raspberry pi lcd display i2c quotation

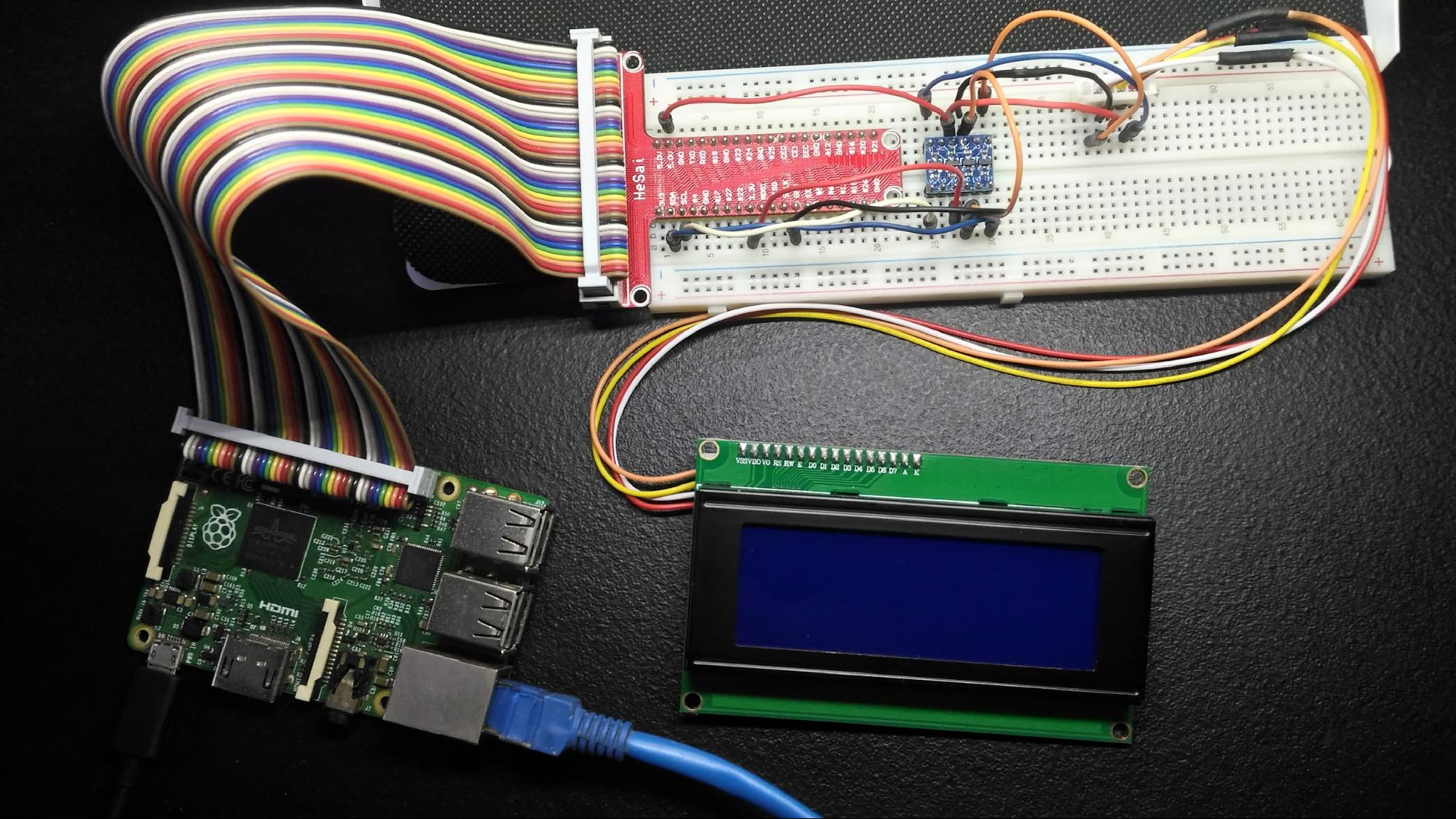

This repository contains all the code for interfacing with a 16x2 character I2C liquid-crystal display (LCD). This accompanies my Youtube tutorial: Raspberry Pi - Mini LCD Display Tutorial.

During the installation, pay attention to any messages about python and python3 usage, as they inform which version you should use to interface with the LCD driver. For example:

It is possible to define in CG RAM memory up to 8 custom characters. These characters can be prompted on LCD the same way as any characters from the characters table. Codes for the custom characters are unique and as follows:

For example, the hex code of the symbol ö is 0xEF, and so this symbol could be printed on the second row of the display by using the {0xEF} placeholder, as follows:

This demo uses ping and nc (netcat) to monitor the network status of hosts and services, respectively. Hosts and services can be modified by editing their respective dictionaries:

exchangerate-api.com / free.currencyconverterapi.com: There are a lot of currency apis but these ones offer free currency exchange info. Both are used, one as main, the other as backup. Requires an API key to use.

In order to use the script, you need to get API key tokens for both exchange rate services and the weather api. Once you"ve done that, edit the script to put your tokens in the USER VARIABLES section.

A simple solution (although it may sound strange) is to lower the power voltage used for the LCD (VCC), by simply connection it through a small diode (1N4148) so the LCD"s VCC becomes 4.5V. LCD will work with that voltage, and its expected logical high voltage drops below 3.3V.

That"s total, absolute and complete nonsense. The HD44780 wired to EN == GPIO16, RS == GPIO26, D7 == GPIO12, D6 == GPIO5, D5 == GPIO6 and D4 == GPIO13 on my A+ works perfectly when I adjust the trimpot to the right contrast value. The power is pin#2, GND is pin#6.

you are right that for this particular LCD controller VIH is not a problem, it seems to need an VIH of just 2.2V (when powered with 5V), but many other controllers, and TTL compatible logic, need 70% of their VCC, so 3.5V, and that leads to the blocks in the display syndrome, and to garbled screens.

Slightly off topic but have you seen i2c LCD adapters, just have to wire up SDA & SCL, can use them with 3.3v versions of the LCD1602 display meaning less components and there is a contrast pot on the i2c adapter.

ViaBitz wrote:Slightly off topic but have you seen i2c LCD adapters, just have to wire up SDA & SCL, can use them with 3.3v versions of the LCD1602 display meaning less components and there is a contrast pot on the i2c adapter.

DougieLawson wrote:ViaBitz wrote:Slightly off topic but have you seen i2c LCD adapters, just have to wire up SDA & SCL, can use them with 3.3v versions of the LCD1602 display meaning less components and there is a contrast pot on the i2c adapter.

Dougie, do you know about aliexpress ? I"ve bought lots of these i2c adapter modules and they"re great, from memory, I though price was close to 50p each but just looked and you can get them delivered for 38p inc shipping.

If I could be bothered with working with lead-free solder I"d buy lots of PCF8574s and lots of HD44780 LCDs and turn a small profit. Although that stuff isn"t covered by my professional indemnity insurance.

However one thing that is often overlooked is tying the unused lower nibble bits to GND, as most of the code and examples are using the LCD is 4-bit mode.

That"s total, absolute and complete nonsense. The HD44780 wired to EN == GPIO16, RS == GPIO26, D7 == GPIO12, D6 == GPIO5, D5 == GPIO6 and D4 == GPIO13 on my A+ works perfectly when I adjust the trimpot to the right contrast value. The power is pin#2, GND is pin#6.

You could use level converters to ensure the high levels are high enough, but you would need half a dozen of them, simply lowering the voltage the LCD controller uses also solves the problem, and a diode in the VCC line does just that without affecting the LCD too much.

Luckily manufacturers of these LCD"s are catching up with the fact that electronics moves away from purely 5V logic signals, and they start using LCD controllers that do not suffer from this problem, but that doesn"t mean you cannot still run into LCD"s that use the older chips.

The only one where things don"t work quite how I"d like it is connected to a PCF8574 running with the controller chip"s Vcc @ 3V3 and the backlight isn"t bright enough to give good contrast on the display.

Obviously when your LED backlighting uses two LED"s on series, (which is often the case with LCD"s that do not use white LED"s) and each LED has a forward voltage of say 2.0Volt, then you need at least more than 4.0 Volt to get any current through them, its elementary.

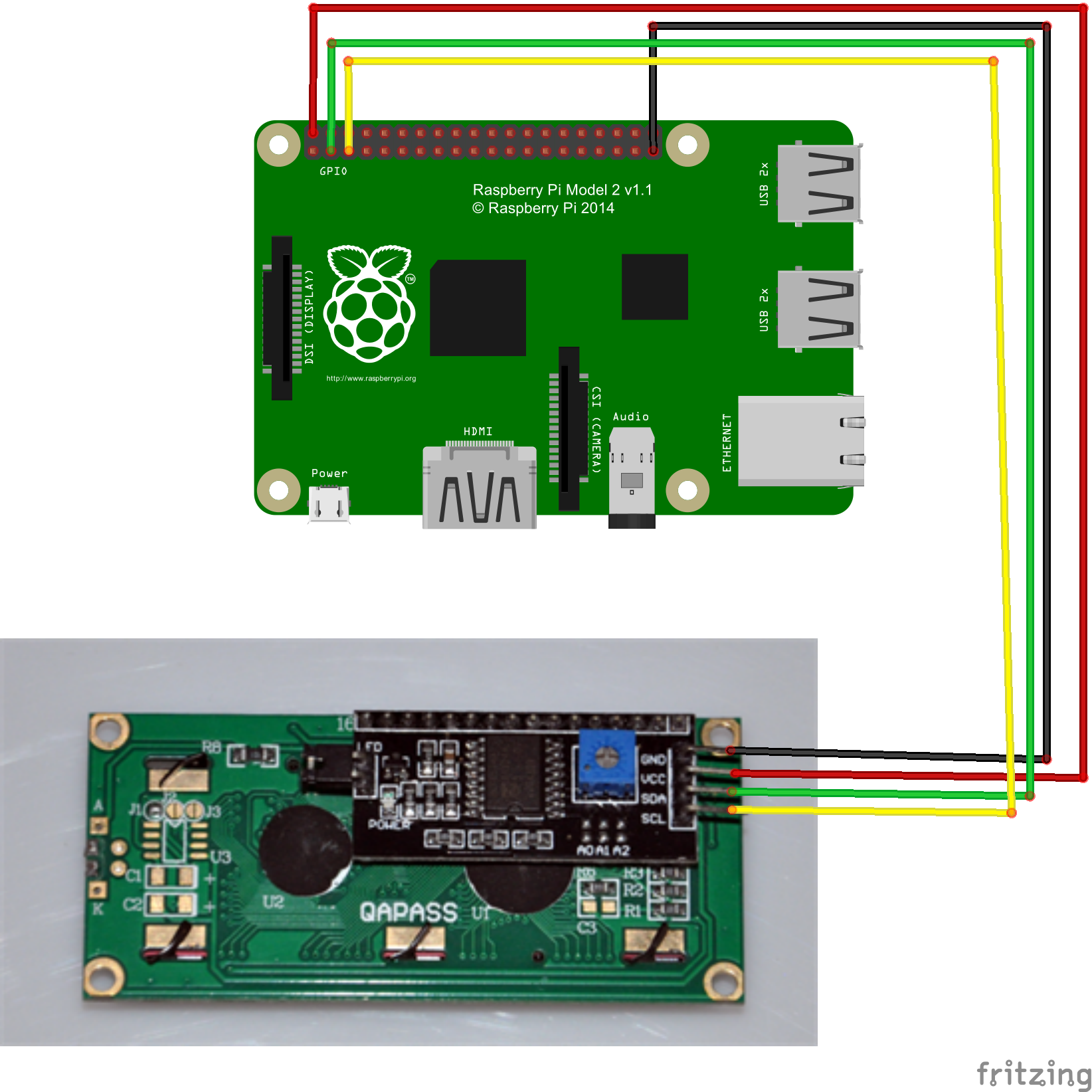

Connecting an LCD to your Raspberry Pi will spice up almost any project, but what if your pins are tied up with connections to other modules? No problem, just connect your LCD with I2C, it only uses two pins (well, four if you count the ground and power).

In this tutorial, I’ll show you everything you need to set up an LCD using I2C, but if you want to learn more about I2C and the details of how it works, check out our article Basics of the I2C Communication Protocol.

There are a couple ways to use I2C to connect an LCD to the Raspberry Pi. The simplest is to get an LCD with an I2C backpack. But the hardcore DIY way is to use a standard HD44780 LCD and connect it to the Pi via a chip called the PCF8574.

The PCF8574 converts the I2C signal sent from the Pi into a parallel signal that can be used by the LCD. Most I2C LCDs use the PCF8574 anyway. I’ll explain how to connect it both ways in a minute.

I’ll also show you how to program the LCD using Python, and provide examples for how to print and position the text, clear the screen, scroll text, print data from a sensor, print the date and time, and print the IP address of your Pi.

I2C (inter-integrated circuit) is also known as the two-wire interface since it only uses two wires to send and receive data. Actually it takes four if you count the Vcc and ground wires, but the power could always come from another source.

Connecting an LCD with an I2C backpack is pretty self-explanatory. Connect the SDA pin on the Pi to the SDA pin on the LCD, and the SCL pin on the Pi to the SCL pin on the LCD. The ground and Vcc pins will also need to be connected. Most LCDs can operate with 3.3V, but they’re meant to be run on 5V, so connect it to the 5V pin of the Pi if possible.

If you have an LCD without I2C and have a PCF8574 chip lying around, you can use it to connect your LCD with a little extra wiring. The PCF8574 is an 8 bit I/O expander which converts a parallel signal into I2C and vice-versa. The Raspberry Pi sends data to the PCF8574 via I2C. The PCF8574 then converts the I2C signal into a 4 bit parallel signal, which is relayed to the LCD.

Before we get into the programming, we need to make sure the I2C module is enabled on the Pi and install a couple tools that will make it easier to use I2C.

Now we need to install a program called I2C-tools, which will tell us the I2C address of the LCD when it’s connected to the Pi. So at the command prompt, enter sudo apt-get install i2c-tools.

Next we need to install SMBUS, which gives the Python library we’re going to use access to the I2C bus on the Pi. At the command prompt, enter sudo apt-get install python-smbus.

Now reboot the Pi and log in again. With your LCD connected, enter i2cdetect -y 1 at the command prompt. This will show you a table of addresses for each I2C device connected to your Pi:

We’ll be using Python to program the LCD, so if this is your first time writing/running a Python program, you may want to check out How to Write and Run a Python Program on the Raspberry Pi before proceeding.

I found a Python I2C library that has a good set of functions and works pretty well. This library was originally posted here, then expanded and improved by GitHub user DenisFromHR.

There are a couple things you may need to change in the code above, depending on your set up. On line 19 there is a function that defines the port for the I2C bus (I2CBUS = 0). Older Raspberry Pi’s used port 0, but newer models use port 1. So depending on which RPi model you have, you might need to change this from 0 to 1.

The function mylcd.lcd_display_string() prints text to the screen and also lets you chose where to position it. The function is used as mylcd.lcd_display_string("TEXT TO PRINT", ROW, COLUMN). For example, the following code prints “Hello World!” to row 2, column 3:

On a 16×2 LCD, the rows are numbered 1 – 2, while the columns are numbered 0 – 15. So to print “Hello World!” at the first column of the top row, you would use mylcd.lcd_display_string("Hello World!", 1, 0).

You can create any pattern you want and print it to the display as a custom character. Each character is an array of 5 x 8 pixels. Up to 8 custom characters can be defined and stored in the LCD’s memory. This custom character generator will help you create the bit array needed to define the characters in the LCD memory.

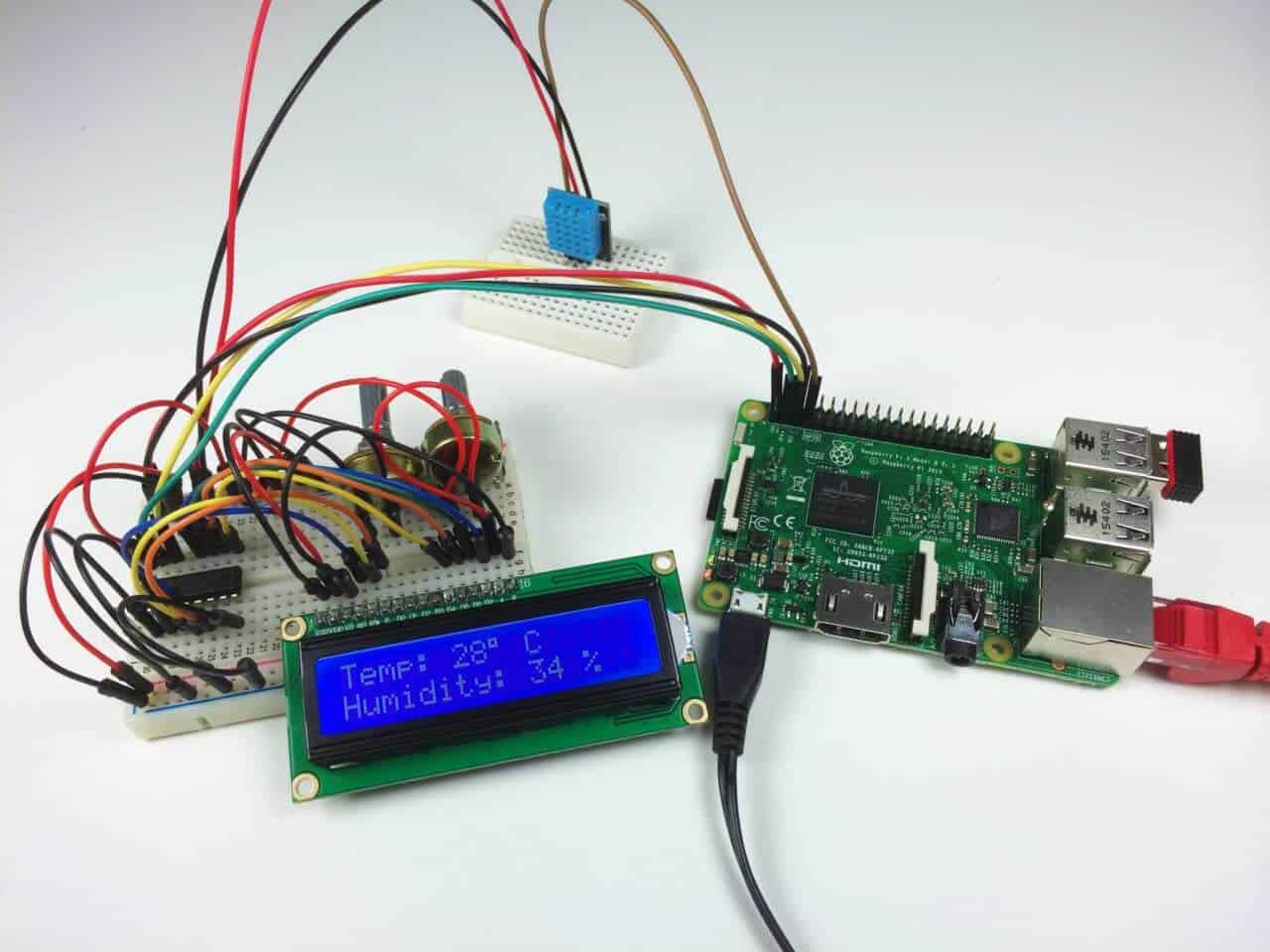

The code below will display data from a DHT11 temperature and humidity sensor. Follow this tutorial for instructions on how to set up the DHT11 on the Raspberry Pi. The DHT11 signal pin is connected to BCM pin 4 (physical pin 7 of the RPi).

By inserting the variable from your sensor into the mylcd.lcd_display_string() function (line 22 in the code above) you can print the sensor data just like any other text string.

These programs are just basic examples of ways you can control text on your LCD. Try changing things around and combining the code to get some interesting effects. For example, you can make some fun animations by scrolling with custom characters. Don’t have enough screen space to output all of your sensor data? Just print and clear each reading for a couple seconds in a loop.

Connecting an LCD display to your Raspberry Pi is sure to take any project up a notch. They’re great for displaying sensor readings, songs or internet radio stations, and stuff from the web like tweets and stock quotes. Whatever you choose to display, LCDs are a simple and inexpensive way to do it.

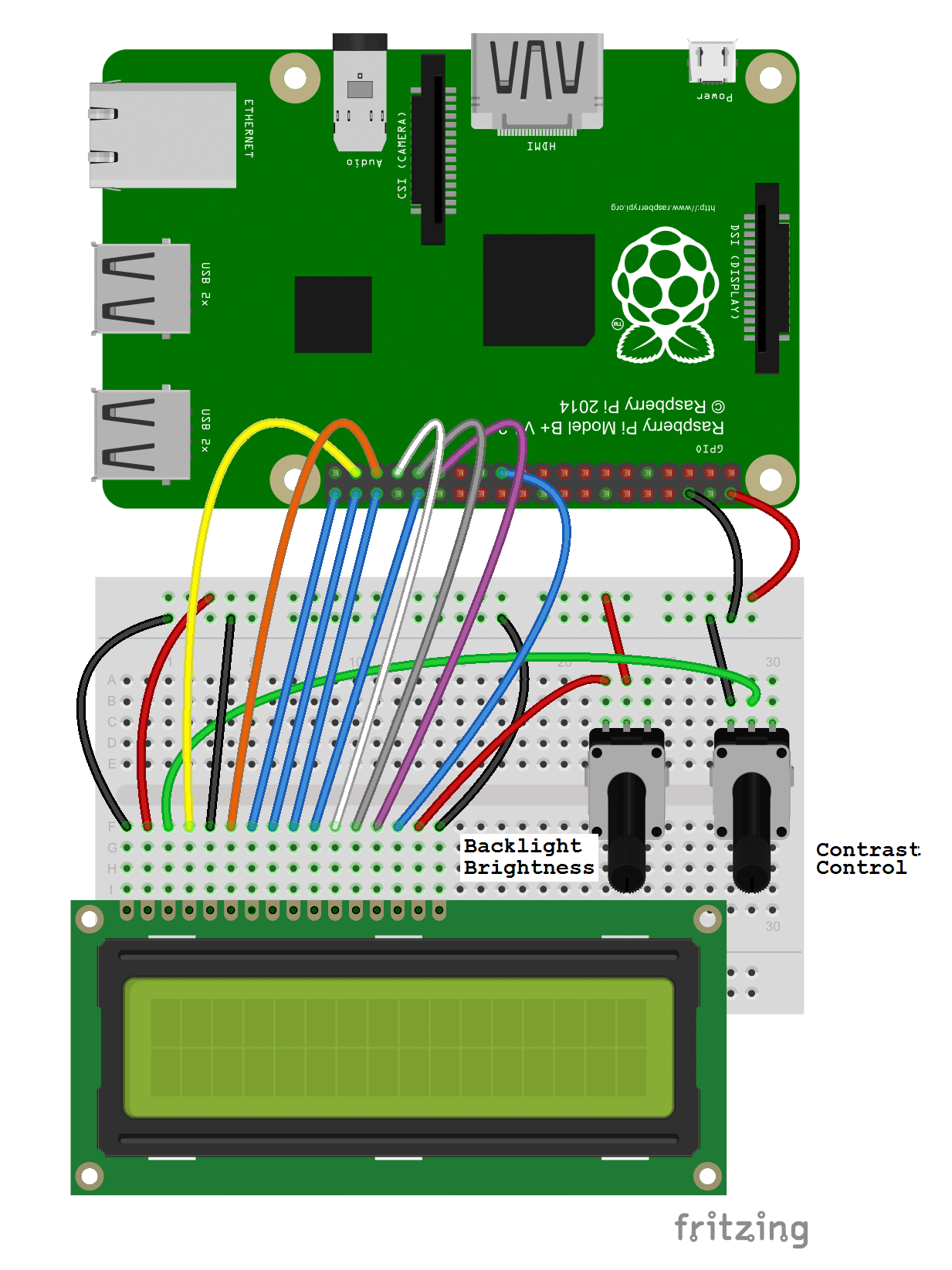

In this tutorial, I’ll show you two different ways to connect an LCD to the Raspberry Pi with the GPIO pins. The first way I’ll show you is in 8 bit mode, which uses 10 GPIO pins. Then I’ll show you how to connect it in 4 bit mode, and that uses only 6 pins. After we get the LCD hooked up I’ll show you how to program it with C, using Gordon Henderson’s WiringPi LCD library.

I’ll show you how to print text to the display, clear the screen, position the text, and control the cursor. You’ll also see how to scroll text, create custom characters, print data from a sensor, and print the date, time and IP address of your Pi.

There’s another way to connect your LCD that uses only two wires, called I2C. To see how to do that, check out our tutorial How to Set Up an I2C LCD on the Raspberry Pi.

Most people probably want to connect their LCD in 4 bit mode since it uses less wires. But in case you’re interested, I’ll show you how to connect it in 8 bit mode as well.

In 8 bit mode, each command or character is sent to the LCD as a single byte (8 bits) of data. The byte travels in parallel over 8 data wires, with each bit travelling through it’s own wire. 8 bit mode has twice the bandwidth as 4 bit mode, which in theory translates to higher data transfer speed. The main downside to 8 bit mode is that it uses up a lot of GPIO pins.

In 4 bit mode, each byte of data is sent to the LCD in two sets of 4 bits, one after the other, in what are known as the upper bits and lower bits. Although 8 bit mode transfers data about twice as fast as 4 bit mode, it takes a longer time for the LCD driver to process each byte than it takes to transmit the byte. So in reality, there isn’t really a noticeable difference in speed between 4 bit mode and 8 bit mode.

If you’ve never worked with C programs on the Raspberry Pi, you may want to read our article How to Write and Run a C Program on the Raspberry Pi first. It will explain how to write, compile, and run C programs.

WiringPi is a C module that makes it easy to program the LCD. If you already have WiringPi installed on your Pi, you can skip this section. If not, follow the steps below to install it:

WiringPi has it’s own pin numbering system that’s different from the Broadcom (BCM) and RPi physical (BOARD) pin numbering systems. All of the programs below use the WiringPi pin numbers.

To use different pins to connect the LCD, change the pin numbers defined in lines 5 to 14. You’ll need to convert the WiringPi pin numbers to the physical pin numbers of the Raspberry Pi. See here for a diagram you can use to convert between the different numbering systems.

To use the LCD in 4 bit mode, we need to set the bit mode number to 4 in the initialization function (line 20 below). The following code prints “Hello, world!” to the screen in 4 bit mode:

By default, text is printed to the screen at the top row, second column. To change the position, use lcdPosition(lcd, COLUMN, ROW). On a 16×2 LCD, the rows are numbered from 0 to 1, and the columns are numbered from 0 to 15.

The function lcdClear(lcd) clears the screen and sets the cursor position at the top row, first column. This program prints “This is how you” for two seconds, clears the screen, then prints “clear the screen” for another two seconds:

Each LCD character is a 5×8 array of pixels. You can create any pattern you want and display it on the LCD as a custom character. Up to 8 custom characters can be stored in the LCD memory at a time. This website has a nice visual way to generate the bit array used to define custom characters.

To print a single custom character, first define the character. For an example of this see lines 12 to 19 below. Then use the function lcdCharDef(lcd, 2, omega) to store the character in the LCD’s memory. The number 2 in this example is one of the 8 locations in the LCD’s character memory. The 8 locations are numbered 0-7. Then, print the character to the display with lcdPutchar(lcd, 2), where the number 2 is the character stored in memory location 2.

Here’s an example of using multiple custom characters that prints the Greek letters omega, pi, and mu, plus thermometer and water drop symbols for temperature and humidity:

As an example to show you how to display readings from a sensor, this program prints temperature and humidity readings to the LCD using a DHT11 temperature and humidity sensor. To see how to set up the DHT11 on the Raspberry Pi, see our article How to Set Up the DHT11 Humidity Sensor on the Raspberry Pi.

Hopefully this helped you get your LCD up and running on your Raspberry Pi. The programs above are just basic examples, so try combining them to create interesting effects and animations.

If you have any problems or questions about installing the LCD or programming it, just leave a comment below. And don’t forget to subscribe to get an email when we publish new articles. Talk to you next time!

That’s right! In today’s tutorial I show you how to wire up and program your very own mini LCD display to your Raspberry Pi! By the end the of this video you will be printing your own messages to your very own screen module and will understand all of the Python code behind it. A good, cheap and enjoyable little project for Raspberry Pi – with plenty of scope for your own further developments!

My question is: Is that safe to use 3.3V line to power that display? I guess GPIO pins are OK with that solution, but won"t it damage 3.3V line of Raspberry ?

This guide is for OLED I2C display that is designed to work on 3.3V, but my I2C display is designed to work with 5V. I don"t want to use 5V because lots of people says its not safe, as 5V display is returning that voltage to signal pins of Raspberry"s GPIO that shouldn"t be treated with 5V.

Most of people says that to use 5V display I should use logic level converter that will trim returning voltage to 3.3V. But as I discovered my display works with 3.3V there is nothing to trim. However using 3.3V line is confusing as I don"t know if now 3.3V line is not in danger.

I"m trying to use some Python code to write text on a 16x2 LCD display ("compatible" with classics Hitachi HD44780) connected to a RaspberryPi model B+ via an I2C "back-pack".

The problem is that running multiple times this sample code, in sequence, one time it goes OK and the next time the LCD displays random characters; then again, one OK, one wrong.

This is my 3rd tutorial on using LCD displays with the Raspberry Pi. I recommend you check out the first tutorial because this one builds on the former. The video demonstrates how to use I²C (pronounced I squared C) to control LCD Displays with PCF8574 and MCP23008 chips in Python:

The PCF8574 wiring is very straight forward. A0 – A2 are used to specify an I²C address. Each I²C device requires a unique address. Grounding all 3 pins equates to hex address 20. P0 – P7 are basically 8 additional GPIO pins that you can control from the Pi. In this demo, 6 of these pins are used to control the LCD display in 4 bit mode. You can use any 6 pins in any order to control RS, Enable and the 4 data lines. SDA and SCL are the serial data and serial clock lines. The wiring in the video may be a bit confusing so just to be clear: SCL and SDA on the PCF8574 are connected to GPIO2 and GPIO3 on the Pi respectively. VCC on the PCF8574 is connected to one of the Pi’s 3.3 V pins and the chip’s ground is connected to one of the Pi’s grounds. I redrew the wiring to make the pinout easier to read:

The latest version of Raspbian now makes it much easier to set up I²C. The only software requirements is to enable the I²C interface. From the Pi’s menu click Preferences – Raspberry Pi Configuration . Click the Interfaces tab and enable the I²C interface:

You can use the i2cdetect utility to check if everything is hooked up correctly. The last parameter 1 may need to be changed to 0 on earlier revision Pi’s. The chart below shows one I²C device connected at hex address 20:

It’s no longer necessary to create a PCF8574 class, because Adafruit has added a PCF8574 class to their python GPIO library which is automatically installed when you install the above CharLCD library.

Unlike the video, the code imports the Adafruit GPIO PCF8574 class which is passed the hex address 20 when instantiated. All you have to do is pass this GPIO as the optional GPIO parameter when you declare the Adafruit_CharLCD object. Then you can use the LCD display as if it were directly connected to the Pi’s GPIO.

The great thing about I²C is that you can daisy chain multiple devices while only using 2 Pi GPIO pins. Just extend SDA and SCL to the additional devices and provide power and ground. Each device must have a unique I²C address. In the wiring diagram below, I add a 2nd PCF8574 and change A0 to high which changes the hex address from 20 to 21.

Here is sample code to control 2 LCD displays. A 2nd GPIO2 is declared for the device at hex address 21. A 2nd LCD is declared with GPIO2 passed for the GPIO parameter. Now 2 displays can controlled from Python:

The MCP23008 is another I²C expander chip that is commonly used to control LCD displays. The wiring is similar to the PCF8574. You just need to make sure that the Reset pin is pulled high by connecting it to 3.3 V. Please note that the schematic in the video had an error. Here is the corrected version:

The Adafruit Char_LCD library has built-in support for the MCP23008 so the Python code is even easier. Import the Adafruit_MCP230xx class and use it to declare a GPIO. The rest of the code remains the same as for the PCF8574.

In our opinion, the only thing the Raspberry Pi 3, Pi 3, and Pi 2 are truly lacking is an I2C port. (Of course you may have guessed by looking at our product offerings that we are admittedly a little biased. No worries.)

The I2C port points outward toward the outside edge of the board, and may interfere with some enclosures without modifications. The OUTPI2 does not consume the 40-pin expansion port, as it is equipped with a pass-through connector, freeing the 40-pin connector for other purposes, making it a truly non-invasive design.

Chain expansion devices using nodeLynk. Connect a wide variety of accessories to expand the capabilities of a nodeLynk compatible controller. Use nodeLynk to add Relay Controllers, Sensors, PWM Drivers, Displays, and a wide variety of 4-20mA, 0-10V ADCs and DACs, as well as a wide array of TTL & Isolated GPIO devices. All nodeLynk devices use I2C communications to chain devices together. nodeLynk is an easy way to expand functionality without soldering. nodeLynk allows expansion in seconds so you can focus on your software and firmware development.

ERM4004FS-1 is 40 characters wide,4 rows character lcd module,SPLC780C controller (Industry-standard HD44780 compatible controller),6800 4/8-bit parallel interface,single led backlight with white color included can be dimmed easily with a resistor or PWM,fstn-lcd positive,black text on the white color,high contrast,wide operating temperature range,wide view angle,rohs compliant,built in character set supports English/Japanese text, see the SPLC780C datasheet for the full character set.Optional 3.3v or 5v power supply and optional pin header connection.

It"s easily controlled by MCU such as 8051,PIC,AVR,ARDUINO,ARM and Raspberry Pi.It can be used in any embedded systems,industrial device,security,medical and hand-held equipment.

The Internet is full of real time data. Weather information, stock quotes, etc, can be obtained from different service providers. Since most of the Raspberry Pi computers come with Wifi, and it’s extremely easy to handle the data obtained from the Internet with Python, it makes sense to use Raspberry Pi to fetch data from the Internet automatically.

On the other hand, every Raspberry Pi comes with GPIOs, which can be used to connect different devices. For example, we can connect a 16 x 2 character LCD display to the Raspberry Pi.

A communication interface called I2C is frequently used by many devices. Any I2C device uses 4 pins: one for power, one for the ground, one for data (“SDA”) and one for clock signals (“SCL”). For instance, this character LCD display can be connected to Raspberry Pi or other microcontroller via I2C.

This all sounds complicated. Fortunately, Adafruit has created the CircuitPython library for the Raspberry Pi. With this library, we can use I2C devices on Raspberry Pi very easily.

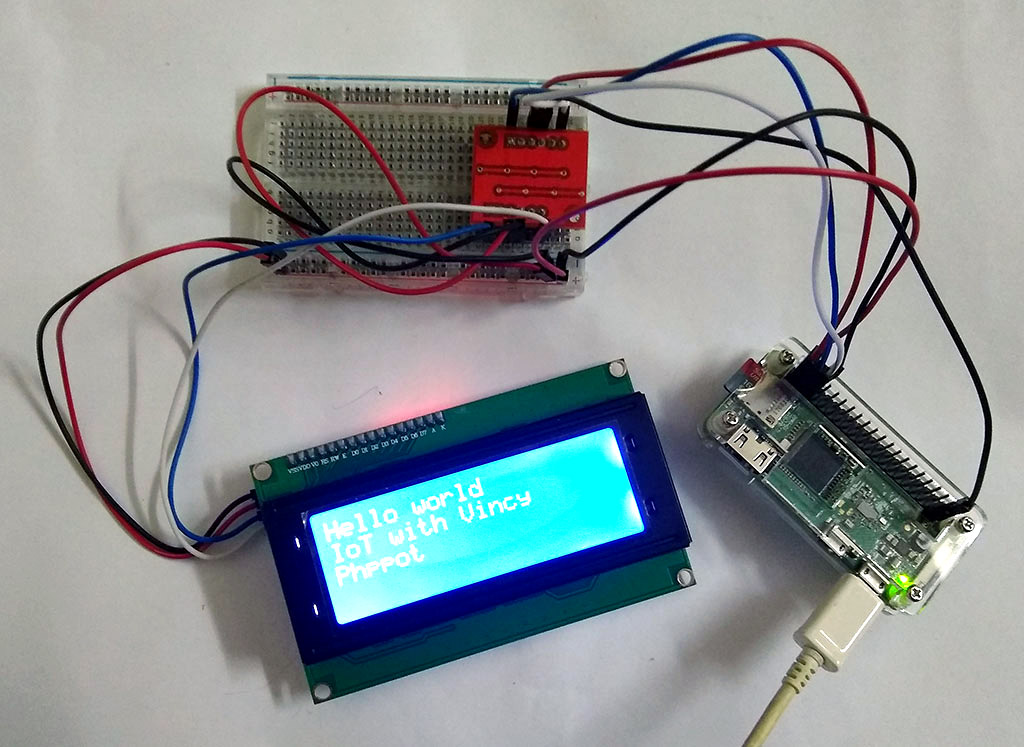

To achieve the above learning outcomes, we will use a Raspberry Pi Zero W to fetch some weather data from the Internet, and display the fetched data on a character LCD screen:

We usually use a browser to look for information on the Internet. We type a URL in the browser, and the browser will display an HTML page. However, if you look at the source of a HTML page, you will see that HTML is actually kind of messy.

For example, the Hong Kong Observatory provides a set of Open Data API so it’s actually really easy to get the latest weather update from the Observatory. To get the latest local weather forcast, all you need to do is to enter this URL in the browser:

NOTE: You may see the term ‘RESTful APIs’ from time to time. Many of these data services are indeed RESTful APIs, which means you can interact with these services with standard HTTP methods (GET, POST, etc.). Since we only need to get this time, we won’t go into the details of RESTful APIs.

Next, we are going to install two Python libraries: Adafruit’s CircuitPython and the library for the LCD1602 display. Let’s create a new folder on the Raspberry Pi for this project inside the terminal.

Then, make sure that the Raspberry Pi Zero W is on the Internet. We will download the libraries from the Internet and install them. If everything is ready, use pip3 to install RPI.GPIO and adafruit-blinka:

NOTE: We only need cd_api.py and circuitpython_i2c_lcd.py only, so it’s better to just copy the python scripts and not to install the entire library.

Both board and busio are from the CircuitPython library. As you will see in a minute, you don’t need to worry about typing the wrong pin numbers when you initialize an I2C device if you use the CircuitPython library. Also, we import the I2cLcd class and the sleep function.

This is where the CircuitPython really shines: the exact same code can be used in other microcontrollers running CircuitPython! So if you get yourself a Circuit Playground Bluefruit, you can use the character LCD display with the exact same code.

DEFAULT_I2C_ADDR = 0x27 defines the address of character LCD display. Every I2C device has an address. This address is important because multiple I2C devices can be connected to the Raspberry Pi, and the Raspberry Pi needs that address to communicate with the device correctly. Finally, we create an instance of I2cLcd with the i2c object, the I2C address, the number of rows and the number of columns as the parameters for the constructor. The backlight is turned on by calling the backlight_on method.

NOTE: This particular LCD1602 display’s address is 0x27, but yours may have a different one. You may need to call busio.I2C.scan() to check the actual address, as described in this Adafruit guide.

Next, rather than printing out all the JSON data in the console, we extract the information that we want and display it on the LCD display. For example, we can just display the temperatures in different regions. Replace print(data) with the following lines of code:

For each entry in the temp_data array, we first clear the display by calling clear(). Then, we move the cursor to (0, 0), i.e. the first position in the first row, and display the first 16 characters of the ‘place’ entry (a string) in the first row. Similarly, we move the cursor to (0, 1), i.e. the first position in the second row, and display the ‘value’ entry (a number). Finally, we pause the program for 2 seconds before showing the next entry.

You can get other data like real time stock quotes in the same way, and create things that are more exciting, such as stock market analysis with AI. Also, you can use other methods in the requests library to interact with other RESTful APIs. For instance, you can POST the data from a sensor attached to a Raspberry Pi to a Google Sheets spreadsheet via Google’s APIs. The possibility of this paradigm is only limited by our imagination.

Everyone love the 1602 character LCD, is cheap and works out of box! But the need for 6 to 10 GPIOs is the pain :) It takes most of GPIO of Arduino and other microcontroller. Now with this I2C or Two wires interface LCD, you will save a lot of GPIO for your sensor and motor control.

LCD shield after connected with a certain quantity of sensors or SD card. However, with this I2C interface LCD module, you will be able to realize data display via only 2 wires. If you already has I2C devices in your project, you can still program this LCD with the correct I2C address. It is fantastic for Arduino based project.

In this article discuss about the interfacing of a 16x2 Liquid Crystal Display with Arduino Uno. And then read the analog value using the inbuilt ADC of Arduino Uno. Here I am going to connect the LCD in parallel way. We can also interface this LCD with only just 4 wires. (I2C communication is used there). Stay tuned for that article. This article help you to interface LCD with Arduino and make your project to fight against Covid -19This article is mainly for beginners.The code explained line by line.

Why it is called 16x2 ? Because you can write 16 characters or numbers in column wise and 2 in row wise. This display have total of 16 pins. Here I only use 12 pins. Here we use the pins except D0, D1, D2, D3. Because here I interface the LCD in 4 bit mode.

It represent the Read Write pin. When this pin is LOW, the MCU write to register. And when the pin is HIGH, MCU read from the register. Here we want to write. It connect it permanently to GND.

Next initialize the library with the number of the interface pins. With the function "LiquidCrystal lcd()". The function has six attributes. These are the interface pins in the order of "RS, E, D4, D5, D6, D7". Here we use pins 12, 11, 5, 4, 3, 2. corresponding to above.LiquidCrystal lcd(12, 11, 5, 4, 3, 2);

Now can call this display by "lcd". Next program the setup part. We need to set the number of columns and number of rows. Here I am using the LCD with 16 column and 2 rows. Set the number of columns and rows by the function "lcd.begin(16, 2)". If you have a display with 16 columns and 4 rows this become "lcd.begin(16, 4)". And set the A0 pin as input.lcd.begin(16,2);

We need a starting point to start printing. So set the cursor to that particular point by the function "lcd.setCursor()". This function have only two attribute. It is that starting points.(The number of column and number of row). Here I am staring from first column first row. The first column is represented as 0, second is 1, and so on and the first raw is represented as 0, second is 1. So we need to start from the position (0, 0). You can easily understand if you know about matrix. The piece of code become,lcd.setCursor(0,0);

Next is the core part of this article. The instruction to print. I am going to print "Hello Hackster" by the instruction "lcd.print()". Alternatively you can print any thing. Please don, t forgot the double quote marks.lcd.print("Hello Hackster");

In the above printing statement we use total of 14 characters. So the current position of cursor is at (14, 0). Next I am going to print on the next line, ie the position (0, 1). Set the cursor to that point by the function "lcd.setCursor()".lcd.setCursor(0,1);

Now the cursor is at the position of second row and first column(0, 1). Then print another text "Value" by the function lcd.print().lcd.print("Value : ");

Here we use 8 characters in second line. So the current position of cursor is (8, 1). Next we need to read the analog value from the pin A0. For more about analog value conversion please see my previous article here. And print it to the display. I use the function "analogRead()" function to read the analog value and use the "lcd.print()" function to print the value to the display. And there is no need of double qunotes.lcd.print(analogRead(A0));

Next I add some delay. Otherwise the text will blinks continusoly. That because of the first instruction "lcd.clear()". Every time when see this command the Arduino will clear the display, This results the blinking of display. But use of delay will decrease this blinking.delay(500);

Connect the LCD to the Arduino Uno. You can use a breadboard or just use the jumber wires. For permanent connection use a LCD shield for Arduino Uno.The connection diagram is given in the Schematics part. Please careful about the backlight LED connection. Over voltage will kill that LED.Please don"t copy-paste my code. Try to understand the code line by line and create your own sketch.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey