lcd display troubleshooting supplier

Encoder, LCD, rotating equipment and vacuum pump repair services. Capabilities include rebuilding, testing, asset and inventory management, barcoding, troubleshooting, predictive and preventative maintenance, database management, engineering and reverse engineering. Entertainment, food and beverages, government, military, OEM, pharmaceuticals, steel, aerospace, agriculture, alternative energy, automotive, chemical, power generation, electronics and other industries served.

Liquid crystal displays (LCDs) are the most widely used display technology. Their applications cover TV, mobile phone, appliances, automotive, smart home, industrial meters, consumer electronics, POS, marine, aerospace, military etc. LCD screen display problem can occur for several reasons.

Effect of environmental conditions on the LCD assembly. Environmental conditions include both the effects of temperature and humidity, and cyclic loading.

Effect of manufacturing process. With the development of LCD for more than 40 years and the modern manufacturing equipment, this kind if defects are getting rear.

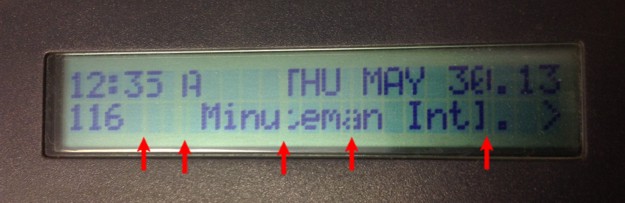

Common failures seen in LCDs are a decrease in screen contrast, non-functioning pixels or the whole display, and broken glass. Different kinds of LCD display problem need to have different kinds of fix methods or make the decision not worthwhile to repair.

Broken glassIf you accidently drop the LCD and you find it broken on the surface but the display still works. You might just break the touch panel; you can find a repair house or find a youtube video to replace the touch panel. If you find the display not showing, especially you find the fluid leaking out. You need to reply the whole display modules.

Dim LCD displayLCD can’t emit light itself. It uses backlight. Normally, the backlight is not fully driven, you can increase the LED backlight to make a dim LCD display brighter. But if you LCD display has been used for a long time, it is possible that the LED backlight has to be the end of life (not brightness enough) if you turn on 100% backlight brightness. In that case to fix LCD screen, you have to find a way to change the backlight. For some display, it is an easy job but it can be difficult for other displays depending on the manufacturing process.

Image sticking (Ghosting)Sometimes, you will find the previous image still appearing at the background even if you change to another image. It is also called burn in. This kind of failure doesn’t need to repair by professionals. You can simply shut off the display overnight, this kind of problem will go away. Please do remember that displaying a static image for a long time should be avoided.

With the modern manufacturing process and design, this kind of failure rarely happens. Normally, it is caused by no power. Please check if the battery dead or adapter (power supply) failure or even check if you have plug in firmly or with the wrong power supply. 99% the display will be back on.

LCD has white screen – If a LCD has a white screen which means the backlight is good. Simply check your signal input sources which are the most causes. It can also be caused by the display totally damaged by ESD or excess heat, shock which make the LCD controller broken or the connection failure which has to be repaired by professionals.

Blur ImagesAs the LCD images are made of RGB pixels, the screen shouldn’t be blur like old CRT displays. If you do see blur images, they might be caused by two reasons. 1) LCD has certain response time, if you are playing games or watch fast action movies, some old LCD displays can have image delays. 2) The surface of the LCD is made of a layer of plastic film with maximum hardness of 3H. If you clean the surface often or use the wrong detergent or solvent which cause the surface damage. To fix damage on LED screen it’s need to be changed with professionals.

If you have any questions about Orient Display displays and touch panels. Please feel free to contact: Sales Inquiries, Customer Service or Technical Support.

How do I know if my monitor is really showing true 4K video?Make sure that that the signal you are sending is 4K resolution (3840x2160). You can test this by pressing the monitor’s Menu button. The monitor’s Menu screen will display the incoming video resolution and timing in the top-right corner of the screen.

My monitor is displaying a message saying “Sync Out of Range”If you are seeing this on your monitor, it means you are sending a video resolution to your monitor that is higher than your monitor’s native resolution.

With an array of different timing profiles and the use of a video-signal generator, full testing is available on most display models we can offer support for.

CRT Monitors: given the nature of the CRT displays, repairing them is often not a viable option. To a large extent this depends on the severity of the damage. When something fails within a CRT display, it often triggers deterioration of other components at the same time. This sometimes leads to a repaired CRT monitor fail again and again, even after a thorough repair.

Troubleshooting CRTs versus LCDs begins with similar steps, but diverges due to the differing natures of the two display types. The first troubleshooting steps are similar for either display type: power down the system and display and then power them back up; make sure the power cable is connected and that the outlet has power; verify that the signal cable is connected firmly to both video adapter and display and that there are no bent pins; verify that the video adapter is configured properly for the display; try the problem display on a known-good system, or try a known-good display on the problem system; and so on. Once you"ve tried the "obvious" troubleshooting steps, if the problem persists, the next step you take depends on the type of display. The following sections cover basic troubleshooting for CRTs and LCDs.

CRTs seldom fail outright without obvious signs, such as a loud snap or a strong odor of burning electrical components. Most CRT problems are really problems with the power, video adapter, cable, or hardware/software settings. To eliminate the CRT as a possible cause, connect the suspect CRT to a known-good system, or connect a known-good display to the suspect system. It is worth noting, that older CRTs eventually wear out, and starts dimming. Common signs of a weak CRT are a dim picture, dysfunctional brightness and/or color controls, image smearing at high brightness, and in color CRTs, a tint towards a single color (Red Green Blue)

CRTs contain multiple filaments, which can be broken, or gas may have leaked into the vacuum inside the CRT. CRTs damaged this way are unrepairable without specialist equipment. With the display open. check if all three filaments are glowing bright orange. Excessive redness or purple arcing signifies gas has leaked in. There may also be an internal short inside the CRT, which is also unfixable without specialist equipment.

If you have ACPI or APM power management enabled, it may be causing the problem. Some systems simply refuse to wake up once power management puts them to sleep. We have seen such systems survive a hardware reset without restoring power to the CRT. To verify this problem, turn off power to the system and CRT and then turn them back on. If the CRT then displays an image, check the power management settings in your BIOS and operating system and disable them if necessary.

The horizontal and/or vertical deflection system has failed. The CRT tube itself is fine, but the circuitry driving the tube has failed. Replace the display.

There are two likely causes. First, you may be driving the CRT beyond its design limits. Some CRTs display a usable image at resolutions and/or refresh rates higher than they are designed to use, but under such abuse the expected life of the CRT is shortened dramatically, perhaps to minutes. To correct this problem, change video settings to values that are within the CRT"s design specifications. Second, the power receptacle may be supplying voltage lower than the CRT requires. To correct this problem, connect the CRT to a different circuit or to a UPS or power conditioner that supplies standard voltage regardless of input voltage.

The video card settings are likely outside the range supported by the CRT, particularly if you have just installed the CRT or have just changed video settings. To verify this, restart the system in Safe Mode (press F8 during boot to display the Windows boot menu and choose Safe Mode). If the system displays a VGA image properly, change your display settings to something supported by the CRT.

Most modern CRTs can display signals at many different scan frequencies, but this doesn"t mean that the CRT will necessarily automatically display different signals full-screen and properly aligned. Use the CRT controls to adjust the size and alignment of the image.

The CRT may need to be degaussed. A CRT that sits in one position for months or years can be affected even by the earth"s very weak magnetic field, causing distortion and other display problems. Exposing a CRT to a strong magnetic field, such as unshielded speakers, can cause more extreme image problems. Many modern CRTs degauss themselves automatically each time you cycle the power, but some have a manual degauss button that you must remember to use. If your CRT has a manual degauss button, use it every month or two. The degaussing circuitry in some CRTs has limited power. We have seen CRTs that were accidentally exposed to strong magnetic fields, resulting in a badly distorted image. Built-in degaussing did little or nothing. In that case, you can sometimes fix the problem by using a separate degaussing coil, available at RadioShack and similar stores for a few dollars. We have, however, seen CRTs that were so badly "magnet burned" that even a standalone degaussing coil could not completely eliminate the problem. The moral is to keep magnets away from your CRT, including those in speakers that are not video-shielded.

An incorrect yoke may have been attached to the CRT. Unless you have a lot of spare time on your hands, this is usually not worth fixing. Replace the display.

If your LCD displays no image at all and you are certain that it is receiving power and video signal, first adjust the brightness and contrast settings to higher values. If that doesn"t work, turn off the system and LCD, disconnect the LCD signal cable from the computer, and turn on the LCD by itself. It should display some sort of initialization screen, if only perhaps a "No video signal" message. If nothing lights up and no message is displayed, contact technical support for your LCD manufacturer. If your LCD supports multiple inputs, you may need to press a button to cycle through the inputs and set it to the correct one.

Unlike CRTs, where increasing the refresh rate always reduces flicker, LCDs have an optimal refresh rate that may be lower than the highest refresh rate supported. For example, a 17" LCD operating in analog mode may support 60 Hz and 75 Hz refresh. Although it sounds counterintuitive to anyone whose experience has been with CRTs, reducing the refresh rate from 75 Hz to 60 Hz may improve image stability. Check the manual to determine the optimum refresh rate for your LCD, and set your video adapter to use that rate.

First, try setting the optimal refresh rate as described above. If that doesn"t solve the problem and you are using an analog interface, there are several possible causes, most of which are due to poor synchronization between the video adapter clock and the display clock, or to phase problems. If your LCD has an auto-adjust, auto-setup, or auto-synchronize option, try using that first. If not, try adjusting the phase and/or clock settings manually until you have a usable image. If you are using an extension or longer than standard video cable, try connecting the standard video cable that was supplied with the display. Long analog video cables exacerbate sync problems. Also, if you are using a KVM switch, particularly a manual model, try instead connecting the LCD directly to the video adapter. Many LCDs are difficult or impossible to synchronize if you use a KVM switch. If you are unable to achieve proper synchronization, try connecting the LCD to a different computer. If you are unable to achieve synchronization on the second computer, the LCD may be defective. Finally, note that some models of video adapter simply don"t function well with some models of LCD.

If the screen is displaying a full, stable image, but that image is of poor quality, first verify that the display is not connected through a KVM switch or using an extension cable. If so, connect the display directly to the video adapter using the standard cable. If that is already the case, adjust the brightness, contrast, and focus controls. If you are unable to get a proper image using these controls, the problem is most likely a clock or phase mismatch, which you can cure by taking the steps described in the preceding item.

Your video card is supplying a video signal at a bandwidth that is above or below the ability of your LCD to display. Reset your video parameters to be within the range supported by the LCD. If necessary, temporarily connect a different display or start Windows in Safe Mode and choose standard VGA in order to change video settings.

This occurs when you run an LCD at other than its native resolution. For example, if you have a 19" LCD with native 1280x1024 resolution but have your display adapter set to 1024x768, your LCD attempts to display those 1024x768 pixels at full screen size, which physically corresponds to 1280x1024 pixels. The pixel extrapolation needed to fill the screen with the smaller image results in artifacts such as blocky or poorly rendered text, jaggy lines, and so on. Either set your video adapter to display the native resolution of the LCD, or set your LCD to display the lower-resolution image without stretching the display (a feature sometimes referred to as display expansion), so that pixels are displayed 1:1, which results in the lower resolution using less than the entire screen.

This is a characteristic of LCDs, particularly older and inexpensive models, caused by defective pixels. Manufacturers set a threshold number below which they consider a display acceptable. That number varies with the manufacturer, the model, and the size of the display, but is typically in the range of 5 to 10 pixels. (Better LCDs nowadays usually have zero dead pixels.) Nothing can be done to fix defective pixels. Manufacturers will not replace LCDs under warranty unless the number of defective pixels exceeds the threshold number.

Some people claim that leaving the unit powered off for a day or two will "erase" a persistent after-image. Others suggest leaving a neutral gray screen (like the one used for phase adjustment) up on the screen to "equalize" the display. I dunno. FWIW, I"ve seen this problem on older Samsung panels but never on the Sony or NEC/LaCie panels I use.

Again, this is a characteristic of LCDs, particularly older and inexpensive models. The after-image occurs when the display has had the same image in one place for a long time. The after-image may persist even after you turn the display off.

Transistor-based pixels in an LCD respond more slowly than the phosphors in a CRT. The least-expensive LCDs exhibit this problem even with slow image movement, as when you drag a window. Better LCDs handle moderately fast image movement without ghosting, but exhibit the problem on fast-motion video. The best LCDs handle even fast-motion video and 3D gaming very well. The only solution to this problem is to upgrade to an LCD with faster response time.

Use the brightness control to increase image brightness. If you have set brightness to maximum and the image is still too dim, contact the display manufacturer. The CCRTs used to backlight the screen have a finite lifetime and may begin to dim as they near the end of their life.

If one or more horizontal and/or vertical lines appear on the display, first power-reset the computer and display. If the lines persist, run the auto-setup function of your display. If that does not solve the problem, power the system and display down, remove the video cable, and verify that the video plugs and jacks on both computer and display ends do not have broken or bent pins. Even if all appears correct, try a different video cable. If the problem persists, contact the display manufacturer.

4. #Press the LCD glass side of the panel, if the vertical lines disappear or reappear, it can be judged that the cause of poor contact, OM checking should be able to find the poor contact.

5. #If there is no display change in pressing, confirm whether ITO is damaged under the OM microscope, or pin signal waveform corresponding to needle COF.

The above is the full text of LCD screen failure repair guide, we hope it is helpful to you. If you need to buy LCD and find a reliable LCD supplier, we suggest you to read our other great blog – How to find a reliable LCD supplier.

Founded in 2014, VISLCD is a professional LCD supplier. We provide LCD modules, touch LCD and customized LCD in various sizes with stable quality and competitive price. Welcome to contact us for any LCD demand, thank you.

VISLCD has been engaged in LCD production and sales for 9 years, and we have met many customers who shared with us that they had encountered unreliable LCD suppliers.

For example, the answer is not what you asked for, the LCD product cannot be delivered on time, the price of the LCD suddenly increases, the LCD module suddenly breaks down during the use of the product, or even the LCD is discontinued after less than 1 year of delivery…etc. In addition, there are many customers who are not sure what type of LCD supplier they are looking for.

In view of all the above, VISLCD has written this article to share knowledge about LCD suppliers and other issues related to LCD. We believe it will be helpful to LCD customers.

To understand LCD suppliers, we first need to know what kinds of LCD suppliers are available. Then LCD customers can find the right supplier based on information such as their product applications, LCD requirements and forecast volume.

LCD original manufacturer refers to the original manufacturer of LCD panel. Originated from the USA in the 1960’s, after more than 50 years of development, the manufacturers are now mainly located in China mainland, Korea and Taiwan. Among them, the Chinese manufacturers in recent years rely on the rapid scale, technology development and price advantage, has gradually occupied the main market share.

The video below is an official video presentation of the BOE display factory and Century Display (CTC), which will give you a more visual understanding of the original LCD manufacturer.

The 5.1 generation TFT-LCD line of Century Display in Shenzhen, China, for example, has been put into operation since 2008 with a cumulative fixed investment of more than $4 billion, and the cost of water, electricity, employee wages and equipment depreciation is as high as $0.5~100 million/month. The monthly production capacity is about 100,000 sheets ( 1300*1200mm/sheet). If all of them are used to produce 7-inch LCD panels, then the monthly shipment volume is up to 9,000,000 pcs. Therefore, a very large monthly shipment volume is required to meet the normal operation of the factory.

This is only the 5.1 generation TFT-LCD line, if it is 8.5 generation line or even 10 generation line or more, then the cost and shipment volume may be several times or even ten times more. It should be noted that the number of generations of LCD lines does not mean that the technology is high or low. The higher the generation, then the larger the size of the LCD can be put into production, of course, the greater the volume of shipments and investment amount.

LCD original manufacturers generally provide mainly LCD panels, but also provide COG (LCD + IC), FOG (LCD + IC + FPCA cable) and other kinds of LCD semi-finished products. Also includes a small amount of the original LCD module. But the original LCD factory will only deal with the famous brand companies directly (such as Apple, Dell, Xiaomi, etc.), or through agents to ship. And the MOQ quantity requirement is very high (generally 1,000,000 pcs/month or more), the unit price of original LCD module is also high and the degree of customization is low.

LCD original manufacturers usually have an order MOQ requirement for their agents, which translates into an LCD unit quantity of no less than 100,000pcs/month. When the LCD demand is high, this will not be a problem; but when the market is low, the agent must buy the agreed MOQ quantity of LCD from the original LCD manufacturer even if there is no customer demand for the time being. So when the low season, if your order quantity is large enough, then you may get a very good LCD panel price from the LCD agent, which may even be lower than the agent’s purchase price.

LCD module manufacturers is to purchase LCD semi-finished products (such as LCD panel, COG or FOG) from LCD agents, then purchase ICs from IC agents, produce or purchase backlight, FPCA cable and touch screen components, and then integrate all the above components into LCD module or touch LCD module. LCD module factories vary in size from tens of millions of pcs to hundreds of thousands of pcs shipped per month.

Medium and large size module factory generally get the semi-finished products are FOG LCD (also known as open cell LCD) from the original LCD manufacturers or LCD agents, and then add the backlight assembly into the finished LCD module. The advantage of doing so is that the quality is relatively stable, but the degree of customization will be much lower. Because FOG LCD already includes FPCA cable, generally speaking, the only thing that can be customized is the brightness of the backlight and the touch panel and cover glass (if needed). The rest are difficult to change, unless the customer’s LCD demand is very large.

The small and medium size module factory after years of mature development of the industry, the degree of customization will be much more flexible. The semi-finished products are mainly LCD panels, which means that the backlight size, backlight brightness, FPCA cable design, shape and PIN number, as well as the touch panel and cover glass can all be customized according to the customer’s requirements. But the MOQ requirement is higher for the backlight size. Other parts of the customization generally require LCD MOQ of at least 2,000~5,000 pcs, which varies depending on the LCD size.

Since LCD module manufactures vary in size and quality control(especially small and medium size LCD module factories), and most of the components are sourced, the selection of module factories is particularly important if customers want to buy LCDs with good quality and competitive prices.

For example, if the factory’s customers are mostly low-cost products or repaired product manufacturers, then it can be assumed that the quality of his products is not too good, LCD panels and some other components may be B-grade products, not A, can only meet short-term use.

This is essential to ensure supply. In case of supply shortage, many module factories with insufficient upstream channels sometimes cannot even start production. Because they can not buy raw materials such as LCD panels and ICs.

As the name implies, trading companies do not have their own factories, but directly sell finished LCD products from LCD resellers or LCD modules from module manufacturers. Generally speaking, the LCD prices of trading companies are relatively high and the quality and reliability are a little weaker. However, there is no shortage of good trading companies with good quality management teams and good upstream channel resources. The biggest advantage of trading companies is their flexibility, which can meet the diversified needs of customers.

2) Shenzhen has 3 types of buildings related to lcd (including other electronic products): office buildings, factories and markets. Almost all LCD panel and IC agents are located in various office buildings in Shenzhen, while component factories such as FPCA, Touch panel and backlight are located in various industrial parks in the suburbs. It is possible to find the right components and develop new products in the shortest time. Of course, there is also the famous Huaqiang bei(north) Electronic Market, a very complex place.

VISLCD was a trading company in the early days. But after nearly 9 years of development, it has developed into a combination of LCD module factory and LCD agent. The company is located in LCD base Shenzhen, China and operates in both Hong Kong and Shenzhen. We have our own module factory and have direct relationship with Century Display, LG, HKC and other LCD original manufacturers. Our main employees are also from these LCD manufacturers. We also accept all kinds of customized LCD business. Therefore, VISLCD is one of the best choices for medium-sized customers in terms of quality stability, semi-finished parts supply and customization.

Chances are you selected an LCD display supplier to work with your CM and now feel locked into the relationship. You’ve already gone through the qualification process, investing time and money. Not to mention approving the PO in good faith, believing the CM would be getting the right cost, on-time delivery, and high-quality components from your LCD supplier.

A CM had a quality issue with an LCD module. The CM felt comfortable notifying the LCD supplier of the problem. A comprehensive QA check at the supplier’s factory did not reveal any quality issues. The LCD supplier, taking accountability for their role in the end product, scheduled a visit to the CM’s factory. Working collaboratively with the CM, they discovered missing steps in the CM’s process that were compromising the quality of the displays. Quick and intelligent action meant the impact was negligible. The OEM, while informed, was not involved or burdened throughout this process.

Given the LCD supplier’s role and responsibilities, they should keep the OEM informed on aspects that pose a significant impact on products or customer perception:

Lead time: Contrary to the lines you may be fed, lead-time problems are not just part of doing business. Sure, uncertainty and circumstances happen, but an experienced LCD supplier will have safety nets in place to address this, like safety stock of the longest lead time component, multiple delivery options, and pull with their factory to increase or speed production.

Quality: Shoddy displays? Field failures? Dimensional tolerances not being met? These types of quality issues are a sure sign it’s time to start a new LCD supplier search.

Performance: Are the displays you’re receiving simply not performing as expected or designed? There may be excessive component variability or process variability. Either way, it’s time to look for a supplier that will meet your performance expectations.

For specialty components like LCD displays, it’s typical that you dictate to your CM the supplier they need to use. And if you are observing any issues with lead time, quality, performance, cost, or obsolescence, you should look for an alternate supplier.

Find an LCD display supplier that has experience dealing with a contract manufacturer. There are some items that are dealt directly with the CM, such as schedules, payments, and RMAs. But the supplier needs to know when to get the OEM involved, which is any time there may be a significant impact to your products or customer perception.

Typically, the default blame starts with the supplier. However, it could be an issue with your assembly process, the design integration between the product and the display, or even a problem with a non-display component that fails (that affects the display).

Issues with non-conforming performance, where the product no longer meets the performance specification, may be tied to a lack of quality of the components, LCD manufacturing, or in some rarer circumstance a change on the end-product that affected the LCD display.

Additionally there can be mechanical non-conformities, where there are aspects exceeding the defined tolerance as described in the specification. And in some instances, there may be variations not designated in the specification, but quite different from the original qualification units. These non-conformances are capable of affecting the fit, form, or function of the LCD display when assembled.

If your supplier has excessive component variability or possible process variability, there is the potential for a number of LCD display performance-related issues. These issues can be one-off or related to a larger batch of products manufactured together. Good serialization and traceability will help in isolating these occurrences and get to the root cause quickly.

While out-of-the-box nonconformance is typically the responsibility of the supplier, but it becomes a little more ambiguous when the non-conformance is not covered specifically by the governing specification. In this case, common sense and reasonable expectations of variation, the concept of the TEAM is considered. But at the end of the day, the LCD displays need to work in the finished product, and both parties should take the responsibility together to help get to the most efficient solution.

On the other hand, you need to be aware that performance degradation is sometimes caused by a change in another component upstream of the LCD display. Sometimes, a non-display component that is malfunctioning or is incompatible and interfaces with the display may cause the display to exhibit irregular behavior or render it inoperable altogether.

To verify this, swap displays to a fully functioning assembly and see whether the problem follows the display. If the issue does not reappear, the cause is likely a non-LCD display component.

The likelihood of damage, or the display being non-functional from the supplier’s end, is fairly low, as it is standard to test 300%, or three times throughout the process. Additionally, the final packaging itself is subject to drop testing during the initial development phase prior to mass production to ensure a damage-free trip despite your carrier’s best efforts to drop the packaging. That means the defect is likely latent or occurred during installation into the end-product.

This could be a manufacturing issue during the LCD display production or a quality issue with an upstream component that exposed a failure mode. In this case, fault may lie with the design itself, which indicates the need for a more robust design. Alternatively, a burn-in test process may be needed to expose potential defects prior to final inspection.

The final assembly process could also be a problem area. If the process is complicated, difficult to maneuver, or there are new operators involved there is a much higher probability of damage while assembling the LCD display into the end-product.

There is also the potential for misusing the product. A good example of this is using the product in an unintended environment such as extreme moisture. Impact is another unmistakable failure mode as it can manifest itself as a broken touch panel or cracked LCD glass.

People often ask how to repair the LCD display. In fact, this is a very professional problem, because precision instruments can not be explained in one word or two, so today I will tell you

A cookie is a small text file that a website saves on your computer or mobile device when you visit the site. It enables the website to remember your actions and preferences (such as login, language, font size and other display preferences) over a period of time, so you don’t have to keep re-entering them whenever you come back to the site or browse from one page to another.

People often ask how to repair the LCD display. In fact, this is a very professional problem, because precision instruments can not be explained in one word or two, so today I will tell you

Depending on your display stand, you might find that the LCD display defaults to being upside-down. You can fix this by rotating it with /boot/config.txt.

At the moment you can’t use HDMI and the LCD together in the X desktop, but you can send the output of certain applications to one screen or the other.

repair lcd panel provide the touch interface in smartphones, which are vital for them to function. Alibaba.com stocks a stunning range of high-tech repair lcd panel with vibrant color depictions. Truly crystal-clear displays of repair lcd panel are available covering various brands and models such as the Samsung Galaxy Edge 2, OnePlus 7T, Samsung Galaxy C5, and many more.

repair lcd panel are the most commonly used displays, as they produce great image quality while consuming low power. Rather than emitting light directly, they use back lights or reflectors to produce images, which allows for easy readability even under direct sunlight. repair lcd panel are energy-efficient, and are comparatively safer to dispose of, than CRTs. repair lcd panel are much more efficient when it comes to usage in battery-powered electronic equipment, due to their minimal power consumption.

Some other advantages of repair lcd panel over the CRT counterparts are - sharper images, little to no heat emission, unaffected by magnetic fields, narrow frame borders, and extreme compactness, which make them very thin and light. Some types of repair lcd panel are transmissive, reflective, and transflective displays. Transmissive displays provide better image quality in the presence of low or medium-light, while reflective displays work best in the presence of bright light. The third type of repair lcd panel, transflective, combine the best features of both the other types and provide a well-balanced display.

Whether as an individual purchaser, supplier or wholesaler, browse for an extensive spectrum of repair lcd panel at Alibaba.com if you don"t want to stretch a dollar yet find the best fit.

Many Apple products use liquid crystal displays (LCD). LCD technology uses rows and columns of addressable points (pixels) that render text and images on the screen. Each pixel has three separate subpixels—red, green and blue—that allow an image to render in full color. Each subpixel has a corresponding transistor responsible for turning that subpixel on and off.

Depending on the display size, there can be thousands or millions of subpixels on the LCD panel. For example, the LCD panel used in the iMac (Retina 5K, 27-inch, 2019) has a display resolution of 5120 x 2880, which means there are over 14.7 million pixels. Each pixel is made up of a red, a green, and a blue subpixel, resulting in over 44 million individual picture elements on the 27-inch display. Occasionally, a transistor may not work perfectly, which results in the affected subpixel remaining off (dark) or on (bright). With the millions of subpixels on a display, it is possible to have a low number of such transistors on an LCD. In some cases a small piece of dust or other foreign material may appear to be a pixel anomaly. Apple strives to use the highest quality LCD panels in its products, however pixel anomalies can occur in a small percentage of panels.

In many cases pixel anomalies are caused by a piece of foreign material that is trapped somewhere in the display or on the front surface of the glass panel. Foreign material is typically irregular in shape and is usually most noticeable when viewed against a white background. Foreign material that is on the front surface of the glass panel can be easily removed using a lint free cloth. Foreign material that is trapped within the screen must be removed by an Apple Authorized Service Provider or Apple Retail Store.

If you are concerned about pixel anomalies on your display, take your Apple product in for closer examination at an Apple Store, Apple Authorized Service Provider, or an Independent Repair Provider. There may be a charge for the evaluation. Genuine Apple parts are also available for out-of-warranty repairs through Self Service Repair.*

There’re more than 300 procedures to produce TFT LCD. The most advanced LCD, in which the array and cell process are highly automatic. Technically, every step in the process can lead to defects, and most of the defects have been eliminated through the development of TFT LCD technology.

Point defect is a kind of defect that some point on your screen don’t display correctly. There are mainly three situations: the point keeps displaying black or whitewhen the screen is working or the point can only display a single color.

In LCD, newton’s rings may occur on screen when two glass substrate haven’t been sealed well, so that one of the glass may form a convex lens and lead to light interference.

You may notice there are some screens have uneven display, which means some white area appears in dark picture or vice versa. We call this ‘mura’, a word originated from Japanese.

Mura is very common but it doesn’t affect the screen function severely, however it still bring bad look. Hence, many high end display manufacturers have their own standards of mura, and the displays without mura are of the best quality.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey