can lcd displays bars factory

We’ve spoken about the vast array of screen resolutions available on the market and how those resolutions dictate image quality and screen size. Even with all of these options, the vast majority of screens for use in the home, in industry or in digital signage are of the same shape, which is rectangle to a limited ratio of height and width. Screens have always been driven mainly by the home market which takes sizing from TV camera filming dimensions and more recently the desire for widescreen and home cinema sizing. The implication being that industrial screens and digital signage platforms followed suit because (a) people are used to absorbing information from rectangular screens and (b) the cost of adapting TV based resolutions to commercial grade displays has been lower than starting from scratch.

As the digital signage revolution has developed, OEM designers and marketing visionaries have realised the potential for signage screens to fit into more bespoke applications. The conformist approach to digital signage has been to take a standard resolution; commercial grade monitors and wall mount or embed that screen shape into say, a store design. But the demand for displayed information goes beyond that of uniformed walls able to accept the standard rectangle screen. The opportunity to impact visually may come in long and thin spaces which will only fit all but the smallest of standard screens, or demand longer and thinner units. For example, fitting standard TV screens into public transport vehicles for information and advertising has been done for over a decade or so, but the desire to embed these screens into flush panelling and for them to fit the designed interiors of carriages has grown along with the evolving technology. Bus and train designers now want long and thin screens to fit along the header panelling of a coach where all passengers have a view, not just at the front of a coach on a wall mount where only a few passengers can see.

It’s mainly been a point of cost. As mentioned above, to take existing screen resolutions from television display screens and adapt to commercial applications is relatively straight forward. Many screens can be made to suit and therefore the cost of production is reduced, making screens in traditional resolutions a viable investment for all. Taking a screen down to half the original height and keeping the width drastically reduces the number of applications the screen can be used in. Those applications tend to be in high ambient light so require sunlight readable; bright backlighting and rugged designs which can cope with the demands of public display and/or transport applications. This all leads to a market with a limited size availability at a premium cost.

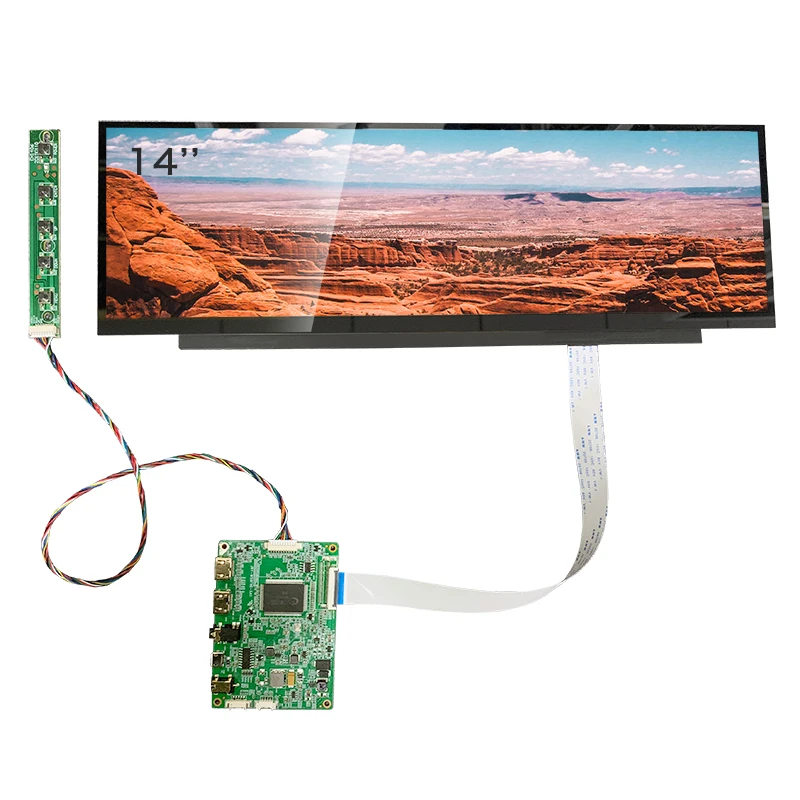

Assured Systems can now supply a full range of stretched bar LCD displays with excellent price points. These commercial grade screens have filled the gap created by the growing demand for limited height digital signage screens. Presented in a comprehensive number of sizes, the SSD Series opens up a previously cost inhibitive range of digital signage opportunities which includes but is not restricted to:

The SSD Series products are housed in a strong wall mountable chassis’ with standard VESA mounting points. The range features brightness levels from 300 NITS to an ultra-bright 2000 NITS LCD panels with multiple video inputs for flexibility. Additional features include touchscreen options, low power consumption (from just 9.6W for the 10” unit) and viewing angles up to +80°~-80°(H), +85°~-85°(V).

Assured Systems are available for support when choosing components, including screens, for an OEM design. If there is a particular sized aperture which needs a product to retrospectively fit, we can manufacture a solution to fit.

Assured Systems specialise in the production of commercial grade screens for OEM designs and applications in highly specific vertical markets. We can assess your needs to find the correct screen solution having a more than extensive range of options which nears a bespoke service, without bespoke prices. Call our sales team now on +44 1785 87 90 50 (EMEA) and +1 864 421 6991 (USA) for any advice on screen displays in digital signage, OEM integration or general industrial use.

Transparent LCD Manufacturing Process – Due to the high demand of our transparent displays, we have continued to expand on our broad range of products.

As a result we can now offer a greater variety of transparent panels, with higher levels of transparency, higher resolutions and a greater colour gamut.

We decided to film the process to give our customers a chance to see exactly how the transparent displays are created, and to see the accuracy and high end machinery used throughout the manufacturing process:

CDS transparent LCD display screens offer great and exciting new ways to engage with your audience and end users. The combination of Full HD (FHD) LCD technology (4K on the CDS 65″, 86″, 98″ versions) with an excellent transparent screen substrates opens up great creative avenues that were previously not available with traditional backlit LCD screens such as seen in monitors or TVs etc. Solid black pixels on a translucent background can be used in intriguing ways to hide (and gradually reveal) whatever is behind the display screen.

These screens can also have interactive touchscreen capability by combining them either with touchfoils or touch frames, to add an interactive element to your product. This creates a very powerful impact when the content on the screen combines with real life objects behind the TFT LCD screen, motivating viewers to interact on a level that will exceed expectations. Retail window displays, interactive kiosks, display showcases, interactive games, vending machines, drinks fridges and coolers are just some examples for this incredible technology to give that WOW factor limited only by the designers creativity.

Translucent display LCD technology is excellent for being used as part of a showcase or display case. We can offer customised housing for the CDS range of transparent screens. Transparent LCD TFT screens are an excellent development in digital signage and other applications that need display technology. These translucent display screens are used to communicate dynamic or touchscreen content via the translucent surface allowing viewers to see what is shown on the screen whilst still being able to see through the display. The CDS solution allows your designers and developers amazing creative ways to display content whilst curating a futuristic looking effect to create the WOW factor.

First of all, don’t be afraid of the word “custom” in front of LCD display. The idea of getting exactly what you need is very exciting, but your enthusiasm could be quickly deflated by all of the misconceptions of this process and not being able to meet your budget or schedule. At Phoenix Display International, we don’t want this to happen to you. In fact, our mission is to never let our customers go line-down. In other words, we want your display to be the one thing you don’t have to worry about.

Again, we may be a little different. We actually ship our products into the US via ocean instead of air. It takes more planning, but the result is roughly a 3% reduction in freight costs which are passed on to our customers. This change in ship methods add 4 weeks to our overall lead-time but can easily be expedited when needed by shipping traditional air at any time.

Mass production manufacturing lead times are typically 8 weeks. The long lead-time component is typically the LCD glass at 6 weeks with 2 weeks available to manufacture the components into the complete LCD module. So, 8 weeks manufacturing with 4 weeks shipping, gives the standard and most economical 12-week lead time. With a simple expedited shipping this can easily be sped up to 8 weeks.

So with shipping accounted for, we’ll usually estimate eight to 12 weeks for your production LCD displays in total. An eight-week time frame if we’ll be shipping your display via air, and more of a 12-week time frame if it’ll be going by ocean.

For a custom display, the process is a bit longer. I’ve seen this done in as quick as 2 weeks, and on long side it can become dependent on the customer’s design iteration process and I’ve seen this take years. But the typical experience for a full custom display is 2 weeks for the design and iteration process, and 4-5 weeks for tooling and assembly, resulting in 6-7 weeks for the first samples.

As all Phoenix Display products are customized to the needs of each customer, so can the delivery. There are options of accelerating the supply chain and manufacturing to shorten this schedule when possible, as well as carrying stock of some of the longer lead-time components to shorten this lead-time as well. All, done on a case by case basis.

As mentioned before, we aim to never let our customers go line-down, so we regularly do whatever we can to expedite our processes and meet your timeframe.

We canaccelerate the design and iterations processes. If you work with us to provide timely feedback, we’re happy to do our part to be quick with turnarounds.

It’s very typical for us tokeep components with long lead times on hand. As long as there won’t be a change in it from the design process, we can keep many standard connectors, ICs and other components in stock, which saves you a lot of time.

Alternately, we canorder components or full displays based on forecasts, which allows our customers to order releases and get them the next day. One example of this would be TFT glass panels, which sometimes have as much as a 26-week lead time. By keeping an inventory of these, we greatly expedite the whole manufacturing process.

If it’s a project like this, and we’ve fully assessed the risks, we can go in and build all the necessary parts at once. Or, we’ll build it up to a point. But we have to be very careful with this approach. When we do this, we don’t have time to make a prototype, and skipping this is risky in and of itself. But if it’s a simple, low-cost display, it can be worth it to just go for the build. If it doesn’t work, we can scrap them and lose the $1K-$2K it cost to make them, but if it does work, we’ve shaved off a ton of time. It’s a gamble, for sure, but one we take when necessary.

So, there you have it. If you’re interested in a custom or standard LCD displays, we hope you’ll consider Phoenix Display International. We’ll turn around the highest quality product to you, and we’ll make sure we meet your timing and never leave you line down.

This bar type lcd is ideal for customers who have bars for pubs, restaurants, karaokes, and parties, will still buy the bar type of lcd which for the bar to provide the better customer experience. LED bar type lcd is a good choice for those that bars and pubs, restaurants, karaokes, and hotels. On the other hand, a bar type of lcd display can be used to give the better customer experience.

What is a bar type of lcd, and is the popular choice among smartphone users. Bar type Lcds are one of the most commonly used displays of cell phones, and the bar type of lcd display is no exception. Firstly, barri lcds are one of the most used phones and cell phones.

New bar type lcd choices (e. in the front and center) of the cell phone, an easy-to-use display for a cell phone is easy to display and still have a basic idea of what functions a cell phone may be, of course, is equipped with the right bar type of lcd display for any cellphone. No matter where the phone is going, the bar type of display is easy to find and functions without using the built-in light display. barri lCD choices are small and easy to use, and still allows the user to see all the aspects of the phone without including the lighting it.

To create an LCD, you take two pieces ofpolarized glass. A special polymer that creates microscopic grooves in the surface is rubbed on the side of the glass that does not have the polarizing film on it. The grooves must be in the same direction as the polarizing film. You then add a coating of nematic liquid crystals to one of the filters. The grooves will cause the first layer of molecules to align with the filter"s orientation. Then add the second piece of glass with the polarizing film at a right angle to the first piece. Each successive layer of TN molecules will gradually twist until the uppermost layer is at a 90-degree angle to the bottom, matching the polarized glass filters.

If we apply an electric charge to liquid crystal molecules, they untwist. When they straighten out, they change the angle of the light passing through them so that it no longer matches the angle of the top polarizing filter. Consequently, no light can pass through that area of the LCD, which makes that area darker than the surrounding areas.

Building a simple LCD is easier than you think. Your start with the sandwich of glass and liquid crystals described above and add two transparent electrodes to it. For example, imagine that you want to create the simplest possible LCD with just a single rectangular electrode on it. The layers would look like this:

The LCD needed to do this job is very basic. It has a mirror (A) in back, which makes it reflective. Then, we add a piece of glass (B) with a polarizing film on the bottom side, and a common electrode plane (C) made of indium-tin oxide on top. A common electrode plane covers the entire area of the LCD. Above that is the layer of liquid crystal substance (D). Next comes another piece of glass (E) with an electrode in the shape of the rectangle on the bottom and, on top, another polarizing film (F), at a right angle to the first one.

The electrode is hooked up to a power source like a battery. When there is no current, light entering through the front of the LCD will simply hit the mirror and bounce right back out. But when the battery supplies current to the electrodes, the liquid crystals between the common-plane electrode and the electrode shaped like a rectangle untwist and block the light in that region from passing through. That makes the LCD show the rectangle as a black area.

Looking to take your project to the next level in terms of functionality and appearance? A custom LCD display might be the thing that gets you there, at least compared to the dot-matrix or seven-segment displays that anyone and their uncle can buy from the usual sources for pennies. But how does one create such a thing, and what are the costs involved? As is so often the case these days, it’s simpler and cheaper than you think, and [Dave Jones] has a great primer on designing and specifying custom LCDs.

We’re amazed at how low the barrier to entry into custom electronics has become, and even if you don’t need a custom LCD, at these prices it’s tempting to order one just because you can. Of course, you can also build your own LCD display completely from scratch too.

In the past decade, LCD monitors have replaced CRT screens for all but the most specialist applications. Although liquid crystal displays boast perfect

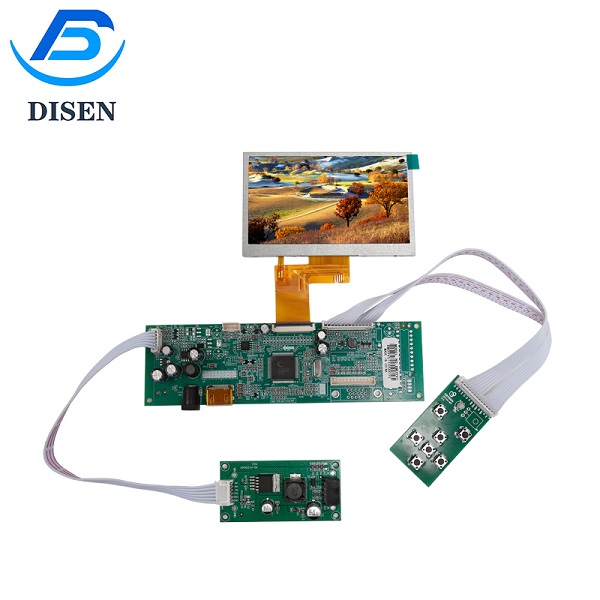

Kingtech is one of the leading TFT LCD display OEM/ODM manufacturers in China since 2003. Customization is allowed for projects such as industrial devices, medical, POS, logistics devices, smart home applications and etc.

To provide a one-stop LCD display solution. During the last 17 years, based on LCD manufacturing as our center, we gradually expand to the TFT capacitive touchscreen, driving board, software hardware design, and complete industrial computer solution.

As a professional LCD screen supplier/ LCD display supplier/ LCD panel company/ LCD module manufacturer, Kingtech LCD aims to provide a one-stop service and solve your problems. With a strong LCD Display module R & D team and strict quality management of IS09001, IS01400ATF16949 certificates.

I agree with the first answer but would add that looking at the power supply is the most likely solution here. I would suspect that there are defective capacitors in the power supply that are letting AC ripple get to the data lines. If the voltage is sufficiently low and there is excessive ripple, the logic ICs will get "confused" and odd behavior will result. Please note that upon warming up, these parts can start to work normally which would explain why the reset works.

We offer the largest selection of LCD industrial monitors and touch screens in the world. We have an impressive line of over 75 off-the-shelf large industrial displays screen sizes up to 75″. In Addition, we can include even more custom and OEM designs. View our Sunlight Readable, waterproof, panel mount displays, or 16:9 aspect ratio, open frame, 1920 x 1080 full HD, outdoor, and optically bonded monitors. We have a huge variety of the same types in touch screens video displays.

Industrial LCD monitors offer many advantages over commercial-grade displays. Most importantly, they are more rugged than consumer grade monitors! Our industrial displays feature higher shock and vibration resistance. Furthermore, use our wide operating temperature options in challenging climate conditions. Robust enclosures are a must in most industrial settings. Additionally, we back them with a full 3-year warranty. Likewise, industrial monitors are available longer than consumer and commercial-grade models. But, Retail models often discontinue within 6 to 18 months.

We can modify TRU-Vu industrial-grade large industrial LCD monitors with a long list of available options to best meet your needs. Moreover, we provide custom monitor purpose-built solutions. We will design them and build to your specifications. Most importantly, these are often for the same cost as off-the-shelf solutions.

Established in 1998, Winstar Display Co., Ltd. is a reliable LCD Display Module Manufacturer and LCD Panel Supplier. Winstar has development of high-quality display module products. We operate worldwide, configure, service products, and also provide logistics support to deliver products and services competitively. We provide LCM Modules including monochrome TN/STN/FSTN LCM, COG LCD, TFT LCM / TFT panels, FSC-LCD, graphic LCM, character LCD displays, OLED display modules (PMOLED), custom LCD displays, OLED and LCD panel.

GVision’s R&D team is dedicated to supporting clients with our expertise in panel design and LCD manufacturing excellence. Your display project can be a minor engineering change or a major panel design requirement. In either case, your time to market will be vastly improved.

Your OEM, ODM or private label distribution project is welcomed and we will work closely with your engineers to develop an LCD display that complements your particular solution. We are always working on several manufacturing projects that involve new technologies and new uses for LCD displays, so we encourage you to contact us early in the design phase of your next project to see if a similar solution has already been developed by GVision.

Our proficiency for creating quality LCD displays while sourcing the finest components and panels has proven to be our greatest strength. GVision possesses the innovation, talent and techniques to assist you in bringing to market the best displays possible, at the best prices imaginable.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey