tft lcd source driver ic factory

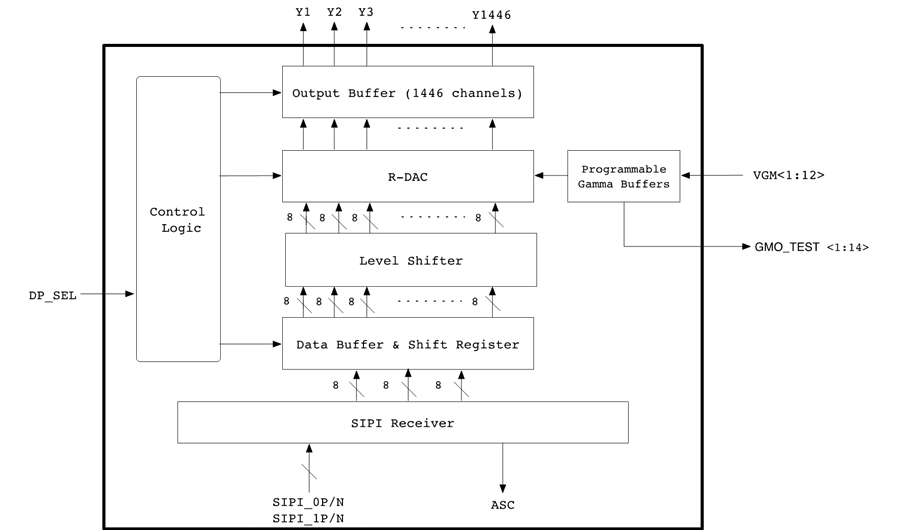

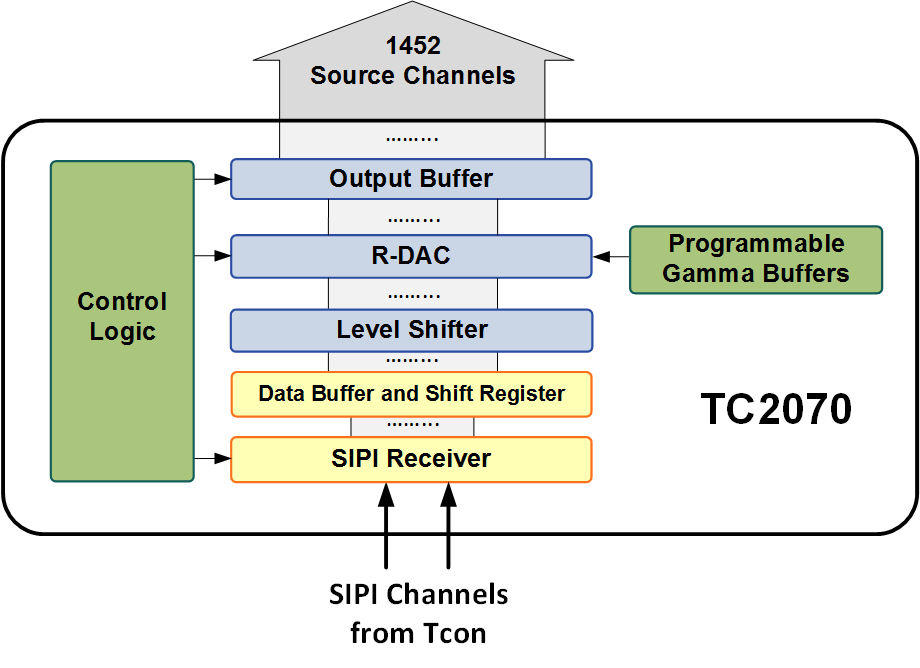

TC2079 is a 1446-channel source driver for high resolution TFT LCD. It is designed for COG (Chip-on-glass) application. The input interface is SIPI™ (Scalable Intra Panel Interface) which has been developed and patented by Parade Technologies. SIPI™ is a point-to-point interface between Timing Controller (TCON) and Source Driver (SD). The SIPI™ intra panel interface provides scalable bandwidth with reduced bus width, low EMI and low power, more robust protocol to establish link and enhance system reliability to address existing and future growth of high resolution digital display on notebook and tablet PCs and other consumer electronics applications.

This article will take you through a high level overview of all of the parts of a TFT LCD display. The vast majority of what I have read on the internet makes this whole issue massively complex. I’m quite sure that this complexity problem is a real reflection of the serious design and manufacturing complexity in these displays and drivers. That being said, to get a conceptual understanding is much simpler, and is the point of this article.

A significant amount of my learning about this subject came from a 195 page powerpoint presentation by Dr. Fang-Hsing Wang entitled “Flat Panel Display : Principle and Driving Circuit Design“. He has graciously allowed me to reproduce a few of his images. This dude knows way way more about these circuits than I do and I would encourage you to read his work.

The fundamental element in a TFT display is the liquid crystal. These elements have the property that the crystals will align from horizontal (which blocks the light) to vertical (which lets most of the light through) based on the electric field applied to them. Basically, you shine light through the liquid crystal, which blocks some or all of the light, the remainder of the white light then goes through a color filter to make red, green, or blue. It works like this:

This architecture means that every pixel in the display will require a red, green and blue element. And, you will need to control the voltage on all of the elements (which will be quite a lot on a screen of any size)

What does the schematic for one element in a pixel look like? And where is the T(transistor) in the TFT? The three letter acronym TFT stands for a thin film transistor that is physically on the top of the LCD matrix right next to each liquid crystal element. Here is a schematic model for one element in the array. C-LC represents the capacitance of the liquid crystal. CS is a storage capacitor that is used to hold the electric field across the liquid crystal when the transistor is OFF. To apply a voltage across the LC you just turn on the gate and apply the correct voltage to the column commonly known as the source.

You should notice that the “back” terminal of the two capacitors is called “VCOM” and is physically on the other side of the liquid crystal matrix from the TFT. All of the liquid crystal backsides in the display are connected to the same VCOM. A bit of painfulness in this system is that the CS capacitor leaks, which means that the LCD changes state which means that each pixel must be updated, properly called refreshed, on a regular basis.

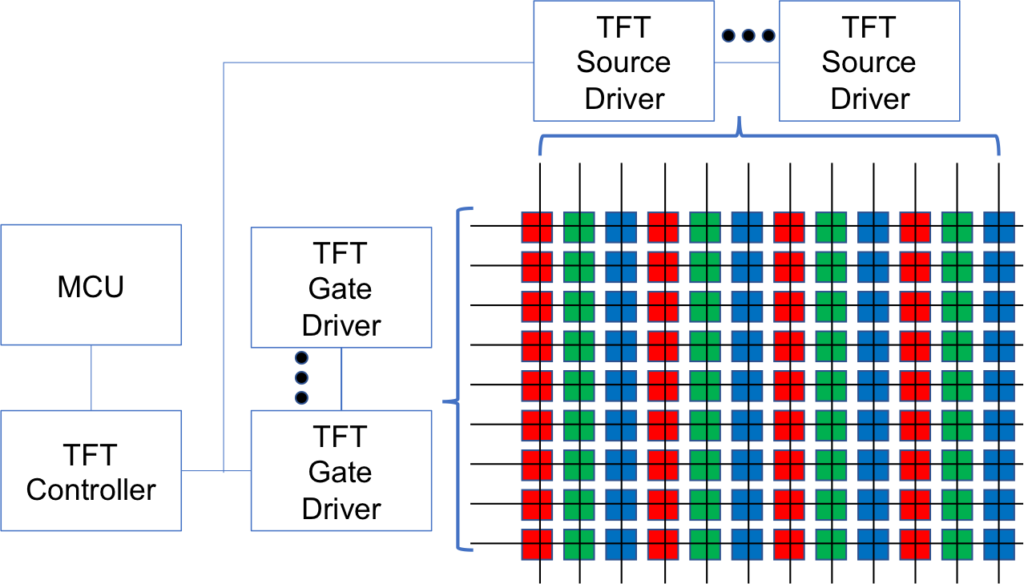

We know that each pixel has three three thin film transistors, three capacitors, three color filters (red, green and blue) and that we need to control the voltage on the source/drain of each transistor in order to cause the right amount of light to come through the liquid crystal. How do we do that? The first step is to arrange all of the pixels in a matrix. Each row of matrix has all of the gates connected together. And each column of the matrix has all of the sources tied together. In order to address a specific pixel RGB element, you turn on the correct row and then apply a voltage to the correct column at the right time.

If you have been thinking about this system you might have done a little bit of math and figured out that you are going to need an absolute boatload of source and gate driver signals. And you would be right! For example, a 4.3″ screen with 480×272 will require 480x272x3 elements which are probably organized into 480 rows by 816 columns. This would require a chip with at least 480+816=1296 pins, that is a lot. It turns out that for small screens <=3.5″ there are chips with enough pins to do the job. But, for larger screens, it requires multiple chips to do the job. The “…” in the picture above shows the driver chips being cascaded. The next thing to know is that “TFT Glass” usually has the driver chip(s) embedded into the screen at the edge (you can see that in the picture from Innolux above).

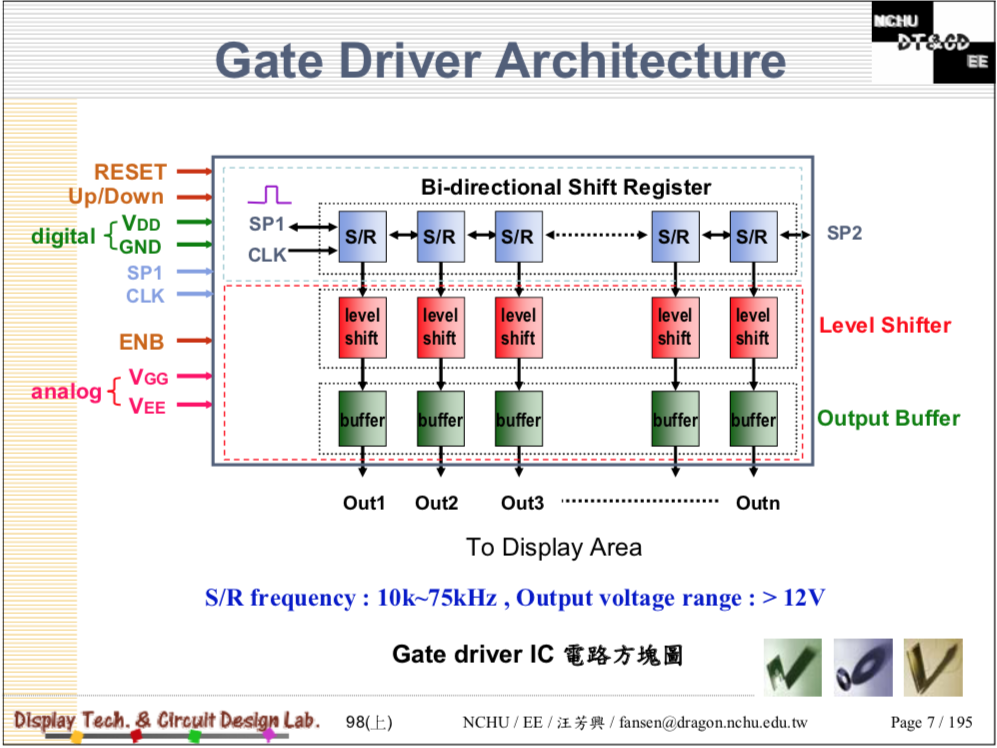

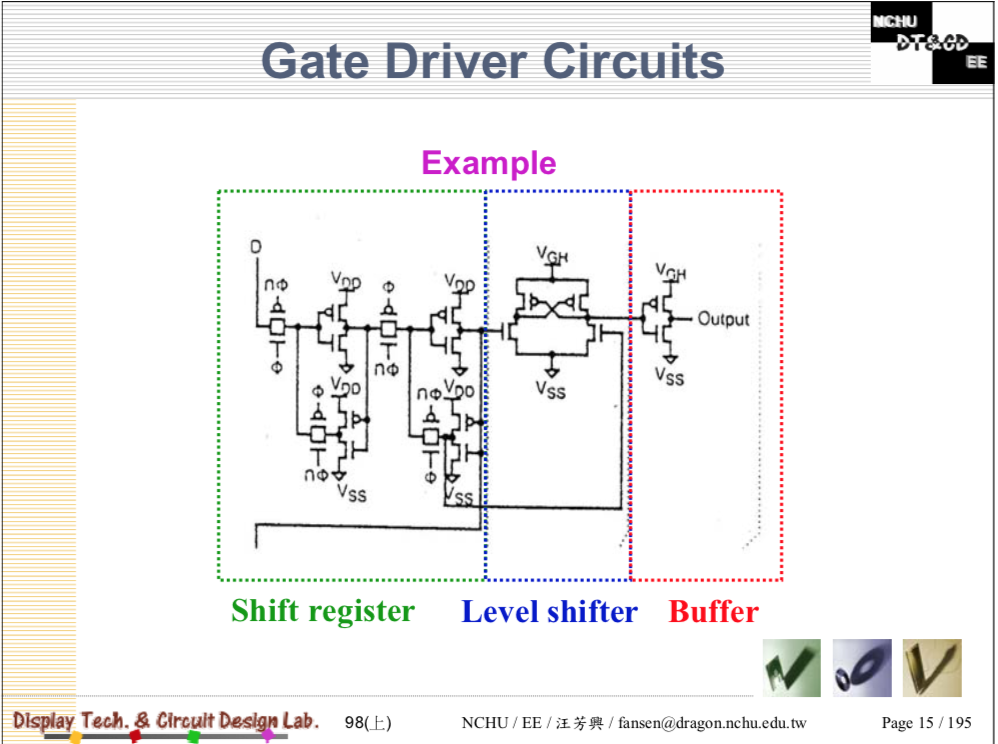

You must put a quite high voltage source >20v and drain <-10V across the liquid crystal at the right time to get it to do its thing. In order to pass that source voltage, the gate must be turned on at the right time to the right voltage, this is the purpose of the Gate Driver IC. The gate driver is conceptually simple and Dr. Wang drew a nice picture on page 7 of his presentation. You can see that it is basically a shift register, with one element per gate. You shift in a “1” and then clock it through the entire shift register which will have the effect of applying a 1 to each gate.

However, a 3.3v logic 1 is not anywhere high enough to drive the gate so that it can pass the much higher source voltage. So, you need to level shifter and a buffer to get the “right” voltage. On page 15, Dr. Wang made a nice picture of this circuit as well.

It turns out that this picture is conceptually correct, but the exact implementation has “a lot going on”. You can read about the next layer of circuit design in his presentation on pages 15-35.

In its most basic form, the TFT source driver is responsible for taking an 8-bit digital input value representing the value of an individual LCD element and turning it into a voltage, the driving the voltage. Like this:

In reality there is some compromise of chip size, number of pins and time that is made by multiplexing pins, columns and rows. For example, many of the small screens appear to have 1 column driver for all of the reds, 1 driver for the blues and one for greens.

What appears to happen in real life on bigger screens is some combination of column and row multiplexing. In one display that I found there were 2x the number of rows which allows the columns to be multiplexed 2-1. The display is 1024×600. That requires 1024*3 RGBs in the column = 1536 pins. This means that you need to double the number of gate drivers, resulting in 1200 pins in the row direction. Here is a picture from their datasheet.

The last issue that I will address in TFT LCD drivers is called Gamma Correction or more simply Gamma. Gamma is an intensity adjustment factor. For any given digital intensity input, you will need a non-linear translation to a voltage output on the source. For example a doubling of digital input (so that a pixel appears twice as bright) you will not double but instead will have some non-linear translation of the output voltage.

The good news is that this gamma correction is built into the display drivers. From my reading, this is sometimes done with digital processing, and sometimes done with an analog circuit. But in general, it appears to be tuned and programmed into the driver by the panel vendor for these smaller display.

INT070ATFT and INT070ATFT-TS are embedded display driver boards based on the Displaytech 7 inch 800 x 480 RGB resolution TFT display module. This embedded driver board includes a 7" standard or resistive touchscreen display. Mounted on the embedded board is the Solomon Systech SSD1963 LCD controller that supports common RAM-less LCD drivers and offers the following features and benefits:

Abstract:A two-stage driving circuit of a one-chip TFT-LCD driver IC for portable electronic devices is proposed.The driving buffers of the new circuit are built in the γ-correction circuit rather than in the source driver.The power consumption,die area,and driving capability of the driving circuit are discussed in detail.For a two-stage driving circuit with 13 driving buffers,the settling time of the driving voltage within 0.2% error is about 19.2μs when 396 pixel-loads are driven by the same grayscale voltage.The quiescent current of the whole driving circuit is 518μA,and the power consumption can be reduced by 77%.The proposed driving circuit is successfully applied in a 132RGB×176-dot,260k color one-chip driver IC developed by us for the TFT-LCD of mobile phone,and it can also be used in other portable electronic devices, such as PDAs and digital cameras.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Samsung Electronics Co. Ltd., a leader in advanced silicon technology solutions, today announced a new interface standard for display driver ICs for large-screen TFT-LCD panels. Samsung"s new current-mode interface of cascade chip-on-glass (COG)/chip-on-film (COF) (CICC) standard uses a new technology for data transfer where the LCD driver IC (the source driver) is interfaced with the timing controller.

Today, electromagnetic interference (EMI) is a growing issue in the LCD panel industry. EMI is caused by the increased size in LCD monitors and TVs, the rapid advancement in high-resolution pictures, a continuous surge in display data size and a rising number of data bus lines to accelerate the data transmission speeds.

To address EMI, Samsung"s CICC standard operates on a lower current swing method (DI=200uA, DV£10mV) and adopts a serialized, cascade data transfer method that allows data to directly flow between adjacent LCD driver ICs.

“Samsung will apply this new CICC standard to its own products while expanding its use as an industry standard,” said vice president Jin-tae Kim of Display Driver Development Team, System LSI Division, Samsung Electronics. “We are convinced that the CICC standard will be widely adopted as a next-generation interface standard for large-screen TFT-LCD driver IC, with its features benefiting LCD Panel makers.”

The data bus line can be halved from 18 lines to 9 in a 6-bit LCD driver IC using the CICC standard, minimizing EMI and reducing power consumption by 20 percent. In addition, the chip size of the timing controller can be decreased, while the driver board can be simplified with the 50 percent reduction of peripheral parts.

Conventional interfaces such as reduced swing differential signaling (RSDS) and transistor-transistor logic (TTL) can only be used for source driver ICs in film type packages, such as tape carrier package (TCP) or COF. CICC can be applied, on the other hand, with COG where the chip is attached directly on the LCD glass, as well as the COF package.

The object of the invention is to overcome above-mentioned defect of the prior art, TFT-LCD under a kind of low cost Tri-gate framework is provided, be intended to by the OP in P_GammaIC is implanted in to the mode that SourcedriverIC realizes, reduce cost and the volume of P_GammaIC, thereby reach the TFT-LCD cost reducing under whole Tri-gate framework.

The invention provides the TFT-LCD under a kind of low cost Tri-gate framework, comprise PCBA, SourcedriverIC and panel, described PCBA is provided with TCON, P_GammaIC and Connector, it is characterized in that: described P_GammaIC realizes gamma and generates, inside comprises IICinterfacelogic, memory and a DAC, and inside does not arrange an OP; Described SourcedriverIC is provided with RX, linebuffer, an OP, the 2nd DAC and the 2nd OP; A described DAC organizes initial gamma voltage by the n of its generation and transports to an OP who is arranged on SourcedriverIC, the one OP organizes initial gamma voltage to described n and carries out current driving ability and amplify the n group gamma reference voltage generating after correcting and transport to the 2nd DAC, to carry out follow-up work.

The implementation method of TFT-LCD under above-mentioned low cost Tri-gate framework, be specially: at P_GammaIC, OP is not set, in described P_GammaIC, a DAC completes and described IICinterfacelogic is carried out to IIC protocol logic data after treatment carries out analog-to-digital conversion and generate n and organize the outwards i.e. output of initial gamma voltage, increase an OP is set at SourcedriverIC, the one OP organizes initial gamma voltage to described n and carries out current driving ability and amplify the n group gamma reference voltage generating after correcting and transport to the 2nd DAC, TCON in described PCBA will be through synchronous sequence data after treatment successively through RX (data sink), linebuffer (line storage) reaches the 2nd DAC, the 2nd DAC organizes gamma reference voltage by data after treatment described synchronous sequence by n and produces the each gray scale voltage that meets gamma2.2, then again carrying out becoming n group output voltage after current driving ability amplification is corrected through the 2nd OP exports to panel, realize the normal demonstration of panel.

Tri-gate framework TFT-LCD under HD resolution of the present invention, by the OP of P_GammaIC is transferred in SourcedriverIC and is realized, because OP occupies the volume of existing whole P_GammaIC nearly 40% and 50% cost, significantly reduce volume and the cost of P_gammaIC; Simultaneously in manufacturing process, because also there is the 2nd OP module in SourcedriverIC, an OP of the former P_GammaIC of being located at is arranged on to SourcedriverIC, can under same process, completes P_GammaOP and make, make the increase of SourcedriverIC cost extremely small; And, can meet use because the Tri-gate framework TFT-LCD under HD resolution only needs a SourcedriverIC, and more than one conventionally of P_GammaIC quantity is more given prominence to the present invention in cost and the less advantage of volume.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey