custom lcd display heater free sample

Because of its transparency and thinness, it can be incorporated into LCD module, such as between liquid crystal and backlight, and between touch panel and liquid crystal.

We support you from the product design stage. We will customize the design such as heater size & shape, wiring, and temperature control, according to the customer’s request.

Whether supplying the heater film alone or as part of the module including the laminated cover glass, touch sensor and LCD display Nissha can support. Our project and QA management experience for film touch sensor programs seamlessly extends to the inclusion of optically clear film heater from development through to mass production.

Orient Display is a company that specializes in manufacturing LCD displays, touch panels, OLED displays with competitive prices. The company was founded in 1996 by specializing in fields of production, R&D, quality controls. Thanks for the management and employee’s continuous hardworking and enormous effort and shareholder continuous investment over years, Orient Display factory is now the world’s leading custom LCD manufacturer in flat panel industry and is listed as a public company in China stock market. Now, Orient Display factory has 2 production lines that can produce PMOLED and AMOLED custom display modules. Factories have complete quality and environment management system, ISO9001, ISO/IATF16949, ISO14001, IECQ QC080000. Orient Display takes around 18% market share in global automotive market and is No.1 in automotive capacitive touch screen.

Orient Display has supported customers with custom LCD displays for tens of thousands of types and models for automotive, appliances, medical, smart homes, point of sales, industrial advices, etc. Whether your design requires a small custom LCD display glass, or a fully customized LCD module, or custom monitors and displays equipped with complicated embedded control board with touch panels, our experienced engineers in North America, Europe or in China factory will assist you in designing your customized displays.

Orient Display customer service sends quotation to you (might come with technical suggestions according to your targeted applications). The time will depend on the complexity of the project and the time to source components, normally, it takes 1-3 days for custom LCD glass panels, 2-5 days for custom LCD display modules or touch panels.

Orient Display engineers provide custom LCD display counter-drawings for you to approve with your signature on the drawing. The drawings might be modified several times until the designs are fully achieved your technical requirements. There can be a lot of technical discussions at this stage. The time our engineers take to arrange drawings also depend on the complexity of the project. Normally, it takes 1-3 days for custom LCD glass panels, 2-5 days for custom LCD display modules or touch panels.

After your drawing approval, Orient Display will start to make samples or prototypes for you to test. The lead time also varies depending on the production complexity and component/material sourcing. Normally, it takes 4-6 weeks for custom LCD glass panels, 8-10 weeks for custom LCD display modules or touch panels.

After your sample / prototype approval, Orient Display is ready for production. Orient Display welcomes trial production between the prototypes to large scale production so that you have the opportunity to fully test the custom LCD display or touch panel to run well in your designed products.

Congratulations! You have accomplished the journey of the idea, design, prototype and production in the market. The journey can take from 3 months to 3 years. Whatever the voyage, Orient Display’s engineers, customer services are proud to be part of your design. Our happiness is based on your success.

Dimensions (Specification / Drawing / Sketch of the LCD, if available). If it is a drop-in replacement, it is great to provide files in dwg. or dxf. format.

LCD Mode Preference if you have an idea or let us to decide (TN Positive/Negative, STN Positive YG, STN Negative Blue, STN Positive Gray, FSTN Positive, FSTN Negative, FFSTN Negative);

Dimensions (Specification / Drawing / Sketch of the LCD module, if available). If it is a drop-in replacement, it is great to provide files in dwg. or dxf. format.

LCD Mode Preference if you have an idea or let us to decide (TN Positive/Negative, STN Positive YG, STN Negative Blue, STN Positive Gray, FSTN Positive, FSTN Negative, FFSTN Negative);

Fully custom made TFT LCD display module can be very expensive, the NRE ranges from $80,000 to $1M depending on the size and the resolution of the LCD display and the generation of the production line the LCD display to be produced. For over 99% of our projects, we are talking about the modifications of the standard TFT LCD display. There are a lot of standard color TFT displays available in the market. You are highly likely to find one matching your requirement. If you can’t find a suitable one on our website, please check with our engineers, we have a database in factory with much more types.

Dimensions (Specification / Drawing / Sketch of the LCD module, if available). If it is a drop replacement, it is great to provide files in dwg. or dxf. format.

The above information can be overwhelming. Actually, we design a lot of touch panel and LCD custom display projects without being provided detailed information. Our engineers and customer service can quickly decide the parameters based on the customer’s application. Please feel free to contact our engineers for details.

Orient Display LCD displays are the general category that includes LCD display glass panels, character LCD modules, graphic lcd modules, Arduino LCD displays, and our featured JAZZ series graphic LCD displays.

Graphic LCD Displays: Our standard LCD Graphic display products range from 122 x 32 pixels to 320 x 240-pixel resolution. These displays are available in positive or negative STN, blue STN, FSTN, or FFSTN with multiple backlight color options. They can be either traditional Chip-On-Board (COB) LCDs or Chip-On-Glass (COG) LCDs for displays with a smaller footprint and lower power consumption. COGs come in the same display types and colors as our other LCD modules but are designed without a PCB to allow for a slimmer profile.

JAZZ Graphic LCD Displays: The series are exclusive for Orient Display 128 x 64 pixels with the selection of yellow green STN, blue STN, positive or negative FSTN display, with the options of yellow green, green amber, blue, red or RGB tricolor backlights, with or without resistive touch panels. JAZZ series have two sizes: 1.0” and 2.7”.

VTN Character LCD Displays: Orient Display VTN is vertical alignment LCDs which provide superior black background and then great contrast with the options of yellow green, green amber, blue, red or RGB tricolor backlights.

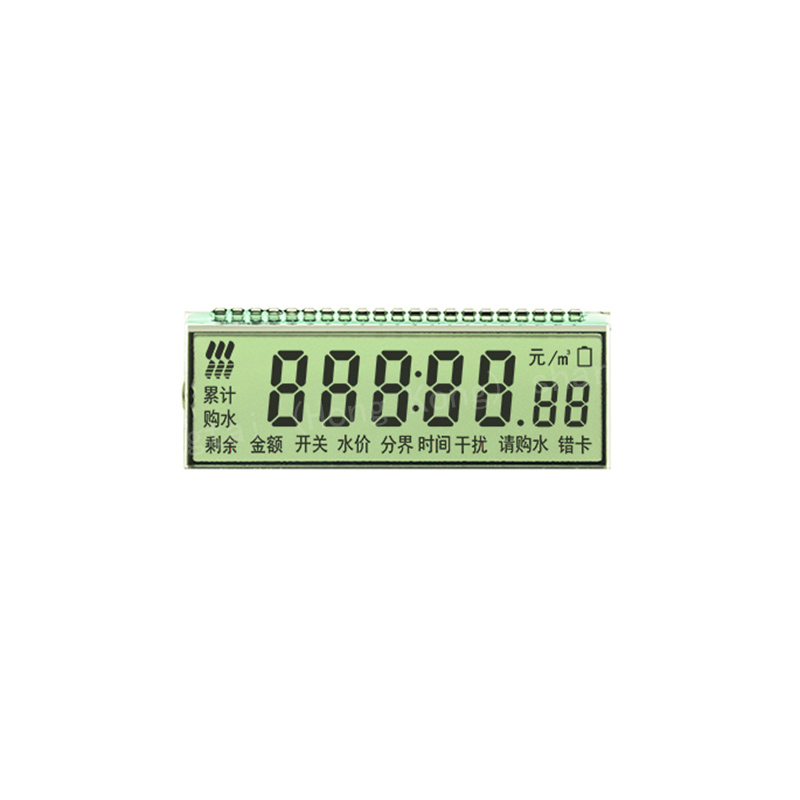

LCD Glass Screens (Panels): Orient Display LCD display panels include different options of polarizer in reflective (saving power), transmissive (better contrast) or transflective (sunlight readable and battery powered) types. Orient LCD glass panels include 1; 2; 2.1/2; 3; 3.1/2; 3.3/4; 4; 4.1/2; 5; 6; 8; and 24 digits. Orient LCD glass panels also include 7 , 14 or 16 segments to display digits and alphanumeric letters. The temperature ranges are from room temperature to wide temperature applications. Orient LCD glass panels can have metal pin or zebra connections.

ARDUINO LCD Displays: Orient Display creates special character LCD displays with SPI interface which is easily hooked up with Arduino, which has been widely acceptable in the electronic design. The series includes 8 x 2 characters, 16 x 2 characters, 20 x 2 characters and 20 x 4 characters with either yellow green STN with yellow green LED backlight or blue STN with white LED backlight.

Although Orient Display provides many standard small size OLED, TN or IPS Arduino TFT displays, custom made solutions are provided with larger size displays or even with capacitive touch panel.

If you have any questions about Orient Display TFT LCD displays or if you can’t find a suitable product on our website. Please feel free to contact our engineers for details.

NHD-C12864A1Z-FSB-FBW-HTT | Monochrome Graphic COG | 128x64 Pixels | Transflective LCD | Side Blue Backlight | FSTN (+) Positive Display | Built-in 12V Heater & Temp Comp Circuit

Newhaven 128x64 graphic Chip-On-Glass (COG) Liquid Crystal Display shows dark pixels on a blue background. This transflective LCD Display is visible with ambient light or a backlight while offering a wide operating temperature range from -40 to 70 degrees Celsius. This NHD-C12864A1Z-FSB-FBW-HTT display includes a built-in 12V heater, and temperature compensation circuit. It has an optimal view of 6:00, operates at 3V supply voltage and is RoHS compliant.

Easily modify any connectors on your display to meet your application’s requirements. Our engineers are able to perform soldering for pin headers, boxed headers, right angle headers, and any other connectors your display may require.

Choose from a wide selection of interface options or talk to our experts to select the best one for your project. We can incorporate HDMI, USB, SPI, VGA and more into your display to achieve your design goals.

NHD-C12864A1Z-FSR-FBW-HTT | Monochrome Graphic COG | 128x64 Pixels | Transflective LCD | Side Red Backlight | FSTN (+) Positive Display | Built-in 12V Heater & Temp Comp Circuit

Newhaven 128x64 graphic Chip-On-Glass (COG) Liquid Crystal Display shows dark pixels on a red background. This transflective LCD Display is visible with ambient light or a backlight while offering a wide operating temperature range from -40 to 70 degrees Celsius. This NHD-C12864A1Z-FSR-FBW-HTT display includes a built-in 12V heater, and temperature compensation circuit. It has an optimal view of 6:00, operates at 3V supply voltage and is RoHS compliant.

Easily modify any connectors on your display to meet your application’s requirements. Our engineers are able to perform soldering for pin headers, boxed headers, right angle headers, and any other connectors your display may require.

Choose from a wide selection of interface options or talk to our experts to select the best one for your project. We can incorporate HDMI, USB, SPI, VGA and more into your display to achieve your design goals.

The use of liquid crystal displays (LCDs) in user interface assemblies is widespread across nearly all industries, locations, and operating environments. Over the last 20 years, the cost of LCD displays has significantly dropped, allowing for this technology to be incorporated into many of the everyday devices we rely on.

The odds are high you are reading this blog post on a laptop or tablet, and it’s likely the actual screen uses LCD technology to render the image onto a low-profile pane of glass. Reach into your pocket. Yes, that smartphone likely uses LCD technology for the screen. As you enter your car, does your dashboard come alive with a complex user interface? What about the menu at your favorite local drive-thru restaurant? These are some everyday examples of the widespread use of LCD technology.

But did you know that the U.S. military is using LCD displays to improve the ability of our warfighters to interact with their equipment? In hospitals around the world, lifesaving medical devices are monitored and controlled by an LCD touchscreen interface. Maritime GPS and navigation systems provide real-time location, heading, and speed information to captains while on the high seas. It’s clear that people’s lives depend on these devices operating in a range of environments.

As the use of LCDs continues to expand, and larger screen sizes become even less expensive, one inherent flaw of LCDs remains: LCD pixels behave poorly at low temperatures. For some applications, LCD displays will not operate whatsoever at low temperatures. This is important because for mil-aero applications, outdoor consumer products, automobiles, or anywhere the temperature is below freezing, the LCD crystal’s performance will begin to deteriorate. If the LCD display exhibits poor color viewing, sluggish resolution, or even worse, permanently damaged pixels, this will limit the ability to use LCD technologies in frigid environments. To address this, there are several design measures that can be explored to minimize the impact of low temperatures on LCDs.

Most LCD displays utilize pixels known as TFT (Thin-Film-Transistor) Color Liquid Crystals, which are the backbone to the billions of LCD screens in use today. Since the individual pixels utilize a fluid-like crystal material as the ambient temperature is reduced, this fluid will become more viscous compromising performance. For many LCD displays, temperatures below 0°C represent the point where performance degrades.

Have you tried to use your smartphone while skiing or ice fishing? What about those of you living in the northern latitudes - have you accidently left your phone in your car overnight where the temperatures drop well below freezing? You may have noticed a sluggish screen response, poor contrast with certain colors, or even worse permanent damage to your screen. While this is normal, it’s certainly a nuisance. As a design engineer, the goal is to select an LCD technology that offers the best performance at the desired temperature range. If your LCD display is required to operate at temperatures below freezing, review the manufacturer’s data sheets for both the operating and storage temperature ranges. Listed below are two different off-the-shelf LCD displays, each with different temperature ratings. It should be noted that there are limited options for off-the-shelf displays with resilience to extreme low temperatures.

For many military applications, in order to comply with the various mil standards a product must be rated for -30°C operational temperature and -51°C storage temperature. The question remains: how can you operate an LCD display at -30°C if the product is only rated for -20°C operating temperature? The answer is to use a heat source to raise the display temperature to an acceptable range. If there is an adjacent motor or another device that generates heat, this alone may be enough to warm the display. If not, a dedicated low-profile heater is an excellent option to consider.

Made of an etched layer of steel and enveloped in an electrically insulating material, a flat flexible polyimide heater is an excellent option where space and power are limited. These devices behave as resistive heaters and can operate off a wide range of voltages all the way up to 120V. These heaters can also function with both AC and DC power sources. Their heat output is typically characterized by watts per unit area and must be sized to the product specifications. These heaters can also be affixed with a pressure sensitive adhesive on the rear, allowing them to be “glued” to any surface. The flying leads off the heater can be further customized to support any type of custom interconnect. A full-service manufacturing partner like Epec can help develop a custom solution for any LCD application that requires a custom low-profile heater.

With no thermal mass to dissipate the heat, polyimide heaters can reach temperatures in excess of 100°C in less than a few minutes of operation. Incorporating a heater by itself is not enough to manage the low temperature effects on an LCD display. What if the heater is improperly sized and damages the LCD display? What happens if the heater remains on too long and damages other components in your system? Just like the thermostat in your home, it’s important to incorporate a real-temp temperature sensing feedback loop to control the on/off function of the heater.

The first step is to select temperature sensors that can be affixed to the display while being small enough to fit within a restricted envelope. Thermistors, thermocouples, or RTDs are all options to consider since they represent relatively low-cost and high-reliability ways to measure the display’s surface temperature. These types of sensors also provide an electrical output that can be calibrated for the desired temperature range.

The next step is to determine the number of temperature sensors and their approximate location on the display. It’s recommended that a minimum of two temperature sensors be used to control the heater. By using multiple sensors, this provides the circuit redundancy and allows for a weighted average of the temperature measurement to mitigate non-uniform heating. Depending on the temperature sensors location, and the thermal mass of the materials involved, the control loop can be optimized to properly control the on/off function of the heater.

Another important consideration when selecting a temperature sensor is how to mount the individual sensors onto the display. Most LCD displays are designed with a sheet metal backer that serves as an ideal surface to mount the temperature sensors. There are several types of thermally conductive epoxies that provide a robust and cost-effective way to affix the delicate items onto the display. Since there are several types of epoxies to choose from, it’s important to use a compound with the appropriate working life and cure time.

For example, if you are kitting 20 LCD displays and the working life of the thermal epoxy is 8 minutes, you may find yourself struggling to complete the project before the epoxy begins to harden.

Before building any type of prototype LCD heater assembly, it’s important to carefully study the heat transfer of the system. Heat will be generated by the flexible polyimide heater and then will transfer to the LCD display and other parts of the system. Although heat will radiate, convect, and be conducted away from the heater, the primary type of heat transfer will be through conduction. This is important because if your heater is touching a large heat sink (ex. aluminum chassis), this will impact the ability of the heater to warm your LCD display as heat will be drawn toward the heat sink.

Insulating materials, air gaps, or other means can be incorporated in the design to manage the way heat travels throughout your system on the way toward an eventual “steady state” condition. During development, prototypes can be built with numerous temperature sensors to map the heat transfer, allowing for the optimal placement of temperature sensors, an adequately sized heater, and a properly controlled feedback loop.

Before freezing the design (no pun intended) on any project that requires an LCD display to operate at low temperatures, it’s critical to perform low temperature first. This type of testing usually involves a thermal chamber, a way to operate the system, and a means to measure the temperature vs time. Most thermal chambers provide an access port or other means to snake wires into the chamber without compromising performance. This way, power can be supplied to the heater and display, while data can be captured from the temperature sensors.

The first objective of the low-temperature testing is to determine the actual effects of cold exposure on the LCD display itself. Does the LCD display function at cold? Are certain colors more impacted by the cold than others? How sluggish is the screen? Does the LCD display performance improve once the system is returned to ambient conditions? These are all significant and appropriate questions and nearly impossible to answer without actual testing.

As LCD displays continue to be a critical part of our society, their use will become even more widespread. Costs will continue to decrease with larger and larger screens being launched into production every year. This means there will be more applications that require their operation in extreme environments, including the low-temperature regions of the world. By incorporating design measures to mitigate the effects of cold on LCD displays, they can be used virtually anywhere. But this doesn’t come easy. Engineers must understand the design limitations and ways to address the overarching design challenges.

A full-service manufacturing partner like Epec offers a high-value solution to be able to design, develop, and manufacture systems that push the limits of off-the-shelf hardware like LCD displays. This fact helps lower the effective program cost and decreases the time to market for any high-risk development project.

Whether by special request or recognizing a need that hasn"t been satisfied, General Digital creates many uniquely innovative LCD monitors, smart displays and keyboards, among other highly specialized HMI products. By working closely with our customers, we can specially design a component to perfectly satisfy your requirements. Below is a sampling of the interesting display systems and keyboards we"ve produced in recent years.

General Digital designed a custom version of our Barracuda environmentally-sealed monitor to meet customer-supplied specifications for fit, form and function. The display system is used as a fire control system (digital sight) for a portable rocket grenade launcher in combat situations. Design of this complex solution required General Digital’s mechanical, electrical, optical and software engineering expertise and integration skill sets. Watch the video of the L40-2 Grenade Launcher in action on the Department of Defence Australia YouTube channel.

As an advanced avionic monitor, it is equipped with multiple optional specialized features, such as an optically bonded LCD with EMI mesh and heater, panel mount adaptor, military-grade connectors, On/Off toggle switch with finger guard, and more.

Designed to meet specific requirements and specifications for a flight simulator application, General Digital’s new 21.5" ruggedized LCD monitor boasts a 1920 x 1080 full high definition resolution, and a sunlight readable LED night vision goggle-compatible backlight. This second generation LED/NVIS backlight provides more brightness, better uniformity and less power than the original backlight, which was designed for maritime applications. Configurations include an LED/NVIS display head assembly (with optional backlight driver board), and a standalone/mountable ruggedized enclosure, as pictured here.

Model TEC offers easy-to use programming and high accuracy, with a 200 ms sampling rate. The line of compact temperature controllers with bright, multicolor display is offered in 1/32 DIN through 1/4 DIN sizes and new DIN-rail-mount size. Features include Fuzzy+ PID control and autotuning; ease of programming; true universal inputs of thermocouple, RTD, milliamp and volts; soft-start function; ramp-and-soak profiler; and remote setpoint and up to six event inputs. Agency approvals include UL, cUL, CE and RoHS. They can be used to control temperature, pressure-flow and humidity.

See Permanently Germ-Free Touch Screen Monitors below. Impact Display Solutions specializes in developing customized display solutions to our clients’ exact specifications. Our design and engineering teams have the technical skill and experience to bring your LCD display plans to fruition. No matter what LCD panel types you need (customized or

Impact Display Solutions is a distributor of over 20 lines of touch screen manufacturers. Whether you need standard resistive and capacitive touch screens or have specialized requirements, we have your solution. Talk to our team about your specific application, such as use with gloves, rugged environments, clean rooms and more. Because we have the latest touch technologies including IR, SAW, and multi touch solutions, we are your one-stop-shop for the LCD touch screen monitor products you need. Don’t miss out on the new products based on latest technological advances in this field. Examples of unconventional options include:

PIT technology is a patented multi-touch technology. Based on the traditional infrared touch technology and the theory of total internal reflection (TIR), placing the infrared emission diode and reception diode on the lower surface of glass, the infrared beams generated by emission diodes are reflected through a prism light-guide specially designed and transmit across the front glass surface. Compared to traditional infrared touch technology, PIT touch screen has slimmer bezel, lower elevated height, and better multi-touch experience. Impact Display Solutions PIT touch screens have Win8 certification. PIT touch screens support multi-touch capability, allowing more people to touch the screen simultaneously. That allows users to have a better interactive experience. Compared to traditional infrared touch screen, 0.5mm ultralow elevated height enables PIT touch screen recognize human touch very accurately. Ultra-narrow bezel allows near-true flat appearance (as the touch transducers are placed under the screen). Protection performance enhancements are optional: waterproof or vandal-resistant.

Based on proven SAW touch technology, Impact Display Solutions has the capability of offering curved SAW touch screens in sizes of 21.5”, 27”, 32”, 35”, 42”. Furthermore, curved SAW touchscreens inherit and enjoy the benefits of SAW technology such as high reliability, protracted durability, sharp image clarity and vandal proofing. It’s the ideal touch solution for gaming and interactive kiosks.

So many applications demand a bright, vibrant, highly visible display in sun lit conditions. We address the need for bright displays through variety of innovative methods to enhance color, contrast, and brightness to maximize the clarity and impact of your message in very bright conditions. Don’t miss out on the new products based on latest technological advances in this area. Examples of unconventional options include:

Impact Display Solutions has extensive experience supporting projects in some of the harshest environments. Whether you are dealing with extreme temperatures, wet, oily or dirty conditions we have LCD panel types that will work for you. We can create shock, vibration and impact resistant solutions. We are experienced with Mil Spec standards and can meet your engineering specifications. Don’t miss out on the new products based on latest technological advances in this field. Examples of cover options include (stronger glass substrates in order of toughness):

Optical bonding can increase the brightness and contrast of a display. Typically, there are air gaps between the layers of the completed LCD assembly including the substrate, cover glass and touch screen. Optical bonding can be employed to strengthen the assembly and in most cases, to improve the overall brightness, contrast ratio and readability by mitigating the light reflection between the layers. We offer variety of bonding solutions to meet your LCD touch screen monitor requirements. Don’t miss out on the new products based on latest technological advances in this field. Examples of options include:

When you need to increase readability (especially in direct sunlight) by eliminating air gap between LCD and touch screen or protective lens, or both, Impact effectively achieves that goal with optical clear adhesive (OCA) lamination process. Dry bonding with OCA is an inexpensive bonding method with a reliable track record.

Performed in the U.S., Impact uses UV-curing process for optical bonding that involves no heat with a unique patented non-optical silicone OCR bonding material (urethane acrylate) to be brought into a gel state in a Class 100 environment. Wet bonding ensures superior quality over infrared/IR curing technique and solves any delamination concerns for customers compared to dry-bonding. The following options are available:

Mesh EMI Shielding (with woven mesh optimized for displays with silver busbar termination, non-glare or hard-coated laminated polycarbonate, 1.5, 2.0, 2.5, 3.0, or 4.0 mm, max size 500x660 mm)

For use with your own computer, media player, or video source, Impact can deliver completed closed frame monitor designs, or simply open frame display panels of virtually any size specialized for medical, gaming, military, industrial automation and more. Unique customizations are available upon request. Don’t miss out on the new products based on latest technological advances in this field. Examples of options include:

Because Impact specializes in LCDs, touch screens, computer motherboards, and value-added enhancements & assemblies, we are able to put all those products into convenient “all-in-ones” / AIOs, which include enclosures with either desktop mounts or backside VESA mounts. Click HERE for list of standard models of 15.6” to 21.5” diagonal, which consist of HD LCD, PCAP touch screen, internal computer motherboard, memory, and other components that encompass full computer functionality with convenient use interface. Please contact us to modify a standard model or make a custom-made AIO product from ground up.

While many standard displays are rated for -30C already, both displays and computer motherboards can be operational all the way at -40C with optional heaters. Heaters may be controlled via manual adjustment or automatically when paired with thermistors.

Character LCD Displays (aka Alphanumeric) are one of the most common display technologies available and for that reason we hold inventory for samples and prototypes in our Chandler, Arizona location.

These displays have been in use for many years, and in some ways the technology has become a commodity, but it is important to select the best options to fit your design. There are many details concerning this technology, including: fluid type, operating voltage, controller/drivers and other key details that can make your design excel or under-perform.

Our team of LCD specialists can assist you in selecting the best options so that your design is able to meet your needs and at a cost that is within your budget. Call today with any questions.

These displays are used in applications such as change machines, measurement devices, and data loggers. The module has the ability to display letters, numbers and punctuation marks.

One reason for the popularity of Character LCD displays is that they are equipped with a controller/driver chip containing a built in character (or font) table.

The table holds preloaded letters, numbers, and punctuation for each language. The font table allows the designer to request any character by addressing (selecting) the number of that character. In other words, the letter capital ‘T’ may be assigned the number 31 and the “&” symbol could be assigned number 141. This eliminates the work required to create each charter from scratch and reduces the amount of time necessary to program the LCD module.

The LCD you choose for your new design sets the perceived value of your product. Think about it: The first thing your customer looks at when they are deciding whether to purchase your product, is the LCD display. If it looks good, then your product looks good.

Negative mode displays are popular for new designs since they stand out. Negative mode means the background is a darker color, like black or blue and the characters/icons/segments are a lighter color such as: White, Red or Green.

Negative mode displays must have a backlight on all the time to be readable. The challenge is that the LED backlight will draw/drain 10 times more power than the LCD without a backlight. So, if this is a battery application, it is best to stick with a positive mode.

Positive mode displays are readable without a backlight if there is enough ambient light. The LCD without a backlight will draw around 1uA. LED backlights can draw as little as 15mA up to 75mA or more depending on the number and brightness of the LEDs.

The first question to answer is ‘what size of LCD?’ The larger the display the more information that can be displayed and the larger the characters can be. We recommend you choose one of the standard sizes on this page to reduce cost and lead time. Focus Display Solutions (aka FocusLCDs) carries many of the industry standard sizes in inventory and may be able to ship the same day.

Character LCD Displays are built in standard configurations such as 8×1, 20×2 and 40×4. The two numbers identify the number of characters in each row and then the number of rows. An example of this is a 20×2 which means there are 20 characters in each row and there are two rows. This will provide you a total of 40 characters. The more characters there are on the display, the more drivers are required to drive the LCD. The controller and drivers are included with the LCD.

Note: It is possible to program the software to scroll your letters and numbers across the screen, allowing you to choose a smaller sized LCD and still display all your information.

The cost of character displays is driven more by the size of the glass, then by the number of characters. A larger 8×1 can be more expensive than a small 16×2.

It is possible to custom build a unique combination such as a 12×2 or a 16×8. This would be considered a custom LCD and would require a one-time tooling cost and possibly a higher MOQ. Go to our

Character LCD modules are available in two temperature ranges, Normal (for indoor use) and Extended (for outdoor use). The outdoor version will continue to operate down to -30C. The cost difference between normal and wide (extended) temperature range is 5% to 7% higher for the extended versions. In most cases, if cost is not critical, we recommend that you incorporate the wider temperature version.

There are three types of backlights available for a character LCD module: No backlight; LED; or EL backlight. Before introducing the various backlight options, it is helpful to cover two terms that are common for backlights: NITs and half-life.

Engineers designing a battery powered product may request a character module with no backlight since the backlight draws more than ten times (10x) the power required for the LCD alone. The goal with a battery powered product is to conserve power and extend the life-time of the battery.

If the product needs to be readable in the dark or low light conditions, then it will be necessary to attach a backlight of one type or another. The best way to conserve power is to keep the amount of time the backlight is on to a minimum. Turn off the backlight as soon as the user no longer needs it. This is a common practice in cell phones. The backlight turns off a few seconds after the number is dialed or the phone is answered. The person using the phone will continue to talk, but the display will be dark.

DC Current – LEDs are driven by DC (Direct Current), which is the same type of power required for the character LCD logic voltage. Also, batteries supply DC which makes it easy to integrate the LED backlight with a battery. EL backlights require an AC (Alternating Current) to operate. The AC signal needs to be generated by an inverter. The added inverter increases the cost of the display and produces electrical noise that can interfere with neighboring circuits.

Character LCDs that include an EL (ElectroLuminescent) backlight are not as common and their popularity is decreasing. EL backlights are AC driven which requires an inverter to be supplied by the customer or attached to the LCD. Their half-life is rated at 3K hours which makes this a poor choice for products where the backlight will be on all the time. Their MOQ (Minimum Order Quantities) have increased in the last few years. At this time there is a 500 piece MOQ.

There are some key advantages to EL backlights. They are very thin, around one to two millimeters in thickness. And they provide a very even flow of light. We carry inventory on a few EL character displays, but the majority of the character displays we sell are LED.

A character LCD is constructed by placing the nematic fluid between two layers of ITO (Indium tin oxide) glass. The function of the fluid is to either block or allow light to pass through.

A TN (Twisted Nematic) monochrome LCDs is the lowest cost option. TN does not provide a very sharp contrast and has a smaller viewing angle then STN or FSTN. A smaller viewing angle means the display is readable if you look directly at it, but if you rotate it more than 40 degrees in either direction, the characters will be difficult to read.

STN (Super Twisted Nematic) fluid is the most popular option. It provides a sharper contrast and a wider viewing angle than TN. Below is a photo of a STN 16 x2 character display.

FSTN monochrome character LCD displays are assembled by taking the STN fluid and adding a film or retardation coating to the glass. This produces a sharper contrast than STN. FSTN is more popular on higher end products such as medical applications. Below is a photo of a FSTN 16×2 monochrome LCD

There are three types of polarizers: Reflective; Transflective; and Transmissive. The correct polarizer is determined by the various lighting conditions your character LCD display will operate in.

The job of the polarizer is to allow some light to pass through and some of the light to be reflected. Depending on where your display will be operating, will decide which polarizer to choose. There is no cost difference between the three polarizers. Below is a quick summary:

The reflective polarizer is basically a mirror. It will reflect 100% of the ambient light and is ideal for displays operating in direct sunlight or in situations with very bright indoor lights.

A reflective polarizer cannot be used with a LED backlight or EL backlight since it will not allow any of the light to pass through, but it is possible to use with a LED edge-lit or side-lit display. An advantage of an edge-lit display is that it is thinner than a LED backlight, but not as thin as a display equipped with an EL backlight.

A Transflective polarizer is the most popular of the three options and works best with a display that requires the backlight to be on some of the time and off some of the time. It does not perform as well in direct sunlight as a reflective polarizer, but is sufficient in most cases.

The Transmissive polarizer is used when the backlight is on all the time. This is not the best option for battery powered products, but provides a brighter backlight. This polarizer must be used for displays that run in negative mode. Negative mode is when the characters are light colored and the background is a dark.

V Logic is the voltage used to drive an LCD and draws very little current, somewhere around 1mA or less. Character displays can be driven with a VL at 3.3V or 5V.

V LED is the voltage used to drive the LED backlight only. This can be 3.3V or 5V. LED backlights can draw up to ten times (10X) the amount of current of just the LCD alone (VLCD). If your product is a battery application, the backlight should be turned off when not in use. Or build in a sensor that only turns it on in the dark.

Is it possible to drive the LCD and the LED backlight from the same connection, but not recommended since interference from the LED backlight could affect the performance of the LCD.

3.3V is popular for battery applications since it can be driven by two ‘AA’ batteries. The downside is their performance suffers in colder temperatures and may require a heater to continue operation.

A key advantage of character LCDs over multicolor technology such as TFT (Thin Film Transistor) and OLED (Organic Light Emitting Diodes) it their low thirst for current.

TFTS and OLEDs require power to generate light to be readable. In many cases, their backlight needs to be even brighter in direct sunlight. This could draw 50mA or more depending on the size and brightness of the display.

When the ambient temperature of the display drops too low, the display’s performance suffers. The colder the fluid in the display, the slower the response. At some point, the display freezes up and the characters no longer change.

As long as the temperature doesn’t drop too low, there will be no damage to the display, and it will return to normal operation when the temperature rises.

This is a much more affordable solution. A small PCB (Printed Circuit Board) is attached to the back of the LCD. The board is populated with several quarter watt resistors in series that generate heat. This option draws a great deal of power. In fact, it draws more than most LED backlights.

Believe it or not, LEDs do generate heat, but nothing close to resistors or heater film. In some cases, it is enough to give the display a little extra warmth to keep it operating when the temperature drops below its threshold.

Nothing saves heat and power like insulation. Putting your LCD into something that breaks the wind and holds in the heat, will save your batteries. Many times, a protected display will continue to operate even when the temperature drops far below the threshold. This should always be the first step taken when worrying about display functionality at low temperatures. Once your product is insulated, the heat producing options noted above can be implemented.

There are three fluid types used in character LCDs: TN, STN and FSTN. TN operates the best at colder temperatures and offers a faster response time. TN does not provide the wide viewing range found in STN and FSTN, but is sufficient for most industrial uses.

The five most common types of LCD technology are: Segment, Character, Graphic, TFT and OLED. Character and Segment are the least likely options to be discontinued. They have been around for many years and are still very popular.

The displays are made up of small squares that contain a 5x8, 7x10 or 16x16 dot matrix configurations. That means there are 5 dots across and 8 dots up for a total of 40 dots. Each dot is individuality addressed on or off to produce any letter or number.

Used to read or write the data being transferred between the LCD and the microprocessor. Tie this to ground if you only plan to write data for one-way communications.

DB 0. Most character LCDs have eight (8) data bits for faster transfer. But can operate on just four (4) data bits if you are running low on I/O (In/Outs) pins.

Positive connection of the LED backlight or side lit. The voltage could range from 5V or 3.3V. Not all character LCDs contain a LED backlight. In this case, the two pins are no connect.

Polarity is an issue with LED backlights, since they are DC (Direct Current). That means positive must connect to positive. Half of the character LCDs have pin 15 as positive and 16 as ground. The other half are reversed. If you need the polarity reversed, there is a jumper on the back of the PCB to switch polarity.

This page contains a partial list of our standard displays. Simply choose the number of characters, the size of the display and the color combination that will meet your needs. If you need a size not listed on this page, please call us. We can still supply it to you.

Our lead time on standard Character LCD displays – that are not in stock – range from five to seven weeks. This rapid lead time is due to the fact that we do not ship LCD’s via boat, but FedEx Air. By shipping via FedEx Air, we receive the LCD glass within four to five days after it is completed, compared to shipping by boat which can add several additional weeks to your lead time.

Don’t see the exact display you want on this page? Focus Display Solutions can supply you a display to match the exact configuration you want, even if it is not in our current inventory.

The cost to design and tool up a custom replacement LCD is much less than the cost associated with retooling a case or having to redesign the customer’s PCB to accept a different LCD. The customer may also need the exact display to repair units that are in the field.

This custom character design allows the customer to avoid any redesign cost or delays in the manufacturing of their product and to offer replacement displays for products that had been in the field for over ten years.

Character LCD displays are built in standard sizes and configurations. This makes the process of locating an equivalent LCD a simple process, but it is critical to make sure that the replacement display is a drop -in equivalent to your current display. It may not be possible to build a 100% equivalent product without some modifications.

We are able to match and replace these discontinued Liquid Crystal Displays. There may be a one-time NRE (Non-Recurring Engineering) fee required to modify the ITO glass, PCB (Printed Circuit Board) and bezel to match the dimensions and characteristics necessary for your production.

If your current LCD supplier has discontinued your display, Focus Display Solutions (aka Focus LCDs) has the ability to cross it over to an equivalent display and in many cases Fed Ex/UPS a sample to you the same day.

Note: when you begin ordering LCD displays from Focus, we will supply you with the data sheet. If you purchase the display, you should own the data sheet.

Providing us the full part number of the LCD allows us to determine not only the size of the display, but also the type of construction such as COB (Chip on Board) or COG (Chip on Glass), number of characters, backlight option, operating temperature range, background and backlight colors, viewing angle, backlight and LCD logic voltage, and in most cases the controller driver used.

With the part number, we will attempt to locate a full data sheet with enough details allowing us to quote a replacement for your discontinued display. If we cannot locate a data sheet, we will ask if your previous supplier had provided one to you.

If we are unable to locate the data sheet of your current LCD, we will request a data sheet. If possible, please forward over the data sheet or a link to the data sheet. If your LCD supplier is no longer in business or they will not provide you the data sheet, the next option is a photo of the display.

If you decided to move forward with us and order samples of your replacement display based on the estimated cost, we will require two of your discontinued samples. They do not need to be working displays, but need to be in good condition. Please note: We will not be able to return the two displays.

Note: when you begin ordering LCD displays from Focus, we will supply you with the data sheet. If you purchase the display, you should own the data sheet.

All of our Military COTS displays are flight certified or have been air qualified by our customers and are currently deployed on a variety of military aircraft. They are built to meet aerospace MIL Standard requirements for durability and reliability. Our aircraft LCD displays accept pressure gradients from sea level to 40,000 ft. LCD heaters permit reliable operation from -50C up to 70C. They have a compact, light design to minimize payload size and weight. All displays are tailored to meet shock and vibration profiles for large jets, small turboprops, and helicopters.

LED segment display is one of the commonly used display screens. By inputting the corresponding current to its different pins, it will light up, so as to display the number, date, temperature, and so on.

Because of its relatively low cost and simple use, it is widely used in the fields of electrical appliances, especially household, such as air conditioners, water heaters, refrigerators, and so on.

LED segment displays are composed of many SMD LEDs mounted on the circuit board and plastic shell to display fixed and simple numbers and other information patterns. The most common forms are the numbers 0 to 9, one or two decimal points, alphabet, marks, and symbols.

The shell is made of flame retardant PC plastic, with high strength, impact resistance, aging resistance, UV protection, dust prevention, and moisture resistance. LED segment displays have the advantages of low power consumption, low heat, impact resistance, and long serving time. With the help of a controller, it can realize the effects of running water, gradual change, jump, and chase, etc. It can be divided into common cathode and common anode according to the attribution. A wide range of colors are available: white, red, green, blue, orange, etc.

With the development of technology, it is supposed to be replaced by segment LCD display in some areas. If we compare it with segment LCD display, it is much cheaper and much brighter, suitable for industrial illumination and indication, but low class and much thicker.

Settings saved in EEPROM persist across reboots and still remain after flashing new firmware, so always send M502, M500 (or “Reset EEPROM” from the LCD) after flashing.

#define CUSTOM_STATUS_SCREEN_IMAGE STRING_CONFIG_H_AUTHOR is shown in the Marlin startup message to identify the author (and optional variant) of the firmware. Use this setting as a way to uniquely identify your custom configurations. The startup message is printed whenever the board (re)boots.

This is the name of your printer as displayed on the LCD and by M115. For example, if you set this to “My Delta” the LCD will display “My Delta ready” when the printer starts up.

Enable this if you don’t want the power supply to switch on when you turn on the printer. This is for printers that have dual power supplies. For instance some setups have a separate power supply for the heaters. In this situation you can save power by leaving the power supply off until needed. If you don’t know what this is leave it.

Enable this option to use sensor 1 as a redundant sensor for sensor 0. This is an advanced way to protect against temp sensor failure. If the temperature difference between sensors exceeds MAX_REDUNDANT_TEMP_SENSOR_DIFF Marlin will abort the print and disable the heater.

Err: MAXTEMP: This error usually means that the temperature sensor wires are shorted together. It may also indicate an issue with the heater MOSFET or relay that is causing it to stay on.

Marlin uses PID (Proportional, Integral, Derivative) control (Wikipedia) to stabilize the dynamic heating system for the hotends and bed. When PID values are set correctly, heaters reach their target temperatures faster, maintain temperature better, and experience less wear over time.

Disable PIDTEMP to run extruders in bang-bang mode. Bang-bang is a pure binary mode - the heater is either fully-on or fully-off for a long period. PID control uses higher frequency PWM and (in most cases) is superior for maintaining a stable temperature.

Enable PID_AUTOTUNE_MENU to add an option on the LCD to run an Autotune cycle and automatically apply the result. Enable PID_PARAMS_PER_HOTEND if you have more than one extruder and they are different models.

M301 can be used to set Hotend PID and is also accessible through the LCD. M304 can be used to set bed PID. M303 should be used to tune PID values before using any new hotend components.

Enable PIDTEMPBED to use PID for the bed heater (at the same PWM frequency as the extruders). With the default PID_dT the PWM frequency is 7.689 Hz, fine for driving a square wave into a resistive load without significant impact on FET heating. This also works fine on a Fotek SSR-10DA Solid State Relay into a 250 W heater. If your configuration is significantly different than this and you don’t understand the issues involved, you probably shouldn’t use bed PID until it’s verified that your hardware works. Use M303 E-1 to tune the bed PID for this option.

Thermal protection is one of the most vital safety features in Marlin, allowing the firmware to catch a bad situation and shut down heaters before it goes too far. Consider what happens when a thermistor comes loose during printing. The firmware sees a low temperature reading so it keeps the heat on. As long as the temperature reading is low, the hotend will continue to heat up indefinitely, leading to smoke, oozing, a ruined print, and possibly even fire.

Marlin offers two levels of thermal protection: Check that the temperature is actually increasing when a heater is on. If the temperature fails to rise enough within a certain time period (by default, 2 degrees in 20 seconds), the machine will shut down with a “Heating failed” error. This will detect a disconnected, loose, or misconfigured thermistor, or a disconnected heater.

For false thermal runaways not caused by a loose temperature sensor, try increasing WATCH_TEMP_PERIOD or decreasing WATCH_TEMP_INCREASE. Heating may be slowed in a cold environment, if a fan is blowing on the heat block, or if the heater has high resistance.

Use this option if you’ve connected the probe to a pin other than the Z MIN endstop pin. With this option enabled, by default Marlin will use the Z_MIN_PROBE_PIN specified in your board’s pins file (usually the X or Z MAX endstop pin since these are the most likely to be unused). If you need to use a different pin, define your custom pin number for Z_MIN_PROBE_PIN in Configuration.h.

Even if you have no bed probe you can still use any of the core AUTO_BED_LEVELING_* options below by selecting this option. With PROBE_MANUALLY the G29 command only moves the nozzle to the next probe point where it pauses. You adjust the Z height with a piece of paper or feeler gauge, then send G29 again to continue to the next point. You can also enable LCD_BED_LEVELING to add a “Level Bed” Menu item to the LCD for a fully interactive leveling process. MANUAL_PROBE_START_Z sets the Z-height the printer initially moves to at each mesh point during manual probing. With this disabled, the printer will move to Z0 for the first probe point. Then each consecutive probe point uses the Z position of the probe point preceding it.

The ANTCLABS BLTouch probe uses custom circuitry and a magnet to raise and lower a metal pin which acts as a touch probe. The BLTouch uses the servo connector and is controlled using specific servo angles. With this option enabled the other required settings are automatically configured (so there’s no need to enter servo angles, for example).

These offsets specify the distance from the tip of the nozzle to the probe — or more precisely, to the point at which the probe triggers. The X and Y offsets are specified as integers. The Z offset should be specified as exactly as possible using a decimal value. The Z offset can be overridden with M851 Z or the LCD controller. The M851 offset is saved to EEPROM with M500.

Use these settings to specify the distance (mm) to raise the probe (or lower the bed). The values set here apply over and above any (negative) probe Z Offset set with Z_PROBE_OFFSET_FROM_EXTRUDER, M851, or the LCD. Only integer values >= 1 are valid for these settings. Example: M851 Z-5 with a CLEARANCE of 4 => 9 mm from bed to nozzle.

Heatinging the bed and extruder for probing will produce results that more accurately correspond with your bed if you typically print with the bed heated. Enable PROBING_HEATERS_OFF if you are experiencing electrical noise. A delay can also be added to allow noise and vibration to settle.

These settings reverse the motor direction for each axis. Be careful when first setting these. Axes moving the wrong direction can cause damage. Get these right without belts attached first, if possible. Before testing, move the carriage and bed to the middle. Test each axis for proper movement using the host or LCD “Move Axis” menu. If an axis is inverted, either flip the plug around or change its invert setting.

AUTO_BED_LEVELING_UBL (recommended) combines the features of 3-point, linear, bilinear, and mesh leveling. As with bilinear leveling, the mesh data generated by UBL is used to adjust Z height across the bed using bilinear interpolation. An LCD controller is currently required.

MESH_BED_LEVELING provides a custom G29 command to measure the bed height at several grid points using a piece of paper or feeler gauge. See G29 for MBL for the full procedure. This type of leveling is only compatible with PROBE_MANUALLY.

#if ENABLED(LCD_BED_LEVELING) #define MESH_EDIT_Z_STEP 0.025 // (mm) Step size while manually probing Z axis. #define LCD_PROBE_Z_RANGE 4 // (mm) Z Range centered on Z_MIN_POS for LCD Z adjustment //#define MESH_EDIT_MENU // Add a menu to edit mesh points

Enable this option if a probe (not an endstop) is being used for Z homing. Z Safe Homing isn’t needed if a Z endstop is used for homing, but it may also be enabled just to have XY always move to some custom position after homing.

These are the default values for the Prepare > Preheat LCD menu options. These values can be overridden using the M145 command or the Control > Temperature > Preheat Material X conf submenus.

Choose your preferred language for the LCD controller here. Supported languages include: Code Language Code Language Code Language en English (Default) an Aragonese bg Bulgarian

This option applies only to character-based displays. Character-based displays (based on the Hitachi HD44780) provide an ASCII character set plus one of the following language extensions: JAPANESE … the most common

The SDSUPPORT option must be enabled or SD printing will not be supported. It is no longer enabled automatically for LCD controllers with built-in SDCard slot.

Disable all menus and only display the Status Screen with NO_LCD_MENUS, or just remove some extraneous menu items to recover space with SLIM_LCD_MENUS.

This option reverses the encoder direction for navigating LCD menus. If CLOCKWISE normally moves DOWN this makes it go UP. If CLOCKWISE normally moves UP this makes it go DOWN.

The duration and frequency for the UI feedback sound. Set these to 0 to disable audio feedback in the LCD menus. Test audio output with the G-code M300 S

Marlin includes support for several controllers. The two most popular controllers supported by Marlin are: REPRAP_DISCOUNT_SMART_CONTROLLER A 20 x 4 character-based LCD controller with click-wheel.

REPRAP_DISCOUNT_FULL_GRAPHIC_SMART_CONTROLLER A monochrome 128 x 64 pixel-based LCD controller with click-wheel. Able to display simple bitmap graphics and up to 5 lines of text.

LCD_I2C_PANELOLU2 PANELOLU2 LCD with status LEDs, separate encoder and click inputs. The click input can either be directly connected to a pin (if BTN_ENC is defined) or read through I2C (with BTN_ENC undefined). Requires LiquidTWI2 library v1.2.3 or later.

Use software PWM to drive the fan, as with the heaters. This uses a very low frequency which is not as annoying as with the hardware PWM. On the other hand, if this frequency is too low, you should also increment SOFT_PWM_SCALE.

Incrementing this by 1 will double the software PWM frequency, affecting heaters (and the fan if FAN_SOFT_PWM is enabled). However, control resolution will be halved for each increment; at zero value, there are 128 effective control positions.

Temperature status LEDs that display the hotend and bed temperature. If all hotend and bed temperature set-point are < 54C then the BLUE led is on. Otherwise the RED led is on. There is 1C hysteresis.

#define NEOPIXEL_PIXELS 30 // Number of LEDs in the strip, larger of 2 strips if 2 NeoPixel strips are used #define NEOPIXEL_IS_SEQUENTIAL // Sequential display for temperature change - LED by LED. Disable to change all LEDs at once. #define NEOPIXEL_BRIGHTNESS 127 // Initial brightness (0-255) //#define NEOPIXEL_STARTUP_TEST // Cycle through colors at startup

A heated chamber can greatly improve print quality. Check the pins file of your board for TEMP_CHAMBER_PIN. The spare extruder and hotend temperature pins can be used for HEATER_CHAMBER_PIN and TEMP_CHAMBER_PIN.

With Dual X-Carriage the HOTEND_OFFSET_X setting for T1 overrides X2_HOME_POS. Use M218 T1 X[homepos] to set a custom X2 home position, and M218 T1 X0 to use X2_HOME_POS. This offset can be saved to EEPROM with M500.

#if EITHER(ULTIPANEL, EXTENSIBLE_UI) #define MANUAL_FEEDRATE { 50*60, 50*60, 4*60, 60 } // Feedrates for manual moves along X, Y, Z, E from panel #define SHORT_MANUAL_Z_MOVE 0.025 // (mm) Smallest manual Z move (< 0.1mm) #if ENABLED(ULTIPANEL) #define MANUAL_E_MOVES_RELATIVE // Display extruder move distance rather than "position" #define ULTIPANEL_FEEDMULTIPLY // Encoder sets the feedrate multiplier on the Status Screen #endif

#if ENABLED(LED_CONTROL_MENU) #define LED_COLOR_PRESETS // Enable the Preset Color menu option #if ENABLED(LED_COLOR_PRESETS) #define LED_USER_PRESET_RED 255 // User defined RED value #define LED_USER_PRESET_GREEN 128 // User defined GREEN value #define LED_USER_PRESET_BLUE 0 // User defined BLUE value #define LED_USER_PRESET_WHITE 255 // User defined WHITE value #define LED_USER_PRESET_BRIGHTNESS 255 // User defined intensity //#define LED_USER_PRESET_STARTUP // Have the printer display the user preset color on startup

#if ENABLED(LCD_PROGRESS_BAR) #define PROGRESS_BAR_BAR_TIME 2000 // (ms) Amount of time to show the bar #define PROGRESS_BAR_MSG_TIME 3000 // (ms) Amount of time to show the status message #define PROGRESS_MSG_EXPIRE 0 // (ms) Amount of time to retain the status message (0=forever) //#define PROGRESS_MSG_ONCE // Show the message for MSG_TIME then clear it

Show a progress bar on HD44780 LCDs for SD printing. Sub-options determine how long to show the progress bar and status message, how long to retain the status message, and whether to include a progress bar test in the Debug menu.

Add an option for the firmware to abort SD printing if any endstop is triggered. Turn on with M540 S1 (or from the LCD menu) and make sure endstops are enabled (M120) during SD printing.

This option makes it easier to print the same SD Card file again. Whenever an SD print completes the LCD Menu will open with the same file selected. From there you can click to start a new print, or you can navigate elsewhere.

Use the optimizations here to improve printing performance, which can be adversely affected by graphical display drawing, especially when doing several short moves, and when printing on DELTA and SCARA machines.

Some of these options may result in the display lagging behind controller events, as there is a trade-off between reliable printing performance versus fast display

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey