lcd displays random characters supplier

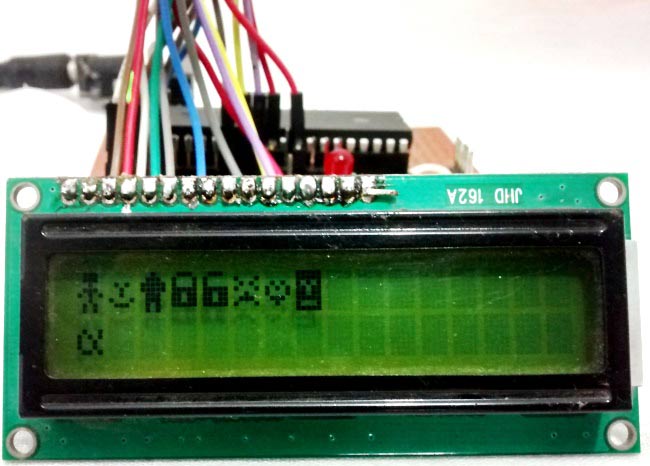

My LCD is showing random characters, see the picture below (the last character blinks, some characters change and over time there are slowly more and more characters). I"m starting to wonder if the LCD I chose has a driver compatible with the LiquidCrystal library, what do you think? If so what can I do to avoid buying another one?

ive got my code working and im able to see the output on the serial monitor but when i go to display this onto my lcd random characters show up instead of the characters.

In present scenario, we are giving supply to the LCD display with the help of 10 pin connector with 2 pins of 10 pin connector not connected and we attach power supply to the 2 wires left open.

I"m working on a project whose objective is to control two ac loads (one ac fan, controlled by phase angle control and one ac motor controlled by a 5V relay) and output to an LCD the room temperature and the % of fan speed.

First, I put the lcd.clear() function in my code to "rebuild" the info from time to time but it doesen"t work 100% and it"s not a "clean" solution for the pourpose.

Many of these LCD controllers differ slightly from the HD44780 controller in things like the initialization sequence, minimum delay between commands and maybe other ways I don"t know of.

try putting a 1n4148 diode between the 5V supply and the 5V of the LCD, so the LCD will get around 4.5V, that is enough for the LCD, and lowers its logical input levels enough so that it sees 3V3 logic highs as "1" reliably. The garbled letters, and blocks are due to the LCD sometimes seeing a "1" as a zero and that corrupts all communication between the PI and the LCD.

Its a well know problem when trying to drive an LCD with 3V3 levels, it actually needs minimally 3.5V when its powered with 5V (70 % of VCC = 0.7 x 5.0 = 3.5).

In the photos above the Pi is a Model B Rev 2 so should work fine with my tutorial. Random characters is usually a sign it has not been initialized correctly. Again this could be caused by intermittent connections.

I was having the same problem as the OP on my current build with an I2C back-packed LCD getting corrupted. I"d tried all kinds of things to fix the problems - changing the delays, trying different libraries, and pulling out hair with no joy in fixing it.

For anyone else with this problem, you may have what I have if you"re doing event-driven code e.g. from from a switch or rotary encoder. I was getting events triggered while the python code was trying to communicate with the LCD screen - which themselves tried to write to the LCD.

I also had the same problem with scrambled characters on my display. I found that there was a short between the data lines on the expander board where it is soldered to the display board. Once I cleaned up the messy solder, the display worked perfectly.

So I am ultimately trying to build a fun security system using a 4x4 number pad, arduino, and a solenoid. While trying to get the number pad and LCD to work together, I keep running into issues for reasons unknown to me. The code below is what I have so far:

After a few hours, even using the lcd module I recommended above, the random jibberish appeared again. By using RUI’s example from his “Home Automation Using 8266, Project 6, Unit 4 (which uses an ESP8266 instead of ESP32, I no longer get jibberish.

I have been struggling for days with the same issue. what did help me getting rid of the “random gibberish” is to put 10k pullup resistors to VCC on both the data and clock lines

Also create a sketch that uses the 10K pullups using the same libraries, LCD and sensor with MQTT, in other words just reading the temperature and displaying it to the LCD and then it works.

In place of lcd.clear(), use lcd.setCursor(0, row) where row is the row you want to clear, than fill it with spaces ” ” like this: lcd.print(std::string(” “, lcdColumns).c_str()). After go back to the init of the row with setCursor and write what you want.

For slow down and not have bad characters use this before print in lcd: Wire.setClock(10000), i tried only in setup() but it not worked, maybe because of rtos task in the example. you need to #include

I am getting strange characters on the LCD screen only when I supply the ESP32 from a separate PSU via the USB port. When I have it plugged into the PC, it works fine.

I read that it’s important to use two separate PSUs for the relays and the ESP, but while the relays work as expected and the code runs fine, the LCD (after a while) starts to show garbage weird characters.

In this project, a digital dice will be designed. The objective of this project is to teach that how custom characters can be displayed on an LCD. In Arduino projects using 16X2 LCD for display, the characters can be directly printed on one of the two rows using print() function of the LCD library of Arduino. However, sometimes displaying custom characters on the LCD is the demand of the project. The same feature has been illustrated in this project by designing a digital dice.

A digital dice is a digital version of the regular dice. Any dice has six faces on which numbers from 1 to 6 are printed. On throwing a dice, one of the face and so one of the numbers between 0 and 7 appears on the upright face. It can be any random number between 0 and 7. The digital dice will also display a random number between 0 and 7 on every trial. When the project will be powered on, the LCD display will show a custom built “0” character. The trial will be simulated by pressing a switch on which a random number between 0 and 7 will be displayed on the 16X2 LCD. For the next trial, the LCD could be reset to display custom built “0” character on pressing another switch. Whenever custom character “6” will be randomly generated on LCD, a buzzer will start sounding to indicate that the user has got an additional trial.

The project is built on Arduino UNO and has a 16X2 LCD, a buzzer and a 2-switch keypad interfaced to it. The project code has been written Arduino IDE and burnt to the Arduino board through USB using AVR Dude.

In the project, LCD display is controlled by the Arduino UNO. The Arduino board runs the project code to generate a random number and display it as a custom character on the LCD display. The circuit has the following sections- :

16X2 LCD – The 16X2 LCD display is connected to the Arduino board by connecting its data pins to pins 3 to 6 of the Arduino board. The RS and E pins of the LCD are connected to pins 13 and 12 of the Arduino UNO respectively. The RW pin of the LCD is grounded.

The standard open-source library for interfacing LCD with Arduino UNO is used in the project. The library works as expected and needs no changes or modifications.

The project is based on generating a random number between 0 and 7 and displaying the digit as a custom character on 16X2 LCD. The custom characters will be displayed using four character blocks of the LCD of which two character blocks will be on top row and other two character blocks will be in the bottom row adjacent to the blocks in top row. Each character block on 16X2 LCD is 5X8 pixels. The individual pixels of the character block can be switched ON or OFF by passing HIGH or LOW logic respective to those pixels to the LCD’s inbuilt controller. Any custom character can be displayed on a character block by switching individual pixels ON or OFF together. In this project four character blocks will be passed custom characters to form a single large-size character. The character blocks used for displaying a large custom character on LCD will be Column 0 Row 0, Column 1 Row 0, Column 0 Row 1 and Column 1 Row 1.

When the project is powered on, it displays custom built zero “0” on the LCD. When trial switch is pressed, a random number between 0 and 7 is generated by the program code. Corresponding to the random number generated, predefined pixel maps are assigned to the four character blocks for displaying the respective large size custom character on LCD. If that number turns out to be “6”, the buzzer is started blowing to indicate that user gets an additional trial. The user can reset the LCD display to show large size zero again by pressing the Reset button.

The project will utilize standard open-source library of Arduino for LCD interfacing. So include LCD.h and define an object of LCD class. A constant for delay of 300 milliseconds is defined and variables to represent buzzer, dice button and reset button are defined and assigned to Arduino pins. A global variable to represent random number is declared.

A setup() function is called where the baud rate for serial transmission is set 9600 bits per second. The LCD is initialized using LCD.begin() function. The pinMode() function is used to set buzzer pin as output and button pins as digital input. Then, some initial messages are flashed on LCD screen.

A loop() function is called in which first the default character 0 is displayed on the LCD. The pressing of buttons is detected by detecting LOW logic at the pins. If Dice button is pressed, a random number between 0 and 7 is generated using random() function and assigned to “num” variable. If reset button is pressed, LCD display is cleared and “num” variable is assigned value 0. If the random number is 6 then a HIGH and LOW logic is passed to the buzzer pin for a delay of 100 milliseconds.

The value of “num” variable is checked through If-else statements and for value from 0 to 6, respective custom characters are created by assigning pixel map to character blocks using LCD.CreateChar() function. The parts of the large custom character are printed to the respective blocks by placing cursor at the respective character block and printing the character using lcd.write() function.

.jpg)

If no message appears, the contrast may need to be adjusted. To do this, turn the potentiometer until "hello, world!" until you can view characters on the screen. Adjust the contrast by twisting the potentiometer. If it’s incorrectly adjusted, you won’t be able to read the text clearly. Also, check the potentiometer and make sure it"s connected correctly. If you still don"t see anything, double-check your wiring to ensure that the wires are fully connected. Also, check your solder joints to ensure that there is a sufficient connection.

If you see 16x rectangles (like “█”) or random characters on the first row, it may be due to the jumper wires being loose on the breadboard. This is normal and can happen with other LCDs wired in parallel with a microcontroller. Make sure that the wires are fully inserted into the breadboard, then try pressing the reset button and adjusting the contrast using the potentiometer. Also, make sure that the defined pins match your current setup.

Yes. However, the ESP8266 Thing Dev is 3.3V. You"d have to use two logic level converters (like the four channel bidirectional logic level converter) to convert 6x pins at a minimum if you were using a 5V basic character display. That"s a lot of wires. Make sure to avoid using pin D0, D16, Tx, and Rx. There are issues displaying characters using those pins since they are tied to other functions such as the reset or deep sleep. The pin definitions can be defined as the following.

On-screen text can be displayed as squares or other random characters. This occurs when using a non-Latin script and language, such as Arabic, when System Data Encryption (SDE) is also enabled.

This is not official manufacturer"s information. It is distilled from information on many different data sheets and from my own experience. I have never used some of these displays. I have extrapolated what I know about the displays that I have used to the ones that I have just read about. I welcome any suggestions and corrections. Contact information is at the bottom of the page.

The HD44780 type controller chip is used with a wide variety of Liquid Crystal Displays. These LCDs come in many configurations each with between 8 and 80 viewable characters arranged in 1, 2, or 4 rows.

The problem is that there is no way to inform the controller of the configuration of the display that it is driving. The controller operates exactly the same way for all displays and it is up to the programmer of the device that is controlling the LCD controller (usually a host microcontroller) to deal with this situation.

The controller contains 80 bytes of Display Data Random Access Memory which is usually referred to as DDRAM. When the controller is used with a 40 x 2 display (forty characters on each of two rows) the operation is quite straightforward and that operation will be explained first. Each of the other configurations introduces one or more quirks so it is best to understand the operation of the 40 x 2 before proceeding to the description of the operation of any of the others.

You can tell the controller where you want the first ASCII character that you send it to be stored, this is usually address 00h. After receiving that character it will automatically update its address pointer and put the next ASCII character you send into an adjacent memory location with no more addressing work on your part. You can specify whether to increment or decrement the address counter but normally it is incremented, so the next character will be put into address 01h. The LCD controller automatically accounts for the gap in addresses and after storing an ASCII code in address 27h it puts the next code in address 40h. Similarly it increments from address 67h back to 00h.

Here is a simplified diagram of the display on a 40 x 2 LCD Module. Each of the boxes in the diagram represents a location where a character can be displayed.

When the host controller wants to display a string of characters on the display all it has to do is specify a starting DDRAM address and then start sending the string of ASCII codes corresponding to the desired characters to the LCD controller, one after another. The LCD controller takes the first code that it receives, stores it at the specified address, and simultaneously displays the corresponding character on the display. It then increments it"s internal address counter and stores the next ASCII code that it receives in the next DDRAM location which causes the corresponding character to appear in the next location on the display. As mentioned before the LCD controller automatically accounts for the gap in addresses and after storing an ASCII code in address 27h it puts the next code in address 40h. Similarly it increments from address 67h back to 00h.

This display also has 80 characters, but the relationship between the DDRAM addresses and the character locations on the LCD is not quite as straightforward as the LCD with two rows of 40 characters. Here is a diagram of the device.

Here is the same memory map, rearranged this time to show how the memory addresses relate to the character positions on a 20 x 4 LCD. Note how the right half of the previous diagram is now below the left half and note the resulting sequence of starting addresses for each display row (00h, 40h, 14h, 54h).

Remember that the LCD controller still considers this to be two lines of RAM. It is important to understand that this way of picturing the DDRAM addresses helps relate the memory addresses to the character locations but does not change the fact that as far as the controller is concerned there are only two lines of memory. In other words, although this diagram shows the DDRAM differently than before, the actual DDRAM configuration and operation is exactly the same as described above for the 40 x 2 display since there is no way of telling the LCD controller that there are now 4 rows of 20 characters instead of 2 rows of 40 characters.

When a long string of ASCII codes is sent to this LCD controller the action is not quite as simple as for the 40 x 2 display. After the first row is full the characters will continue on to the third row. The normal automatic incrementing from 27h to 40h will then cause the display to continue on the second row, and from there it will continue to the fourth row. After that the following characters will appear back on the first row, and so on.

In order to get a coherent display on sequential rows it is necessary to compensate for the design of the LCD controller when programming the host microcontroller. Basically the program on the host microcontroller can keep track of the DDRAM addresses, and when appropriate it can set up a new starting DDRAM address.

For each of the above displays there are 80 addresses in memory and there are 80 character locations on the display so it should be obvious that any time you send an ASCII code to the controller the corresponding character will show up somewhere on the display. If you mess up the address the character may not show up where you expected it, but it will be visible somewhere. If you work back from where it actually appears you can usually figure out where you made your mistake. All of the displays that follow have fewer character locations on the display than memory addresses in the controller. This makes the operation somewhat more complicated and troubleshooting more difficult.

It is important to understand that, although this diagram shows only the part of the DDRAM that is normally used to display information on the 20 x 2 LCD, the actual memory map and controller operation is exactly the same as described above for the previous displays. Again that is because there is no way of telling the LCD controller that there are only 40 characters on the attached display.

Although this display has only 40 characters there are still 80 bytes of DDRAM and they are still configured the same as they were before. The greyed out addresses are the locations in DDRAM that do not have corrresponding locations on the display. Any ASCII codes that are written to those locations are not lost, and it is possible to display them by "shifting" the display window, but in normal use as described here they are simply not displayed.

When a long string of ASCII codes is sent to this LCD controller the action is not quite as simple as for either of the 80 character displays. Assume that the host controller is sending a string of characters as described above. Consider what happens after the LCD controller stores an ASCII code in address 13h and displays the corresponding character at the right end of the top row on the LCD. It then stores the next ASCII code in address 14h, which has no corresponding location on this 20x2 display. As more ASCII codes are sent to the LCD controller they are stored in the DDRAM but do not appear on the display until the LCD controller finally increments it"s address counter from 27h to 40h at which time subsequent characters start to appear on the second row of the display. As far as a viewer of the display is concerned there is a gap of 20 missing characters. The same thing will happen on the second row when ASCII codes are stored in addresses 54h - 67h.

In order to prevent any missing characters the program on the host microcontroller can keep track of the DDRAM addresses, and when appropriate it can set up a new starting DDRAM address. On the other hand the display can be shifted to display those missing characters, but the techniques to do that will not be covered here.

This is a commonly found configuration and its operation is almost identical to that of the 20 x 2. The relationship between the DDRAM addresses and the character locations on the LCD is a subset of the example shown above. Here is a drawing of the device.

Once again it is important to understand that although this diagram shows only the part of the DDRAM that is normally used to display information on the 16 x 2 LCD the actual DDRAM configuration and operation is exactly the same as described above for the 40 x 2 display. This is because there is no way of telling the LCD controller that there are only 32 characters on the attached display.

The operation of this display when a long string of characters is sent to it is that same as described for the 20 x 2 display except that there is a gap of 24 missing characters at the end of each line (instead of 20).

There are actually two different varieties of 16 x 1 LCD displays and the initialization and operation of each is different so it is important to determine which one you have.

When power is first applied to any of the multi-row LCD modules and before the controller is initialized you will see that the character locations corresponding to the first line of memory are dark and the others are light (assuming that the contrast adjustment is properly set). If you apply power to a 16 x 1 LCD module and only the left 8 character locations are dark you have what I will call a type 1 module. If only the right 8 character locations are dark this is also a type 1 module but it is upside down! If all 16 character locations are dark then it is what I will call a type 2 module. This is my own terminology used only for the purpose of keeping them differentiated while describing their operation. The type 1 modules will have only one IC on the back of the pcb while the type 2 will have 2 (I guess this tidbit gives away the source of my "type" designations). This distinction may apply to newer devices with epoxy blobs instead of ICs, but I believe that sometimes one blob may cover more than one equivalent IC function.

From this you can see that although the display has only a single row of characters, as far as the LCD controller is concerned it is using two lines of memory and it must be considered to be a 2 line device when initializing the controller.

Here is a drawing of the complete memory map. Note that this drawing is the same as the one for the 20 x 2 and 16 x 2 displays except that a different range of addresses on the right side are greyed out.

Here you can see that if the host controller sends a long string of characters without periodically adjusting the DDRAM starting address then after each 8 characters are displayed the next 32 will "disappear".

Also, to display a message of more than 8 characters on the 16 character display the host controller will have to readjust the DDRAM address after displaying the first 8 characters.

Here you can see that if the host controller sends a long string of characters after the first 16 characters are displayed the next 64 will "disappear".

At the expense of an extra IC you get some slightly easier programming since, in order to display a message of more than 8 characters on the 16 character display, the host microcontroller does not have to readjust the DDRAM address after displaying the first 8 characters.

Since only one line of memory is in use this LCD module should be configured as a 1-line device. As far as I can determine, this changes the multiplex frequency which changes the display brightness and/or contrast. Also, there are some single row LCDs that are capable of displaying a larger 5x10 font instead of the more common 5x7 font.

Here is the same memory map, rearranged this time to show how the memory addresses relate to the character positions on a 16 x 4 LCD. Note how the center of the previous diagram is now below the left part, the right part is missing, and the resulting sequence of starting addresses for each display row is different than for the 20 x 4 (00h, 40h, 10h, 50h).

Here you can see that if the host controller sends a long string of characters without periodically adjusting the DDRAM starting address then after the first row is full the characters will continue on to the third row. After the third row is full the next eight characters "disappear". The normal automatic incrementing from 27h to 40h will then cause the display to continue on the second row, and from there it will continue to the fourth row. After the fourth row is full the next eight characters will "disappear" and then it"s back to the first row.

The 40 x 4 LCD is treated essentially as two 40 x 2 devices stacked one on top of another in the same glass enclosure. Electrically it uses what amounts to two HD44780 controller chips and it therefore has two separate memory maps each with the same address range. One is used for the top two lines and the other is used for the bottom two lines. The memories are accessed individually by strobing the desired Enable pin of which there are now two. Here is a diagram of the device.

To display a really long string of characters on this display the host controller would start out just like it did for the 40 x 2 display. It would specify a starting DDRAM address (typically 00h) and then start sending the string of ASCII codes corresponding to the desired characters to the LCD controller, one after another, making sure to strobe the enable pin associated with the upper memory bank. After storing an ASCII code in address 67h the LCD controller will automatically increment to address 00h as before and at this time the host controller must stop strobing the enable pin for the upper bank and start strobing the one for the lower bank.

There are other LCD configurations available but I believe that any of them can be handled by a technique similar to one of the examples above. If you have a display that seems to be considerably different from any of these I would like to hear from you.

(2) As implied above the number of rows of characters that can be displayed on the LCD is not the same as the number of lines of memory used by its controller. Only some of the 16x1 displays use "one line" of memory, all of the other displays including most 16x1 displays, use "two lines" of memory.

This tutorial shows how to use the I2C LCD (Liquid Crystal Display) with the ESP32 using Arduino IDE. We’ll show you how to wire the display, install the library and try sample code to write text on the LCD: static text, and scroll long messages. You can also use this guide with the ESP8266.

Additionally, it comes with a built-in potentiometer you can use to adjust the contrast between the background and the characters on the LCD. On a “regular” LCD you need to add a potentiometer to the circuit to adjust the contrast.

Before displaying text on the LCD, you need to find the LCD I2C address. With the LCD properly wired to the ESP32, upload the following I2C Scanner sketch.

Displaying static text on the LCD is very simple. All you have to do is select where you want the characters to be displayed on the screen, and then send the message to the display.

The next two lines set the number of columns and rows of your LCD display. If you’re using a display with another size, you should modify those variables.

Scrolling text on the LCD is specially useful when you want to display messages longer than 16 characters. The library comes with built-in functions that allows you to scroll text. However, many people experience problems with those functions because:

In a 16×2 LCD there are 32 blocks where you can display characters. Each block is made out of 5×8 tiny pixels. You can display custom characters by defining the state of each tiny pixel. For that, you can create a byte variable to hold the state of each pixel.

In summary, in this tutorial we’ve shown you how to use an I2C LCD display with the ESP32/ESP8266 with Arduino IDE: how to display static text, scrolling text and custom characters. This tutorial also works with the Arduino board, you just need to change the pin assignment to use the Arduino I2C pins.

4. If the customer is having difficulty reading the information displayed on the LCD or its too light, try changing the contrast setting. Adjusting the contrast will give the LCD a sharper and more vivid appearance.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey