lcd panel backlight quotation

LED backlighting is the most commonly used backlight for small, LCD panels. Light-emitting diodes, or LEDs, are practical components for a light source because of their small size. LED backlighting is popular due to its overall low cost, long life, variety of colors and high brightness.

LED backlights are housed in a light box that has a diffuser to evenly distribute the LED light. The light box is then mounted behind the LCD’s viewing area. The LED backlight comes in two configurations: array and edge lit. The array configuration has the LEDs mounted in a uniform, grid layout within the light box. This configuration gives off a very bright, even light. The disadvantage of an array configuration is that it requires a thick light box design to accommodate the number of LEDs required. The high number of LEDs in this configuration also means it consumes more power.

The other configuration for LED backlights is edge lit. An edge lit configuration is the most commonly used construction for LED backlights. This configuration mounts the LEDs along one edge of the light box. The layout results in a thin design. Edge lit also uses less LEDs overall and therefore consumes less power than an array configuration.

Another type of backlight options is the use of fiber optic technology. Fiber optic backlights use sheets of fiber optic woven cloth and are bundled by a ferrule (metal cap) to an LED or halogen light source. Advantages for the fiber optic technology includes low voltage, low power, and a very uniform brightness. This type of backlighting is ideal for custom display shapes or sizes however it is priced at a higher cost compared to other technologies available.

A third type of backlight option available uses an electroluminescent (EL) panel. The EL backlight is constructed of a series of different material layers that work together to create the light. The EL panel generates light when an electric current (AC power) is applied to its conductive surfaces. The advantage with EL backlighting is its low power consumption, no heat emission, and overall thin composition. EL backlighting is limiting in that it requires an invertor to generate the VAC needed to emit the light.

The last common backlight option available are cold cathode fluorescent lamps (CCFLs). CCFL backlights are a cost effective option typically found in graphic displays. The CCFL backlight for LCDs is usually configured with the lamp on the edge of a diffuser to distribute the light. An inverter is required to supply the voltage required by the fluorescent lamp. CCFLs offer a bright white light with low power consumption. This backlight option is not ideal for cold-temperature applications (less than 15°C) as the light output decreases with decreased ambient temperature.

There are many different backlight options available for your LCD. The most common types are LED, fiber optic, EL, and CCFL backlights. Cost and application of your product will have the highest influences on which backlight technology is best for your LCD.

You can get custom made lcd backlight with an operation range that suits your specific application, choosing from a wide selection of suppliers. Source wholesale custom made lcd backlight on Alibaba.com for your business and enjoy a wide variety and great deals.

custom made lcd backlight (Liquid crystal display) are made of liquid crystals that form digital images made visible through ambient light or through LED backlight. LCDs are used in the place of other displays that are less efficient such as cathode ray tubes (CRTs) and have become the most popular display type on the market.

custom made lcd backlight enable metal and position detection without having to physically contact the metal object. They offer a wide range of applications in robotics, rail, material handling, aerospace, military, as well as heavy machinery. Choose from different custom made lcd backlight types, from the shielded versions that have electromagnetic fields concatenated in the front and unshieldated versions that allow wider sensing distances. Whether you want to use your sensors for industrial purposes or source for your brand, there is a wide selection of wholesale custom made ledcd backlights to choose from that will suit different applications.

Sizes of wholesale lcd backlight led available can vary from small one-person tables to very large tables capable of seating large numbers of people. Unlike traditional tables, bar table sets are designed to support different preferences of customers: they can either be very high or low, based on their placement within the bar. Wholesale outdoor bar tables are a fast-selling and popular line of bar tables. Buy this popular product in bulk today at Alibaba.com.

Wholesale lcd backlight led create atmosphere and ambiance at bars, which is important for retaining customers. The vintage design of some table and bar stools make them good fits for gentlemen"s clubs, luxury bars, hotel lobby bars, and many more establishments. Alternatively, for tables that can be used in commercial coffee shops, malls, and also in office coffee rooms, choose wholesale coffee bar tables. No matter your customer preferences, find good deals on wholesale lcd backlight led, including wholesale high-top tables and chairs at Alibaba.com.

Wholesalers on Alibaba.com offer lcd backlight led for various kinds of bars. Wholesale pub tables and chairs are available in various colors and patterns. Find bar sets with stools made of different materials; different wood types, and metal types. Get unique deals on these and more, including wholesale tall glass tables, now.

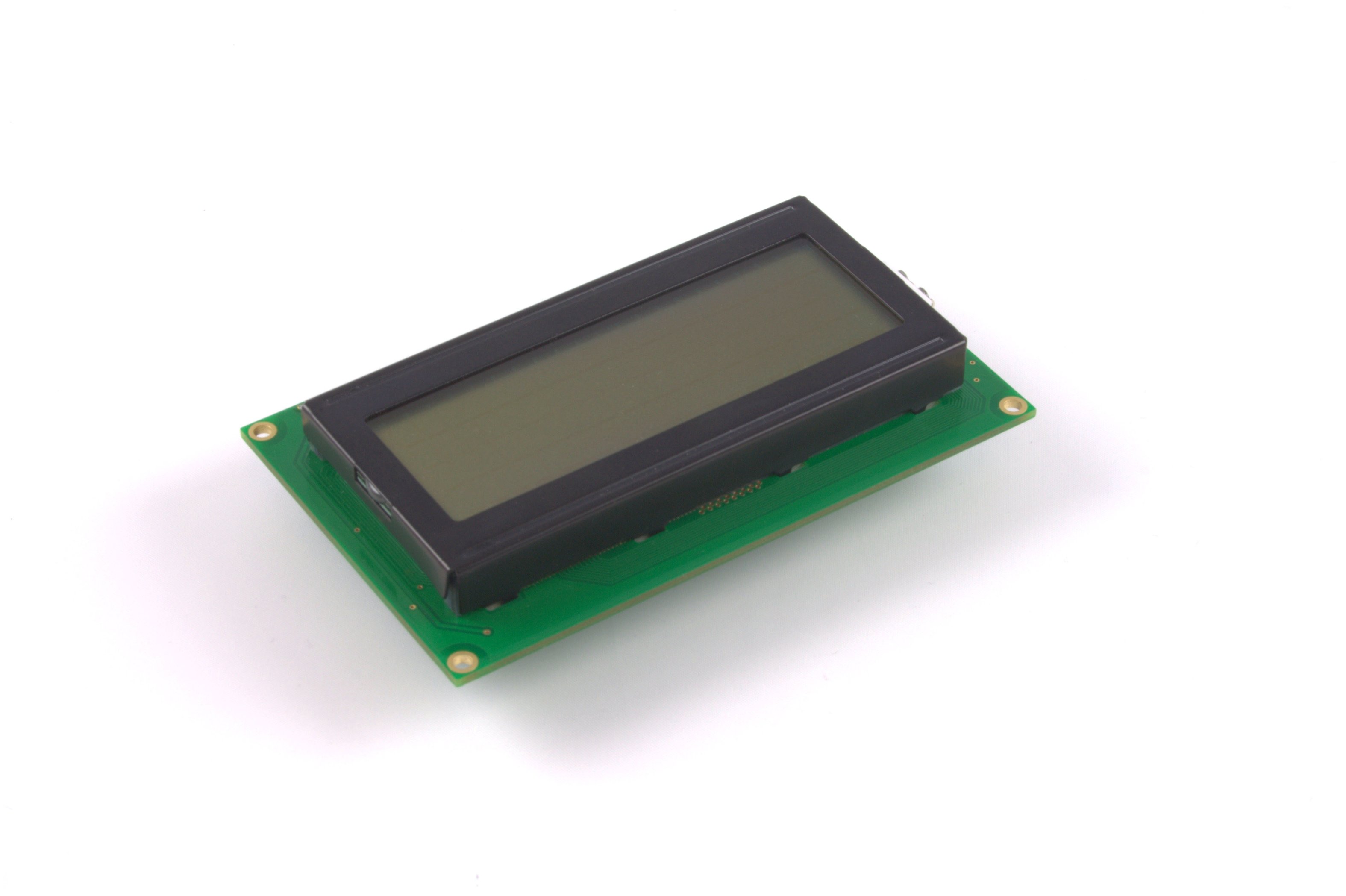

LCD Panel are used for TV,Personal Computer, Mobile Phone, Degital Camera etc widely. LCD Panel can not emit light by itself. To emit light, it need the backlight(light source) on the back of LCD Panel. Minebea develops and manufactures the parts used for backlight and backlight using LED light source,for Mobile phone, PC application.

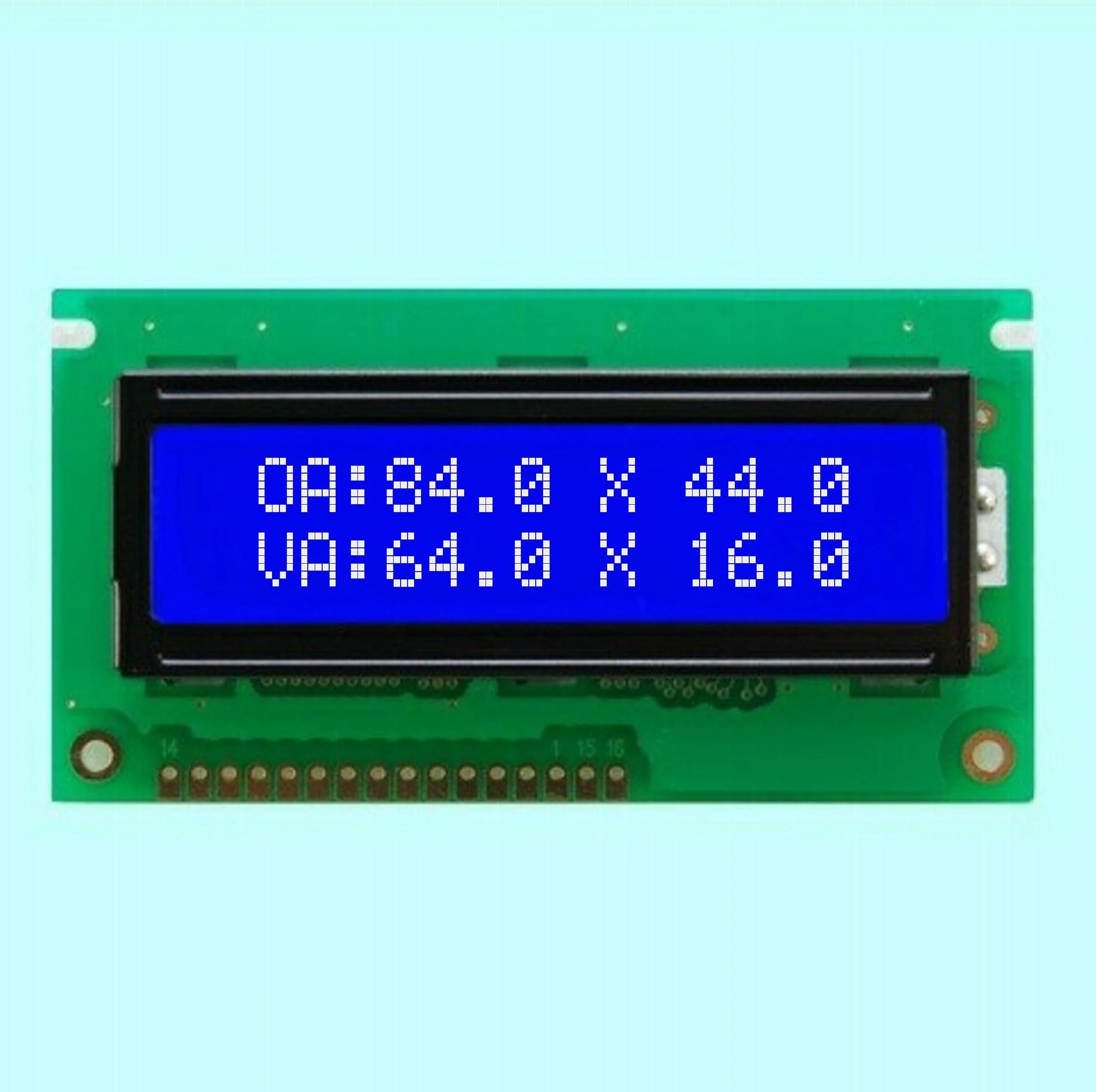

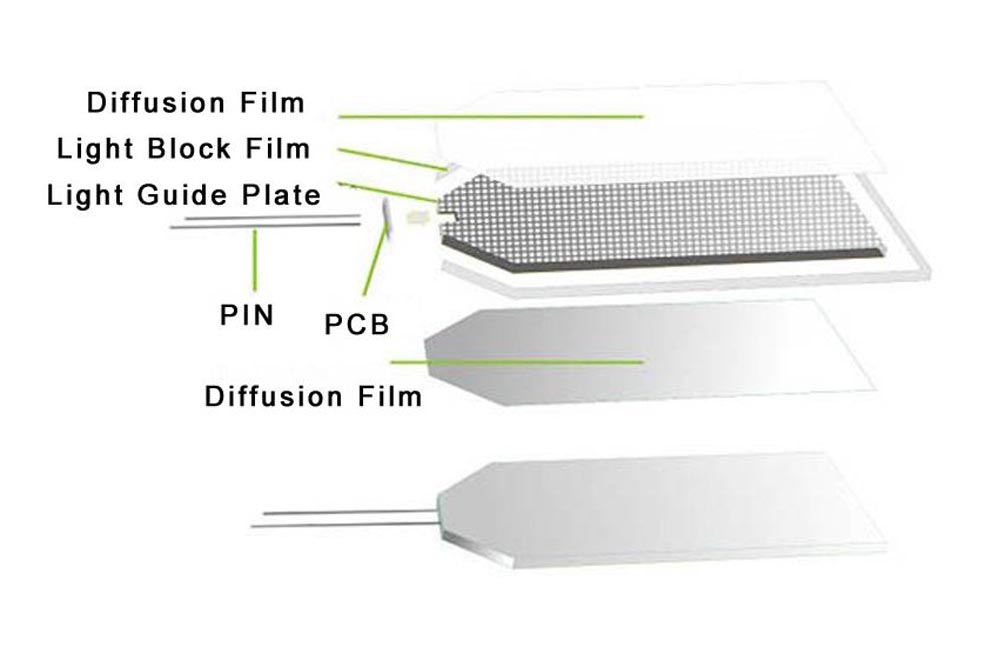

As below picture,Backligt are made with some optical parts.Key parts of Backligtht Unit are light guide plate and housing frame. Minebea"s principal competitive advantages are its ultraprecision machining and mass production technologies. Injection mold die need sub-micron ultraprecision machining and stable injection mold technologies.Minebea has amassed precision ball bearing"s technologies enables it to achieve levels of precision unmatched by its competitors. Minebea also uses these technologies for in-house parts, modl die,tooling and product of Backlight Unit.The function of light guide plate are transforming positional light source to surface light on display uniformly and efficiently.It realize optical design by own optical simulation and independently developed design program. Minebea assembles Backlight Unit by the technologies it put parts into limited space, greatly contributing to the precision and reliability. Minebea put into force exhaustive environmental control at Thai and China factories and enable manufacturing the bulk of Backlight with high quality and stable supply.

Broken LCD, or flickering display, or a dull dark display, we have the solution. We can repair or replace the LCD. Backlight or display card problem we have solution for all.

This article is about backlights in liquid crystal displays. For the rear window of an automobile, see Car glass. For the lighting design practice, see Backlighting (lighting design). For other uses, see Backlight (disambiguation).

A backlight is a form of illumination used in liquid crystal displays (LCDs). As LCDs do not produce light by themselves—unlike, for example, cathode ray tube (CRT), plasma (PDP) or OLED displays—they need illumination (ambient light or a special light source) to produce a visible image. Backlights illuminate the LCD from the side or back of the display panel, unlike frontlights, which are placed in front of the LCD. Backlights are used in small displays to increase readability in low light conditions such as in wristwatches,smart phones, computer displays and LCD televisions to produce light in a manner similar to a CRT display. A review of some early backlighting schemes for LCDs is given in a report Engineering and Technology History by Peter J. Wild.

Simple types of LCDs such as in pocket calculators are built without an internal light source, requiring external light sources to convey the display image to the user. Most LCD screens, however, are built with an internal light source. Such screens consist of several layers. The backlight is usually the first layer from the back. Light valves then vary the amount of light reaching the eye, by blocking its passage in some way. Most use a fixed polarizing filter and a switching one, to block the undesired light.

An ELP gives off uniform light over its entire surface, but other backlights frequently employ a diffuser to provide even lighting from an uneven source.

Backlights come in many colors. Monochrome LCDs typically have yellow, green, blue, or white backlights, while color displays use white backlights that cover most of the color spectrum.

Colored LED backlighting is most commonly used in small, inexpensive LCD panels. White LED backlighting is becoming dominant. ELP backlighting is often used for larger displays or when even backlighting is important; it can also be either colored or white. An ELP must be driven by relatively highAC power, which is provided by an inverter circuit. CCFL backlights are used on larger displays such as computer monitors, and are typically white in color; these also require the use of an inverter and diffuser. Incandescent backlighting was used by early LCD panels to achieve high brightness, but the limited life and excess heat produced by incandescent bulbs were severe limitations. The heat generated by incandescent bulbs typically requires the bulbs to be mounted away from the display to prevent damage.

For several years (until about 2010), the preferred backlight for matrix-addressed large LCD panels such as in monitors and TVs was based on a cold-cathode fluorescent lamp (CCFL) by using two CCFLs at opposite edges of the LCD or by an array of CCFLs behind the LCD (see picture of an array with 18 CCFLs for a 40-inch LCD TV). Due to the disadvantages in comparison with LED illumination (higher voltage and power needed, thicker panel design, no high-speed switching, faster aging), LED backlighting is becoming more popular.

LED backlighting in color screens comes in two varieties: white LED backlights and RGB LED backlights.blue LED with broad spectrum yellow phosphor to result in the emission of white light. However, because the spectral curve peaks at yellow, it is a poor match to the transmission peaks of the red and green color filters of the LCD. This causes the red and green primaries to shift toward yellow, reducing the color gamut of the display.a red, a blue, and a green LED and can be controlled to produce different color temperatures of white. RGB LEDs for backlighting are found in high end color proofing displays such as the HP DreamColor LP2480zx monitor or selected HP EliteBook notebooks, as well as more recent consumer-grade displays such as Dell"s Studio series laptops which have an optional RGB LED display.

RGB LEDs can deliver an enormous color gamut to screens.additive color) the backlight can produce a color spectrum that closely matches the color filters in the LCD pixels themselves. In this way, the filter passband can be narrowed so that each color component lets only a very narrow band of spectrum through the LCD. This improves the efficiency of the display since less light is blocked when white is displayed. Also, the actual red, green, and blue points can be moved farther out so that the display is capable of reproducing more vivid colors.

A newNanosys, claims that the color output of the dots can be tuned precisely by controlling the size of the nanocrystals. Other companies pursuing this method are Nanoco Group PLC (UK), QD Vision, 3M a licensee of Nanosys and Avantama of Switzerland.Sony has adapted Quantum Dot technology from the US company QD Visionedge-lit LED backlight marketed under the term Triluminos in 2013. With a blue LED and optimized nanocrystals for green and red colors in front of it, the resulting combined white light allows for an equivalent or better color gamut than that emitted by a more expensive set of three RGB LEDs. At the Consumer Electronics Show 2015, Samsung Electronics, LG Electronics, the Chinese TCL Corporation and Sony showed QD-enhanced LED-backlighting of LCD TVs.

CCFL backlighting has also improved in this respect. Many LCD models, from cheap TN-displays to color proofing S-IPS or S-PVA panels, have wide gamut CCFLs representing more than 95% of the NTSC color specification.

There are several challenges with LED backlights. Uniformity is hard to achieve, especially as the LEDs age, with each LED aging at a different rate. Also, the use of three separate light sources for red, green, and blue means that the white point of the display can move as the LEDs age at different rates; white LEDs are also affected by this phenomenon, with changes of several hundred kelvins being recorded. White LEDs also suffer from blue shifts at higher temperatures varying from 3141K to 3222K for 10 °C to 80 °C respectively.Benq G2420HDB consumer display has a 49W consumption compared to the 24W of the LED version of the same display (G2420HDBL).

To overcome the aforementioned challenges with RGB and white LED backlights an "advanced remote phosphor" cockpit displays,Air Traffic Control displays and medical displays. This technology uses blue pump LEDs in combination with a sheet on which phosphorous luminescent materials are printed for colour conversion. The principle is similar to Quantum Dots, but the phosphors applied are much more robust than the quantum dot nano-particles for applications that require long lifetime in more demanding operational conditions. Because the phosphor sheet is placed at a distance (remote) of the LED it experiences much less temperature stress than phosphors in white LEDs. As a result, the white point is less dependent on individual LEDs, and degrading of individual LEDs over lifetime, leading to a more homogenous backlight with improved colour consistency and lower lumen depreciation.

The use of LED backlights in notebook computers has been growing. Sony has used LED backlights in some of its higher-end slim VAIO notebooks since 2005, and Fujitsu introduced notebooks with LED backlights in 2006. In 2007, Asus, Dell, and Apple introduced LED backlights into some of their notebook models. As of 2008Lenovo has also announced LED-backlit notebooks. In October 2008, Apple announced that it would be using LED backlights for all of its notebooks and new 24-inch Apple Cinema Display, and one year later it introduced a new LED iMac, meaning all of Apple"s new computer screens are now LED. Almost every laptop with a 16:9 display introduced since September 2009 uses LED-backlit panels. This is also the case for most LCD television sets, which are marketed in some countries under the misleading name LED TV, although the image is still generated by an LCD panel.

Most LED backlights for LCDs are edge-lit, i.e. several LEDs are placed at the edges of a lightguide (Light guide plate, LGP), which distributes the light behind the LC panel. Advantages of this technique are the very thin flat-panel construction and low cost. A more expensive version is called full-array or direct LED and consists of many LEDs placed behind the LC panel (an array of LEDs), such that large panels can be evenly illuminated. This arrangement allows for local dimming to obtain darker black pixels depending on the image displayed.

For a non-ELP backlight to produce even lighting, which is critical for displays, the light is first passed through a lightguide (Light guide plate, LGP) - a specially designed layer of plastic that diffuses the light through a series of unevenly spaced bumps. The density of bumps increases further away from the light source according to a diffusion equation. The diffused light then travels to either side of the diffuser; the front faces the actual LCD panel, the back has a reflector to guide otherwise wasted light back toward the LCD panel. The reflector is sometimes made of aluminum foil or a simple white-pigmented surface.

The LCD backlight systems are made highly efficient by applying optical films such as prismatic structure to gain the light into the desired viewer directions and reflective polarizing films that recycle the polarized light that was formerly absorbed by the first polarizer of the LCD (invented by Philips researchers Adrianus de Vaan and Paulus Schaareman),

The evolution of energy standards and the increasing public expectations regarding power consumption have made it necessary for backlight systems to manage their power. As for other consumer electronics products (e.g., fridges or light bulbs), energy consumption categories are enforced for television sets.

Dimming options for LCD brightness; J. Moronski; Electronicproducts.com; 3 Januari 2004; "Dimming options for LCD brightness control". March 2004. Archived from the original on 2017-07-28. Retrieved 2017-11-20.

LCD Television Power Draw Trends from 2003 to 2015; B. Urban and K. Roth; Fraunhofer USA Center for Sustainable Energy Systems; Final Report to the Consumer Technology Association; May 2017; "Archived copy" (PDF). Archived from the original (PDF) on 2017-08-01. Retrieved 2017-11-20.link)

Controlling Power Consumption for Displays With Backlight Dimming; Claire Mantel et al; Journal of Display Technology; Volume: 9, Issue: 12, Dec. 2013; Mantel, Claire; Burini, Nino; Nadernejad, Ehsan; Korhonen, Jari; Forchhammer, Soren; Pedersen, Jesper Meldgaard (2013). "Controlling Power Consumption for Displays with Backlight Dimming". Journal of Display Technology. 9 (12): 933–941. Bibcode:2013JDisT...9..933M. doi:10.1109/JDT.2013.2260131. S2CID 24082090.

There’s been a significant growth in the monitor market when it comes to screens with LED backlighting. I wanted to provide an article which explains the technology in more detail as it is bound to become more and more widespread. The technology was originally quite expensive, but reduced production costs and improved manufacturing processes have allowed LED backlighting to be used in even the lower cost monitor market. We are now seeing an influx of new screens in all different sizes using LED backlighting, and it is also being combined with TN Film, VA and IPS panel technologies.

RGB LED Backlighting – This type of backlighting is based on RGB triads, each including one red, one green and one blue LED. RGB LED backlighting ensures an excellent colour gamut and very pure colours, but is only really used in professional-grade displays such as the Samsung XL20, XL24, XL30 screens, and modern professional models like the HP DreamColor LP2480zx. This type of backlighting is only used in this sector due to its high cost and it is not economical to produce at the moment.

An edge backlight with white LEDs (W-LEDs) –The LEDs are placed in a line along the edge of the matrix, and the uniform brightness of the screen is ensured by a special design of the diffuser. This backlight does not offer the option of zonal control over brightness like the direct lit method does (see below). It can not offer an extended color gamut either. Instead, it is economical and compact, which makes it popular among notebook makers and with manufacturers producing ultra-thin displays and keen to keep costs to a minimum. This is the variation commonly being used in desktop displays at the moment.

A flat backlight based on white LEDs (W-LEDs) – As there is only one third of the total amount of LEDs here, this backlight is much cheaper than the triad-based backlight, but it cannot deliver an extended color gamut. In the backlight of this type LEDs are uniformly distributed in the plane parallel to the matrix, which allows setting the backlight intensity differently in different parts of the screen when necessary. This is the further development of the dynamic contrast technology. It is currently employed in LCD TV-sets only and is also referred to as ‘direct lit’ W-LED. A note about white LEDs – A white LED is actually a blue LED with yellow phosphor to give the impression of white light. The spectral curve has big gaps in the green and red parts.

If marketing is to be believed, LED backlighting offers you all kinds of advantages, but it’s important to understand what is true, and what is not. We will discuss different aspects and whether they are influenced by a different backlight source:

Colour Gamut– this is controlled in monitors by the properties of the colour filters of the LCD matrix, and by the backlight’s radiation spectrum. You will see CCFL backlighting offering colour gamuts covering between 72% (commonly referred to as “standard gamut” / sRGB) and 102% of the NTSC reference colour space. The CCFL backlighting above 72% are commonly referred to as wide gamut, or W-CCFL / WCG-CCFL. In LED backlighting, the RGB LED format can offer really large colour gamuts with pure and saturated colours. These can cover typically >114% of the NTSC colour space, and is one of the reasons they are often employed in high end professional screens. W-LED backlighting cannot offer these extended gamuts, and on paper actually cover slightly less of the NTSC colour space than standard gamut CCFL (typically 68%). The difference is hardly detectable by the naked eye however.

Colour Accuracy – aspects of colour reproduction do not depend on the type of backlight at all. They are determined by how accurately the monitor is set up in the factory, the characteristics of the panel technology and the internal electronics to a degree.

Static contrast ratio – LED backlighting models are advertised with massive contrast ratios, ranging commonly into the millions now! Figures of up to 20 million:1 are common at the time of writing. Be aware though that these are normally headline dynamic contrast ratio figures, with the normal static contrast ratio rarely even mentioned. It is important to understand that static contrast ratio is only determined by the characteristics of the LCD matrix itself and not by the backlighting type or nature. It is determined by the ratio of the transparency levels of open and closed pixels.

Dynamic contrast ratio – As opposed to gas-discharge lamps (CCFL), LEDs can be lit up instantly or turned out completely. This can lead to extremely high levels of dynamic contrast as we have mentioned above. Figures in the millions are very common now. But in real applications, for example when watching a movie, there are no absolutely black frames even in the credits. Most of the time there is something on the screen besides blackness and a monitor with a huge specified dynamic contrast will never have the chance to deliver it in practice. As a result, there is no real practical point in increasing the dynamic contrast higher than about 10,000:1 which has already become standard for many monitors, including those with a backlight based on CCFL lamps. Keep in mind that DCR figures are often exagerated as a result, and since you will probably never get to utlise the full figure in practice, don’t be fooled into buying into the hype too much!

Uniformity – Most desktop monitors use edge-lit W-LED backlighting with a line of LEDs along the edge of the panel. The whole screen is lit by means of a special diffuser, and so it is this which really determines the brightness uniformity you experience. The uniformity of brightness depends only on the design of the diffuser and you can often see various defects like bright spots or a brighter zone at the edge of the screen where the lamp or the line of LEDs resides. Having an LED backlight does not guarantee you better uniformity. In fact, good uniformity is harder to achieve in the long term as the LEDs age, with each LED possibly aging at a different rate. With RGB LED units, the use of three separate light sources for red, green, and blue means that the white point / colour temperature of the display can move as the LEDs age at different rates as well.

Instantly On – some manufacturers mention that an LED can be instantly turned on, meaning there is no warm up time like there is with a CCFL backlight. This is true, but it’s debatable how important this really is to an end user.

Size – LED backlighting units can be very thin, allowing manufacturers to produce ultra-thin displays with sleek and attractive designs. You also see this technology used in laptops and LCD TV’s for the same purposes. This technology has allowed production of thinner screens which are in high demand by consumers. Manufacturers are actively working on reducing the size of the LEDs to be used in these modules to improve things even more. Screens using a flat W-LED or RGB backlight behind the panel cannot offer the same thin profile however.

Environmental – LEDs do not contain mercury, unlike CCFL’s and so can be recycled more easily. You will see mention of various certificates and compliance standards as well, such as ‘RoHS compliance’. These can show the displays have met recylcing standards. Certainly a benefit of LED backlighting for the environmentally concious.

Power Consumption– This is perhaps one of the key advantages of LED backlighting in modern times. The technology uses less energy and so you can save money and energy and reduce your carbon footprint at the same time. For example, the non-LED version of the 24″ BenQ G2420HBD consumer display has a 49W consumption compared to the 24W of the LED version of the same display (G2420HBDL). The BenQ LED monitors are typically marketed as offering a reduced power consumption of 36% in comparison to traditional monitors. Other manufacturers quote similar figures, with 35 – 40% energy saving being common. You will also see various ratings and ‘certificates’ applied to these screens such as Energy Star and the likes.

At the professional end of the market where RGB LED backlighting is used, it is combined with high end panel technologies such as AMVA (from AU Optronics) or IPS (from LG.Display). These panel technologies are more expensive to produce than the widely used TN Film panels in the mainstream market. When you are using an expensive backlighting unit, it obviously should be paired with a higher-end panel though. In fact, modern RGB LED displays such as the HP DreamColor LP2480zx even use a one-of-a-kind true 10-bit H-IPS panel (not 8-bit +AFRC like some of the other modern “10-bit” screens). RGB LED models are few and far between though of course.

W-LED backlit models are becoming more and more mainstrea. Initially the technology was combined exclusively with TN Film panels, since low production costs (and low retail costs) were the name of the game. There are many TN Film based models out there with LED backlighting now. More recently, in the later half of 2010, we have seen models emerge combining W-LED backlighting with VA and IPS matrices. AU Optronics have released modules in several sizes which combine their AMVA panel technology with LED, and LG.Display have begun to release a combination of IPS and LED. The BenQ EW2420 and VW2420H were two of the first VA based screens on the market with LED. The NEC EA232WMi and forthcoming models from LG will be some of the first to use IPS + LED. We expect this trend will continue.

.jpg)

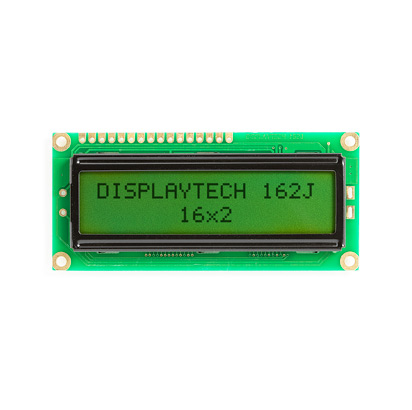

NHD-C12865BR-FSW-GBW | Monochrome Graphic COG | 128x65 Pixels | Transflective LCD | Side White Backlight | STN (+) Positive Gray Display | Non-Stocked

Newhaven 128x65 graphic Chip-On-Glass (COG) Liquid Crystal Display shows blue pixels on a gray background. This transflective LCD Display is visible with ambient light or a backlight while offering a wide operating temperature range from -20 to 70 degrees Celsius. This NHD-C12865BR-FSW-GBW display has an optimal view of 6:00, operates at 3.3V supply voltage and is RoHS compliant.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey