high temperature lcd display free sample

Liquid crystal displays (LCD) have become an essential component to the industry of display technology. Involved in a variety of contexts beyond the indoors like LCD TVs and home/office automation devices, the LCD has expanded its usage to many environments, such as cars and digital signage, and, thus, many temperature variations as well.

As with any substance that requires a specific molecular characteristic or behavior, LCDs have an operating temperature range in which the device, if within, can continue to function properly and well. In addition to that, there is also an ideal storage temperature range to preserve the device until used.

This operating temperature range affects the electronic portion within the device, seen as falling outside the range can cause LCD technology to overheat in hot temperatures or slow down in the cold. As for the liquid crystal layer, it can deteriorate if put in high heat, rendering it and the display itself defective.

In order for the LCD panel to avoid defects, a standard commercial LCD’s operation range and storage range should be kept in mind. Without adaptive features, a typical LCD TV has an operating range from its cold limit of 0°C (32°F) to its heat limit of 50°C (122°F) (other LCD devices’ ranges may vary a bit from these numbers).

The storage range is a bit wider, from -20°C (-4°F) to 60°C (140°F). Though these ranges are quite reasonable for many indoor and even outdoor areas, there are also quite a few regions where temperatures can drop below 0°C or rise above 32°C, and in these conditions, LCDs must be adapted to ensure functionality.

Heat, can greatly affect the electronics and liquid crystals under an LCD screen. In consideration of heat, both external heat and internally generated heat must be taken into consideration.

Seen as the liquid crystals are manipulated in a device by altering their orientations and alignments, heat can disrupt this by randomizing what is meant to be controlled. If this happens, the LCD electronics cannot command a certain formation of the liquid crystal layer under a pixel, and the LED backlighting will not pass through as expected, which can often lead to dark spots, if not an entirely dark image. This inevitably disrupts the display’s readability.

Depending on the upper limit of the operation temperature range, LCD device can be permanently damaged by extreme heat. With long exposure to extreme heat, besides the destruction of the liquid crystals, battery life can shorten, hardware can crack or even melt, response time may slow to prevent even more heat generation from the device.

The LED backlight and the internal circuitry, typically TFT-based in the common TFT LCDs, are components that can generate heat that damages the device and its display. To address this concern with overheating, many devices use cooling fans paired with vents.

Some devices that are used in extremely high ambient temperatures may even require air conditioning. With air vents to carry the heat out, the device can expel it into the surroundings.

But this leads to another problem: how can moisture be prevented from entering through the vent? If moisture enters the device and high heat is present, condensation can occur, fogging the display from inside, and in some cases, short-circuiting may cause the device to turn off. In order to circumvent this issue, the shapes of the air vents are specific in a way that allows only for air movement, not forms of moisture.

In the opposite direction is extreme cold. What typically occurs in the cold is “ghosting” (the burning of an image in the screen through discoloration) and the gradual slowing and lagging of response times. Like heat-affected LCD modules, the extreme temperature can affect the liquid crystals. This layer is a medium between the liquid and solid state, so it is still susceptible to freezing.

An LCD device can be left in freezing temperatures because it will likely not be permanently damaged like in the heat, but it is important to understand the device’s limits and how to take precautions when storing the device. The standard and most common lower-bound storage range limit is -20°C, below freezing, but if possible, it would be best to keep it above that limit, or else there is still a risk of permanent damage.

If the device is not adapted for the cold, it would be good to keep it bundled up, trapping the heat within layers. However, this is only a temporary solution. Adapted, rugged devices have advantages such as screen enclosure insulation for heat level preservation and, in more extreme cases, heaters to generate extra heat to raise the internal temperature to a level above the minimum.

When selecting the appropriate module, it is necessary to understand the device’s expected primary application. The application will decide factors such as display type, environmental conditions, whether or not power consumption is a factor, and the balance between performance and cost. These factors can have an effect on the operation and storage temperature ranges for the device.

Display types have a lot of variation. Choices like alphanumeric or graphic LCD, human-machine interactive LCD modules and touchscreen panels capabilities, the width of the viewing angle, level of contrast ratios, types of backlighting, and liquid crystal alignment methods are often considered. For example, the twisted nematic LCD provides for the fastest response time at the lowest cost, but cannot offer the highest contrast ratio or widest viewing angle.

Environment-based factors must consider things besides the obvious temperature like UV exposure and humidity/moisture, as they all are necessary in finding the perfect fit extreme temperature LCD module.

Besides the LCD modules, recent new products have opened doors in wide temperature range displays, such as OLED displays. OLED displays offer better displays in regard to contrast, brightness, response times, viewing angles, and even power consumption in comparison to traditional LCD displays.

These benefits, in addition to its ability to achieve a wide temperature range, provide more options for consumers in search of high quality displays for extreme climates.

LCD panel is an advanced glass product that has precise and specific orientation processing. If the panel is under tremendous pressure, the orientation of the panel may be disturbed and it is very difficult to return to the original state. If it is dropped on a floor or hit on a hard object, it is very easy to be cracked or broken.

b. When glass LCD panel is installed in the enclosure, you must be careful and not put excess pressure on the glass with your fingers. Otherwise, it may shorten the using time of LCD screen because of the mistaken operation.

d. You should be careful when you touch the polarizer film because it is very tender and susceptible to be damage. You should remove the protective film which protects the polarizer film before you install the LCD panel.

a. It should avoid being stored in a hot and humid conditions. If it is going to be stored for a long time, it should be stored at a temperature between 15 ℃ to 35 ℃ and humidity less than 65%.

Description The OM-CP-TCTEMP2000 is a battery powered thermocouple temperature data logger with an LCD display. This data logger has an internal temperature sensor and one external input for J, K, T, E, R, S, B, and N type thermocouples. The 8-button keypad and large LCD provide convenient access to current data and recorder setup. Additionally, memory and battery levels, external power status, and sampling and recording status are shown on the LCD.

Available on-screen data includes: statistics (min, max, average) recording status (start, stop and recording rate) display options (units, text size) and calibration information (date calibrated, date for recalibration). Statistics can be cleared at any time during logging. With 131,071 readings, the OM-CP-TCTEMP2000 has one of the largest memory capacities of any similar data recorder on the market. The non-volatile memory will retain recorded data, even if AC and battery power are lost. The OM-CP-TCTEMP2000 runs on a 9 V battery with a typical battery life of 1 year at a 1 min reading rate with the display off. With continuous LCD and no backlight usage, the average battery life is 30 days. For power savings, both the LCD and backlight have configurable auto-off options.

Those wanting to keep the LCD display and backlight continuously active need only to connect the unit to an AC power supply, keeping the 9 V battery connected as a back-up. NIST traceable calibration is available for users needing to meet regulatory requirements. Creating permanent records, performing data calculations, and the graphing of data is quick and easy: Simply connect the interface cable to an availableUSB or serial port and, with a few clicks of the mouse, data is downloaded and ready for review or export to Excel.

The use of liquid crystal displays (LCDs) in user interface assemblies is widespread across nearly all industries, locations, and operating environments. Over the last 20 years, the cost of LCD displays has significantly dropped, allowing for this technology to be incorporated into many of the everyday devices we rely on.

The odds are high you are reading this blog post on a laptop or tablet, and it’s likely the actual screen uses LCD technology to render the image onto a low-profile pane of glass. Reach into your pocket. Yes, that smartphone likely uses LCD technology for the screen. As you enter your car, does your dashboard come alive with a complex user interface? What about the menu at your favorite local drive-thru restaurant? These are some everyday examples of the widespread use of LCD technology.

But did you know that the U.S. military is using LCD displays to improve the ability of our warfighters to interact with their equipment? In hospitals around the world, lifesaving medical devices are monitored and controlled by an LCD touchscreen interface. Maritime GPS and navigation systems provide real-time location, heading, and speed information to captains while on the high seas. It’s clear that people’s lives depend on these devices operating in a range of environments.

As the use of LCDs continues to expand, and larger screen sizes become even less expensive, one inherent flaw of LCDs remains: LCD pixels behave poorly at low temperatures. For some applications, LCD displays will not operate whatsoever at low temperatures. This is important because for mil-aero applications, outdoor consumer products, automobiles, or anywhere the temperature is below freezing, the LCD crystal’s performance will begin to deteriorate. If the LCD display exhibits poor color viewing, sluggish resolution, or even worse, permanently damaged pixels, this will limit the ability to use LCD technologies in frigid environments. To address this, there are several design measures that can be explored to minimize the impact of low temperatures on LCDs.

Most LCD displays utilize pixels known as TFT (Thin-Film-Transistor) Color Liquid Crystals, which are the backbone to the billions of LCD screens in use today. Since the individual pixels utilize a fluid-like crystal material as the ambient temperature is reduced, this fluid will become more viscous compromising performance. For many LCD displays, temperatures below 0°C represent the point where performance degrades.

Have you tried to use your smartphone while skiing or ice fishing? What about those of you living in the northern latitudes - have you accidently left your phone in your car overnight where the temperatures drop well below freezing? You may have noticed a sluggish screen response, poor contrast with certain colors, or even worse permanent damage to your screen. While this is normal, it’s certainly a nuisance. As a design engineer, the goal is to select an LCD technology that offers the best performance at the desired temperature range. If your LCD display is required to operate at temperatures below freezing, review the manufacturer’s data sheets for both the operating and storage temperature ranges. Listed below are two different off-the-shelf LCD displays, each with different temperature ratings. It should be noted that there are limited options for off-the-shelf displays with resilience to extreme low temperatures.

For many military applications, in order to comply with the various mil standards a product must be rated for -30°C operational temperature and -51°C storage temperature. The question remains: how can you operate an LCD display at -30°C if the product is only rated for -20°C operating temperature? The answer is to use a heat source to raise the display temperature to an acceptable range. If there is an adjacent motor or another device that generates heat, this alone may be enough to warm the display. If not, a dedicated low-profile heater is an excellent option to consider.

Made of an etched layer of steel and enveloped in an electrically insulating material, a flat flexible polyimide heater is an excellent option where space and power are limited. These devices behave as resistive heaters and can operate off a wide range of voltages all the way up to 120V. These heaters can also function with both AC and DC power sources. Their heat output is typically characterized by watts per unit area and must be sized to the product specifications. These heaters can also be affixed with a pressure sensitive adhesive on the rear, allowing them to be “glued” to any surface. The flying leads off the heater can be further customized to support any type of custom interconnect. A full-service manufacturing partner like Epec can help develop a custom solution for any LCD application that requires a custom low-profile heater.

With no thermal mass to dissipate the heat, polyimide heaters can reach temperatures in excess of 100°C in less than a few minutes of operation. Incorporating a heater by itself is not enough to manage the low temperature effects on an LCD display. What if the heater is improperly sized and damages the LCD display? What happens if the heater remains on too long and damages other components in your system? Just like the thermostat in your home, it’s important to incorporate a real-temp temperature sensing feedback loop to control the on/off function of the heater.

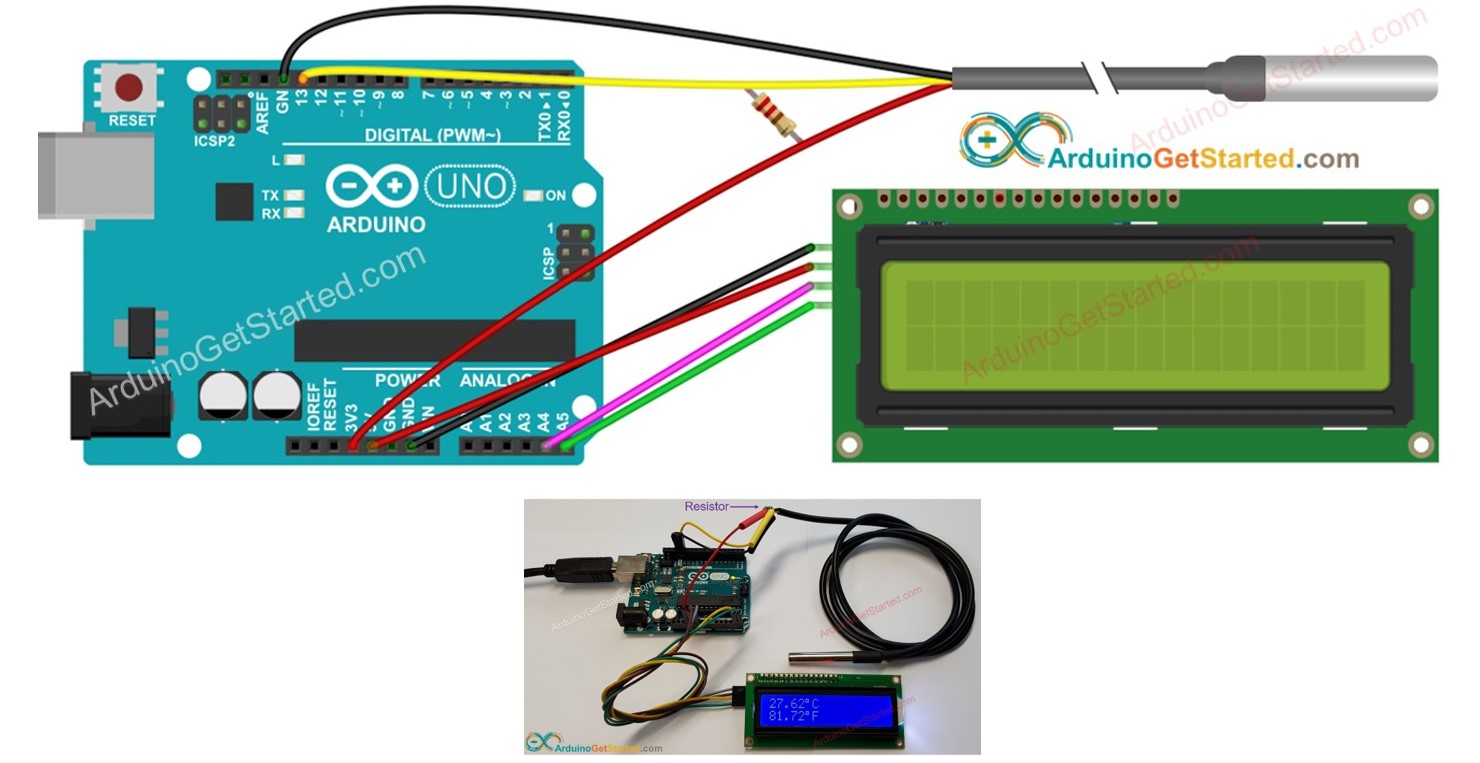

The first step is to select temperature sensors that can be affixed to the display while being small enough to fit within a restricted envelope. Thermistors, thermocouples, or RTDs are all options to consider since they represent relatively low-cost and high-reliability ways to measure the display’s surface temperature. These types of sensors also provide an electrical output that can be calibrated for the desired temperature range.

The next step is to determine the number of temperature sensors and their approximate location on the display. It’s recommended that a minimum of two temperature sensors be used to control the heater. By using multiple sensors, this provides the circuit redundancy and allows for a weighted average of the temperature measurement to mitigate non-uniform heating. Depending on the temperature sensors location, and the thermal mass of the materials involved, the control loop can be optimized to properly control the on/off function of the heater.

Another important consideration when selecting a temperature sensor is how to mount the individual sensors onto the display. Most LCD displays are designed with a sheet metal backer that serves as an ideal surface to mount the temperature sensors. There are several types of thermally conductive epoxies that provide a robust and cost-effective way to affix the delicate items onto the display. Since there are several types of epoxies to choose from, it’s important to use a compound with the appropriate working life and cure time.

For example, if you are kitting 20 LCD displays and the working life of the thermal epoxy is 8 minutes, you may find yourself struggling to complete the project before the epoxy begins to harden.

Before building any type of prototype LCD heater assembly, it’s important to carefully study the heat transfer of the system. Heat will be generated by the flexible polyimide heater and then will transfer to the LCD display and other parts of the system. Although heat will radiate, convect, and be conducted away from the heater, the primary type of heat transfer will be through conduction. This is important because if your heater is touching a large heat sink (ex. aluminum chassis), this will impact the ability of the heater to warm your LCD display as heat will be drawn toward the heat sink.

Insulating materials, air gaps, or other means can be incorporated in the design to manage the way heat travels throughout your system on the way toward an eventual “steady state” condition. During development, prototypes can be built with numerous temperature sensors to map the heat transfer, allowing for the optimal placement of temperature sensors, an adequately sized heater, and a properly controlled feedback loop.

Before freezing the design (no pun intended) on any project that requires an LCD display to operate at low temperatures, it’s critical to perform low temperature first. This type of testing usually involves a thermal chamber, a way to operate the system, and a means to measure the temperature vs time. Most thermal chambers provide an access port or other means to snake wires into the chamber without compromising performance. This way, power can be supplied to the heater and display, while data can be captured from the temperature sensors.

The first objective of the low-temperature testing is to determine the actual effects of cold exposure on the LCD display itself. Does the LCD display function at cold? Are certain colors more impacted by the cold than others? How sluggish is the screen? Does the LCD display performance improve once the system is returned to ambient conditions? These are all significant and appropriate questions and nearly impossible to answer without actual testing.

As LCD displays continue to be a critical part of our society, their use will become even more widespread. Costs will continue to decrease with larger and larger screens being launched into production every year. This means there will be more applications that require their operation in extreme environments, including the low-temperature regions of the world. By incorporating design measures to mitigate the effects of cold on LCD displays, they can be used virtually anywhere. But this doesn’t come easy. Engineers must understand the design limitations and ways to address the overarching design challenges.

A full-service manufacturing partner like Epec offers a high-value solution to be able to design, develop, and manufacture systems that push the limits of off-the-shelf hardware like LCD displays. This fact helps lower the effective program cost and decreases the time to market for any high-risk development project.

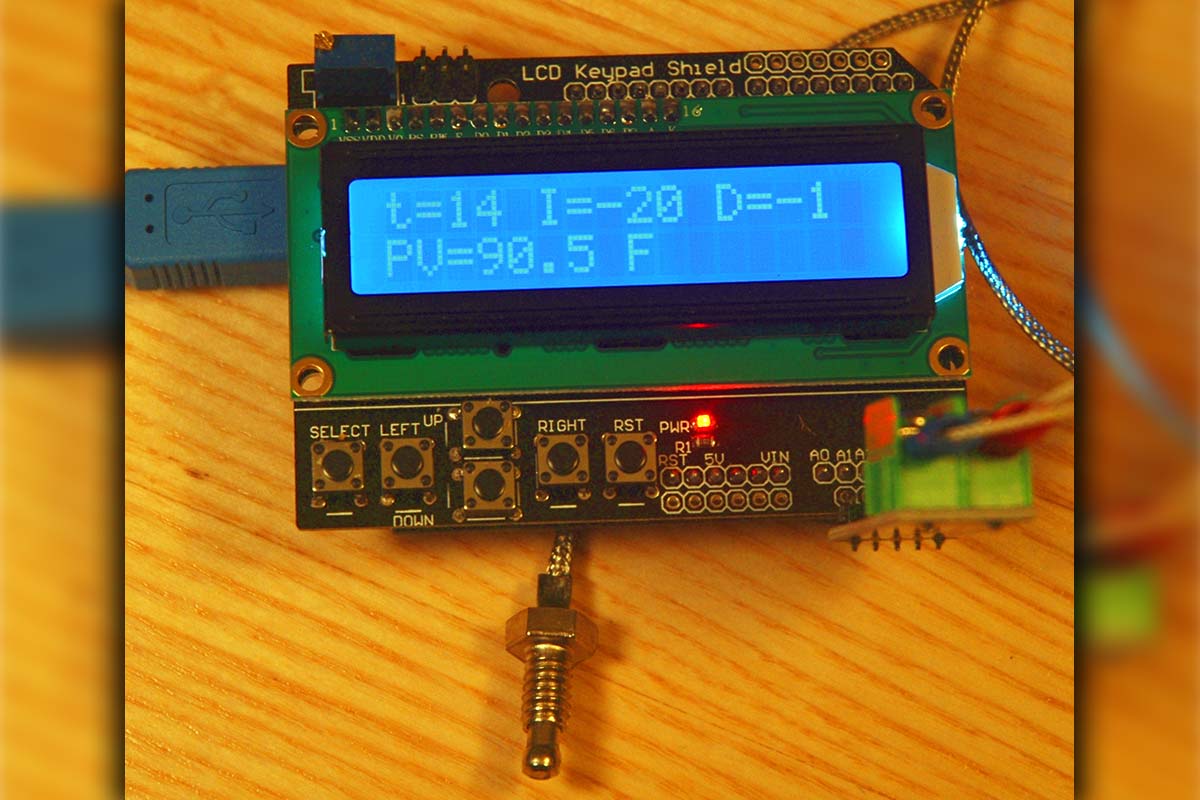

The EL-USB-TP-LCD is a stand-alone single channel thermistor data logger. With a measurement range from -40 to +125°C (-40 to +257°F), the included 1 meter thermistor probe is accurate to within ±1.5°C (±2°F). With a storage capacity of 32,510 readings, and sample intervals ranging from 1 second to 12 hours, the EL-USB-TP-LCD can log temperature data for days, weeks or months at a time. Programmable alarms allow you illuminate a LED when temperatures rise above or fall below user-defined levels.

A high contrast LCD display allows you to view the current temperature, the scale (°C or °F) and the minimum/maximum logged value. The included EL-WIN-USB software allows you to choose a thermistor type, set the sample interval, and specify alarm levels. In addition, the software allows you to graph recorded data, print it, or export it to Microsoft Excel format.

The EL-USB-2-LCD data logger measures and stores up to 16,379 relative humidity and 16,379 temperature readings over 0 to 100%RH and -35 to +80°C (-31 to +176°F) measurement ranges. The user can easily set up the logger and view downloaded data by plugging the data logger into a PC’s USB port and using the supplied software. Relative humidity, temperature and dew point (the temperature at which water vapour present in the air begins to condense) data can then be graphed, printed and exported to other applications. The high contrast LCD can show a variety of temperature and humidity information. At the touch of a button, the user can cycle between the current temperature and humidity, along with the maximum and minimum stored values for temperature and humidity. The data logger is supplied complete with a long-life lithium battery, which can typically allow logging for up to 1 year.

This compact, 4-20mA loop powered panel meter features a 3½ digit LCD with 11mm (0.43") digit height, LED backlighting and one-piece snap-in housing. Calibration is by two multi-turn potentiometers and connection to the current loop is via two screw terminals.

10.1inch lanscape screen, wide temperature -30~+80 , 1000nits, high brightness, sunlight readable, USB touch panel, I2C touch screen, HDMI board, 10.1 inch LCD display, 10.1"" display, 1280x800, 40pin, LVDS interface, Free/All/Wide viewing ang

I"ve gone through a fair number of thermometers in the kitchen, as they never seem to last, but I was extremely impressed with the ThermPro TP-16. Fast, accurate temperatures, from a small device with a very good build quality. The size of this is perfect for keeping in a drawer so that it is always ready when needed. And with the quality of the product you always know you will be able to get an accurate temperature, which is important when dealing with food safety. I did receive this item for free to test, but I would definitely purchase it given my experience. I will be recommending this brand and model to any of my friends and family who would benefit from a quality meat thermometer.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey