lcd module 1602a qapass datasheet price

16x2 charsli thisLCD screenUsed over the parallel port. This LCD screen with all the necessary pins at the top left of the screen and this blue backlight can be easily used with Arduino and similar prototype development boards.

This is slightly difficult guide for the beginners as it involves soldering and wiring is complex. Here is detailed steps on how to for 1602A LCD display Arduino connection. In this guide we will also talk about the soldering part. The units do not cost more than 3 USD per unit but there is no in-built pins – usually male header pins supplied. We talked about different types of wires in electronics. We can use solid core wires instead of male header pins and solder. Arduino has the needed Library included :

With the above connection, again connect your Arduino with computer, the LCD will light up. Adjust the potentiometer and you’ll be able to see from blank to white all units like [] [] [] []. That [] [] [] [] is full contrast and blank is minimum contrast.

When I bought that lcd I had 0 experience, and didn"t knew that there were I2C ones, and I didn"t noticed that it was a inverted LCD that totally needs the backlight. Before I got the light working I had to shine a flashlight from the side in order to see that the lcd was actually doing something.

If the datasheet for the display is unclear (as it usually is), a good strategy would be to get an Arduino native I2C tutorial and demo, and capture correct I2C sequences, and then master the USB calls to match the I2C output. It might save you a lot of development time.

EDIT: It looks like the format of Funduino controller (from I2C to parallel 1602A display interface) is not disclosed. So the only way would be to reverse engineer the "LCD Arduino (tm) Library" from circuitattic.com, and write the USB (con)version of it.

I don"t think you have much to worry about from a regression standpoint since things that really do depend on order are all handled by callbacks except for those few instances which use the sleep method in exactly this manner. It"s only used in Expander, LCD and in the Brat example file.

In this tutorial we will see How to Interface a 16×2 character LCD module with PIC 16F877A Microcontroller using MPLAB X IDE and MPLAB XC8 C Compiler. 16×2 Character LCD is a very basic and low cost LCD module which is commonly used in electronic products and projects. 16×2 means it contains 2 rows that can display 16 characters. Its other variants such as 16×1 and 16×4 are also available in the market. In these displays, each character is displayed using 5×8 or 5×10 dot matrix.

For controlling LCD using MPLAB XC8 compiler we need to know the hardware of LCD. These LCDs commonly uses HD44780 compliant controllers. So we need to learn HD44780 Dot Matrix LCD Controller Datasheet. Don’t worry we already developed an LCD library including commonly used functions, so you can use it without any hardware knowledge of LCD.

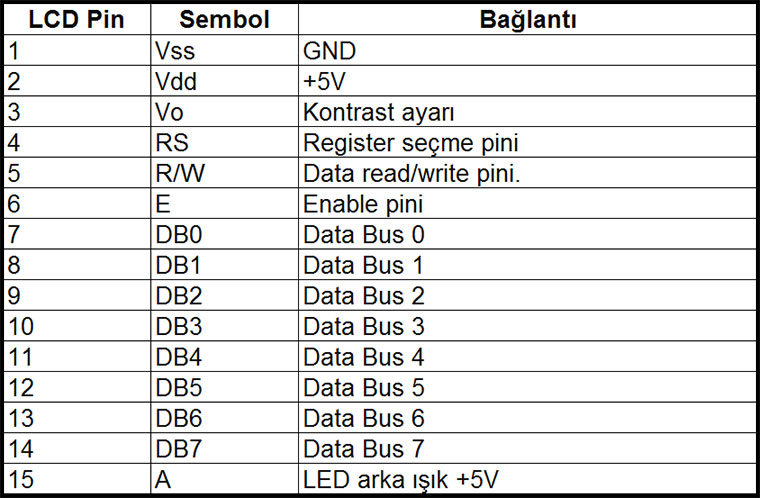

First two pins GND and VCC (VSS and VDD) are for providing power to LCD display. 3ed pin VEE is used to control the contrast of the LCD display. A 10KΩ preset whose fixed ends connected to VDD, VSS and variable end connected to VEE can be used to control contrast of the LCD. A microcontroller or microprocessor need to send 2 types of information for operating this LCD Module, Data Information and Command Information. Data Information is the ASCII value of the characters to be displayed in the LCD screen and Command Information determines other operations such as position to be displayed, clear screen, shift etc. Data and Command Information are send to LCD through same data lines (DB0 – DB7) which are multiplexed using RS (Register Select) pin of LCD. When RS is HIGH LCD treats DB0 – DB7 data pins information as Data to be displayed and when it is LOW LCD treats it as Command Information. Enable (E) input of the LCD is used to give Data Strobe. HIGH (5V) Voltage Level in the Enable (E) pin tells the LCD that DB0 – DB7 contains valid information. The input signal R/W (Read or Write) determines whether data is written to or read from the LCD. In normal cases we need only writing hence it is tied to GROUND in circuit shown below.

The interface between this LCD and Microcontroller can be 8 bit or 4 bit and the difference between them is in how the data or commands are send to LCD. In the 8 bit mode, 8 bit data and commands are send through the data lines DB0 – DB7 and data strobe is given through E input of the LCD. But 4 bit mode uses only 4 data lines. In this 8 bit data and commands are splitted into 2 parts (4 bits each) and are sent sequentially through data lines DB4 – DB7 with its own data strobe through E input. The idea of 4 bit communication is introduced to save pins of a microcontroller. You may think that 4 bit mode will be slower than 8 bit. But the speed difference is only minimal. As LCDs are slow speed devices, the tiny speed difference between these modes is not significant. Just remember that microcontroller is operating at high speed in the range of MHz and we are viewing LCD with our eyes. Due to Persistence of Vision of our eyes we will not even feel the speed difference.

Hope that you got rough idea about how this LCD Module works. Actually you need to read the datasheet of HD44780 LCD driver used in this LCD Module to write a MPLAB XC8 program for PIC. But we solved this problem by creating a header file lcd.h which includes all the commonly used functions using 4 bit mode. Just include it and enjoy.

Lcd_Set_Cursor(int row, int column) : This function is used to set row and column of the cursor on the LCD screen. By using this function we can change the position of the character or string displayed by following functions.

sprintf() can be used to write formatted string to a variable. It can be used with this LCD library to format displayed texts. This enables us to display integers and floating point numbers on the LCD very easily. You should include the header file stdio.h for using sprintf().

At the product description it said that the controller is HD44780. I followed the initializing sequence in the datasheet, but all I get is one line of white full rectangles.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey