arduino graphic tft lcd with touch screen master class supplier

![]()

In this Arduino touch screen tutorial we will learn how to use TFT LCD Touch Screen with Arduino. You can watch the following video or read the written tutorial below.

For this tutorial I composed three examples. The first example is distance measurement using ultrasonic sensor. The output from the sensor, or the distance is printed on the screen and using the touch screen we can select the units, either centimeters or inches.

The next example is controlling an RGB LED using these three RGB sliders. For example if we start to slide the blue slider, the LED will light up in blue and increase the light as we would go to the maximum value. So the sliders can move from 0 to 255 and with their combination we can set any color to the RGB LED, but just keep in mind that the LED cannot represent the colors that much accurate.

The third example is a game. Actually it’s a replica of the popular Flappy Bird game for smartphones. We can play the game using the push button or even using the touch screen itself.

As an example I am using a 3.2” TFT Touch Screen in a combination with a TFT LCD Arduino Mega Shield. We need a shield because the TFT Touch screen works at 3.3V and the Arduino Mega outputs are 5 V. For the first example I have the HC-SR04 ultrasonic sensor, then for the second example an RGB LED with three resistors and a push button for the game example. Also I had to make a custom made pin header like this, by soldering pin headers and bend on of them so I could insert them in between the Arduino Board and the TFT Shield.

Here’s the circuit schematic. We will use the GND pin, the digital pins from 8 to 13, as well as the pin number 14. As the 5V pins are already used by the TFT Screen I will use the pin number 13 as VCC, by setting it right away high in the setup section of code.

As the code is a bit longer and for better understanding I will post the source code of the program in sections with description for each section. And at the end of this article I will post the complete source code.

I will use the UTFT and URTouch libraries made by Henning Karlsen. Here I would like to say thanks to him for the incredible work he has done. The libraries enable really easy use of the TFT Screens, and they work with many different TFT screens sizes, shields and controllers. You can download these libraries from his website, RinkyDinkElectronics.com and also find a lot of demo examples and detailed documentation of how to use them.

After we include the libraries we need to create UTFT and URTouch objects. The parameters of these objects depends on the model of the TFT Screen and Shield and these details can be also found in the documentation of the libraries.

Next we need to define the fonts that are coming with the libraries and also define some variables needed for the program. In the setup section we need to initiate the screen and the touch, define the pin modes for the connected sensor, the led and the button, and initially call the drawHomeSreen() custom function, which will draw the home screen of the program.

So now I will explain how we can make the home screen of the program. With the setBackColor() function we need to set the background color of the text, black one in our case. Then we need to set the color to white, set the big font and using the print() function, we will print the string “Arduino TFT Tutorial” at the center of the screen and 10 pixels down the Y – Axis of the screen. Next we will set the color to red and draw the red line below the text. After that we need to set the color back to white, and print the two other strings, “by HowToMechatronics.com” using the small font and “Select Example” using the big font.

Next is the distance sensor button. First we need to set the color and then using the fillRoundRect() function we will draw the rounded rectangle. Then we will set the color back to white and using the drawRoundRect() function we will draw another rounded rectangle on top of the previous one, but this one will be without a fill so the overall appearance of the button looks like it has a frame. On top of the button we will print the text using the big font and the same background color as the fill of the button. The same procedure goes for the two other buttons.

Now we need to make the buttons functional so that when we press them they would send us to the appropriate example. In the setup section we set the character ‘0’ to the currentPage variable, which will indicate that we are at the home screen. So if that’s true, and if we press on the screen this if statement would become true and using these lines here we will get the X and Y coordinates where the screen has been pressed. If that’s the area that covers the first button we will call the drawDistanceSensor() custom function which will activate the distance sensor example. Also we will set the character ‘1’ to the variable currentPage which will indicate that we are at the first example. The drawFrame() custom function is used for highlighting the button when it’s pressed. The same procedure goes for the two other buttons.

drawDistanceSensor(); // It is called only once, because in the next iteration of the loop, this above if statement will be false so this funtion won"t be called. This function will draw the graphics of the first example.

So the drawDistanceSensor() custom function needs to be called only once when the button is pressed in order to draw all the graphics of this example in similar way as we described for the home screen. However, the getDistance() custom function needs to be called repeatedly in order to print the latest results of the distance measured by the sensor.

Here’s that function which uses the ultrasonic sensor to calculate the distance and print the values with SevenSegNum font in green color, either in centimeters or inches. If you need more details how the ultrasonic sensor works you can check my particular tutorialfor that. Back in the loop section we can see what happens when we press the select unit buttons as well as the back button.

Ok next is the RGB LED Control example. If we press the second button, the drawLedControl() custom function will be called only once for drawing the graphic of that example and the setLedColor() custom function will be repeatedly called. In this function we use the touch screen to set the values of the 3 sliders from 0 to 255. With the if statements we confine the area of each slider and get the X value of the slider. So the values of the X coordinate of each slider are from 38 to 310 pixels and we need to map these values into values from 0 to 255 which will be used as a PWM signal for lighting up the LED. If you need more details how the RGB LED works you can check my particular tutorialfor that. The rest of the code in this custom function is for drawing the sliders. Back in the loop section we only have the back button which also turns off the LED when pressed.

In order the code to work and compile you will have to include an addition “.c” file in the same directory with the Arduino sketch. This file is for the third game example and it’s a bitmap of the bird. For more details how this part of the code work you can check my particular tutorial. Here you can download that file:

drawDistanceSensor(); // It is called only once, because in the next iteration of the loop, this above if statement will be false so this funtion won"t be called. This function will draw the graphics of the first example.

In this tutorial, you will learn how to use and set up 2.4″ Touch LCD Shield for Arduino. First, you’ll see some general information about this shield. And after learning how to set the shield up, you’ll see 3 practical projects.

The role of screens in electronic projects is very important. Screens can be of very simple types such as 7 Segment or character LCDs or more advanced models like OLEDs and TFT LCDs.

One of the most important features of this LCD is including a touch panel. If you are about to use the LCD, you need to know the coordinates of the point you touch. To do so, you should upload the following code on your Arduino board and open the serial monitor. Then touch your desired location and write the coordinates displayed on the serial monitor. You can use this coordination in any other project.

To display pictures on this LCD you should save the picture in 24bit BMP colored format and size of 240*320. Then move them to SD card and put the SD card in the LCD shield. we use the following function to display pictures. This function has 3 arguments; the first one stands for the pictures name, and the second and third arguments are for length and width coordinates of the top left corner of the picture.

If you want to display pictures without using an SD card, you can convert it to code and then display it. You can display even several photos sequentially without delay to create an animation. (Check this) But be aware that in this case, Arduino UNO may not be suitable (because of low processor speed). We recommend using the Arduino Mega or Arduino DUE.

The AZ-Delivery 2.4” TFT LCD Touch Display boasts 320x 240 pixels with 16-bit color. It has Touch capabilities, a built-in SD card drive, and plugs straight onto the top of an Arduino UNO or Mega. Amazon charges less than £11 for this device. It offers a major step up from the tiny SSD1306 128×64 monochrome display.

The TFT screen is much larger than the SSD1306 128×64 and much more colourful. The package includes an SD card reader on the underside and a stylus for accurate touch-screen control.

AZ-Delivery usually supply an e-book (pdf document for download) with their boards. The German version comes first followed by other languages. This has just become available and provides setup instructions and a demonstration graphics only sketch.

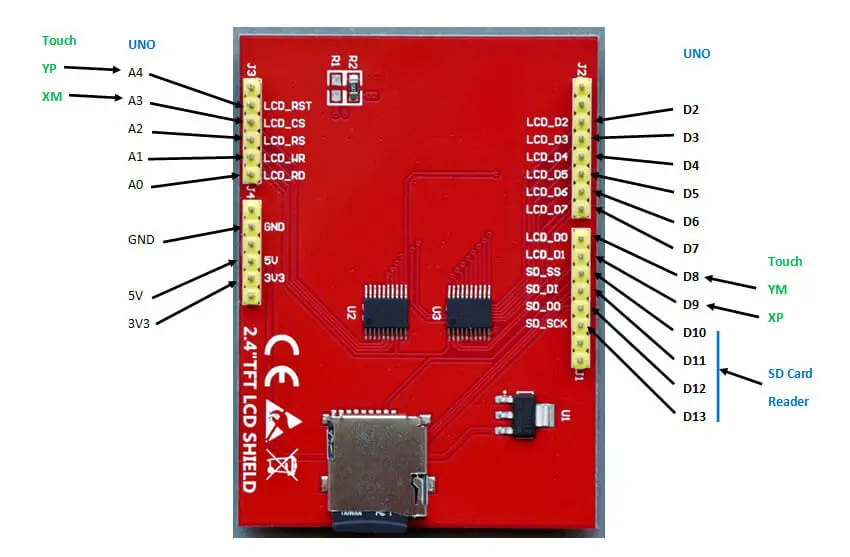

The underside of the board has labels on the pins. As the board is an Arduino shield, it will only fit on a UNO in one position. The SD card reader sits between USB and the power socket. It will also plug into and Arduino MEGA 2560. J1 and J2 fit into the digital pins, covering D0 to D13, while J3 and J4 fit into the analog and power pins.

I searched the Web for drivers and examples and found a great deal of praise for the TFT graphics, reports of problems with the Touch control and nothing about the SD card reader on this board.

In the end I installed several libraries (with all dependencies): Adafruit GFX, Adafruit TFTLCD, Adafruit TouchScreen, Adafruit ILI9341, MCUFRIEND_kbv and SPFD5408-master. (The last 2 are not essential but include some interesting examples). The SD library is included in the basic Arduino set.

I’ve used GFX with mono displays such as SSD1306 and soon got the TFT display working. The following script gives some idea about what it can do. I’ve included pixels, text (of varying sizes), lines, rectangles, triangles, squares, graphs, screen rotation, and text on a path. I was very impressed with the clarity, speed, brightness, and colors produced.

Normally, when setting the colour of an RGB LED you have a range of 0-255 (0-FF hex) for each RGB component which gives white = FFFFFF, red = FF000, green FF00 and blue = FF. This is 24-bit colour and takes 3 bytes. 224 gives 16,777,216 different colours. The TFT screen is a 16-bit colour device which can display 65,536 different colours – more than enough. Here the range is limited to 5 bits each for red and blue and 6 bits for green. (Our eyes are more sensitive to green so It gets the extra bit of accuracy.)

The following sketch gives an indication of the colours available by converting an array of 24-bit colour values into their 16-bit equivalent and displaying them on the screen with the data. There are not enough pixels on the screen to display all the colours at once so the last part of the sketch takes out the least significant green bit and displays half the available colours six ways.

The SD card reader library is included with the basic setup, so we do not need to load a fresh library. The examples cover the simple tasks of creating, writing to, reading from and deleting files at a very basic level, all with strings.

An obvious use for the SD reader is to log readings from sensors and display the results on the TFT display. Unfortunately, the shield covers and uses most of the pins. The solution is to connect just the SD reader and power pins with jump leads which leaves plenty of pins to collect data from sensors.

Most Arduino users seldom use string manipulation. The documentation and a few simple examples of how to use strings are well scattered over the Web and difficult to find. The first sketch demonstrates how to create a file of 5 records/lines, each made up from an integer, a string, and a floating-point variable. The file is called datalog6.txt.

This is the part that often causes the most trouble with many owners giving up at this point. It may be because there are several different configurations of the pins used to connect to the touch layers of the screen on the many varied breakout boards and shields using this display. In this case four of the pins are used, at different times, to control both the graphics or the touch elements of the screen.

This is a resistive touch screen, rather than a capacitive one. Above the graphics, layers are two transparent resistive layers held apart by tiny dimples. One is connected at the top and bottom and the other at the sides. A potential difference is applied across them and when the stylus or a finger presses on the screen an electrical connection is made between the resistive layers.

The Analog pins are used to measure the voltages at that point on the two resistive layers, one at a time, in the same manner as we read the voltage from the wiper of a potentiometer – a potential divider. Using these values, it is possible to calculate, quite accurately, the coordinates of the point on the screen where the pressure has been applied. Calibration is often needed to improve accuracy. Adafruit suggests reading the resistance across the X plate (XP = D8 and XM = A2). On my board, I got 341 Ohms. Use this value as SENSITIVITY.

Try running the sketch to draw on the screen. The BLACK palette ‘button’ clears the screen and the others change the ‘ink’ colour. If the dot drawn is not directly under the stylus you can adjust the ‘fudge factors’ in the scaling section.

As a final example here is a sketch which shows off the Touch screen with buttons, bar graphs and colours. The buttons allow the user to adjust the RGB mix to display all the possible colours available. If you find one you particularly like it displays the hex value of the 16-bit colour.

Gently pressing on the buttons at the bottom with the stylus changes the RGB values within their allowed ranges. The bars move to show the fraction of maximum possible for each of the red, green and blue values.

There is a small amount of jitter as the bar graph re-draws but overall, the shield works quickly and very well. After the screen has updated and waiting for a touch the image is steady, sharp, and bright. Once you have calibrated the touch device it is very accurate as demonstrated with the small (30×30 pixel buttons) and provides excellent, colorful graphics on a usefully large display.

The SD card reader is a bonus, and could always be used, via jump wires, to record values from sensors on the other pins. These values could then be displayed graphically on the display with a different sketch.

I was very pleased with the quality of the display and the accuracy of the Touch device. It sits neatly and securely on a UNO or a MEGA 2560. With an SD card reader included it was excellent value and I will be making good use of it in the future.

The ILI9341 TFT module contains a display controller with the same name: ILI9341. It’s a color display that uses SPI interface protocol and requires 4 or 5 control pins, it’s low cost and easy to use. The resolution of this TFT display is 240 x 320 which means it has 76800 pixels. This module works with 3.3V only and it doesn’t support 5V (not 5V tolerant).

The ILI9341 TFT display board which is shown in the circuit diagram above has 14 pins, the first 9 pins are for the display and the other 5 pins are for the touch module.

As mentioned above, the ILI9341 TFT display controller works with 3.3V only (power supply and control lines). The display module is supplied with 5V that comes from the Arduino board. This module has a built-in 3.3V regulator which supplies the display controller with 3.3V from the 5V source.

To connect the Arduino to the display module, I used voltage divider for each line which means there are 5 voltage dividers. Each voltage divider consists of 2.2k and 3.3k resistors, this drops the 5V into 3V which is sufficient.

The first library is a driver for the ILI9341 TFT display which can be installed from Arduino IDE library manager (Sketch —> Include Library —> Manage Libraries …, in the search box write “ili9341” and choose the one from Adafruit).

The ILI9341 TFT display is connected to Arduino hardware SPI module pins (clock and data), the other pins which are: CS (chip select), RST (reset) and DC (data/command) are defined as shown below:

The following Arduino code is from Adafruit ILI9341 library (graphicstest.ino) with some modifications in order to work with the above circuit diagram.

This post is an introduction to the Nextion display with the Arduino. We’re going to show you how to configure the display for the first time, download the needed resources, and how to integrate it with the Arduino UNO board. We’ll also make a simple graphical user interface to control the Arduino pins.

Nextion is a Human Machine Interface (HMI) solution. Nextion displays are resistive touchscreens that makes it easy to build a Graphical User Interface (GUI). It is a great solution to monitor and control processes, being mainly applied to IoT applications.

The Nextion has a built-in ARM microcontroller that controls the display, for example it takes care of generating the buttons, creating text, store images or change the background. The Nextion communicates with any microcontroller using serial communication at a 9600 baud rate.

The best model for you, will depend on your needs. If you’re just getting started with Nextion, we recommend getting the 3.2” size which is the one used in the Nextion Editor examples (the examples also work with other sizes, but you need to make some changes). Additionally, this is the most used size, which means more open-source examples and resources for this size.

To get started with Nextion, first you need to install Nextion Editor. Go to https://nextion.itead.cc/, select the Resources tab, Download > Nextion Editor and install Nextion Editor. You can either download the .zip file or the .exe file.

Connecting the Nextion display to the Arduino is very straightforward. You just need to make four connections: GND, RX, TX, and +5V. These pins are labeled at the back of your display, as shown in the figure below.

You can power up the Nextion display directly from the Arduino 5V pin, but it is not recommended. Working with insufficient power supply may damage the display. So, you should use an external power source. You should use a 5V/1A power adaptor with a micro USB cable. Along with your Nextion display, you’ll also receive a USB to 2 pin connector, useful to connect the power adaptor to the display.

The best way to get familiar with a new software and a new device is to make a project example. Here we’re going to create a user interface in the Nextion display to control the Arduino pins, and display data.

The user interface has two pages: one controls two LEDs connected to the Arduino pins, and the other shows data gathered from the DHT11 temperature and humidity sensor;

Note: At the time of writing this instructions there is an issue with font types. Whatever font type you chose, it will always look the same.Still, you can edit the font size and if it is bold or not.

All components have an attribute called objname. This is the name of the component. Give good names to your components because you’ll need them later for the Arduino code. Also note that each component has one id number that is unique to that component in that page. The figure below shows the objname and id for the slider.

You should trigger an event for the touchable components (the buttons and the slider) so that the Arduino knows that a component was touched. You can trigger events when you press or when you release a component.

To do that, select one of the buttons, and in the event window, select the Touch Release Event tab, and put a tick on the Send Component ID option. Repeat this process for the other button, and the slider.

Notice that we have labels to hold the units like “ºC”, “ºF” and “%”, and empty labels that will be filled with the readings when we have our Arduino code running.

Once the GUI is ready, you need to write the Arduino code so that the Nextion can interact with the Arduino and vice-versa. Writing code to interact with the Nextion display is not straightforward for beginners, but it also isn’t as complicated as it may seem.

A good way to learn how to write code for the Arduino to interact with the Nextion display is to go to the examples folder in the Nextion library folder and explore. You should be able to copy and paste code to make the Arduino do what you want.

The first thing you should do is to take note of your components in the GUI that will interact with the Arduino and take note of their ID, names and page. Here’s a table of all the components the code will interact to (your components may have a different ID depending on the order you’ve added them to the GUI).

After that, you define led1 and led2. These variables refer to the digital pins 8 and 9 respectively. (led 1 will be controlled with the ON and OFF buttons of the user interface, and led2 brightness will be controlled using the slider).

Here you use the page ID, the component ID and their name – just check the table above with all the components. To define a text you use NexText, to define a button you use NexButton, for a slider you use NexSlider and for the progress bar you use NexProgressBar.

This function will set the led1 to HIGH, as well as update the tState label with the text “State: on”. Updating text labels is as simple as using setText().

In this post we’ve introduced you to the Nextion display. We’ve also created a simple application user interface in the Nextion display to control the Arduino pins. The application built is just an example for you to understand how to interface different components with the Arduino – we hope you’ve found the instructions as well as the example provided useful.

In our opinion, Nextion is a great display that makes the process of creating user interfaces simple and easy. Although the Nextion Editor has some issues and limitations it is a great choice for building interfaces for your electronics projects. We have a project on how to create a Node-RED physical interface with the Nextion display and an ESP8266 to control outputs. Feel free to take a look.

The four sample codes: DisplayString, DrawGraphic, ShowBMP, and TouchPanel are used to display strings, graphics, pictures in BMP format, and touch pen functions.

Before experimenting with the TouchPanel, the touchscreen must be calibrated according to the displayed prompts. Open the corresponding project, burn the program, and you will be prompted when running:

The demos are developed based on the HAL library. Download the program, find the STM32 program file directory, and open the STM32 with four project folders: DisplayString, DrawGraphic, ShowImage, and Touchscreen.

The four sample codes: DisplayString, DrawGraphic, ShowBMP, and TouchPanel are used to display strings, graphics, pictures in BMP format, and touch pen functions.

Before experimenting with the TouchPanel, the touchscreen must be calibrated according to the displayed prompts. Open the corresponding project, burn the program, and you will be prompted when running:

For some development boards without ICSP interface (such as NUCLEO), you need to use 0 ohm resistor or solder to short the pads in the following three positions

In this article, you will learn how to use TFT LCDs by Arduino boards. From basic commands to professional designs and technics are all explained here.

There are several components to achieve this. LEDs, 7-segments, Character and Graphic displays, and full-color TFT LCDs. The right component for your projects depends on the amount of data to be displayed, type of user interaction, and processor capacity.

TFT LCD is a variant of a liquid-crystal display (LCD) that uses thin-film-transistor (TFT) technology to improve image qualities such as addressability and contrast. A TFT LCD is an active matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven LCDs with a few segments.

In Arduino-based projects, the processor frequency is low. So it is not possible to display complex, high definition images and high-speed motions. Therefore, full-color TFT LCDs can only be used to display simple data and commands.

In this article, we have used libraries and advanced technics to display data, charts, menu, etc. with a professional design. This can move your project presentation to a higher level.

There are several components to achieve this. LEDs, 7-segments, Character and Graphic displays, and full-color TFT LCDs. The right component for your projects depends on the amount of data to be displayed, type of user interaction, and processor capacity.

TFT LCD is a variant of a liquid-crystal display (LCD) that uses thin-film-transistor (TFT) technology to improve image qualities such as addressability and contrast. A TFT LCD is an active matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven LCDs with a few segments.

In Arduino-based projects, the processor frequency is low. So it is not possible to display complex, high definition images and high-speed motions. Therefore, full-color TFT LCDs can only be used to display simple data and commands.

In this article, we have used libraries and advanced technics to display data, charts, menu, etc. with a professional design. This can move your project presentation to a higher level.

Size of displays affects your project parameters. Bigger Display is not always better. if you want to display high-resolution images and signs, you should choose a big size display with higher resolution. But it decreases the speed of your processing, needs more space and also needs more current to run.

After choosing the right display, It’s time to choose the right controller. If you want to display characters, tests, numbers and static images and the speed of display is not important, the Atmega328 Arduino boards (such as Arduino UNO) are a proper choice. If the size of your code is big, The UNO board may not be enough. You can use Arduino Mega2560 instead. And if you want to show high resolution images and motions with high speed, you should use the ARM core Arduino boards such as Arduino DUE.

In electronics/computer hardware a display driver is usually a semiconductor integrated circuit (but may alternatively comprise a state machine made of discrete logic and other components) which provides an interface function between a microprocessor, microcontroller, ASIC or general-purpose peripheral interface and a particular type of display device, e.g. LCD, LED, OLED, ePaper, CRT, Vacuum fluorescent or Nixie.

The display driver will typically accept commands and data using an industry-standard general-purpose serial or parallel interface, such as TTL, CMOS, RS232, SPI, I2C, etc. and generate signals with suitable voltage, current, timing and demultiplexing to make the display show the desired text or image.

The LCDs manufacturers use different drivers in their products. Some of them are more popular and some of them are very unknown. To run your display easily, you should use Arduino LCDs libraries and add them to your code. Otherwise running the display may be very difficult. There are many free libraries you can find on the internet but the important point about the libraries is their compatibility with the LCD’s driver. The driver of your LCD must be known by your library. In this article, we use the Adafruit GFX library and MCUFRIEND KBV library and example codes. You can download them from the following links.

You must add the library and then upload the code. If it is the first time you run an Arduino board, don’t worry. Just follow these steps:Go to www.arduino.cc/en/Main/Software and download the software of your OS. Install the IDE software as instructed.

First you should convert your image to hex code. Download the software from the following link. if you don’t want to change the settings of the software, you must invert the color of the image and make the image horizontally mirrored and rotate it 90 degrees counterclockwise. Now add it to the software and convert it. Open the exported file and copy the hex code to Arduino IDE. x and y are locations of the image. sx and sy are sizes of image. you can change the color of the image in the last input.

Upload your image and download the converted file that the UTFT libraries can process. Now copy the hex code to Arduino IDE. x and y are locations of the image. sx and sy are size of the image.

In this template, We converted a .jpg image to .c file and added to the code, wrote a string and used the fade code to display. Then we used scroll code to move the screen left. Download the .h file and add it to the folder of the Arduino sketch.

In this template, We used sin(); and cos(); functions to draw Arcs with our desired thickness and displayed number by text printing function. Then we converted an image to hex code and added them to the code and displayed the image by bitmap function. Then we used draw lines function to change the style of the image. Download the .h file and add it to the folder of the Arduino sketch.

In this template, We added a converted image to code and then used two black and white arcs to create the pointer of volumes. Download the .h file and add it to the folder of the Arduino sketch.

In this template, We added a converted image and use the arc and print function to create this gauge. Download the .h file and add it to folder of the Arduino sketch.

while (a < b) { Serial.println(a); j = 80 * (sin(PI * a / 2000)); i = 80 * (cos(PI * a / 2000)); j2 = 50 * (sin(PI * a / 2000)); i2 = 50 * (cos(PI * a / 2000)); tft.drawLine(i2 + 235, j2 + 169, i + 235, j + 169, tft.color565(0, 255, 255)); tft.fillRect(200, 153, 75, 33, 0x0000); tft.setTextSize(3); tft.setTextColor(0xffff); if ((a/20)>99)

while (b < a) { j = 80 * (sin(PI * a / 2000)); i = 80 * (cos(PI * a / 2000)); j2 = 50 * (sin(PI * a / 2000)); i2 = 50 * (cos(PI * a / 2000)); tft.drawLine(i2 + 235, j2 + 169, i + 235, j + 169, tft.color565(0, 0, 0)); tft.fillRect(200, 153, 75, 33, 0x0000); tft.setTextSize(3); tft.setTextColor(0xffff); if ((a/20)>99)

In this template, We display simple images one after each other very fast by bitmap function. So you can make your animation by this trick. Download the .h file and add it to folder of the Arduino sketch.

In this template, We just display some images by RGBbitmap and bitmap functions. Just make a code for touchscreen and use this template. Download the .h file and add it to folder of the Arduino sketch.

There is little information on the Internet with a combination of this 1.77 inch TFT LCD work on Arduino Mega board. Most of the information is covering the 1.8 inch TFT LCD, and it is a little bit tricky to make this works since the connections on the board, and the code/driver may be different from other LCDs. We use this opportunity to explain the technology behind it besides just showing the readers its schematics. Later, we"ll show how to display both the temperature and humidity on the LCD with the DHT-11 sensor.

In a simple analogy, a computer uses a computer program, device driver, to talk to hardware like a printer and in the Arduino board, there is a microcontroller also uses some drivers to communicate with the LCD device. The communication between the microcontroller and devices can be parallel and/or serial when we look at it from the data transmission level. When we wired two LED lights with two separate I/O PINs on the board, we let the microcontroller sending the data in a parallel fashion. In the serial transmission, the data transmit one bit of data at a time, sequentially, over a communication channel called the bus. In web programming, we have the luxury of sending more complex data on a broader bandwidth, like JSON, a key-value pair data, when comparing with the low-level programming in electronics. There is a pulsing technique controlled by a clock, transmitting one bit every clock pulse. In this way, it compensates for the narrow path for data to pass through while maintaining the understanding of who is talking to whom or how to interpret the pieces of bit information that a device receives. With the clock speed, we can distinguish the data chunk out from the signal stream. It acts like traffic lights in the busiest city where all devices in the SPI bus shared the same clock as it maintains the data flow synchronized and controlled. As a result, paired its data line with a clock signal, the data is transferred synchronously. Many protocols are using this type of methods to communicate, such as SPI, and I2C. In our case, the LCD uses the Serial Peripheral Interface (SPI) protocol to communicate with the microcontroller on the Arduino board. Just like on the Internet, HTTP is a protocol for data communication between a web server and a client computer.

SCK/SCLK (Serial Clock) – A clock signal generated by the Master device to synchronize data transmission, so the slave device knows when to read the input.

The sequence of the events in serial data transmission is initialized when the SS pin set low as in active mode for the slave device. Otherwise, it simply ignores the data sent from the master or the microcontroller on the Arduino board in this scenario since all devices on the SPI bus share the MISO, MOSI, and SCLK lines and the message arrives at the slave devices at the same time. Only the devices that the master wants to communicate have its SS pin set low. During the data transmission, the master begins to toggle the clock line up and down at speed supported by the slave device. For each clock cycle, it sends one bit on the MOSI line, and receive one bit on the MISO line. Until stopping the toggling of the clock line, the transmission is complete, and now the SS pin is returned with a high state. A reset is triggered, and the next sequence of data transmission can be started again. It looks like a controlled escalator moving people up and down in light speed!

In slow motion, when SS (CS) Pin is low, the ST7735S controller chip on the slave device understands that the data carried in two lines, SCK and SDA is a command from the master. When high, the data signal is being sent from the slave to master via a register select signal called RS.

Adafruit_ST7735 tft = Adafruit_ST7735(TFT_CS, TFT_DC, TFT_MOSI, TFT_SCLK, TFT_RST);Two constructors in this class mean that there are two ways to create the tft object. For 1.8 inch LCD, you should use the first constructor shown above. In our case, the 1.77 inch LCD requires us to use the second constructor.

I hope this article helps you set up the 1.77 inch TFT LCD successfully. Sometimes it is difficult to know which library to use when your manufacturer does not provide you with anything else except this label on the package. Remember to make sure that the background and text colors must be different to display characters or else you cannot see anything.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey