different types of touch screen monitors factory

Touch screens are found everywhere from our smartphones to self-serve kiosks at the airport. Given their many uses, it should come as no surprise that there are several touch monitor types. Each has its advantages and disadvantages and is suited to specific tasks.

That’s right. Long before your precious smartphone entered the market in the late 00s, touch panels had already been an established technology for nearly 4 decades.

It’s quite possible that you’re not clear on exactly what a touch panel is, what the touch panel types are, or how they’re applied in your daily life, beyond that of your smartphone. For that and more, we’re here to help.

Quite simply, touch panels, which are also known as touchscreens or touch monitors, are tools that allow people to operate computers through direct touch. More specifically, via the use of internal sensors, a user’s touch is detected, then translated, into an instructional command that parlays into visible function.

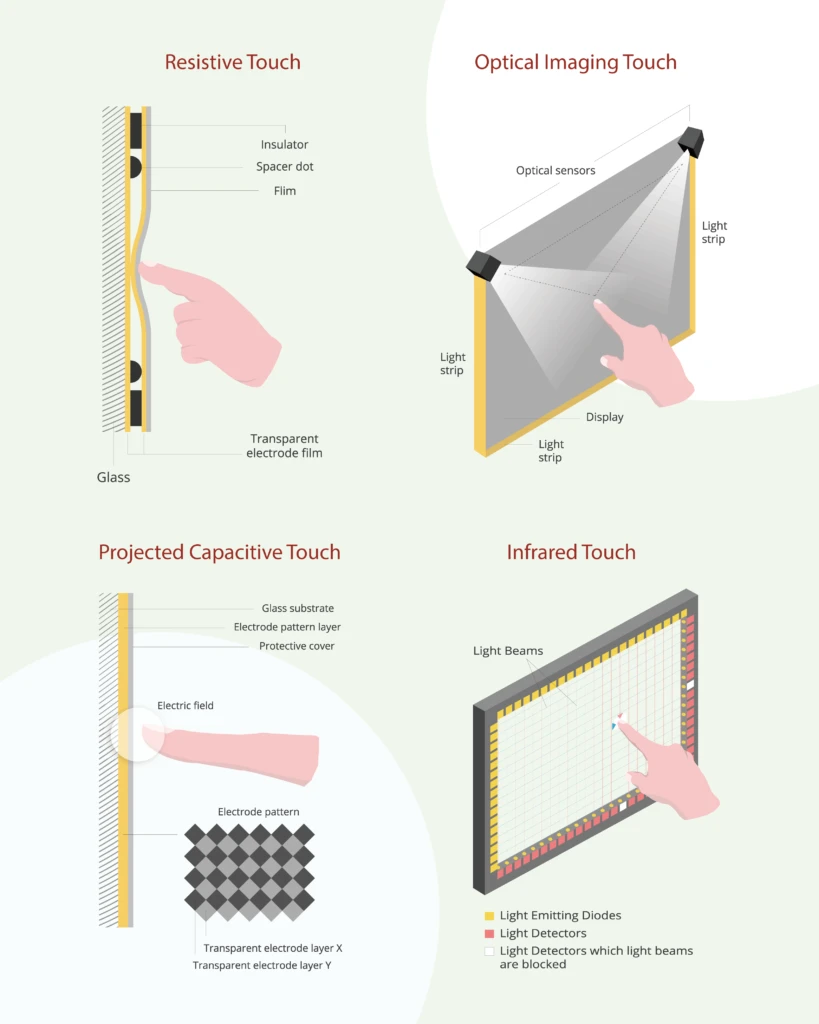

Delving deeper into the technical side of things, touch panels are not as cut-and-dry as they may seem. In fact, the way they sense and react to touch can widely differ based on their inherent designs. As such, there are 4 touch panel types in regular use – Resistive, Optical Imaging, Projected Capacitive, and Infrared. Below, we’ll dig into their specifics, which include their advantages, disadvantages, and real-life product applications.

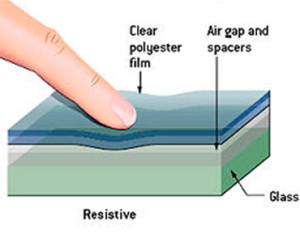

Resistive touch panels are cost-effective variants that detect commands by way of pressure placed on the screen. This pressure sensitivity is generally limited to single-point touch, with a 20-inch maximum screen, which is fine for many usage cases. These range from styluses to fingertips. As a result, if used correctly, resistive touch panels will remain functional even if a water drop has landed on the screen.

As a result of this versatility, however, many will find that resistive touch panels are less durable than their competitors. Moreover, with its reliance on single-point touch, this touch panel type is not actually capable of multi-touch functionality. Regardless, resistive touch panels are often found in grocery stores, where stylus-based signatures are typically required after credit card purchases.

Some like it hot and some don’t. Infrared touch panels definitely fall into the latter category. By setting up a grid of infrared beams across the panel, which may be up to 150-inches, touch is detected by way of this panel’s disruption.

Although infrared touch panels are durable and support multi-touch functionality, it does possess one potential drawback. Depending on where you sit, literally.

Despite infrared implying heat, infrared touch panels actually perform rather poorly in it, particularly in direct sunlight. In those circumstances, the infrared light beams can be disrupted by the sun’s rays, as opposed to your fingers. As such, be sure to place your infrared touch panel device in an appropriately dark location.

Light, and the disruption thereof, is not just a great way to produce a shadow, but also to design a touch panel type. To take advantage of this principle, optical imaging touch panels are designed to sense touch through infrared cameras and the disruption of light strips. This can be achieved through any input you want, across its 100-inch maximum size, from gloves to bare hands, and beyond.

All in all, optical imaging touch panels are just about the most versatile option the touch-based world can offer. From durability to multi-touch, and universal input prospects, the possibilities may truly be endless. Although its only disadvantage may be its non-compact design, common applications of optical imaging touch panels include certain varieties of interactive whiteboards.

If you identify with the phrase, “go with what you know”, then projected capacitive touch panels are the touch panel type for you. For now, you can guess where you know it from.

By way of their electrical-based touch detection, Projected Capacitive touch panels are known for their high precision and high-speed response times. What’s more is that they possess multi-touch functionality and can be used within small, compact, yet expensive, devices. Due to their underlying technology, it has proven challenging to scale up to larger sizes. Figured it out yet?

Assuming you haven’t, or would like to enjoy the gratified feeling associated with being right, allow us to reveal where you interact with projected capacitive touch panels on a daily basis – Smart Phones! What’s more is that they’re not alone, with tablet computers and GPS devices also utilizing projected capacitive touch screens.

It would be a mistake to assume that the applications of all these touch panel types are limited to that of consumer-level devices, or even those that have been previously mentioned. Really, these touch panel types can be found throughout everyday life and in a variety of industries.

What’s more is that in many of these industries, these touch panel types are used less to market products to consumers, and more to sell solutions to businesses. Whether it be in regards to finance, manufacturing, retail, medicine, or education, there is always a need for touch-based solutions. In conjunction with the so-called ‘Internet-of-things’, these touch-based solutions play a key role in practices related to industry 4.0.

In practice, these solutions largely offer a form of personnel management. In hospitals, stores, or banks, for instance, these touch panel types can be used to answer basic questions, provide product information, or offer directions, based on the user’s needs. When it comes to manufacturing, on the other hand, these solutions enable employee management in the possible form of workplace allocation or attendance tracking.

At the end of the day, touch panels are here to stay. In the four decades since their inception, the level of adoption this technology has experienced is remarkable. They transform how we teach in classrooms and collaborate with colleagues.

Although you may not have been clear on the specific details of each touch panel type, we hope that you are now. This knowledge will absolutely serve you well, particularly if you’re interested in ViewSonic’s selection of touch-based solutions.

You interact with a touch screen monitor constantly throughout your daily life. You will see them in cell phones, ATM’s, kiosks, ticket vending machines, manufacturing plants and more. All of these use touch panels to enable the user to interact with a computer or device without the use of a keyboard or mouse. But did you know there are several uniquely different types of Touch Screens? The five most common types of touch screen are: 5-Wire Resistive, Surface Capacitive touch, Projected Capacitive (P-Cap), SAW (Surface Acoustic Wave), and IR (Infrared).

We are often asked “How does a touch screen monitor work?” A touch screen basically replaces the functionality of a keyboard and mouse. Below is a basic description of 5 types of touch screen monitor technology. The advantages and disadvantages of type of touch screen will help you decide which type touchscreen is most appropriate for your needs:

5-Wire Resistive Touch is the most widely touch technology in use today. A resistive touch screen monitor is composed of a glass panel and a film screen, each covered with a thin metallic layer, separated by a narrow gap. When a user touches the screen, the two metallic layers make contact, resulting in electrical flow. The point of contact is detected by this change in voltage.

Surface Capacitive touch screen is the second most popular type of touch screens on the market. In a surface capacitive touch screen monitor, a transparent electrode layer is placed on top of a glass panel. This is then covered by a protective cover. When an exposed finger touches the monitor screen, it reacts to the static electrical capacity of the human body. Some of the electrical charge transfers from the screen to the user. This decrease in capacitance is detected by sensors located at the four corners of the screen, allowing the controller to determine the touch point. Surface capacitive touch screens can only be activated by the touch of human skin or a stylus holding an electrical charge.

Projected Capacitive (P-Cap) is similar to Surface Capacitive, but it offers two primary advantages. First, in addition to a bare finger, it can also be activated with surgical gloves or thin cotton gloves. Secondly, P-Cap enables multi-touch activation (simultaneous input from two or more fingers). A projected capacitive touch screen is composed of a sheet of glass with embedded transparent electrode films and an IC chip. This creates a three dimensional electrostatic field. When a finger comes into contact with the screen, the ratios of the electrical currents change and the computer is able to detect the touch points. All our P-Cap touch screens feature a Zero-Bezel enclosure.

SAW (Surface Acoustic Wave) touch screen monitors utilize a series of piezoelectric transducers and receivers. These are positioned along the sides of the monitor’s glass plate to create an invisible grid of ultrasonic waves on the surface. When the panel is touched, a portion of the wave is absorbed. This allows the receiving transducer to locate the touch point and send this data to the computer. SAW monitors can be activated by a finger, gloved hand, or soft-tip stylus. SAW monitors offer easy use and high visibility.

IR (Infrared) type touch screen monitors do not overlay the display with an additional screen or screen sandwich. Instead, infrared monitors use IR emitters and receivers to create an invisible grid of light beams across the screen. This ensures the best possible image quality. When an object interrupts the invisible infrared light beam, the sensors are able to locate the touch point. The X and Y coordinates are then sent to the controller.

We hope you found these touch screen basics useful. TRU-Vu provides industrial touch screen monitors in a wide range of sizes and configurations. This includes UL60601-1 Medical touch screens, Sunlight Readable touch screens,Open Frame touch screens, Waterproof touch screens and many custom touch screen designs. You can learn more HERE or call us at 847-259-2344. To address safety and hygiene concerns, see our article on “Touch Screen Cleaning and Disinfecting“.

A surface capacitive touchscreen uses a transparent layer of conductive film overlaid onto a glass sublayer. A protective layer is then applied to the conductive film. Voltage is applied to the electrodes on the four corners of the glass sublayer to generate a uniform electric field. When a conductor touches the screen, current flows from the electrodes to the conductor. The location of the conductor is then calculated based on the activity of the currents. Surface capacitive touchscreens are often used for large screen panels.

Projected capacitive touchscreens are extremely precise and quick to respond and are typically found on smaller devices such as iPhones, iPod touches, or iPads. Unlike the surface capacitive touchscreens, which use four electrodes and a transparent conductive film, the projected capacitive touchscreens use a vast amount of transparent electrodes arranged in a specific pattern and on two separate layers. When a conductor moves near the screen, the electrical field between the electrodes changes, and sensors can instantly identify the location on the screen. Projected capacitive touchscreens can accurately register multi-touch events.

Touchscreens are popular, innovative technology applications found in various entertainment, communications, and customer service devices. Touchscreens control devices and use interfaces without the aid of instruments like physical mouse devices and keyboards. Touchscreen interaction works by either tactile digit or stylus pointing and gesturing. While the technology was heavily developed in the past two decades, touchscreens emerged in the 1940s.

Some touchscreen interaction methods require stylus use, while others can be operated by the human hand. These methods rely on different grid controls that pinpoint cursor location based on resistive touch, heat sensors, acoustic disturbance, and electric conductance. Because of certain ergonomic concerns related to user comfort and capabilities, there are general principles for designing and implementing touchscreen technology in specific non-mobile applications.

A resistive touchscreen involves an electrical current that is disrupted by touch from both inorganic and organic instruments. There are multiple layers around this current: two metallic layers, one conductive and one resistive, which are separated by a very small space through the current flows. The metallic layers are above a pane of glass, and below a scratch-resistant layer. When an instrument such as a stylus or a finger touches the top layer, the slight pressure causes the metallic layers to connect. The computer elements of the touchscreen device can then calculate the precise location of the current disruption, allowing interface operation.

Surface acoustic wave technologies transmit ultrasonic acoustic waves across a layer of reflectors. When a finger touches the screen, the waves are disrupted, and the computer can calculate the touch location. Surface acoustic wave is generally one of the crispest image quality touchscreen technology options because it does not use metallic parts and allows 100 percent light translucency.

Capacitive touchscreens incorporate electric charges beneath a charge-storing glass panel. When a conductive instrument touches the panel, the charge is directed by chips beneath the panel that determine the touch location. The screen can detect capacitance at more than one point at once, and it can follow a light touch as it moves. Capacitive touchscreens also provide good image clarity, because of the tendency to use glass parts with them.

In addition to touchscreen type, there are ergonomic concerns for touchscreen user consideration. Because touchscreens have become standard features of mobile devices, arm strain is not typically a concern, but when applying touchscreen functionality to a mounted device, it can cause problems. Mouse and keyboard use for a typical desktop or laptop computer relies on the user’s arms being horizontal on the table, but a touchscreen requires the user to extend his or her arms and hold them aloft for longer periods. This can cause strain and exhaustion, and result in the user choosing a different device.

Additionally, touchscreens rely on various types of physical input. Because capacitive touchscreens operate via conductive touch, typically a user’s fingers, the screen can be dirtied by fingerprints. Most capacitive touchscreens have incorporated oleophobic coatings, which are chemicals that resist adherence to oils, specifically oils common on human skin. For other types of touchscreens that rely on a stylus or other inanimate tool for interaction, it is necessary to find scratch-resistant glass or coating for the upper layer of the device, to prevent dents and discoloration on the touchscreen.

Touchscreen devices are common on portable devices, such as cellular telephones, digital music devices, and handheld organizers, some of which are intended for use in rugged environments. Touchscreens rely on sensitive working properties, so an extreme environment can have adverse effects on their behavior and performance. For example, touchscreens intended for cold environments should probably not be capacitive, because a user will probably be wearing protective gloves and will not be able to properly physically contact the screen.

This article presented an understanding of the different types of touchscreens. For more information on related products, consult our other guides or visit the Thomas Supplier Discovery Platform to locate potential sources of supply or view details on specific products.

Capacitive surface touch screens work by using the electrical signal from the operator’s finger instead of force to complete the action of the interface.

The key benefits of using a capacitive touch screen is that they are temperature resistant and waterproof. Many home appliances like refrigerators and dishwashers use capacitive touch keypads.

However, while capacitive touch screens can only be used with the user’s finger, Projective Capacitive Touch Screens are the new standard for capacitive touch screens and allow for users to control the device even while wearing gloves.

While technically a type of Capacitive Touch Screen by its name, Projective Capacitive (PCAP) Touch Screens are the most common type and the ones used most on the market today.

PCAP touch screens get their name from the way they “project” a small electric field out past the top layer which senses the user’s input even before they come into contact with the screen. In a way, they function much like a proximity sensor. They have mutual capacitance which supports multi-touch activation.

Because of this, users can control the device with a stylus or while wearing thin surgical gloves, food service gloves, or cotton gloves. They also support excellent clarity with high light quality. They’re a great option for incorporating into outside equipment or machinery, as users don’t need to remove their gloves in a cold or rainy climate, and can still see the screen well in the sun.

They can be used in control panels, industrial automation, consumer devices, and commercial applications in retail, gaming, and signage. They are more costly than resistive touch screens.

Interactive touch screens have become such an integral part of everyday life that they’re almost as likely to be found in the playroom of a preschool-age child as on the factory floor or in the field. And as touch screens become increasingly integrated with consumer and industrial IoT, their demand continues to grow across every market sector.

At Pivot International, we are the global one-source partner helping companies worldwide successfully design, engineer, manufacture, distribute, and deploy the latest in consumer and industrial touch screen technologies and IoT innovations. With more than 50 years of experience, in-house DFM expertise that spans fourteen industries, and 320,000 square feet of tricontinental manufacturing capability (including domestic options), we deliver a smooth, seamless, highly collaborative approach to NPD and successful product launch.

There are five types of touch screen technologies: resistive, capacitative, near-field imaging, infrared, and ultrasound. Each is differentially suited for various consumer and industrial applications. Let’s take a look at each.

Resistive touch screens are the most common industrial touch screen technology. They are constructed of two interfacing glass sheets or specialized films that respond to direct pressure. Traditionally, the glass sheets or films used in this type of touch screen are coated with indium tin oxide (ITO), a transparent conductive material. But this material is increasingly being replaced with more advanced materials, including copper microwires, silver metal mesh, silver nanowires, and graphene.

The switch from ITO to these other materials results from the need to integrate touch functions into the LCD panel rather than manufacturing a transparent touch screen overlay. This makes for a thinner, lighter device with enhanced optical benefits. Because resistive touch screens respond to pressure, they are more reliably responsive to touch than the capacitative versions we’ll discuss below. However, resistive touch screens offer lower resolution image quality than their capacitative counterparts. They are also slower to respond to touch and can register only one pressure point at a time, therefore precluding multi-touch functionality.

Capacitive touch screens were first invented in the 1960s but didn’t appear in the consumer market until the advent of the iPhone. The strength of capacitative technology lies in its instant responsiveness and superior image quality. Capacitive touch screens function on electrical conductivity that alters the screen’s electrical field. Multi-touch functions (think “pinch-to-zoom”) are made possible by triangulating electrical alterations to calculate paired coordinates that “read” the touch location. Unlike resistive touch screens, capacitive touch screens are unresponsive to touch that does not emit an electrical charge. (Which is why it’s almost impossible to use an iPhone while wearing a glove.)

Some capacitive touch screens include a protective layer that protects the display from moisture, extreme temperature, impacts, and solvents, making it suitable for industrial and outdoor applications. For example, our teams at Pivot created a control system for dairy farms with IoT data reporting and touch screen technology that controls milk tank temperatures and wash cycles.

Like capacitative touch screens, near-field imaging touch screens read touch commands by measuring an electrostatic field. The difference is that NFI touch screens feature a corner-configured electrostatic charge, making them more responsive to touch from almost any source. (Even if you’re wearing a glove, NFI devices will instantly register and respond.) A primary advantage of NFI touch screens is that they can withstand extreme field conditions. This makes them a perfect fit for the industrial and security and defense applications that Pivot brings specialized experience in.

Infrared touch screens rely on a grid of LEDs and light-detector photocells placed at opposing positions. The LEDs beam an infrared matrix across the screen that, when “broken” by touch, provides the basis for the device to detect the input location. Infrared touch screens require dozens of components and precision manufacturing. Despite being more expensive to produce, they are often the ideal product solution for applications that include ticketing kiosks, ATMs, office automation, medtech, and even beverage dispensers like the one Pivot created with an integrated processor and customizable I/O system.

Ultrasound technology has enjoyed cross-industry applications for more than a century. But today’s surface acoustic wave touch screens are light years beyond their earlier incarnations and make it possible to make almost any surface responsive to touch. SAW touch screens work by projecting ultrasound waves across the surface of a screen. As the soundwaves are absorbed by whatever comes in contact with the surface, the screen’s controller chip can instantly identify, read, and accurately respond to commands.

Touch screen technology is the direct manipulation type of gesture-based technology. Direct manipulation is the ability to manipulate the digital world inside a screen. A Touch screen is an electronic visual display capable of detecting and locating a touch over its display area. This is generally referred to as touching the display of the device with a finger or hand. This technology most widely used in computers, user interactive machines, smartphones, tablets, etc to replace most functions of the mouse and keyboard.

Touch screen technology has been around for a number of years but advanced touch screen technology has come on in leaps and bounds recently. Companies are including this technology in more of their products. The three most common touch screen technologies include resistive, capacitive, and SAW (surface acoustic wave). Most low-end touch screen devices contain a standard printed circuit plug-in board and are used on SPI protocol. The system has two parts, namely; hardware and software. The hardware architecture consists of a stand-alone embedded system using an 8-bit microcontroller, several types of interface, and driver circuits. The system software driver is developed using an interactive C programming language.

A touch screen technology is the assembly of a touch panel as well as a display device. Generally, a touch panel is covered on an electronic visual display within a processing system. Here the display is an LCD otherwise OLED whereas the system is normally like a smartphone, tablet, or laptop. A consumer can give input through simple touch gestures by moving the screen using a special stylus otherwise fingers. In some kinds of touch screens, some normal otherwise gloves are used which are coated to work properly whereas others may simply work with the help of a special pen.

The operator uses the touch screen to respond to what is displayed and if the software of the device permits to control how it can be exhibited like zooming the screen to enhance the size of the text. So touch screen allows the operator to communicate directly through the displayed information instead of using a touchpad, mouse, etc. Touch screens are used in different devices like personal computers, game consoles, EVMs, etc Touch screens are also essential in educational institutions like classrooms in the colleges.

The first concept of a touch screen was described & published in the year 1965 by E.A. Johnson. So, the first touch screen was developed in the 1970s by CERN engineers namely Bent Stumpe 7 Frank Beck. The first touch screen device was created & used in year 1973. The first resistive touch screen was designed in 1975 by George Samuel Hurst however wasn’t launched 7 used until 1982.

Different types of touchscreen technology work in different methods. Some can detect simply one finger at a time & get very confused if you seek to push in two positions at once. Other types of screens can simply notice and differentiate above one key push at once. There are different components used in touchscreen technology which include the following.

A basic touch screen is having a touch sensor, a controller, and a software driver as three main components. The touch screen is needed to be combined with a display and a PC to make a touch screen system.

The sensor generally has an electrical current or signal going through it and touching the screen causes a change in the signal. This change is used to determine the location of the touch of the screen.

A controller will be connected between the touch sensor and PC. It takes information from the sensor and translates it for the understanding of PC. The controller determines what type of connection is needed.

It allows computers and touch screens to work together. It tells OS how to interact with the touch event information that is sent from the controller.

Swiping a finger over the screen is used to type the letters using the keyboard on the screen. It is also used to move the pages from right to left and also close unwanted apps.

The Touch screen is a 2-dimensional sensing device made of 2 sheets of material separated by spacers. There are four main touch screen technologies: Resistive, Capacitive, Surface Acoustical wave (SAW), and infrared (IR).

The resistive touch screen is composed of a flexible top layer made of polythene and a rigid bottom layer made of glass separated by insulating dots, attached to a touch screen controller. Resistive touch screen panels are more affordable but offering only 75% of the light monitor and the layer can be damaged by sharp objects. The resistive touch screen is further divided into 4-, 5-, 6-, 7-, 8- wired resistive touch screen. The construction design of all these modules is similar but there is a major distinction in each of its methods to determine the coordinates of the touch.

A capacitive touch screen panel is coated with a material that stores electrical charges. The capacitive systems can transmit up to 90% of the light from the monitor. It is divided into two categories. In Surface-capacitive technology, only one side of the insulator is coated with a conducting layer.

Whenever a human finger touches the screen, the conduction of electric charges occurs over the uncoated layer which results in the formation of a dynamic capacitor. The controller then detects the position of touch by measuring the change in capacitance at the four corners of the screen.

In projected capacitive technology, the conductive layer (Indium Tin Oxide) is etched to form a grid of multiple horizontal and vertical electrodes. It involves sensing along both the X and Y axis using clearly etched ITO pattern. For increasing the accuracy of the system, the projective screen contains a sensor at every interaction of the row and column.

An infrared touch screen technology, an array of X and Y axis is fitted with pairs of IR LEDs and photodetectors. Photodetectors will detect any image in the pattern of light emitted by the Leds whenever the user touches the screen.

The surface acoustic wave technology contains two transducers placed along the X-axis and Y-axis of the monitor’s glass plate along with some reflectors. When the screen is touched, the waves are absorbed and a touch is detected at that point. These reflectors reflect all electrical signals sent from one transducer to another. This technology provides excellent throughput and quality.

A virtual touch screen is a user interface system that enhances essential objects into reality either using an optical display or projector using sensors to follow an interaction of a person through an object. For example, a person can create a rear projector system or a display to create three-dimensional images which come into view to float within midair.

The PCAP or Projected Capacitive touch screen technology provides the accessible multi-touch experience through tablets, smartphones to operate through extremely light touch using an extremely tough glass surface. These are strong and easily set with protecting glass & the main feature of this technology is a multi-touch function for up to ten fingers by enabling signal control.

These touch screens are equipped with a network of electrodes such as Silver Nanowire, Metal Mesh & ITO which project an electromagnetic field the passes throughout a protecting glass. Once the field alters at one end because of a touching finger, the position of touch can be designed as well as forward toward the controller.

The PCAP touch screens include a mainly scratch-resistant glass surface. Using optional protecting glasses, these screens are vandal-proof & can be utilized in public areas. But, the several touchpoints may change based on the force of the protecting glass used. These types of touch screens are ideal for recent True Flat designs like smartphones otherwise tablet PCs.

Optical sensors are used to identify the touch; so this technology is very popular because of scalability & versatility. This technology mainly depends on infrared lights. Two IR imaging sensors are arranged at the summit, which doubles up like emitters as well as retro-reflective tapes on the three sides. The produced lights are replicated back toward the imaging sensors, which turn into blocked at the end of touch & generate a shadow to place the touch.

An Acoustic Pulse Recognition Touch screen is designed with a glass cover & four transducers connected to the back exterior. Once the screen is stroked, the friction will create acoustic signals. The transducers notice the audio signal, and then it is changed into a signal. These screens are durable, scalable & water-resistant.

Transparent touch screens work by using two modern technologies to make a cutting-edge display that is tough to ignore. These touch screens deliver 4K images or HD based on the display size similar to a normal professional screen. The main difference between a transparent and normal touch screen is a clear screen substrate. White pixels appear completely transparent, black pixels not clear. The full variety of RGB colors has the properties of semi-transparent. Transparent touch screens are available in different types like transparent LCD screens and transparent OLED screens.

Once a bare finer is used to tap on the screen then it registers the commands. If you use a gloved finger otherwise a stylus pen then it doesn’t register the commands. So the main reason is conductive properties. There are different kinds of touchscreen technologies available in the market, but the capacitive type is more popular as compared to others because 90% of the touch screens sold and shipped worldwide are powered through capacitive technology.

These touchscreens depend on conductivity to notice touch commands. If you use a stylus or gloved finger to control them, then they won’t record the commands otherwise react to your commands.

The touch screen is one of the simplest PC interfaces to use, for a larger number of applications. A touch screen is useful for easily accessing the information by simply touching the display screen. The touch screen device system is useful in ranging from industrial process control to home automation.

At the transmission end using a touch screen control unit, some directions will send to the robot for moving into a specific direction like forwarding, backward, rotating left, and rotating right. At the receiving end, four motors are interfaced with the microcontroller. Two of them will be used for Arm and grip movement of the robot and the other two are used for body movement.

Some remote operations can be done with touch screen technology using wireless communication for answering calls, locating and communicating with staff, and operating vehicles and robots. For this purpose RF communication or infrared communication may be used.

It is possible to control the electrical appliances at home using touch screen technology. The whole system works by sending input commands from the touch screen panel through the RF communication which are received at the receiver end and control the switching of loads.

At the transmitter end, a touch screen panel is interfaced with the Microcontroller through a touch screen connector. When an area on the panel is touched, the x and y coordinates of that area are sent to the Microcontroller which generates a binary code from the input.

This 4-bit binary data is given to the data pins of the H12E encoder which develops a serial output. This serial output is now sent using an RF module and an antenna.

The applications of touchscreen technology include the following. Some of the examples of touchscreens like smartphones, a tablet or a computer & a point of sale device.

The touch screen supported most of the computers are Acer, HP, Dell, Microsoft, Lenovo, and other PC designers. And also, some high-end Google Chromebooks use touch screens.

Thus, this is all about an overview of touchscreen technology. The main reasons to choose this technology instead of physical buttons by the manufacturers are; these are instinctive, particularly to younger generations of users. By using this technology, the devices can make smaller. The design of these devices is cheaper. In touch screens, different technologies are used to let the operator operate a screen. Some technologies use a finger whereas others use tools such as a stylus. Here is a question for you, Do touch screens use a keyboard?

A touchscreen or touch screen is the assembly of both an input ("touch panel") and output ("display") device. The touch panel is normally layered on the top of an electronic visual display of an information processing system. The display is often an LCD, AMOLED or OLED display while the system is usually used in a laptop, tablet, or smartphone. A user can give input or control the information processing system through simple or multi-touch gestures by touching the screen with a special stylus or one or more fingers.zooming to increase the text size.

The touchscreen enables the user to interact directly with what is displayed, rather than using a mouse, touchpad, or other such devices (other than a stylus, which is optional for most modern touchscreens).

Touchscreens are common in devices such as game consoles, personal computers, electronic voting machines, and point-of-sale (POS) systems. They can also be attached to computers or, as terminals, to networks. They play a prominent role in the design of digital appliances such as personal digital assistants (PDAs) and some e-readers. Touchscreens are also important in educational settings such as classrooms or on college campuses.

The popularity of smartphones, tablets, and many types of information appliances is driving the demand and acceptance of common touchscreens for portable and functional electronics. Touchscreens are found in the medical field, heavy industry, automated teller machines (ATMs), and kiosks such as museum displays or room automation, where keyboard and mouse systems do not allow a suitably intuitive, rapid, or accurate interaction by the user with the display"s content.

Historically, the touchscreen sensor and its accompanying controller-based firmware have been made available by a wide array of after-market system integrators, and not by display, chip, or motherboard manufacturers. Display manufacturers and chip manufacturers have acknowledged the trend toward acceptance of touchscreens as a user interface component and have begun to integrate touchscreens into the fundamental design of their products.

The prototypeCERNFrank Beck, a British electronics engineer, for the control room of CERN"s accelerator SPS (Super Proton Synchrotron). This was a further development of the self-capacitance screen (right), also developed by Stumpe at CERN

One predecessor of the modern touch screen includes stylus based systems. In 1946, a patent was filed by Philco Company for a stylus designed for sports telecasting which, when placed against an intermediate cathode ray tube display (CRT) would amplify and add to the original signal. Effectively, this was used for temporarily drawing arrows or circles onto a live television broadcast, as described in US 2487641A, Denk, William E, "Electronic pointer for television images", issued 1949-11-08. Later inventions built upon this system to free telewriting styli from their mechanical bindings. By transcribing what a user draws onto a computer, it could be saved for future use. See US 3089918A, Graham, Robert E, "Telewriting apparatus", issued 1963-05-14.

The first version of a touchscreen which operated independently of the light produced from the screen was patented by AT&T Corporation US 3016421A, Harmon, Leon D, "Electrographic transmitter", issued 1962-01-09. This touchscreen utilized a matrix of collimated lights shining orthogonally across the touch surface. When a beam is interrupted by a stylus, the photodetectors which no longer are receiving a signal can be used to determine where the interruption is. Later iterations of matrix based touchscreens built upon this by adding more emitters and detectors to improve resolution, pulsing emitters to improve optical signal to noise ratio, and a nonorthogonal matrix to remove shadow readings when using multi-touch.

The first finger driven touch screen was developed by Eric Johnson, of the Royal Radar Establishment located in Malvern, England, who described his work on capacitive touchscreens in a short article published in 1965Frank Beck and Bent Stumpe, engineers from CERN (European Organization for Nuclear Research), developed a transparent touchscreen in the early 1970s,In the mid-1960s, another precursor of touchscreens, an ultrasonic-curtain-based pointing device in front of a terminal display, had been developed by a team around Rainer Mallebrein[de] at Telefunken Konstanz for an air traffic control system.Einrichtung" ("touch input facility") for the SIG 50 terminal utilizing a conductively coated glass screen in front of the display.

In 1972, a group at the University of Illinois filed for a patent on an optical touchscreenMagnavox Plato IV Student Terminal and thousands were built for this purpose. These touchscreens had a crossed array of 16×16 infrared position sensors, each composed of an LED on one edge of the screen and a matched phototransistor on the other edge, all mounted in front of a monochrome plasma display panel. This arrangement could sense any fingertip-sized opaque object in close proximity to the screen. A similar touchscreen was used on the HP-150 starting in 1983. The HP 150 was one of the world"s earliest commercial touchscreen computers.infrared transmitters and receivers around the bezel of a 9-inch Sony cathode ray tube (CRT).

In 1977, an American company, Elographics – in partnership with Siemens – began work on developing a transparent implementation of an existing opaque touchpad technology, U.S. patent No. 3,911,215, October 7, 1975, which had been developed by Elographics" founder George Samuel Hurst.World"s Fair at Knoxville in 1982.

In 1984, Fujitsu released a touch pad for the Micro 16 to accommodate the complexity of kanji characters, which were stored as tiled graphics.Sega released the Terebi Oekaki, also known as the Sega Graphic Board, for the SG-1000 video game console and SC-3000 home computer. It consisted of a plastic pen and a plastic board with a transparent window where pen presses are detected. It was used primarily with a drawing software application.

Touch-sensitive control-display units (CDUs) were evaluated for commercial aircraft flight decks in the early 1980s. Initial research showed that a touch interface would reduce pilot workload as the crew could then select waypoints, functions and actions, rather than be "head down" typing latitudes, longitudes, and waypoint codes on a keyboard. An effective integration of this technology was aimed at helping flight crews maintain a high level of situational awareness of all major aspects of the vehicle operations including the flight path, the functioning of various aircraft systems, and moment-to-moment human interactions.

In the early 1980s, General Motors tasked its Delco Electronics division with a project aimed at replacing an automobile"s non-essential functions (i.e. other than throttle, transmission, braking, and steering) from mechanical or electro-mechanical systems with solid state alternatives wherever possible. The finished device was dubbed the ECC for "Electronic Control Center", a digital computer and software control system hardwired to various peripheral sensors, servos, solenoids, antenna and a monochrome CRT touchscreen that functioned both as display and sole method of input.stereo, fan, heater and air conditioner controls and displays, and was capable of providing very detailed and specific information about the vehicle"s cumulative and current operating status in real time. The ECC was standard equipment on the 1985–1989 Buick Riviera and later the 1988–1989 Buick Reatta, but was unpopular with consumers—partly due to the technophobia of some traditional Buick customers, but mostly because of costly technical problems suffered by the ECC"s touchscreen which would render climate control or stereo operation impossible.

Multi-touch technology began in 1982, when the University of Toronto"s Input Research Group developed the first human-input multi-touch system, using a frosted-glass panel with a camera placed behind the glass. In 1985, the University of Toronto group, including Bill Buxton, developed a multi-touch tablet that used capacitance rather than bulky camera-based optical sensing systems (see History of multi-touch).

The first commercially available graphical point-of-sale (POS) software was demonstrated on the 16-bit Atari 520ST color computer. It featured a color touchscreen widget-driven interface.COMDEX expo in 1986.

In 1987, Casio launched the Casio PB-1000 pocket computer with a touchscreen consisting of a 4×4 matrix, resulting in 16 touch areas in its small LCD graphic screen.

Touchscreens had a bad reputation of being imprecise until 1988. Most user-interface books would state that touchscreen selections were limited to targets larger than the average finger. At the time, selections were done in such a way that a target was selected as soon as the finger came over it, and the corresponding action was performed immediately. Errors were common, due to parallax or calibration problems, leading to user frustration. "Lift-off strategy"University of Maryland Human–Computer Interaction Lab (HCIL). As users touch the screen, feedback is provided as to what will be selected: users can adjust the position of the finger, and the action takes place only when the finger is lifted off the screen. This allowed the selection of small targets, down to a single pixel on a 640×480 Video Graphics Array (VGA) screen (a standard of that time).

Sears et al. (1990)human–computer interaction of the time, describing gestures such as rotating knobs, adjusting sliders, and swiping the screen to activate a switch (or a U-shaped gesture for a toggle switch). The HCIL team developed and studied small touchscreen keyboards (including a study that showed users could type at 25 wpm on a touchscreen keyboard), aiding their introduction on mobile devices. They also designed and implemented multi-touch gestures such as selecting a range of a line, connecting objects, and a "tap-click" gesture to select while maintaining location with another finger.

In 1990, HCIL demonstrated a touchscreen slider,lock screen patent litigation between Apple and other touchscreen mobile phone vendors (in relation to

An early attempt at a handheld game console with touchscreen controls was Sega"s intended successor to the Game Gear, though the device was ultimately shelved and never released due to the expensive cost of touchscreen technology in the early 1990s.

Touchscreens would not be popularly used for video games until the release of the Nintendo DS in 2004.Apple Watch being released with a force-sensitive display in April 2015.

In 2007, 93% of touchscreens shipped were resistive and only 4% were projected capacitance. In 2013, 3% of touchscreens shipped were resistive and 90% were projected capacitance.

A resistive touchscreen panel comprises several thin layers, the most important of which are two transparent electrically resistive layers facing each other with a thin gap between. The top layer (that which is touched) has a coating on the underside surface; just beneath it is a similar resistive layer on top of its substrate. One layer has conductive connections along its sides, the other along top and bottom. A voltage is applied to one layer and sensed by the other. When an object, such as a fingertip or stylus tip, presses down onto the outer surface, the two layers touch to become connected at that point.voltage dividers, one axis at a time. By rapidly switching between each layer, the position of pressure on the screen can be detected.

Resistive touch is used in restaurants, factories and hospitals due to its high tolerance for liquids and contaminants. A major benefit of resistive-touch technology is its low cost. Additionally, as only sufficient pressure is necessary for the touch to be sensed, they may be used with gloves on, or by using anything rigid as a finger substitute. Disadvantages include the need to press down, and a risk of damage by sharp objects. Resistive touchscreens also suffer from poorer contrast, due to having additional reflections (i.e. glare) from the layers of material placed over the screen.3DS family, and the Wii U GamePad.

Surface acoustic wave (SAW) technology uses ultrasonic waves that pass over the touchscreen panel. When the panel is touched, a portion of the wave is absorbed. The change in ultrasonic waves is processed by the controller to determine the position of the touch event. Surface acoustic wave touchscreen panels can be damaged by outside elements. Contaminants on the surface can also interfere with the functionality of the touchscreen.

The Casio TC500 Capacitive touch sensor watch from 1983, with angled light exposing the touch sensor pads and traces etched onto the top watch glass surface.

A capacitive touchscreen panel consists of an insulator, such as glass, coated with a transparent conductor, such as indium tin oxide (ITO).electrostatic field, measurable as a change in capacitance. Different technologies may be used to determine the location of the touch. The location is then sent to the controller for processing. Touchscreens that use silver instead of ITO exist, as ITO causes several environmental problems due to the use of indium.complementary metal-oxide-semiconductor (CMOS) application-specific integrated circuit (ASIC) chip, which in turn usually sends the signals to a CMOS digital signal processor (DSP) for processing.

Unlike a resistive touchscreen, some capacitive touchscreens cannot be used to detect a finger through electrically insulating material, such as gloves. This disadvantage especially affects usability in consumer electronics, such as touch tablet PCs and capacitive smartphones in cold weather when people may be wearing gloves. It can be overcome with a special capacitive stylus, or a special-application glove with an embroidered patch of conductive thread allowing electrical contact with the user"s fingertip.

A low-quality switching-mode power supply unit with an accordingly unstable, noisy voltage may temporarily interfere with the precision, accuracy and sensitivity of capacitive touch screens.

Some capacitive display manufacturers continue to develop thinner and more accurate touchscreens. Those for mobile devices are now being produced with "in-cell" technology, such as in Samsung"s Super AMOLED screens, that eliminates a layer by building the capacitors inside the display itself. This type of touchscreen reduces the visible distance between the user"s finger and what the user is touching on the screen, reducing the thickness and weight of the display, which is desirable in smartphones.

A simple parallel-plate capacitor has two conductors separated by a dielectric layer. Most of the energy in this system is concentrated directly between the plates. Some of the energy spills over into the area outside the plates, and the electric field lines associated with this effect are called fringing fields. Part of the challenge of making a practical capacitive sensor is to design a set of printed circuit traces which direct fringing fields into an active sensing area accessible to a user. A parallel-plate capacitor is not a good choice for such a sensor pattern. Placing a finger near fringing electric fields adds conductive surface area to the capacitive system. The additional charge storage capacity added by the finger is known as finger capacitance, or CF. The capacitance of the sensor without a finger present is known as parasitic capacitance, or CP.

In this basic technology, only one side of the insulator is coated with a conductive layer. A small voltage is applied to the layer, resulting in a uniform electrostatic field. When a conductor, such as a human finger, touches the uncoated surface, a capacitor is dynamically formed. The sensor"s controller can determine the location of the touch indirectly from the change in the capacitance as measured from the four corners of the panel. As it has no moving parts, it is moderately durable but has limited resolution, is prone to false signals from parasitic capacitive coupling, and needs calibration during manufacture. It is therefore most often used in simple applications such as industrial controls and kiosks.

Although some standard capacitance detection methods are projective, in the sense that they can be used to detect a finger through a non-conductive surface, they are very sensitive to fluctuations in temperature, which expand or contract the sensing plates, causing fluctuations in the capacitance of these plates.

This diagram shows how eight inputs to a lattice touchscreen or keypad creates 28 unique intersections, as opposed to 16 intersections created using a standard x/y multiplexed touchscreen .

Projected capacitive touch (PCT; also PCAP) technology is a variant of capacitive touch technology but where sensitivity to touch, accuracy, resolution and speed of touch have been greatly improved by the use of a simple form of

Some modern PCT touch screens are composed of thousands of discrete keys,etching a single conductive layer to form a grid pattern of electrodes, by etching two separate, perpendicular layers of conductive material with parallel lines or tracks to form a grid, or by forming an x/y grid of fine, insulation coated wires in a single layer . The number of fingers that can be detected simultaneously is determined by the number of cross-over points (x * y) . However, the number of cross-over points can be almost doubled by using a diagonal lattice layout, where, instead of x elements only ever crossing y elements, each conductive element crosses every other element .

In some designs, voltage applied to this grid creates a uniform electrostatic field, which can be measured. When a conductive object, such as a finger, comes into contact with a PCT panel, it distorts the local electrostatic field at that point. This is measurable as a change in capacitance. If a finger bridges the gap between two of the "tracks", the charge field is further interrupted and detected by the controller. The capacitance can be changed and measured at every individual point on the grid. This system is able to accurately track touches.

Unlike traditional capacitive touch technology, it is possible for a PCT system to sense a passive stylus or gloved finger. However, moisture on the surface of the panel, high humidity, or collected dust can interfere with performance.

These environmental factors, however, are not a problem with "fine wire" based touchscreens due to the fact that wire based touchscreens have a much lower "parasitic" capacitance, and there is greater distance between neighbouring conductors.

This is a common PCT approach, which makes use of the fact that most conductive objects are able to hold a charge if they are very close together. In mutual capacitive sensors, a capacitor is inherently formed by the row trace and column trace at each intersection of the grid. A 16×14 array, for example, would have 224 independent capacitors. A voltage is applied to the rows or columns. Bringing a finger or conductive stylus close to the surface of the sensor changes the local electrostatic field, which in turn reduces the mutual capacitance. The capacitance change at every individual point on the grid can be measured to accurately determine the touch location by measuring the voltage in the other axis. Mutual capacitance allows multi-touch operation where multiple fingers, palms or styli can be accurately tracked at the same time.

Self-capacitance sensors can have the same X-Y grid as mutual capacitance sensors, but the columns and rows operate independently. With self-capacitance, the capacitive load of a finger is measured on each column or row electrode by a current meter, or the change in frequency of an RC oscillator.

Self-capacitive touch screen layers are used on mobile phones such as the Sony Xperia Sola,Samsung Galaxy S4, Galaxy Note 3, Galaxy S5, and Galaxy Alpha.

Self capacitance is far more sensitive than mutual capacitance and is mainly used for single touch, simple gesturing and proximity sensing where the finger does not even have to touch the glass surface.

Capacitive touchscreens do not necessarily need to be operated by a finger, but until recently the special styli required could be quite expensive to purchase. The cost of this technology has fallen greatly in recent years and capacitive styli are now widely available for a nominal charge, and often given away free with mobile accessories. These consist of an electrically conductive shaft with a soft conductive rubber tip, thereby resistively connecting the fingers to the tip of the stylus.

Infrared sensors mounted around the display watch for a user"s touchscreen input on this PLATO V terminal in 1981. The monochromatic plasma display"s characteristic orange glow is illustrated.

An infrared touchscreen uses an array of X-Y infrared LED and photodetector pairs around the edges of the screen to detect a disruption in the pattern of LED beams. These LED beams cross each other in vertical and horizontal patterns. This helps the sensors pick up the exact location of the touch. A major benefit of such a system is that it can detect essentially any opaque object including a finger, gloved finger, stylus or pen. It is generally used in outdoor applications and POS systems that cannot rely on a conductor (such as a bare finger) to activate the touchscreen. Unlike capacitive touchscreens, infrared touchscreens do not require any patterning on the glass which increases durability and optical clarity of the overall system. Infrared touchscreens are sensitive to dirt and dust that can interfere with the infrared beams, and suffer from parallax in curved surfaces and accidental press when the user hovers a finger over the screen while searching for the item to be selected.

A translucent acrylic sheet is used as a rear-projection screen to display information. The edges of the acrylic sheet are illuminated by infrared LEDs, and infrared cameras are focused on the back of the sheet. Objects placed on the sheet are detectable by the cameras. When the sheet is touched by the user, frustrated total internal reflection results in leakage of infrared light which peaks at the points of maximum pressure, indicating the user"s touch location. Microsoft"s PixelSense tablets use this technology.

Optical touchscreens are a relatively modern development in touchscreen technology, in which two or more image sensors (such as CMOS sensors) are placed around the edges (mostly the corners) of the screen. Infrared backlights are placed in the sensor"s field of view on the opposite side of the screen. A touch blocks some lights from the sensors, and the location and size of the touching object can be calculated (see visual hull). This technology is growing in popularity due to its scalability, versatility, and affordability for larger touchscreens.

Introduced in 2002 by 3M, this system detects a touch by using sensors to measure the piezoelectricity in the glass. Complex algorithms interpret this information and provide the actual location of the touch.

The key to this technology is that a touch at any one position on the surface generates a sound wave in the substrate which then produces a unique combined signal as measured by three or more tiny transducers attached to the edges of the touchscreen. The digitized signal is compared to a list corresponding to every position on the surface, determining the touch location. A moving touch is tracked by rapid repetition of this process. Extraneous and ambient sounds are ignored since they do not match any stored sound profile. The technology differs from other sound-based technologies by using a simple look-up method rather than expensive signal-processing hardware. As with the dispersive signal technology system, a motionless finger cannot be detected after the initial touch. However, for the same reason, the touch recognition is not disrupted by any resting objects. The technology was created by SoundTouch Ltd in the early 2000s, as described by the patent family EP1852772, and introduced to the market by Tyco International"s Elo division in 2006 as Acoustic Pulse Recognition.

There are several principal ways to build a touchscreen. The key goals are to recognize one or more fingers touching a display, to interpret the command that this represents, and to communicate the command to the appropriate application.

Dispersive-signal technology measures the piezoelectric effect—the voltage generated when mechanical force is applied to a material—that occurs chemically when a strengthened glass substrate is touched.

There are two infrared-based approaches. In one, an array of sensors detects a finger touching or almost touching the display, thereby interrupting infrared light beams projected over the screen. In the other, bottom-mounted infrared cameras record heat from screen touches.

The development of multi-touch screens facilitated the tracking of more than one finger on the screen; thus, operations that require more than one finger are possible. These devices also allow multiple users to interact with the touchscreen simultaneously.

With the growing use of touchscreens, the cost of touchscreen technology is routinely absorbed into the products that incorporate it and is nearly eliminated. Touchscreen technology has demonstrated reliability and is found in airplanes, automobiles, gaming consoles, machine control systems, appliances, and handheld display devices including cellphones; the touchscreen market for mobile devices was projected to produce US$5 billion by 2009.

The ability to accurately point on the screen itself is also advancing with the emerging graphics tablet-screen hybrids. Polyvinylidene fluoride (PVDF) plays a major role in this innovation due its high piezoelectric properties, which allow the tablet to sense pressure, making such things as digital painting behave more like paper and pencil.

TapSense, announced in October 2011, allows touchscreens to distinguish what part of the hand was used for input, such as the fingertip, knuckle and fingernail. This could be used in a variety of ways, for example, to copy and paste, to capitalize letters, to activate different drawing modes, etc.

A real practical integration between television-images and the functions of a normal modern PC could be an innovation in the near future: for example "all-live-information" on the internet about a film or the actors on video, a list of other music during a normal video clip of a song or news about a person.

For touchscreens to be effective input devices, users must be able to accurately select targets and avoid accidental selection of adjacent targets. The design of touchscreen interfaces should reflect technical capabilities of the system, ergonomics, cognitive psychology and human physiology.

Guidelines for touchscreen designs were first developed in the 2000s, based on early research and actual use of older systems, typically using infrared grids—which were highly dependent on the size of the user"s fingers. These guidelines are less relevant for the bulk of modern touch devices which use capacitive or resistive touch technology.

From the mid-2000s, makers of operating systems for smartphones have promulgated standards, but these vary between manufacturers, and allow for significant variation in size based on technology changes, so are unsuitable from a human factors perspective.

Much more important is the accuracy humans have in selecting targets with their finger or a pen stylus. The accuracy of user selection varies by position on the screen: users are most accurate at the center, less so at the left and right edges, and least accurate at the top edge and especially the bot

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey