks like it has a frame. On top of the button we will print the text using the big font and the same background color as the fill of the button. The same procedure goes for the two other buttons.

Now we need to make the buttons functional so that when we press them they would send us to the appropriate example. In the setup section we set the character ‘0’ to the currentPage variable, which will indicate that we are at the home screen. So if that’s true, and if we press on the screen this if statement would become true and using these lines here we will get the X and Y coordinates where the screen has been pressed. If that’s the area that covers the first button we will call the drawDistanceSensor() custom function which will activate the distance sensor example. Also we will set the character ‘1’ to the variable currentPage which will indicate that we are at the first example. The drawFrame() custom function is used for highlighting the button when it’s pressed. The same procedure goes for the two other buttons.

getDistance(); // Gets distance from the sensor and this function is repeatedly called while we are at the first example in order to print the lasest results from the distance sensor

So the drawDistanceSensor() custom function needs to be called only once when the button is pressed in order to draw all the graphics of this example in similar way as we described for the home screen. However, the getDistance() custom function needs to be called repeatedly in order to print the latest results of the distance measured by the sensor.

Here’s that function which uses the ultrasonic sensor to calculate the distance and print the values with SevenSegNum font in green color, either in centimeters or inches. If you need more details how the ultrasonic sensor works you can check my particular tutorialfor that. Back in the loop section we can see what happens when we press the select unit buttons as well as the back button.

Ok next is the RGB LED Control example. If we press the second button, the drawLedControl() custom function will be called only once for drawing the graphic of that example and the setLedColor() custom function will be repeatedly called. In this function we use the touch screen to set the values of the 3 sliders from 0 to 255. With the if statements we confine the area of each slider and get the X value of the slider. So the values of the X coordinate of each slider are from 38 to 310 pixels and we need to map these values into values from 0 to 255 which will be used as a PWM signal for lighting up the LED. If you need more details how the RGB LED works you can check my particular tutorialfor that. The rest of the code in this custom function is for drawing the sliders. Back in the loop section we only have the back button which also turns off the LED when pressed.

In order the code to work and compile you will have to include an addition “.c” file in the same directory with the Arduino sketch. This file is for the third game example and it’s a bitmap of the bird. For more details how this part of the code work you can check my particular tutorial. Here you can download that file:

getDistance(); // Gets distance from the sensor and this function is repeatedly called while we are at the first example in order to print the lasest results from the distance sensor

No! For about the price of a familiar 2x16 LCD, you get a high resolution TFT display. For as low as $4 (shipping included!), it"s possible to buy a small, sharp TFT screen that can be interfaced with an Arduino. Moreover, it can display not just text, but elaborate graphics. These have been manufactured in the tens of millions for cell phones and other gadgets and devices, and that is the reason they are so cheap now. This makes it feasible to reuse them to give our electronic projects colorful graphic displays.

There are quite a number of small cheap TFT displays available on eBay and elsewhere. But, how is it possible to determine which ones will work with an Arduino? And what then? Here is the procedure:ID the display. With luck, it will have identifying information printed on it. Otherwise, it may involve matching its appearance with a picture on Google images. Determine the display"s resolution and the driver chip.

Find out whether there is an Arduino driver available. Google is your friend here. Henning Karlsen"s UTFT library works with many displays. (http://www.rinkydinkelectronics.com/library.php?i...)

Download and install the driver library. On a Linux machine, as root, copy the library archive file to the /usr/share/arduino/libraries directory and untar or unzip it.

Load an example sketch into the Arduino IDE, and then upload it to the attached Arduino board with wired-up TFT display. With luck, you will see text and/or graphics.

For prototyping and testing:A solderless breadboard male-to-male jumpers male-to-female jumpers 22 gauge insulated hookup wire, solid Graph paper, for planning and sketching wiring diagrams and layouts

We"ll begin with a simple one. The ILI9163 display has a resolution of 128 x 128 pixels. With 8 pins in a single row, it works fine with a standard Arduino UNO or with a Mega. The hardware hookup is simple -- only 8 connections total! The library put together by a smart fella, by the name of sumotoy, makes it possible to display text in multiple colors and to draw lines.

Note that these come in two varieties, red and black. The red ones may need a bit of tweaking to format the display correctly -- see the comments in the README.md file. The TFT_ILI9163C.h file might need to be edited.

It is 5-volt friendly, since there is a 74HC450 IC on the circuit board that functions as a level shifter. These can be obtained for just a few bucks on eBay and elsewhere, for example -- $3.56 delivered from China. It uses Henning Karlsen"s UTFT library, and it does a fine job with text and graphics. Note that due to the memory requirement of UTFT, this display will work with a standard UNO only with extensive tweaking -- it would be necessary to delete pretty much all the graphics in the sketch, and just stay with text.

on the far side of the display. It has 220x176 resolution (hires!) and will accept either 3.3 or 5 volts. It will work hooked up to an Uno, and with a few pin changes, also with a Mega. The 11-pin row is for activating the display itself, and the 5-pin row for the SD socket on its back.

This one is a 2.2" (diagonal) display with 176x220 resolution and parallel interface. It has a standard ("Intel 8080") parallel interface, and works in both 8-bit and 16-bit modes. It uses the S6D0164 driver in Henning Karlsen"s UTFT library, and because of the memory requirements of same, works only with an Arduino Mega or Due. It has an SD card slot on its back

This one is a bit of an oddball. It"s a clone of the more common HY-TFT240, and it has two rows of pins, set at right angles to one another. To enable the display in 8-bit mode, only the row of pins along the narrow edge is used. The other row is for the SD card socket on the back, and for 16-bit mode. To interface with an Arduino ( Mega or Due), it uses Henning Karlsen"s UTFT library, and the driver is ILI9325C. Its resolution is 320x240 (hires!) and it incorporates both a touch screen and an SD card slot.

Having determined that a particular TFT display will work with the Arduino, it"s time to think about a more permanent solution -- constructing hard-wired and soldered plug-in boards. To make things easier, start with a blank protoshield as a base, and add sockets for the TFT displays to plug into. Each socket row will have a corresponding row next to it, with each individual hole "twinned" to the adjacent hole in the adjoining row by solder bridges, making them accessible to jumpers to connect to appropriate Arduino pins. An alternative is hard-wiring the socket pins to the Arduino pins, which is neater but limits the versatility of the board.

The key to an effective DIY shield is a neat and logical layout. Sketching the prospective shield on quadrille (graph) paper may be helpful. A multitester or continuity tester might be useful for detecting wiring and soldering errors.

In step 5, you mention that the TFT01 display can"t be used with the UTFT library on an Arduino Uno because of its memory requirements. It can - all you have to do is edit memorysaver.h and disable any display models you"re not using.

I think you should add a disclaimer that the code might make the Arduino Uno unprogrammable afterward (due to use up the two 0 and 1 pin) and link to how to fix it: https://stackoverflow.com/questions/5290428/how-to-reset-an-arduino-board/8453576?sfb=2#84535760

Not at all - it was your Instructable that got me going with the display to begin with! We all build off each other"s work, to the benefit of everyone.0

Tho I realize this is quickly becoming legacy hardware, these 8,16 bit parallel spi with 4 wire controller 3.2in Taft touch display 240x380. It has become very inexpensive with ally of back stock world wide so incorporating them into any project is easier then ever. Sorry to my question. I’m having difficulty finding wiring solution for this lcd. It is a sd1289 3.3 and 5v ,40 pin parallel 8,16 bit. I do not want to use a extra shield,hat or cape or adapter. But there’s a lot of conflicting info about required lvl shifters for this model any help or links to info would be great .. thank you. I hope I gave enough information to understand what I’m adoing

#1 you need a data sheet for the display and pinout and the i/o board attached to the cable.Than before you buy check for a driver for this chip Raydium/RM69071.if no driver lib are you able to write one and do you have the necessary tools to work on this scale to wire it up ..if you answer no than search for an arduino ready product.WCH0

hooking up and adding a lib is no piece of cake insure the screen you buy is arduino ready and sold by a reputable shop with step by step directions...WCH0

I"m sorry that I can"t help you with this. You"ll have to do your own research. See if you can identify the chipset and find out if there"s an Arduino driver for it.0

Thanks for the wealth of knowledge! It is amazing at what is possible with items the average person can easily acquire. I hope to put some of your tips to use this winter as I would like to build sensors and other items for home automation and monitoring. Being able to have small displays around the house in addition to gathering and controlling things remotely will help the family see room conditions without going to the computer. The idea of a touchscreen control for cheap is mind blowing.

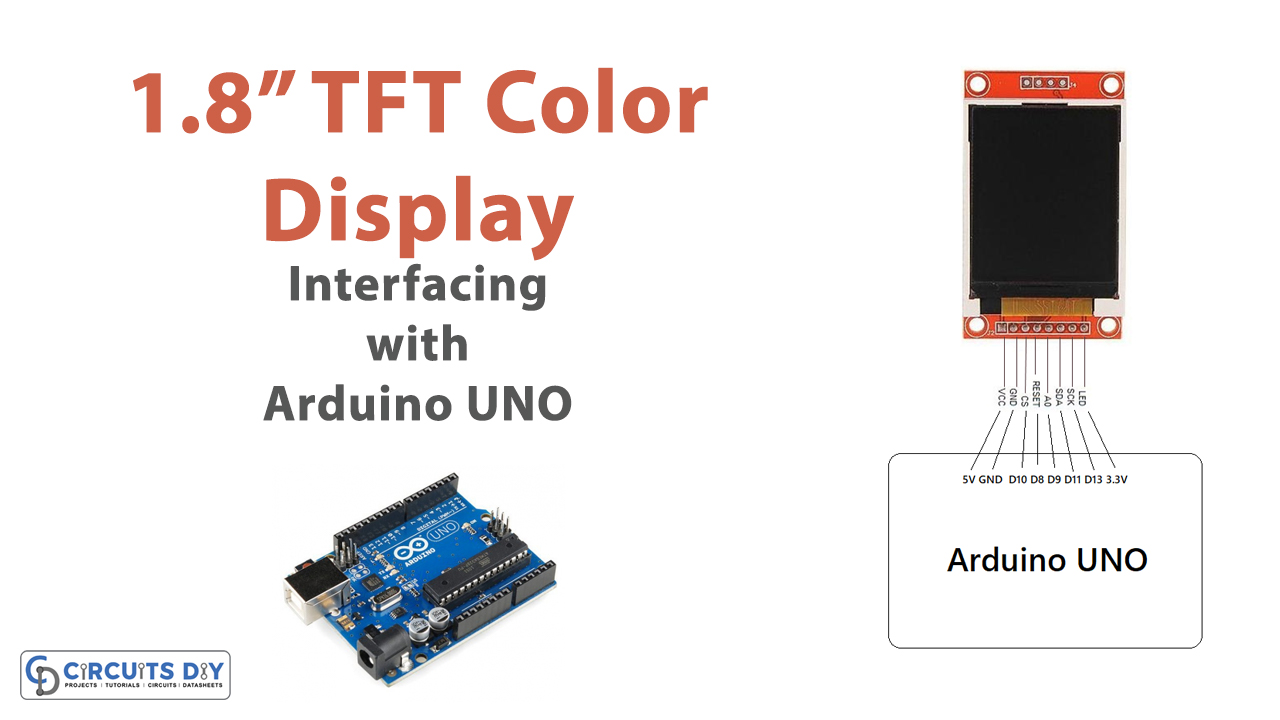

In this guide we’re going to show you how you can use the 1.8 TFT display with the Arduino. You’ll learn how to wire the display, write text, draw shapes and display images on the screen.

The 1.8 TFT is a colorful display with 128 x 160 color pixels. The display can load images from an SD card – it has an SD card slot at the back. The following figure shows the screen front and back view.

This module uses SPI communication – see the wiring below . To control the display we’ll use the TFT library, which is already included with Arduino IDE 1.0.5 and later.

The TFT display communicates with the Arduino via SPI communication, so you need to include the SPI library on your code. We also use the TFT library to write and draw on the display.

In which “Hello, World!” is the text you want to display and the (x, y) coordinate is the location where you want to start display text on the screen.

The 1.8 TFT display can load images from the SD card. To read from the SD card you use the SD library, already included in the Arduino IDE software. Follow the next steps to display an image on the display:

Note: some people find issues with this display when trying to read from the SD card. We don’t know why that happens. In fact, we tested a couple of times and it worked well, and then, when we were about to record to show you the final result, the display didn’t recognized the SD card anymore – we’re not sure if it’s a problem with the SD card holder that doesn’t establish a proper connection with the SD card. However, we are sure these instructions work, because we’ve tested them.

In this guide we’ve shown you how to use the 1.8 TFT display with the Arduino: display text, draw shapes and display images. You can easily add a nice visual interface to your projects using this display.

You can hook up the "Adafruit_ST7735" or from what i later learned after getting my Esplora. Thats when i had my adruino-epiphany. Okay so IF your wondering why im including this super rad Controller shaped arduino, the answer is, its a leonardo. well its just a different flavor of the Atmega32u4 whis is the chip that made ext serial programmers kinda obsolete and makes the uno and megas so unique as well. so with that being said the Esplora has a native language when refering back the tft libraries, but its not too far from a simple (ctrl+F) and replace Esplora references with actual defines and references. and in this case the Leonardo would need to have the icsp header used by the corresponding pins on the display (for this instance of using an SPI connection with the serial display we will not swap the Miso and Mosi like we would a nother instance.just connect miso to miso and mosi to mosi i usually plug up the whole icsp header and then that wwill leave you with the two pins you MUST DEFINE to make it work which would be :

but the point i had to bring up is that i believe the guy before mentioned that it is a muchslower connectionor process than if it were.....were you saying softwareserial was the option then?

because im not an explert or novice or maker by any means. but i have picked up along the lines that hardware serial will always trump software serial compilation any day once you get your head wrapped around the brevity of what ports and pins are actually what are used or have the data displayed on the serial ports. and like software is a necessity im afraid, but its as simple as reasigning pins and when that gets too hard going out and just bbuying a mega, haahah hope i sorta helped. id say go out and snag an esplora whilst their like toing a fire clearance sale on the originallt 50$+ boards. but their reference and prebuilt array of sensors is a bit underwhelming for the newbies in what it alll does, but kinda overwhelmine and difficult to transistion onece having looked at some code as it is, but the language is more forg9ving, but i believe their also officially retiring the leonardo espolora and micro series so good luck this tft display kicks bum man and is the only one that hsnt broke

A-Z Guide to Interfacing TFT LCD Displays W/ Arduino: In this article, you will learn how to use TFT LCDs by Arduino boards. From basic commands to professional designs and tech…

Hi guys, welcome to today’s tutorial. Today, we will look on how to use the 1.8″ ST7735 colored TFT display with Arduino. The past few tutorials have been focused on how to use the Nokia 5110 LCD display extensively but there will be a time when we will need to use a colored display or something bigger with additional features, that’s where the 1.8″ ST7735 TFT display comes in.

The ST7735 TFT display is a 1.8″ display with a resolution of 128×160 pixels and can display a wide range of colors ( full 18-bit color, 262,144 shades!). The display uses the SPI protocol for communication and has its own pixel-addressable frame buffer which means it can be used with all kinds of microcontroller and you only need 4 i/o pins. To complement the display, it also comes with an SD card slot on which colored bitmaps can be loaded and easily displayed on the screen.

The schematics for this project is fairly easy as the only thing we will be connecting to the Arduino is the display. Connect the display to the Arduino as shown in the schematics below.

Due to variation in display pin out from different manufacturers and for clarity, the pin connection between the Arduino and the TFT display is mapped out below:

We will use two libraries from Adafruit to help us easily communicate with the LCD. The libraries include the Adafruit GFX library which can be downloaded here and the Adafruit ST7735 Library which can be downloaded here.

We will use two example sketches to demonstrate the use of the ST7735 TFT display. The first example is the lightweight TFT Display text example sketch from the Adafruit TFT examples. It can be accessed by going to examples -> TFT -> Arduino -> TFTDisplaytext. This example displays the analog value of pin A0 on the display. It is one of the easiest examples that can be used to demonstrate the ability of this display.

The second example is the graphics test example from the more capable and heavier Adafruit ST7735 Arduino library. I will explain this particular example as it features the use of the display for diverse purposes including the display of text and “animated” graphics. With the Adafruit ST7735 library installed, this example can be accessed by going to examples -> Adafruit ST7735 library -> graphics test.

The first thing, as usual, is to include the libraries to be used after which we declare the pins on the Arduino to which our LCD pins are connected to. We also make a slight change to the code setting reset pin as pin 8 and DC pin as pin 9 to match our schematics.

Next, we create an object of the library with the pins to which the LCD is connected on the Arduino as parameters. There are two options for this, feel free to choose the most preferred.

Next, we move to the void setup function where we initialize the screen and call different test functions to display certain texts or images. These functions can be edited to display what you want based on your project needs.

testdrawtext("Lorem ipsum dolor sit amet, consectetur adipiscing elit. Curabitur adipiscing ante sed nibh tincidunt feugiat. Maecenas enim massa, fringilla sed malesuada et, malesuada sit amet turpis. Sed porttitor neque ut ante pretium vitae malesuada nunc bibendum. Nullam aliquet ultrices massa eu hendrerit. Ut sed nisi lorem. In vestibulum purus a tortor imperdiet posuere. ", ST7735_WHITE);

All the functions called under the void setup function, perform different functions, some draw lines, some, boxes and text with different font, color and size and they can all be edited to do what your project needs.

The complete code for this is available under the libraries example on the Arduino IDE. Don’t forget to change the DC and the RESET pin configuration in the code to match the schematics.

Uploading the code to the Arduino board brings a flash of different shapes and text with different colors on the display. I captured one and its shown in the image below.

That’s it for this tutorial guys, what interesting thing are you going to build with this display? Let’s get the conversation started. Feel free to reach me via the comment section if you have any questions as regards this project.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

In this article, you will learn how to use TFT LCDs by Arduino boards. From basic commands to professional designs and technics are all explained here.

There are several components to achieve this. LEDs, 7-segments, Character and Graphic displays, and full-color TFT LCDs. The right component for your projects depends on the amount of data to be displayed, type of user interaction, and processor capacity.

TFT LCD is a variant of a liquid-crystal display (LCD) that uses thin-film-transistor (TFT) technology to improve image qualities such as addressability and contrast. A TFT LCD is an active matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven LCDs with a few segments.

In Arduino-based projects, the processor frequency is low. So it is not possible to display complex, high definition images and high-speed motions. Therefore, full-color TFT LCDs can only be used to display simple data and commands.

In this article, we have used libraries and advanced technics to display data, charts, menu, etc. with a professional design. This can move your project presentation to a higher level.

There are several components to achieve this. LEDs, 7-segments, Character and Graphic displays, and full-color TFT LCDs. The right component for your projects depends on the amount of data to be displayed, type of user interaction, and processor capacity.

TFT LCD is a variant of a liquid-crystal display (LCD) that uses thin-film-transistor (TFT) technology to improve image qualities such as addressability and contrast. A TFT LCD is an active matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven LCDs with a few segments.

In Arduino-based projects, the processor frequency is low. So it is not possible to display complex, high definition images and high-speed motions. Therefore, full-color TFT LCDs can only be used to display simple data and commands.

In this article, we have used libraries and advanced technics to display data, charts, menu, etc. with a professional design. This can move your project presentation to a higher level.

Size of displays affects your project parameters. Bigger Display is not always better. if you want to display high-resolution images and signs, you should choose a big size display with higher resolution. But it decreases the speed of your processing, needs more space and also needs more current to run.

After choosing the right display, It’s time to choose the right controller. If you want to display characters, tests, numbers and static images and the speed of display is not important, the Atmega328 Arduino boards (such as Arduino UNO) are a proper choice. If the size of your code is big, The UNO board may not be enough. You can use Arduino Mega2560 instead. And if you want to show high resolution images and motions with high speed, you should use the ARM core Arduino boards such as Arduino DUE.

In electronics/computer hardware a display driver is usually a semiconductor integrated circuit (but may alternatively comprise a state machine made of discrete logic and other components) which provides an interface function between a microprocessor, microcontroller, ASIC or general-purpose peripheral interface and a particular type of display device, e.g. LCD, LED, OLED, ePaper, CRT, Vacuum fluorescent or Nixie.

The display driver will typically accept commands and data using an industry-standard general-purpose serial or parallel interface, such as TTL, CMOS, RS232, SPI, I2C, etc. and generate signals with suitable voltage, current, timing and demultiplexing to make the display show the desired text or image.

The LCDs manufacturers use different drivers in their products. Some of them are more popular and some of them are very unknown. To run your display easily, you should use Arduino LCDs libraries and add them to your code. Otherwise running the display may be very difficult. There are many free libraries you can find on the internet but the important point about the libraries is their compatibility with the LCD’s driver. The driver of your LCD must be known by your library. In this article, we use the Adafruit GFX library and MCUFRIEND KBV library and example codes. You can download them from the following links.

You must add the library and then upload the code. If it is the first time you run an Arduino board, don’t worry. Just follow these steps:Go to www.arduino.cc/en/Main/Software and download the software of your OS. Install the IDE software as instructed.

By these two functions, You can find out the resolution of the display. Just add them to the code and put the outputs in a uint16_t variable. Then read it from the Serial port by Serial.println(); . First add Serial.begin(9600); in setup().

First you should convert your image to hex code. Download the software from the following link. if you don’t want to change the settings of the software, you must invert the color of the image and make the image horizontally mirrored and rotate it 90 degrees counterclockwise. Now add it to the software and convert it. Open the exported file and copy the hex code to Arduino IDE. x and y are locations of the image. sx and sy are sizes of image. you can change the color of the image in the last input.

Upload your image and download the converted file that the UTFT libraries can process. Now copy the hex code to Arduino IDE. x and y are locations of the image. sx and sy are size of the image.

In this template, We just used a string and 8 filled circles that change their colors in order. To draw circles around a static point ,You can use sin(); and cos(); functions. you should define the PI number . To change colors, you can use color565(); function and replace your RGB code.

In this template, We converted a .jpg image to .c file and added to the code, wrote a string and used the fade code to display. Then we used scroll code to move the screen left. Download the .h file and add it to the folder of the Arduino sketch.

In this template, We used sin(); and cos(); functions to draw Arcs with our desired thickness and displayed number by text printing function. Then we converted an image to hex code and added them to the code and displayed the image by bitmap function. Then we used draw lines function to change the style of the image. Download the .h file and add it to the folder of the Arduino sketch.

In this template, We added a converted image to code and then used two black and white arcs to create the pointer of volumes. Download the .h file and add it to the folder of the Arduino sketch.

In this template, We added a converted image and use the arc and print function to create this gauge. Download the .h file and add it to folder of the Arduino sketch.

while (a < b) { Serial.println(a); j = 80 * (sin(PI * a / 2000)); i = 80 * (cos(PI * a / 2000)); j2 = 50 * (sin(PI * a / 2000)); i2 = 50 * (cos(PI * a / 2000)); tft.drawLine(i2 + 235, j2 + 169, i + 235, j + 169, tft.color565(0, 255, 255)); tft.fillRect(200, 153, 75, 33, 0x0000); tft.setTextSize(3); tft.setTextColor(0xffff); if ((a/20)>99)

while (b < a) { j = 80 * (sin(PI * a / 2000)); i = 80 * (cos(PI * a / 2000)); j2 = 50 * (sin(PI * a / 2000)); i2 = 50 * (cos(PI * a / 2000)); tft.drawLine(i2 + 235, j2 + 169, i + 235, j + 169, tft.color565(0, 0, 0)); tft.fillRect(200, 153, 75, 33, 0x0000); tft.setTextSize(3); tft.setTextColor(0xffff); if ((a/20)>99)

In this template, We display simple images one after each other very fast by bitmap function. So you can make your animation by this trick. Download the .h file and add it to folder of the Arduino sketch.

In this template, We just display some images by RGBbitmap and bitmap functions. Just make a code for touchscreen and use this template. Download the .h file and add it to folder of the Arduino sketch.

TFT LCD screens combined with Human Machine Interface (HMI) technology result in exciting project ideas applicable to a wide variety of industries. STONE HMI TFT LCD Arduino project ideas. After all, HMI is a smart technology that uses touch to draw out information from both the human user and the display machine.

And when high-quality display screen modules such as STONE Tech’s TFT LCD products are laden with HMI technology, the result is outstanding machine performance capable of bringing out the best in every customer and business.

Now, this article will feature STONE HMI. Furthermore, we will also present some exciting project development initiatives carried out by the company using its vast range of TFT LCD modules paired with HMI technology, and the TFT LCD Arduino project.

Human Machine Interface (HMI) is an interface or dashboard that lets human users interact with a machine. HMI allows users to monitor and control a machine through the use of different touch technologies.

The interface with which HMI works consists of both hardware and software. These two work together to let users input signals using direct or indirect touch (such as by using a special screen stylus) on the machine display. Once the touch signals have been inputted, the machine recognizes them and sends them to the software to begin interpretation. The machine then responds by showing the desired information to the human user.

Information that a user can get from an HMI machine greatly varies depending on the setting with which the machine is used. Here are some examples of common HMI machines and the data it presents to its daily users:

Medical equipment in hospital settings uses HMI to display pertinent information regarding a patient. For instance, a ventilator machine can display data such as vital signs and a selection of possible breathing patterns for the patient. It can also alert medical practitioners when there is a problem with the patient or the machine through alarms and sounds.

Another HMI machine used in daily life is the car dashboard. An on-board car control panel using an intelligent touch screen can be used to display important car information like speed, gas levels, and time. The screen dashboard can also be used to toggle many functions like turning the AC and beam on or off using a single touch.

HMIs are user-friendly by nature. Graphics and colors can easily be added to the display to communicate with the end-users. Any problems arising from the HMI screen can also be detected easily using color codes, alarms, and sounds. Furthermore, you’ll need only a few touches to fix any issues detected by an HMI device.

HMI greatly improves productivity when used in industrial settings. These interactive screens and machines help automate several tasks. While these tasks could be carried out by a human worker, using an HMI machine gets the job done in less time, translating to more work finished by the day’s end.

Several HMI machines have the innate ability to record data. This is especially useful in adjusting machine settings or troubleshooting any mechanical issues. Automatic data gathering can be programmed into the HMI software, allowing the machine’s screen and hardware to capture data through a series of commands.

Using HMI machines in workplaces such as factories and corporate offices increases worker satisfaction. This is because the HMI technology allows workers to interact easily with the machine, automating some of their work and providing them more efficiency.

What makes HMI a good choice for industrial use is that it is fully flexible and customizable to fit several industrial needs. The TFT LCD screen sizes can be tailor-made to suit the HMI’s application. Furthermore, the software that comes with the machines can be adjusted as well.

Another exciting opportunity for HMIs is their ability to connect with the Internet, much like an Internet of Things (IoT) device. This allows greater opportunities for productivity such as remote controlling and network monitoring.

STONE Technologies is a proud manufacturer of superior quality TFT LCD modules and LCD screens. The company also provides intelligent HMI solutions that perfectly fit in with its excellent hardware offerings.

There is also a downloadable design software called STONE Designer. This is a completely free GUI design software you can use to create responsive digital module-ready user interfaces.

STONE TFT LCD modules come with a microcontroller unit that has a cortex-m4 32-bit CPU. Such a module can easily be transformed into an HMI screen. Simple hexadecimal instructions can be used to control the module through the UART port. Furthermore, you can seamlessly develop STONE TFT LCD color user interface modules and add touch control, features to it.

You can also use a peripheral MCU to serially connect STONE’s HMI display via TTL. This way, your HMI display can supply event notifications and the peripheral MCU can then execute them. Moreover, this TTL-connected HMI display can further be linked to microcontrollers such as:

Each customizable TFT-LCD HMI display module comes with free access to STONE’s dedicated design software. STONE TOOLBox software is an easy-to-use program that allows you to set up graphical user interface functions such as:

STONE TOOLBox features a drag-and-drop mechanism and comes with simple instructions. Hence, even beginning engineers can quickly and seamlessly create an impressive user interface within minutes.

Intricate and intuitive interfaces will require a bit more steps. Nevertheless, using the TOOLBox program allows you to save time on developing HMI projects due to its ease of use.

HMI projects can quickly be done with Stone’s HMI-ready display modules. As previously mentioned, STONEprovides complete modules that include hardware and a free downloadable GUI design software – everything you need to get started on your HMI concept.

With faster project timelines comes greater production savings. Stone’s modules are cost-effective and since they have superior quality, you’re assured of a quick return on investment (ROI) with fewer costs on maintenance and repairs in the long run.

STONE creates modules that are easy to assemble if you’re doing an HMI project. Add to that its user-friendly GUI software that lets you seamlessly create GUIs for your new HMI device.

Also, STONE manufactures several TFT LCD touch screen sizes that range from 3.5 to 15.1 inches. Customized options are also available depending on your needs. There are also plenty of options and models for each screen size.

Indeed, STONE produces a plethora of HMI-ready TFT LCD screens. You won’t have a hard time finding the right display module compatible with your microcontroller projects.

Over the years, Stone’s modules have been used to create numerous projects featuring its reputable HMI technology. These project ideas cater to a wide variety of fields and industries.

STONE developed an oxygen monitor for an Italian customer. The monitor uses Stone’s 7-inch TFT LCD screen and was connected to an oxygen tank for medical use.

The finished product displays information about the connected oxygen tank such as concentration levels and other advanced data. All these data are displayed on a streamlined interface developed using TOOLBox software.

Communication between the module and the device was established via an MCU connected to a serial port. The device also used the UART interface and TTL.

The end-product featured a touch screen display where fan functions such as speed, dose, and RF are controlled. Moreover, the resulting fan control board can operate at temperatures ranging from -20°C to 70°C, making it a simple yet heavy-duty device.

STONE’s display screen was connected to the Arduino development board through UART. But this required a level conversion achieved by the MAX3232. Meanwhile, the same Arduino board was wired to the MAX30100 module through an IIC interface.

Some modifications to the MAX30100 module were made, specifically to the IIC pull-up resistor. The remainder of the project was finished using Arduino codes to finally create a responsive display for heart rate and blood oxygen monitoring.

This project aims to create a fingerprint door lock that can enter, scan, compare, and delete fingerprints. It utilized an STM32 development board, fingerprint identification module, and Stone’s STVC050WT-01 LCD display.

STONE LCD screen’s role here is to display the fingerprint module’s status. As with all other projects, STONE TOOLBox software was used to generate the user interface flashed on the screen. Meanwhile, Stone’s LCD screen was connected to the development board and fingerprint identification module with MCU through UART-TTL signals.

The idea for this project is a real-time display of pictures collected by the camera on the LCD display screen. The TFT LCD STONE module used for this project is a 7-inch serial display module with 800×480 resolution. A camera module, development board, and some wires are needed to complete the project.

The user interface was designed using STONE TOOLBox and Adobe Photoshop. Then, the hardware parts were wired together; some parts needed welding. After that, a simple program was written following MCU to the command control TFT-LCD module.

This particular project used a STONE serial LCD touch display screen. This functions as the main display for the coffee machine. With the screen installed, you can:

RGB lamps that can be controlled through a touch display – this is the aim of this project idea. STONE’s 7-inch TFT LCD display module in STVC070WT-01 was used to connect and control an RGB lamp.

Last but not least is a basic appliance controller made using STONE’s 7-inch TFT LCD touch screen and an STM32 development board. The touch screen controls lights for various parts of the house. The finished product also collects data about humidity, temperature (indoor and outdoor), and air quality.

This project resulted in a simple electronic scale made by connecting STONE’s 5-inch touch screen to a development board, an ADC conversion module, and a pressure acquisition module. The finished product can:

STONE TOOLBox and graphics software such as Adobe Photoshop was used to design the user interface. Meanwhile, the hardware pieces were wired together and an MCU code was written for the electronic scale to be functional.

STONE’s TFT LCD intelligent touch modules can be paired with Arduino technology to automate a variety of processes. This project clearly demonstrates this.

Here, a sensor directly connected to Arduino Uno is monitored by the display screen in real-time. Moreover, two light bulbs connected to Arduino are directly controlled by the display screen as well.

This project is all about making a car display dashboard using a 10.1-inch STONE LCD touch screen. The on-board display interface for a used car contains the following:

We presented an overview of what HMI technology is, how it works, and which applications use it. Also, we covered Stone’s range of HMI-capable TFT LCD display modules. Furthermore, we discussed a lengthy list of exciting project ideas made using Stone’s superior quality HMI displays.

STONE Technologies is truly your best bet for powering your HMI-driven development ideas(projects based on TFT LCD Arduino, STM32, ESP, etc.). Take inspiration from the actual examples we’ve shown you and build your very own HMI display device today.

Arduino HMI TFT LCD Display Sensor Monitoring- The 10.1” HMI Intelligent TFT LCD Module used in this video is sponsored by the Stone Technologies. Stone Technologies is a professional Manufacturer of HMI Intelligent TFT LCD modules. Depending on the application the Stone Technologies offers Industrial Type, Advanced type, and Civil Type Intelligent TFT LCD modules available in different sizes. The one I am using in this series of videos is the Civil Type 10.1 inch HMI display Module. For more information visitstoneitech.com.

In this tutorial, you will learn how to send the sensors data From Arduino to the HMI Intelligent TFT LCD module using the Serial Communication. For the best understanding, I have used the Variable resistor or potentiometer which of course you can replace with any other sensor you want. The GUI design and the variable memory addresses remain the same.

In tutorial number1 I explained how to design a graphical user interface using the images designed in Adobe Photoshop. How to use the button function, data variable function, Hardware parameter function and how to use the Drag adjustment, and Slider Scale function for controlling the screen brightness.

While in tutorial number2 I explained the commands used for reading and writing, how to control the user interface without pressing the on-screen buttons, how to access the brightness control register and so on. So, I highly recommend first, watch my previous tutorials and then you can resume from here.

As you can see the circuit diagram is really simple. The 10.1 inch TFT LCD Module and Arduino is powered up using a 12v adaptor or battery. All the grounds are connected together. The DIN pin of the TFT LCD module which is data-in is connected with the TX pin of the MAX232, the DOUT pin which is the data-out pin is connected with the RX pin of the DB9. The VCC pin of the MAX232 board is connected with the Arduino’s 5 volts, the ground of the MAX232 is connected with the Arduino’s ground, while the TX and RX pins of the MAX232 Board are connected with the Arduino’s pin number 2 and Pin number 3. Later in the programming, I will explain, why am I using pin number 2 and pin number 3 as the Serial Port.

A variable resistor or Potentiometer is used as the Sensor. The middle leg of the potentiometer is connected with the Arduino’s Analog Pin A0, while the other two legs are connected with the Arduino’s 3.3 volts and ground.

As you can see the MAX232 board has the female type DP9 connector, and the HMI intelligent TFT LCD Module also comes with the female type DB9 connector.

I replaced the female type DB9 connector with the Male type DB9 connector. I simply soldered three wires. I connected the ground of both the male connectors together, connected the TX pin of the one male connector with the RX pin of the other male connector, similarly connected with the RX of the first male connector with the TX of the other DB9 male connector. Now I can use this cable to connect the HMI TFT LCD Module with the Max232 board without any problem.

The VCC of the max232 board is connected with the Arduino’s 5 volts, the ground is connected with the Arduino’s ground, while the TX and RX pins of the Max232 are connected with the Arduino’s pin number 2 and pin number 3.

The GUI design remains the same which I used in my previous two tutorials, the variable memory addresses remain the same. Now we will use Arduino to send the sensor data using Serial communication, the received values will be stored in these two memory locations. Let’s have a look at the Arduino’s programming.

I started off with the SoftwareSerial library. The SoftwareSerial is basically a library that enables the Serial Communication on digital pins other than the Arduino’s default Serial Port. Using the SoftwareSerial library we can create multiple software serial ports with speeds up to 115200bps.

In this particular project, you can also use the Arduino’s default Serial port which is on Pin number 0 and pin number 1. But trust me this will really make you tired, because each time you upload a program, you will have to remove the wires. That’s why I always say never use the Arduino’s default Serial Port for the communication with other devices. The Arduino’s default Serial Port should only be used for debugging purposes.

I created a software Serial Port with the name max232 on the Arduino’s pin number 2 and pin number 3. Pin number 2 is the RX while pin number 3 is the TX.

These are the same commands which I have already explained in my previous tutorial. You can watch my previous tutorial, the link is given in the description.

So, that’s it for now. In the upcoming article, I will explain how to control electrical loads using 10.1” HMI TFT LCD Module and Arduino. If you have any questions, let me know in a comment. Don’t forget to Subscribe to my Website and YouTube channel “Electronic Clinic”.

The 2.4 inch TFT LCD Touch Display Shield for Arduino Uno is fully assembled, tested and ready to go. Add the touch display without wiring, no soldering! Simply plug it in and load up a library – you ‘ll have it running in under 10 minutes! Works best with any classic Arduino ATMEGA328 Board

So spice up your Arduino UNO project with a beautiful large touchscreen display shield with a built-in microSD card connection. This TFT display is big (2.4″ diagonal) bright (4 white-LED backlights) and colorful (18-bit 262,000 different shades)!

The Display comes with 240×320 pixels with individual pixel control. It has way more resolution than a black and white 128×64 display. As a bonus, this display has a resistive touchscreen attached to it already, so you can detect finger presses anywhere on the screen.Interfacing Diagram:

※Controller IC Replacement NoticeDue to the global shortage of IC, the controller RA8876 used in this module has been difficult to purchase. In order not to affect the delivery, we will use the controller LT7683 as replacement which is fully compatible with the same stable performance when the RA8876 is out of stock. (Oct-28-2021)

Spice up your Arduino project with a beautiful large display shield with built in microSD card connection. This TFT display is big (10.1" diagonal) bright (24 white-LED backlight) and colorful (18-bit 262,000 different shades)! 1024x600 pixels with individual pixel control,optional 10.1 inch capacitive touch panel.

The shield is fully assembled, tested and ready to go. No wiring, no soldering! Simply plug it in and load up our library - you"ll have it running in under 10 minutes! Works best with any Arduino Due board.

This display shield has a controller built into it with RAM buffering, so that almost no work is done by the microcontroller. You can connect more sensors, buttons and LEDs.

Of course, we wouldn"t just leave you with a datasheet and a "good luck!" - we"ve written a full open source graphics library at the bottom of this page that can draw pixels, lines, rectangles, circles and text. The code is written for Arduino but can be easily ported to your favorite microcontroller!

If you"ve had a lot of Arduino DUEs go through your hands (or if you are just unlucky), chances are you’ve come across at least one that does not start-up properly.The symptom is simple: you power up the Arduino but it doesn’t appear to “boot”. Your code simply doesn"t start running.You might have noticed that resetting the board (by pressing the reset button) causes the board to start-up normally.The fix is simple,here is the solution.

We covered the basics of accelerometer previously inUsing Arduino with Parts and Sensors – Accelerometer Part 1andUsing Arduino with Parts and Sensors – Accelerometer Part 2. Today we’ll be testing KX022-1020 accelerometer using TFT liquid crystal panel. We’ll discuss how to control the TFT LCD in more detail in the next article. In addition, we’ll further exploreArduino Create. For more information about Arduino Create, please refer back tothisarticle.

Let’s briefly review what accelerometer is. An accelerometer is a sensor that can detect the state of motion, such as “tilt,” “shock,” “vibration” and so forth. Accelerometers are classified into one axis, two axes, and three axes. For example, one axis detects one direction (vertical only); two axes detects two directions (vertical and horizontal); and three axes three directions (vertical, horizontal and height).

Now, let’s test the accelerometer. Download the library from the “Software” section at the bottom of theaccelerometer page from theRohm Sensor Evaluation Kit website.

We’ll continue using Arduino Create Web Editor as we did in our lasttutorial. To add the library, you can upload the zip file by selecting it from “Libraries” on the left menu and clicking on “ADD ZIP LIBRARY.”

After adding the library, attach the accelerometer to the Sensor Shield (I2C I/F) and try running the sample program. The accelerometer should be set to 1.8V or 3.0V.

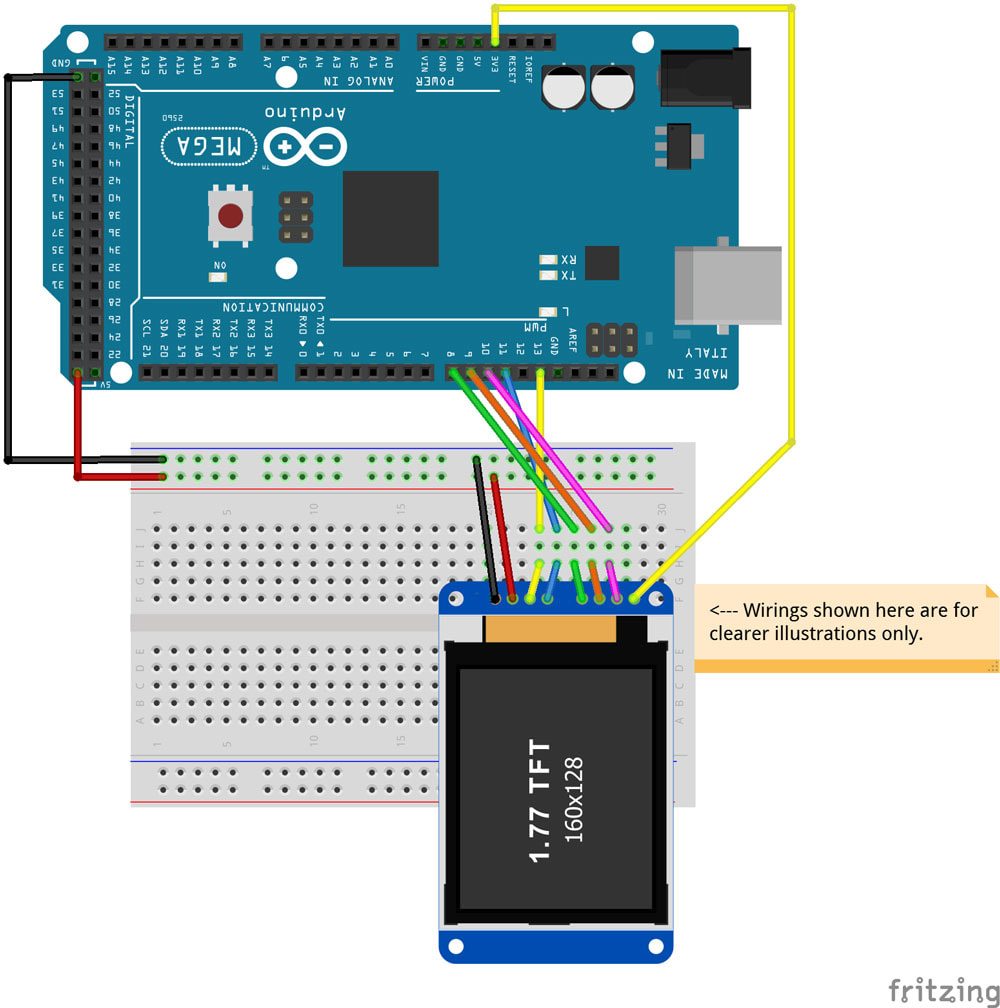

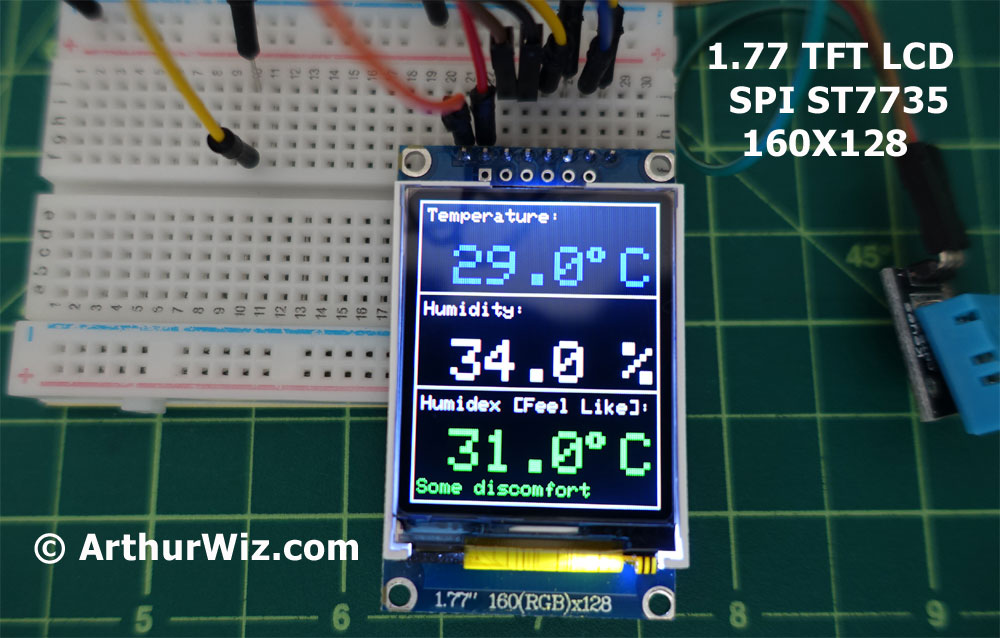

Now the sample program is working fine, let’s try to display the values on a 1.8 inch TFT LCD monitor. Although this TFT liquid crystal monitor has a resolution slightly smaller than 126 x 160 px, it’ll be quite useful when displaying numbers or letters with Arduino etc.

In the past, we used 7-segment LED to display numerical values only. But this time, I tried to display the graph along with the values obtained from the accelerometer.

When using the TFT monitor, the connection method and the library used in the program may be different depending on the specification of each TFT monitor. The TFT monitor used in this tutorial is a monitorSainSmart ST7735R. In addition to Arduino, the monitor is also compatible with Raspberry.

In order to use the monitor to run the program in Arduino, we’ll have to modify the downloaded library a little bit.We’ll go over how to control the TFT LCD in more detail in the next article. Once everything is set, you will be able to output numerical values in the monitor as shown in the video below:

In the next part, we’ll create a simple device using the same accelerometer and TFT monitor. We’ll show how to create graphs and display the values obtained from the accelerometer on the TFT monitor.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

There is little information on the Internet with a combination of this 1.77 inch TFT LCD work on Arduino Mega board. Most of the information is covering the 1.8 inch TFT LCD, and it is a little bit tricky to make this works since the connections on the board, and the code/driver may be different from other LCDs. We use this opportunity to explain the technology behind it besides just showing the readers its schematics. Later, we"ll show how to display both the temperature and humidity on the LCD with the DHT-11 sensor.

In a simple analogy, a computer uses a computer program, device driver, to talk to hardware like a printer and in the Arduino board, there is a microcontroller also uses some drivers to communicate with the LCD device. The communication between the microcontroller and devices can be parallel and/or serial when we look at it from the data transmission level. When we wired two LED lights with two separate I/O PINs on the board, we let the microcontroller sending the data in a parallel fashion. In the serial transmission, the data transmit one bit of data at a time, sequentially, over a communication channel called the bus. In web programming, we have the luxury of sending more complex data on a broader bandwidth, like JSON, a key-value pair data, when comparing with the low-level programming in electronics. There is a pulsing technique controlled by a clock, transmitting one bit every clock pulse. In this way, it compensates for the narrow path for data to pass through while maintaining the understanding of who is talking to whom or how to interpret the pieces of bit information that a device receives. With the clock speed, we can distinguish the data chunk out from the signal stream. It acts like traffic lights in the busiest city where all devices in the SPI bus shared the same clock as it maintains the data flow synchronized and controlled. As a result, paired its data line with a clock signal, the data is transferred synchronously. Many protocols are using this type of methods to communicate, such as SPI, and I2C. In our case, the LCD uses the Serial Peripheral Interface (SPI) protocol to communicate with the microcontroller on the Arduino board. Just like on the Internet, HTTP is a protocol for data communication between a web server and a client computer.

SCK/SCLK (Serial Clock) – A clock signal generated by the Master device to synchronize data transmission, so the slave device knows when to read the input.

The sequence of the events in serial data transmission is initialized when the SS pin set low as in active mode for the slave device. Otherwise, it simply ignores the data sent from the master or the microcontroller on the Arduino board in this scenario since all devices on the SPI bus share the MISO, MOSI, and SCLK lines and the message arrives at the slave devices at the same time. Only the devices that the master wants to communicate have its SS pin set low. During the data transmission, the master begins to toggle the clock line up and down at speed supported by the slave device. For each clock cycle, it sends one bit on the MOSI line, and receive one bit on the MISO line. Until stopping the toggling of the clock line, the transmission is complete, and now the SS pin is returned with a high state. A reset is triggered, and the next sequence of data transmission can be started again. It looks like a controlled escalator moving people up and down in light speed!

In slow motion, when SS (CS) Pin is low, the ST7735S controller chip on the slave device understands that the data carried in two lines, SCK and SDA is a command from the master. When high, the data signal is being sent from the slave to master via a register select signal called RS.

Adafruit_ST7735 tft = Adafruit_ST7735(TFT_CS, TFT_DC, TFT_MOSI, TFT_SCLK, TFT_RST);Two constructors in this class mean that there are two ways to create the tft object. For 1.8 inch LCD, you should use the first constructor shown above. In our case, the 1.77 inch LCD requires us to use the second constructor.

I hope this article helps you set up the 1.77 inch TFT LCD successfully. Sometimes it is difficult to know which library to use when your manufacturer does not provide you with anything else except this label on the package. Remember to make sure that the background and text colors must be different to display characters or else you cannot see anything.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey