rotary encoder lcd display free sample

This is the code. By looking at the structure and the comments I hope you will find it easy to adapt for your specific needs!/*******Interrupt-based Rotary Encoder Menu Sketch*******

volatile byte bFlag = 0; // let"s us know when we"re expecting a rising edge on pinB to signal that the encoder has arrived at a detent (opposite direction to when aFlag is set)

volatile byte encoderPos = 0; //this variable stores our current value of encoder position. Change to int or uin16_t instead of byte if you want to record a larger range than 0-255

volatile byte oldEncPos = 0; //stores the last encoder position value so we can compare to the current reading and see if it has changed (so we know when to print to the serial monitor)

Serial.println(encoderPos);// DEBUGGING. Sometimes the serial monitor may show a value just outside modeMax due to this function. The menu shouldn"t be affected.

Be aware that a key part of menu navigation is feedback to the user while they are scrolling through the option and settings. Therefore if you choose not to include the DEBUGGING lines, you should probably use another visual indicator (e.g. LCD text display, LEDs) that encoder inputs are navigating the menu and changing settings.

Ever wondered about how simple an User Interface (UI) for your next electronics hack or project be? Indeed, and you should also seen the humble rotary encoder and a Display as UI for 3D printer or other gadgets. In this tutorial we will look at building such a system with a Nokia 5110 display and a rotary encoder KY-040.

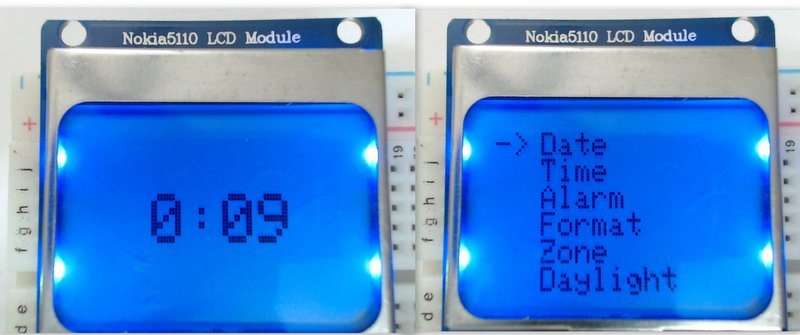

You may use any other character or graphics displays as well as other encoder models. Instead making the code generic, we will start building an UI for a digital clock. On it"s home screen it will show time. The pushing of the select switch on the encoder will display the Menu. The Menu in turn will have numerous setting for time, date, time format (12 Hour vs 24 Hour ), time Zone etc..,

The basic hookup will remain same during the entire tutorial. We will test the encoder first and then the display. You may want to hook-up all the things at once or do it step by step. The encoder first and then the display. I would recommend doing it step by step.

Encoders are great input devices which have infinite travel in both clockwise(CW) and anti-clockwise directions(CCW). What that essentially means is that the input range for your gizmo can be decided in software. As in case of your clock, the user may have to transverse a menu of say 8 items. The range for the Menu will be 0 to 7 in both directions . However to input time from the user, the hours will be (0 to 23), minutes and seconds will be (0 to 60). Encoders will help us do all of the above. Apart from this the encoder we will be using also has a select switch. Which can be used to select menu items or confirm an action.

I would highly recommend you to go through the Improved Arduino Rotary Encoder Reading instructable to understand the types of encoders, the internal mechanism and all the related terminology.

I started out with hooking up just the encoder with Arduino and printing the message on the terminal. The code is brilliantly written. It simply increments a variable called encoderPos if the encoder is turned CW and decremented if turned CCW.

As said earlier I will be using a Nokia 5110 84x48 pixels graphic display for this tutorial. I will be using the well written Adafruit display and graphics libraries. The display is instantiated with the following pins.

The image below shows, exactly what we are trying to achieve. The Menu is stored in the memory as an array of character strings. The display can show 6 lines at one time. We would like to scroll through the menu, giving user an option to select one item at a time.

Takes the 2D character array as input shows it on the display and returns the item selected. Then we use a case switch statement to execute the next action. The code can be further expanded for all cases and user inputs can be validated to a certain range like 0 to 60 for minutes and seconds.

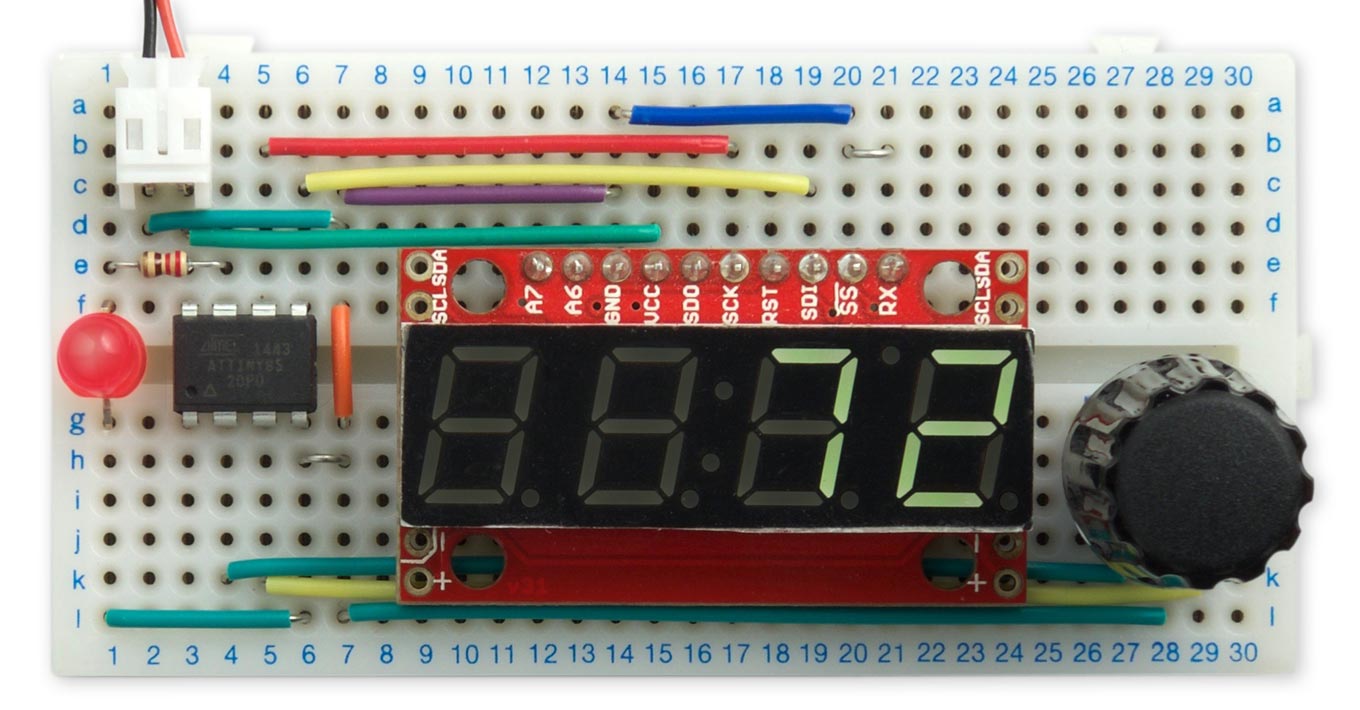

This article describes a simple routine to interface a rotary encoder to a microprocessor; I"ve chosen the ATtiny85 because it"s the simplest processor you could use for such an application. The main routine that does all the work is just 11 lines of C, but I"ve also written a demonstration program that displays the encoder value on a serial 7-segment display, and the direction of rotation on an LED:

Rotary encoders let you control an analogue value by rotating a knob. They generate a series of digital pulses reflecting the distance you"ve turned the knob, and you can also determine the direction it has been turned.

Some of the rotary encoders have click positions, or detents. The routine described here gives two pulses per click position, so you may prefer to divide the count by two if you are using one of these encoders.

My favourite rotary encoder is the one from Bourns. It has a very smooth but precise action, with no detents, and Bourns makes matching potentiometers in an identical housing.

It"s quite hard to find knobs that fit some of these encoders. In particular, the Sparkfun encoder has a very short shaft, so many knobs will be too deep. The Bourns Rotary Encoder has a 3.2mm shaft diameter, which is smaller than the usual 0.25" shaft. This is not a problem with the Adafruit rotary encoder, which includes a matching knob.

Rotary encoders work by providing two switches that are activated in sequence when you rotate the knob. They are usually called A and B, and there"s a third common terminal C that is typically connected to ground. By checking the state of both switches your program can tell both how far the knob has been rotated, and in which direction.

Here"s the circuit of the demo rotary encoder interface. It displays the direction on an LED and the count on a serial seven-segment display module; I chose this because it"s easy to interface to the ATtiny85 using just two SPI lines, clock and data:

In this tutorial we will learn how rotary encoder works and how to use it with Arduino. You can watch the following video or read the written tutorial below.

A rotary encoder is a type of position sensor which is used for determining the angular position of a rotating shaft. It generates an electrical signal, either analog or digital, according to the rotational movement.

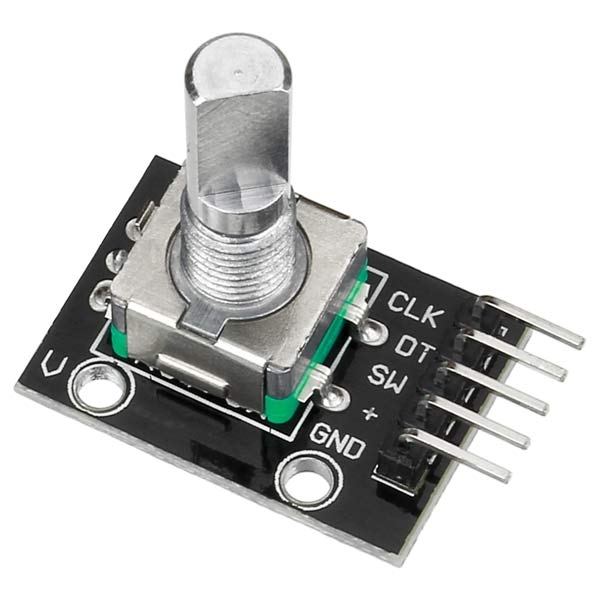

There are many different types of rotary encoders which are classified by either Output Signal or Sensing Technology. The particular rotary encoder that we will use in this tutorial is an incremental rotary encoder and it’s the simplest position sensor to measure rotation.

Let’s take a closer look at the encoder and see its working principle. Here’s how the square wave pulses are generated: The encoder has a disk with evenly spaced contact zones that are connected to the common pin C and two other separate contact pins A and B, as illustrated below.

We can notice that the two output signals are displaced at 90 degrees out of phase from each other. If the encoder is rotating clockwise the output A will be ahead of output B.

So if we count the steps each time the signal changes, from High to Low or from Low to High, we can notice at that time the two output signals have opposite values. Vice versa, if the encoder is rotating counter clockwise, the output signals have equal values. So considering this, we can easily program our controller to read the encoder position and the rotation direction.

Description of the code: So first we need to define the pins to which our encoder is connected and define some variables needed for the program. In the setup section we need to define the two pins as inputs, start the serial communication for printing the results on the serial monitor, as well as read the initial value of the output A and put the value into the variable aLastState.

Then in the loop section we read the output A again but now we put the value into the aState variable. So if we rotate the encoder and a pulse is generated, these two values will differ and the first “if” statement will become true. Right after that using the second “if” statement we determine the rotation direction. If the output B state differ from the output A state the counter will be increased by one, else it will be decreased. At the end, after printing the results on the serial monitor, we need to update the aLastState variable with aState variable.

That’s all we need for this example. If upload the code, start the Serial Monitor and start rotating the encoder we will start getting the values in the serial monitor. The particular module that I have makes 30 counts each full cycle.

Rotary Encoders can be found in radio equipment like amateur radio or hand held, where non-stop or continuous 3600 rotation is required for tuning to right frequency.

In this project, the working of Rotary Encoder is explained with the help of Arduino. The following sections are dived into introduction to rotary encoders, circuit and working.

A Rotary Encoder is an input device that provides the information about the direction and amount of rotation of the knob. There is a select switch associated with the rotary encoders that can be activated by pushing the knob.

The commonly used rotary encoder is an incremental rotary encoder. This type provides an instantaneous result about the rotating shaft by generating two square wave outputs that are 90 degrees out of phase with each other.

The basic function of a rotary encoder can be explained by considering it as a combination of two switches that close or open due to rotation of the shaft.

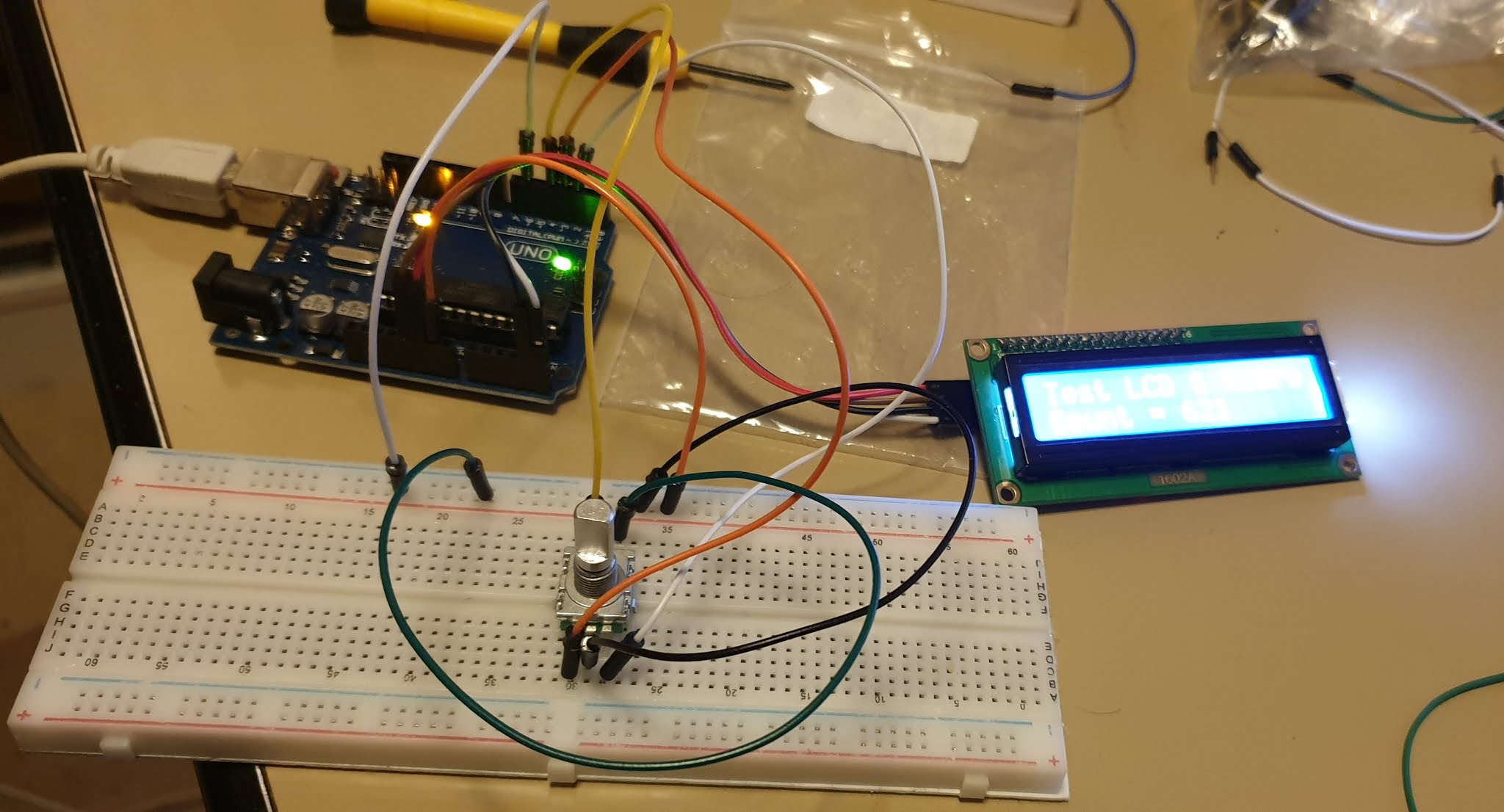

To display the objects of the menu, a 20X4 LCD display is used. The connections are similar to that of 16X2 LCD. RS and E of LCD are connected to pins 5 and 6 of Arduino.

Rotary Encoders provide infinite rotation in either direction with a select button (pushing the knob). Such unique functionality can be used in “menu” selection applications, where the rotation of shaft in either direction will allow us to browse the contents of the menu and push of the button will allow us to select the highlighted menu content.

In this project, the working of rotary encoder as a menu selector is explained with the help of Arduino and LCD. The working of the circuit is as follows.

By rotating the shaft of the rotary encoder in clockwise direction, the menus items will change from left to right with each item being highlighted for every turn of the knob.

If the knob is rotated in anti-clockwise direction, the menus items will be highlighted in reverse direction. The highlighted item will be displayed below the list of items.

If we want to select any highlighted item, the button of the rotary encoder is pushed. This is shown as the selected item and the selected item stays that way until the next item is selected.

This 1024 pulse per rotation rotary encoder outputs [gray code](http://en.wikipedia.org/wiki/Gray_code) which you can interpret using a microcontroller and

I followed your link and used this code. I was able to hook everything up and have it output to serial. How can I calibrate or modify this sketch so that one revolution of the shaft would display 100.00. if I turn CCW 1/4 turn it would display 75.00. There would be a dial on the encoder shaft that would be marked out evenly 1 - 100. I also want to use the high resolution of this encoder to indicate the dial position when it is between a number ie: 12.6572.

Once I can get it working and display it on the serial monitor I would like to have the encoder ouput to my lcd 1620a. I have no idea how to wire this to my adruino mega 2560 board, or how to include the lcd 1620a in the code.

In this tutorial, we’re going to learn how rotary encoders work! Rotary encoders (also shaft encoders) are a fantastic way to dial in a position, or determine the position of a shaft. This could be the position of a knob you are turning, or it could be an encoder connected to a stepper motor to allow you to determine the position it is currently in. Rotary encoders are routinely used in electronics projects (and thus Arduino projects).

A rotary encoder at its most basic description is an electro-mechanical device that converts the angular position and/or motion of a shaft (or axle) to an analog or digital output signal.

That’s a lot of technical jargon indeed and we’re going to break it down to three simple concepts. A rotary encoder allows your project to determine three specific things about a shaft or axle:

So let’s move on and learn how rotary encoders work, or how they capture position, direction, and speed data. It’s quite simple, and utterly fascinating at the same time.

Incremental – The most common is the incremental rotary encoder. These encoders are always in one of four electrical positions, and therefore require a calibration or homing operation to determine their starting location. Or in the case of many projects when power is applied a zero position is simply assumed (You’ll see this method in our counter example). They instantly report speed and direction, but do not keep track of absolute position.

As the incremental rotary encoder will be the most common type, we’re going to stick with those in this tutorial, but we wanted you to be aware that there is another type.

Inside a rotary encoder is a disc containing several electrical pads around its outermost region. The number of these pads will vary by encoder and brand, but ultimately determines how accurate it is. Above these pads are two contacts placed a specific distance apart. These contact are the clock and data lines.

As the shaft of the encoder is rotated, the electrically charged pads will make and electrical connection with the clock and data lines contacts. This will create a two trains of electrical pulses that the electronics or micro-controller (ie. an Arduino, or Raspberry Pi) is listening for.

Due to the positioning of the clock and data line’s contacts, either the clock or the data line will make contact with one of the electrical pads first. If the shaft is turned clockwise, the data line will make contact first. If the shaft is turned counter-clockwise, the clock line will make contact first. This is how rotary encoders work to determine direction of travel!

You can actually see this phasing difference if you connect a rotary encoder’s clock and data lines to your oscilloscope probes and turn the encoder’s shaft! You’ll need a two channel scope (most are). All you need to do is to connect the rotary encoder’s VCC and GND to +5 volt and ground respectively. Connect DT to channel 1, and CLK to channel 2. Connect both ground leads of the scope to the same ground as your rotary encoder.

Lastly, using the same principles from above, your micro controller can time how long it takes for the clock and/or data line to pass from one pad to the next. From this it can determine simple how fast the rotary encoder is turning!

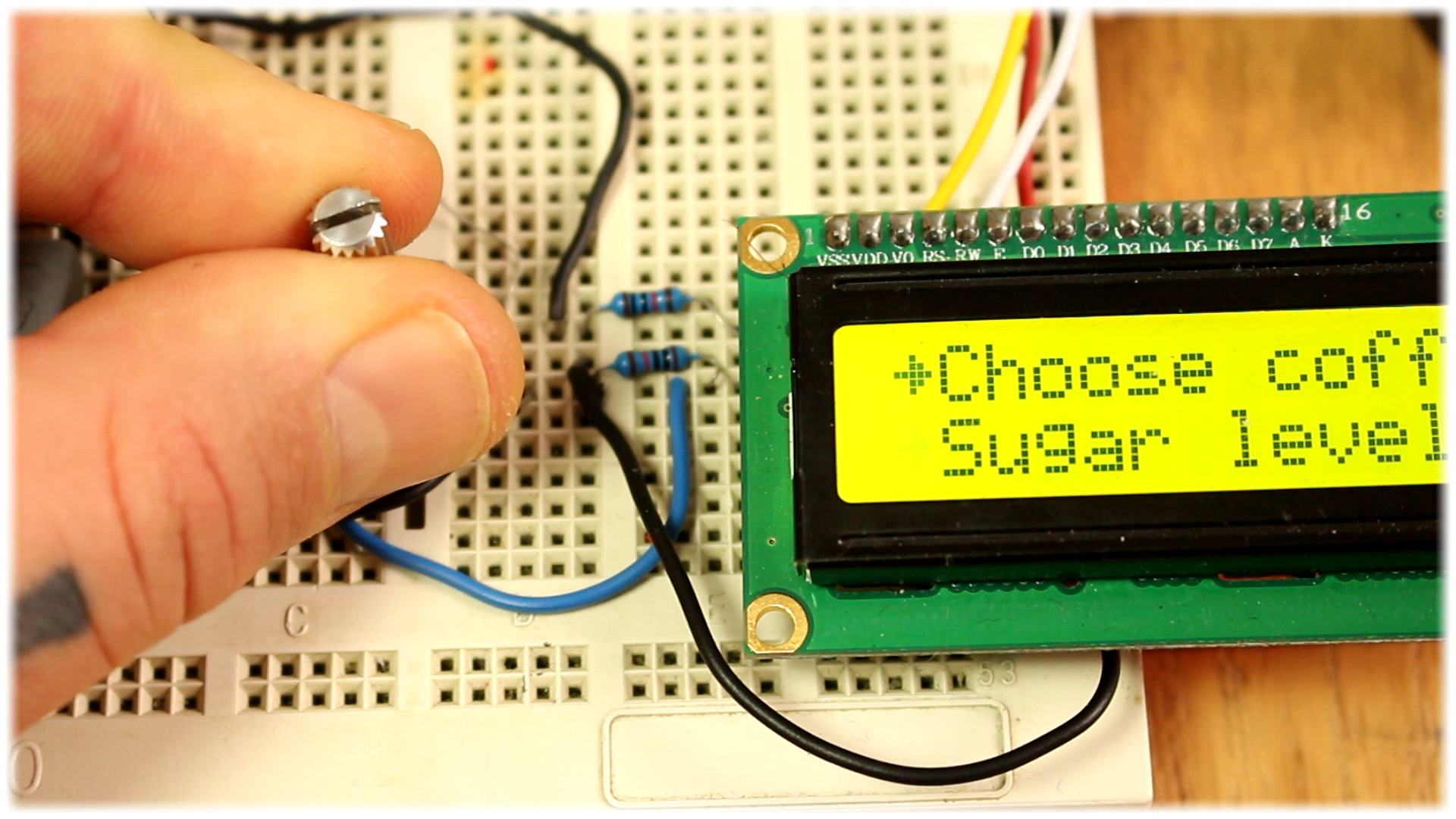

As we continue to learn how rotary encoders work, let’s look at a real world example that we can use in our projects. In this example, we will increment and decrement a a number on an LCD screen using the encoder! Turning the encoder clockwise will increment the number, while turning it counter clockwise will decrement the number.

Follow this Fritzing style diagram to wire up your rotary encoder module to an Arduino Uno. Although not completely necessary, I recommend adding two 1µF capacitors to your project. Connected to the CLK and DT lines. This will help debounce some cheap rotary encoders.

With the project completed, you’re now ready to count numbers on your LCD display! Turning the rotary encoder clockwise and counter clockwise should count numbers up or down! Now you know how rotary encoders work!

Sometimes, especially with cheaper rotary encoders, this code and wiring style will result in an encoder that “bounces.” This is the same type of bounce problem you might find with a momentary push-button switch. If you experience your counter jumping past numbers, such as skipping from 5 straight to 8 for example then you’ve got a bounce problem.

concept is used in big operating systems. So pressing a button will not directly call a “display_screen()” function, it will fire a message (the Object

Inside the Bourns encoders are 8 contactor tracks (which are connected to the 8 external pins on the encoder), and depending on where the shaft of the encoder is, those tracks convert to a specific binary code (00010001).

Since it uses a mechanical way to know where it is, this type of encoder will always return the same results, even when the power is removed from the Arduino.

In this tutorial we didnt’ use the capability of the encoder to ‘remember’ it’s position after a power failure, but this could be a great option for some projects.

As many electronic components, you might not have a use for such an encoder right now, but it’s always good to know it exists and might be the solution for a future project!

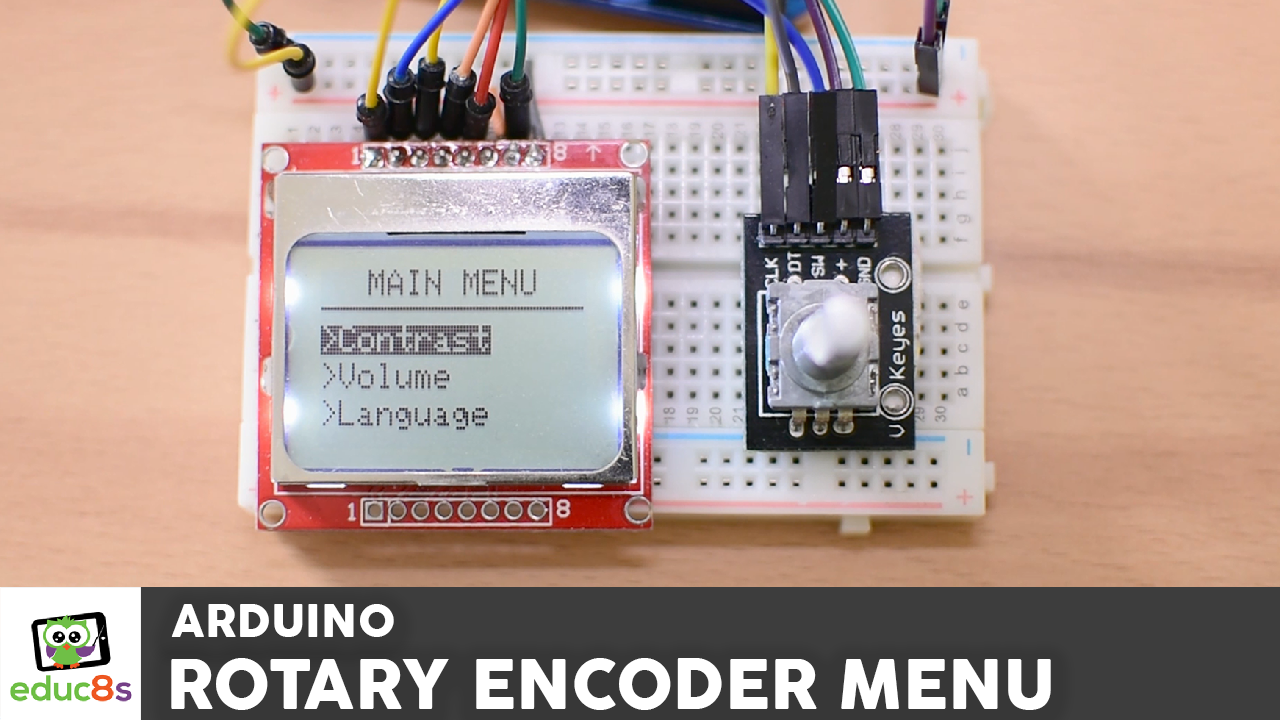

In today’s tutorial, we are going learn how to build our own menu for the popular Nokia 5110 LCD display, in order to make our projects more user-friendly and infuse it with more capabilities. We have built a similar project in the past, but a lot of our viewers suggested that I should prepare another video on this subject so here it is.

The last time out, we used pushbuttons to navigate through the menu, but today, we will be using the rotary encoder to navigate through the menu. We will also be adding more options to the menu from the previous tutorial to enable us fully explore the ability of the rotary encoder to serve as a navigation tool.

A rotary encoder is an electro-mechanical device which converts the angular position or rotation of its shaft or axle to an analog or digital signal. They are used in several systems where precision and feedback in terms of rotational motion or angular position are required. Another good feature of the rotary encoder which will come in handy for this tutorial is that they come with buttons attached, so it can be clicked by pressing the nob and it will be recognized by the Arduino just as it will if it were any other button or switch.

To demonstrate the Arduino rotary encoder menu, we will be creating a simple menu which is displayed on the Nokia 5110 LCD display when the project is powered and with the rotary encoder, we will be able to navigate up or down the menu, selecting a menu option by pressing the rotary encoder button. The menu has 6 items, and as we navigate and select each item, the display will change accordingly. Sound’s exciting then let’s build.

To implement this project, we will be using 4 libraries. Two out of the four libraries will be used for the display, and the remaining two will be used to interface with the rotary encoder.

Next, we write the void setup function. The void setup function contains the code used to initialize our screen and the rotary encoder setting it to start at zero. We also created an interrupt routine which will be used to detect button press during within any of the menu pages.

With the void setup() all done, we proceed to write the void loop function which is the one with some level of complexity. The function basically creates the menu and uses the variables created initially to keep track of the previous, current and next state so when the rotary encoder is turned, it knows the right menu to display. The menu selection part of the code is also handled by a routine within the void loop() function.

LCD Display Modules└ LEDs, LCDs & Display Modules└ Electronic Components & Semiconductors└ Electrical Equipment & Supplies└ Business & IndustrialAll CategoriesAntiquesArtBabyBooks & MagazinesBusiness & IndustrialCameras & PhotoCell Phones & AccessoriesClothing, Shoes & AccessoriesCoins & Paper MoneyCollectiblesComputers/Tablets & NetworkingConsumer ElectronicsCraftsDolls & BearsMovies & TVEntertainment MemorabiliaGift Cards & CouponsHealth & BeautyHome & GardenJewelry & WatchesMusicMusical Instruments & GearPet SuppliesPottery & GlassReal EstateSpecialty ServicesSporting GoodsSports Mem, Cards & Fan ShopStampsTickets & ExperiencesToys & HobbiesTravelVideo Games & ConsolesEverything Else

RoenDi is a rotary encoder with an integrated round color display. Based on an STM32L4 MCU, it can be programmed with the STM32CubeIDE or the Arduino IDE, and be used as an information display, an IoT controller, a locking mechanism, as well as in audio applications.

While I don’t think I had ever seen this type of hardware before, Xtech compared Roendi to two other similar products with the $220 GRAYHILL TE-M32M1-A11U rotary encoder with a touchscreen display but no I/Os, and the ~$130 SLB-10-40-0 rotary encoder with integrated display, but lacking a microcontroller.

RoenDi rotary encoder with display can be found on Crowd Supply for $99 with free worldwide shipping, but that’s without an enclosure. You’d need to pledge $128 for a complete kit adding a matte black aluminum enclosure, and an ST-LINK adaptor board with cable for programming. Backers will need to be patient, as deliveries are expected to start by June 30, 2023. The main culprit for the long lead time is the STM32L4 microcontroller that should be in stock in April 2023 for orders placed now.

Rotary encoders are electronic devices that can measure mechanical rotation. They can be used in two fashions – As a control or as a device to measure the rotation of a shaft.

When used as a control, rotary encoders can be much more versatile than a potentiometer. They can be used when you need a very precision control, and they are not subject to drift due to temperature.

Today we will look at both types of rotary encoders. I will show you how to hook them up to an Arduino and I’ll give you some demonstration sketches that you can run yourself.

Arotary encoder, which can also be referred to as ashaft encoder, is an electro-mechanical device that can convert the angular position (rotation) of a shaft to either an analog or digital output signals. We will be focusing on digital devices today.

There are two main types of rotary encoder: absolute and incremental. The difference is the absolute encoder gives the precise position of the shaft in degrees, whereas the incremental encoder reports how many increments the shaft has moved, but not its actual position.

Rotary encoders are used in many different applications including industrial controls, robotics, optomechanical mice and trackballs, CNC machines and printers.

There are several different types of rotary encoders. I’m restricting this discussion to the simpler “incremental” encoders. These are sometimes calledquadratureorrelativerotary encoders.

These encoders have two sensors and output two sets of pulses. The sensors, which can be magnetic (hall effect) or light (LED or Laser), produce pulses when the encoder shaft is rotated.

In the above example the encoder shaft is spinning clockwise. The sensor on the top is triggered before the bottom one, so the top set of pulses precedes the bottom set.

The control encoder we are going to use is a very common device, and it’s available from several sources. It’s also included in the infamous “37 in one” sensor kit that is available at many electronic stores and online.

The encoder can be mounted exactly like a potentiometer, and it has a D-shaft to accept a knob. It also has its own push button momentary contact switch that can be activated by pressing down upon the shaft.

Motor encoders are mounted on the shaft of a DC motor and can count the amount that the motor shaft has moved. Coupled with a motor driver, this will allow you to create a feedback mechanism that can permit you to specify how much you would like the shaft to turn.

The encoder I’m illustrating here is the one that is attached to the gear motor I am using in my DB1 Robot from my Build a REAL Robot series of articles and videos. It is agoBILDA 5201 Series Spur Gear Motorwith a built-in encoder.

Reading a control encoder with an Arduino is actually fairly straightforward. We just need to read input pulses and count them. We also need to determine which set of pulses is occurring first, so that we can determine the direction of rotation.

You will notice that in addition to the rotary encoder I have added a couple of LEDs. These will indicate the direction that we are spinning the encoder shaft.

The Setup is pretty straightforward, we setup the serial monitor, define the connections to the encoder as inputs and the connections to the two LEDs as outputs.

Next the logic to determine the direction of rotation. We now look at the DT pin on the encoder module and compare it to the current state of the CLK pin.

This is a great application for a rotary encoder as it will let you position the servo motor very precisely. It would be a great way to operate a robot arm, for example, as it would let you precisely position the arm and its grip. Of course, you would need to add more encoders and more servo motors to the design.

Before I hook up the encoder to an Arduino thought it might be a good opportunity to take a look at the pulses that it produces. So I hooked the two outputs up to my oscilloscope.

You could also use the two square waves to make a more accurate encoder, reading the combination of pulses to get much finer resolution. However, as my encoder gives out 374 pulses per rotation it is already accurate to less than a degree. That is accurate enough for my purposes.

Now let’s test the encoder with an Arduino. We will hook it up, along with a motor driver and a potentiometer to control speed and read the RPM of the motor.

In this sketch we will need to use interrupts to count pulses from our encoder, this is because our pulses will be arriving pretty quickly as compared to reading an encoder control.

Before we can use the sketch we need to know how many pulses our encoder will produce for one rotation of the motor. You can determine this from the specification sheet for your motor. Without this value, you won’t be able to get an accurate RPM reading.

We will use the longencoderValueto keep track of the pulses we receive from the encoder. Then we will count how many of these occur in one second. By multiplying this by 60 we’ll know how many pulses we should get in a minute. If we divide this value by theENC_COUNT_REVthen we can determine the RPM of the motor shaft.

I also will be building a complete motor controller using the rotary encoder included with my gear motor. Being able to position my robot to within less than a millimeter is an extremely attractive proposition.

Rotary Encoders can be used in two fashions - as a control with more versatility than a potentiometer, and as a device to measure mechanical rotation. Today I will show you how to use both types of rotary encoders.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey