glass lcd display free sample

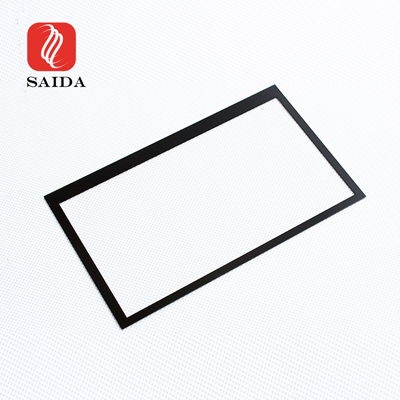

2. Processing: From cutting raw material – glass sheet into little pieces to making physical tempering treatment, the processing procedures are done in our factory. And so is the screen printing step. The production volume reaches 2k – 3k per day. For customized request, that coating anti-fingerprint, anti-reflective (AR) and anti-glare (AG) on the clear surface is workable.

3. Better performance than acrylic glass (acrylic, actually a kind of plastic panel) in yellow resistance ability. The glass frame has a shiny crystal look. Adding a panel of glass to your light switch is just like adding an elegant design to your product, to create the more popular item in market.

Be a protector for the screen and the touch panel. Different printed colors fit to electronics. There is a trend to apply this kind glass panel into the auto controller.

Sticking towards the principle of “Super High-quality, Satisfactory service” ,We’ve been striving to become a superb business partner of you for Free sample for China Hot Selling LCD Touch Control Protective Electric Top Cover Glass, We are glad that we are steadily growing with the active and long term support of our satisfied customers!

Sticking towards the principle of “Super High-quality, Satisfactory service” ,We’ve been striving to become a superb business partner of you for China Toughened Glass, Clear Glass, With its rich manufacturing experience, high-quality products and solutions, and perfect after-sale service, the company has gained good reputation and has become one of the famous enterprise specialized in manufacturing series.We sincerely hope to establish business relation with you and pursue mutual benefit.

3.We can use float glass(clear glass and ultra clear glass) material . Our processing : Cutting -Grinding edge – Cleaning – Tempering – Cleaning – Printing color-Cleaning – Packing

2.High strength: the impact strength tempered glass of the same thickness of ordinary glass 3 to 5 times more than the ordinary glass ,bending strength 3-5 times.

3.Thermal stability: Tempered glass has good thermal stability, can withstand the temperature is more than 3 times that of ordinary glass, can withstand 200 °C temperature changes.

Orient Display is a company that specializes in manufacturing LCD glass panels, glass display screen, glass panel display, glass LED display,cover lens glass and other panels with glass. The company was founded in 1996 by specializing in fields of production, R&D, quality controls. Thanks for the management and employee’s continuous hardworking and enormous effort and shareholder continuous investment over years,Orient Display factory is now the world’s lead display glass panel manufacturer in flat panel industry and is listed as a public company in China stock market. Orient Display factory has 4 plants that can produce lcd glass panels. Factories have complete quality and environment management system, ISO9001, ISO/IATF16949, ISO14001, IECQ QC080000. LCD display glass panel is a traditional product, Orient Display is always working on the ways to reduce glass panel price and cost to meet the simple display market requirement.

Orient Display LCD display panels include different options of polarizer in reflective (saving power), transmissive (better contrast) or transflective (sunlight readable and battery powered) types. Orient LCD glass panels include 1; 2; 2.1/2; 3; 3.1/2; 3.3/4; 4; 4.1/2; 5; 6; 8; and 24 digits. Orient LCD glass panels also include 7 , 14 or 16 segments to display digits and alphanumeric letters. The temperature ranges are from room temperature to wide temperature applications. Orient LCD glass panels can have metal pin or zebra connections. Some of them have different color backlight (blue, white, Yellow-green, pure green and amber) available.

We understand that the standard LCD display screens can’t meet the customer’s various requirements, Orient Display offers custom made LCD glass panel with low NRE (tooling cost), low MOQ, fast sample, and production lead time. Orient Display is proud to have all the display technologies related with LCD glass panel displays.

As far as I know companies only give free samples especially ones that are as expensive as the 640x480 LCD displays to electronics manufacturers. You can check out mourse.com, avnet.com, jameco.com, and digikey.com for pricing information on brand new units. On avnet.com"s page you will find a section where you can request all sorts of sampled, some are more expensive then the LCD display you are looking for, however, you will also find that you will have to have an account with them to get the samples. I hope this somewhat helpful. :lol:

Many Apple products use liquid crystal displays (LCD). LCD technology uses rows and columns of addressable points (pixels) that render text and images on the screen. Each pixel has three separate subpixels—red, green and blue—that allow an image to render in full color. Each subpixel has a corresponding transistor responsible for turning that subpixel on and off.

Depending on the display size, there can be thousands or millions of subpixels on the LCD panel. For example, the LCD panel used in the iMac (Retina 5K, 27-inch, 2019) has a display resolution of 5120 x 2880, which means there are over 14.7 million pixels. Each pixel is made up of a red, a green, and a blue subpixel, resulting in over 44 million individual picture elements on the 27-inch display. Occasionally, a transistor may not work perfectly, which results in the affected subpixel remaining off (dark) or on (bright). With the millions of subpixels on a display, it is possible to have a low number of such transistors on an LCD. In some cases a small piece of dust or other foreign material may appear to be a pixel anomaly. Apple strives to use the highest quality LCD panels in its products, however pixel anomalies can occur in a small percentage of panels.

In many cases pixel anomalies are caused by a piece of foreign material that is trapped somewhere in the display or on the front surface of the glass panel. Foreign material is typically irregular in shape and is usually most noticeable when viewed against a white background. Foreign material that is on the front surface of the glass panel can be easily removed using a lint free cloth. Foreign material that is trapped within the screen must be removed by an Apple Authorized Service Provider or Apple Retail Store.

If you are concerned about pixel anomalies on your display, take your Apple product in for closer examination at an Apple Store, Apple Authorized Service Provider, or an Independent Repair Provider. There may be a charge for the evaluation. Genuine Apple parts are also available for out-of-warranty repairs through Self Service Repair.*

Established in 2010, Topfoison has devoted itself to the manufacturing and development of high-quality products for the Wearable device, Smart Watch, VR, Medical device, Industrial LCD display including Color LCD modules/OLED/LCD display/Round lcd screen/Round AMOLED/ Square transflective lcd screen/ IPS full wide display/ 1080p fhd AMOLED and 2K 1440p lcd. Topfoison focus on1.22-7.0 inch small size displays, all the products produced in our company enjoys the most advanced production craft and technology as well as the strictly ISO quality management system.

With all the advantages and disadvantages, lcdds are essentially a good choice for those who see the TV starting from 4k smartphone. Nowadays, in addition to the wholesale models, lcdds are essentially a good option for those that don ’ t have the capacity of a device.

An import function allows additionally to use Windows fonts. With the FontEditor it is easy to generate for example Cyrillic, Greek and Arabic fonts. The preview function shows immediately the size and style in simulation window. When the testboard EA 9780-2USB is connected to the USB port, you can see the character (or any predefined text) live on the display which is plugged-in!

Closeup of couple holding controllers playing action console games on green screen tv sitting on couch and eating popcorn. young gamers spending free time gaming online on chroma key mockup display.

Accidental Damage is any damage due to an unintentional act that is not the direct result of a manufacturing defect or failure. Accidental damage is not covered under the standard warranty of the product. Such damage is often the result of a drop or an impact on the LCD screen or any other part of the product which may render the device non-functional. Such types of damage are only covered under an Accidental Damage service offering which is an optional add-on to the basic warranty of the product. Accidental Damage must not be confused with an occasional dead or stuck pixel on the LCD panel. For more information about dead or stuck pixels, see the Dell Display Pixel Guidelines.

The LCD glass on the display is manufactured to rigorous specifications and standards and will not typically crack or break on its own under normal use. In general, cracked, or broken glass is considered accidental damage and is not covered under the standard warranty.

Spots typically occur due to an external force hitting the screen causing damage to the LCD panel"s backlight assembly. While the top layer did not crack or break, the underlying area was compressed and damaged causing this effect.

If your Dell laptop LCD panel has any accidental damage but the laptop is not covered by the Accidental Damage service offering, contact Dell Technical Support for repair options.

FlexEnable’s glass-free organic LCD (OLCD) delivers high-brightness, long lifetime flexible displays that are low cost and scalable to large areas, while also being thin, lightweight and shatterproof.

OLCD is a plastic display technology with full colour and video-rate capability. It enables product companies to create striking designs and realise novel use cases by merging the display into the product design rather than accommodating it by the design.

Unlike flexible OLED displays, which are predominantly adopted in flagship smartphones and smartwatches, OLCD opens up the use of flexible displays to a wider range of mass-market applications. It has several attributes that make it better suited than flexible OLED to applications across large-area consumer electronics, smart home appliances, automotive, notebooks and tablets, and digital signage.

OLCD can be conformed and wrapped around surfaces and cut into non-rectangular shapes during the production process. Holes can be also added to fit around the functional design of the system – for example around knobs and switches.

As with glass-based LCD, the lifetime of OLCD is independent of the display brightness, because it is achieved through transmission of a separate light source (the backlight), rather than emission of its own light. For example OLCD can be made ultra-bright for viewing in daylight conditions without affecting the display lifetime – an important requirement for vehicle surface-integrated displays.

OLCD is the lowest cost flexible display technology – it is three to four times lower cost that flexible OLED today. This is because it makes use of existing display factories and supply chain and deploys a low temperature process that results in low manufacturing costs and high yield.

Unlike other flexible display approaches, OLCD is naturally scalable to large sizes. It can be made as small or as large as the manufacturing equipment used for flat panel displays allows.

The flexibility of OLCD allows an ultra-narrow bezel to be implemented by folding down the borders behind the display. This brings huge value in applications like notebooks and tablets where borderless means bigger displays for the same sized device. The bezel size allowed by OLCD is independent of the display size or resolution. In addition, OLCD can make a notebook up to 100g lighter and 0.5mm thinner.

OLCD is the key to the fabrication of ultra-high contrast dual cell displays with true pixel level dimming, offering OLED-like performance at a fraction of the cost. The extremely thin OLCD substrate brings advantages in cost, viewing angle and module thickness compared to glass displays. At the same time OLCD retains the flexibility required for applications such as surface-integrated automotive displays.

Due to its unique properties, OLCD has the potential to transform how and where displays are used in products. The videos below give a glimpse into this innovative technology.

OLCD brings the benefits of being thin, light, shatterproof and conformable, while offering the same quality and performance as traditional glass LCDs. The mechanical advantages of plastic OLCD over glass LCD are further enhanced by the technology’s excellent optical performance, much of which originates from the extreme thinness of plastic TAC substrates compared to glass.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey