difference between amoled and tft display quotation

TFT is an abbreviation for Thin Film Transistor, a flat panel display used to improve the operation and utility of LCD screens. In order to portray an appearance to the audience, a liquid crystal display (LCD) utilizes a crystalline-filled fluid to modify rear lighting polarized origin through the use of an electromagnetic force among two relatively thin metal wires such as indium oxide (ITO). However, color TFT displays are associated with this method, which can be employed in both divided and pixelated display systems.

With motion pictures displayed on an LCD, the intrinsic sluggish rate of increase between liquid phases over a significant number of pixel components can be an issue due to capacitance impacts, which can create a blurring of the visuals. Placing a high-velocity LCD control device inside the formation of a thin-film transistor immediately next to the cell component just on a glass screen, the issue of LCD picture speed may be substantially improved, and image blur can be eliminated for all useful purposes entirely.

Organic light-emitting diodes (AMOLEDs) are a type of flat light-emitting advanced technologies that are created by interspersing a succession of organic thin sheets over two conducting conductors. An electrical charge causes a brilliant light to be produced when the current flows. AMOLED displays are light-emitting screens that do not require a backlight, making them thinner and more energy-efficient than liquid crystal displays (LCDs) (which will need a white backlight).

AMOLED displays are not only thin and fuel-intensive, but they also deliver the highest image quality available, so they can be made translucent, elastic, bendable, or even rollable and stretchy in the future, allowing for a variety of applications. AMOLEDs are a revolutionary technology in terms of display devices! It is possible to create an AMOLED by sandwiching a sequence of thin films across phase conductors. Electric charge causes a brilliant light to be emitted when the current flows through the coil.

The color display is fantastic. Color intensity, sharpness, and luminance settings that are second to none and can be customized to meet the needs of any application.

Half-Life has been expanded. TFT displays have a far longer half-life than its LED equivalents, and they are available in a number of sizes, which might have an effect on the device"s half-life based on the phone"s usage as well as other variables. Touch panels for TFT screens can be either resistant or capacitance in nature.

As it is more affordable than capacitive, resistive is typically the preferred option. However, capacitive technology is compatible with a wide range of contemporary smartphones and digital gadgets.

Due to the apparent glass panels, there is limited functionality. For instance, there are ineffective for outdoor use because the glass can display glares from its natural lighting)

They rely on backlight to give illumination rather than generating their own light. Hence they require constructed light-creating diodes (LEDs) in their backlit display framework to ensure enough brightness.

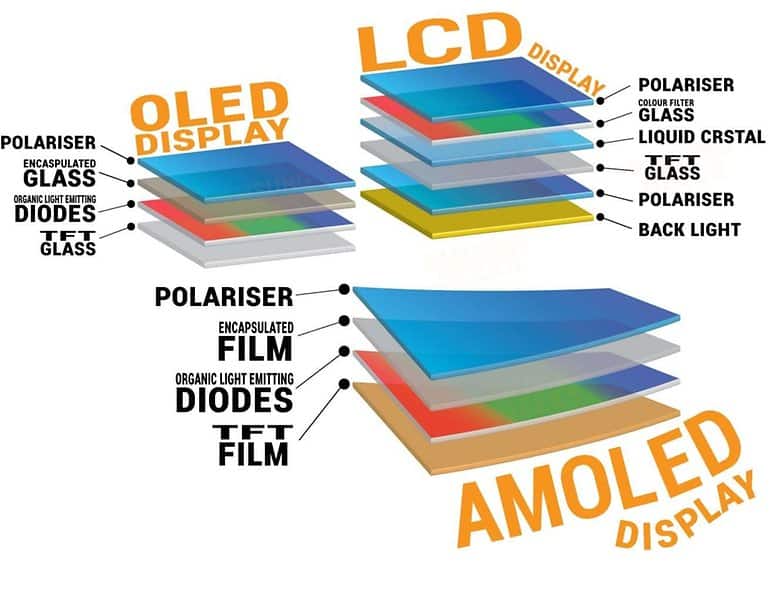

Backlighting is unnecessary for AMOLEDs. LCDs produce images by selectively blocking parts of the illumination, whereas AMOLEDs produce light. AMOLEDs utilize less energy than LCDs since they don"t need backlighting. This is critical for battery-powered devices such as phones.

While AMOLED light-emitting sheets are lightweight, the substrate can also be elastic rather than stiff. AMOLED films are not limited to glass-like LEDs and LCDs.

AMOLEDs offer 170-degree ranges of vision. LCDs operate by obscuring the light. Hence they have intrinsic viewing obstacles. In addition, AMOLEDs have a substantially wider viewing spectrum.

AMOLEDs outperform LEDs. Since AMOLED organic coatings are less than LED inorganic crystal levels, AMOLED conducting and particle emitters layers can just be multi-layered. Also, LEDs and LCDs need glass backing, which absorbs light. AMOLEDs don"t need it.

AMOLEDs seem to be simpler to implement and larger. AMOLEDs are constructed of polymers and may be produced into big sheets. It takes a lot of extra liquid crystals to build and set down.

While red and green AMOLED sheets have a greater lifespan (46,000 to 230,000 hours), azure compounds have significantly shorter longevity (up to roughly 14,000 hours).

Due to the fact that AMOLED displays inherently emit illumination, they do not need a backlight when used on a monitor screen. Conversely, LCDs require backlights since the liquid crystals themselves are incapable of producing light under their own. Direct light emission from AMOLED displays also allows for the developing of lightweight display devices than others using TFT LCDs.

LCD displays have a higher brightness than AMOLED panels. This is owing to the LCD"s usage of led backlight, which may provide a brilliant illumination of the entire display. Despite the fact that AMOLEDs produce high levels of brilliance from their illumination, they will never be able to match the intensity of LCD lighting.

LCD screens use less power than AMOLED displays, which provides a slight advantage. The amount of energy consumed by AMOLED displays is dependent on the intensity of the screen. Lowered luminance results in lower energy usage, however, it might not be the best solution because the contrast would suffer as a result of the decreased brightness. In some situations, such as when to use an AMOLED device in direct sunlight, it is not an optimal situation.

However, the backlit keys of TFT displays account for the majority of their power usage. TFT screens" efficiency is considerably improved when the backlight is set to a lesser brightness level than the default setting. For example, replacing the light of an LCD TV with just an Led flash will have no effect on the image quality, but will result in lower power usage than replacing the light of an AMOLED TV.

With the exception of phones, numerous other technologies make use of displays to allow customers to engage in direct communication with them. To determine whether or not TFT LCD will be able to withstand the development of AMOLED innovation, we should first review the benefits of LCD technology. The backlighting quality ensures that whites are strong and brightness is superb but will deplete a battery much more quickly than just an AMOLED display. Furthermore, the cost of LCD screens is a considerable consideration. In addition to being less expensive and more easily accessible, they are produced in standard industry sizes, allowing them to be purchased for innovative products with relative ease.

AMOLED and TFT are two types of display technology used in smartphones. AMOLED (active-matrix organic light-emitting diode) displays are made up of tiny organic light-emitting diodes, while TFT (Thin-Film Transistor) displays use inorganic thin-film transistors.

AMOLEDs are made from organic materials that emit light when an electric current is passed through them, while TFTs use a matrix of tiny transistors to control the flow of electricity to the display.

Both technologies have their own advantages and disadvantages. So, how do you know which one is best for your needs? We compare these two technologies below.

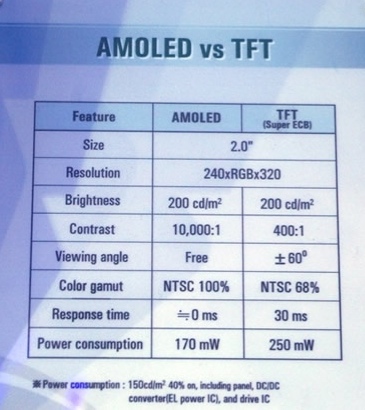

Refresh Rate: Another key difference between AMOLED and TFT displays is the refresh rate. The refresh rate is how often the image on the screen is updated. AMOLED screens have a higher refresh rate than TFT screens, which means that they can display images more quickly and smoothly.

Response Time: The response time is how long it takes for the pixels to change from one colour to another. AMOLED screens have a shorter response time than TFT screens..

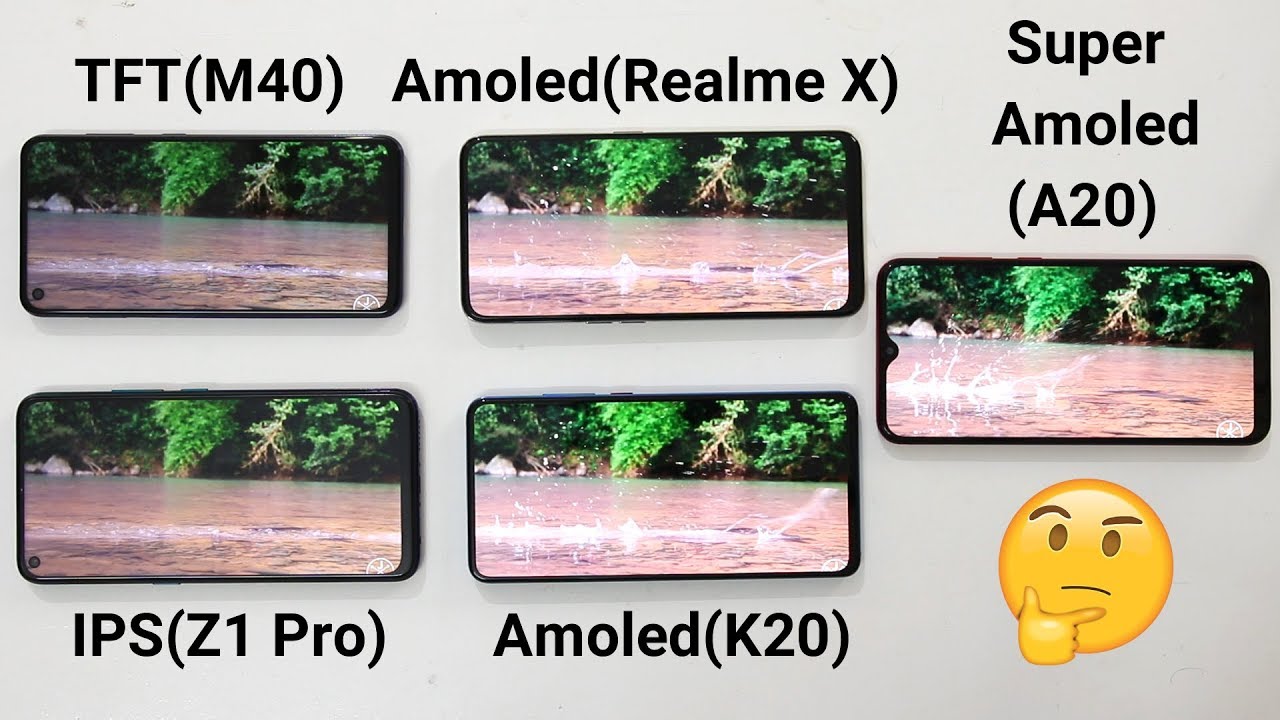

Colour Accuracy/Display Quality: AMOLED screens are more accurate when it comes to displaying colours. This is because each pixel on an AMOLED screen emits its own light, which means that the colours are more pure and true to life. TFT screens, on the other hand, use a backlight to illuminate the pixels, which can cause the colours to appear washed out or less vibrant.

Viewing Angle: The viewing angle is the angle at which you can see the screen. AMOLED screens have a wider viewing angle than TFT screens, which means that you can see the screen from more angles without the colours looking distorted.

Power Consumption: One of the main advantages of AMOLED displays is that they consume less power than TFT displays. This is because the pixels on an AMOLED screen only light up when they need to, while the pixels on a TFT screen are always illuminated by the backlight.

Production Cost: AMOLED screens are more expensive to produce than TFT screens. This is because the manufacturing process for AMOLED screens is more complex, and the materials used are more expensive.

Availability: TFT screens are more widely available than AMOLED screens and have been around for longer. They are typically used in a variety of devices, ranging from phones to TVs.

Usage: AMOLED screens are typically used in devices where power consumption is a concern, such as phones and wearable devices. TFT screens are more commonly used in devices where image quality is a higher priority, such as TVs and monitors.

AMOLED and TFT are two different types of display technology. AMOLED displays are typically brighter and more vibrant, but they are more expensive to produce. TFT displays are cheaper to produce, but they are not as bright or power efficient as AMOLED displays.

The display technology that is best for you will depend on your needs and preferences. If you need a screen that is bright and vibrant, then an AMOLED display is a good choice. If you need a screen that is cheaper to produce, then a TFT display is a good choice. However, if you’re worried about image retention, then TFT may be a better option.

Nauticomp Inc.provides world-class fully customizable touchscreen displays for commercial and industrial settings. With features like sunlight readability, brightness adjustability, infrared lighting, full backlighting, all-weather capabilities, etc., our displays are second to none. Contact us today to learn more.

AMOLED (Active Matrix Organic Light Emitting Diode) and TFT (Thin Film Transistor) are the two types of displays that are used in mobile phones. TFT is actually a process of producing the displays and is used even by AMOLED but for most purposes, TFT is used to refer to LCD displays. The difference between them is the material as AMOLED uses organicmaterials, mainly carbon, while TFT does not.

There are differences between the two that are quite tangible. For starters, AMOLED generates its own light rather than relying on a backlight like a TFT-LCD does. This consequently means that AMOLED displays are much thinner than LCD displays; due to the absence of a backlight. It also results in much better colors than a TFT is capable of producing. As each pixel’s color and light intensity can be regulated independently and no light seeps from adjacent pixels. A side by side comparison of the two displays with the same picture should confirm this. Another effect of the lack of a backlight is the much lower power consumption of the device. This is very desirable when it comes to mobile phones where every single feature competes for the limited capacity of the battery. As the screen is on 90% of the time that the device is being used, it is very good that AMOLED displays consume less. Just how much of a difference is not very fixed though as it really depends on the color and intensity of the image. Having a black background with white text consumes much less energy than having black text on a white background.

The biggest disadvantage that AMOLED has is the shorter lifespan of the screen compared to TFT. Each pixel in the display degrades with each second that it is lit and even more so the brighter it is. Â Despite improvements on the lifetime of AMOLED displays, AMOLED still only lasts a fraction of the lifetime of a TFT display. With that said, an AMOLED display is able to outlast the usable lifetime of the device before parts of it start to degrade.

The main hindrance to the massive adaptation of AMOLED is the low production numbers. TFT has been in production for much longer and the infrastructure is already there to meet the demands.

Devices like smartphones, media players, TVs, laptops, tablets, digital cameras, and other such gadgets require a technology that serves better quality visuals and excellent battery life.

The difference Between AMOLED and TFT is their production and quality. The cost of producing Active-Matrix Organic LED is higher than the Thin-Film Transistor LCDs.

Parameters of ComparisonAMOLEDTFTFull FormsThe full form of an AMOLED Display is an Active-Matrix Organic Light-Emitting Diode.The full form of the TFT is a Thin-Film Transistor.

OLED displays a thin type of film display technology. AMOLED is also a sub-form of it that is consists of organic compounds of the electroluminescent and pixel technology.

The full form of an AMOLED Display is an Active-Matrix Organic Light-Emitting Diode. The AMOLED display is the variant of Light-Emitting Diodes (LEDs).

Its closest technology version is its older form, out of which it is improvised, OLEDs (Organic Light-Emitting Diodes). The display looks black after turning it off.

The product is costlier than TFT. All-round viewing angles. Bright and vibrant colors are available with these LEDs. It provides visuals with loss-resolution quality.

Just like AMOLED, this tech also improves image qualities, contrasts, and their addressability. But it provides visuals with high-resolution quality, even better than the former.

The display does not entirely look black after turning it off. And the Color inversion at extreme viewing angles. Limited contrast options are available.

But it is cheaper than the AMOLED. It is available on easily affordable devices and smartphones. Its closest technology version available is its upgraded form, IPS LCDs (In-Plane Switching LCDs) with improvised features.

Active-Matrix Organic LED displays are available in bright and vibrant colors. On the other hand, Thin-Film Transistor LCDs have limited contrast options.

Thanks for the display technology development, we have a lot of display choices for our smartphones, media players, TVs, laptops, tablets, digital cameras, and other such gadgets. The most display technologies we hear are LCD, TFT, OLED, LED, QLED, QNED, MicroLED, Mini LED etc. The following, we will focus on two of the most popular display technologies in the market: TFT Displays and Super AMOLED Displays.

TFT means Thin-Film Transistor. TFT is the variant of Liquid Crystal Displays (LCDs). There are several types of TFT displays: TN (Twisted Nematic) based TFT display, IPS (In-Plane Switching) displays. As the former can’t compete with Super AMOLED in display quality, we will mainly focus on using IPS TFT displays.

OLED means Organic Light-Emitting Diode. There are also several types of OLED, PMOLED (Passive Matrix Organic Light-Emitting Diode) and AMOLED (Active Matrix Organic Light-Emitting Diode). It is the same reason that PMOLED can’t compete with IPS TFT displays. We pick the best in OLED displays: Super AMOLED to compete with the LCD best: IPS TFT Display.

If you have any questions about Orient Display displays and touch panels. Please feel free to contact: Sales Inquiries, Customer Service or Technical Support.

When we purchase a new smartphone we go through a list of specifications that includes the processor, software, cameras, display type, battery, etc. The display of the smartphone is something which has always been a concern for people. And smartphone technology has advanced so much in the past decade that you get several display technology options to choose from.

Today, a smartphone is not just a means to send and receive calls and texts. It has become a general necessity, so choosing the right technology should be your main priority. Coming back to displays, as we said there are plenty of display types available right now.

Two of the main contenders for display technologies that are widely available are AMOLED and LCD. Here in this article, we will be comprising AMOLED vs LCD and find out which one is better for you.

Starting with the AMOLED first, it is a part of the OLED display technology but with some more advanced features. To completely know about it must understand its all three components. The first one is LED, “Light Emitting Diode”. Then we have “O” which stands for organic and makes the OLED.

It actually means that organic material is placed with two conductors in each LED, which helps to produce the light. And the “AM” in AMOLED means Active Matrix, it has the capability to increase the quality of a pixel.

The AMOLED display is similar to the OLED in various factors like high brightness and sharpness, better battery life, colour reproduction, etc. AMOLED display also has a thin film transistor, “TFT” that is attached to each LED with a capacitor.

TFT helps to operate all the pixels in an AMOLED display. This display might have a lot of positives but there are a few negatives too let’s point both of them out.

It comes with individual LEDs so, the pixels can be turned on and off individually. This will show you true black colours, as the pixels on the black part of the image will be turned off.

A major issue with these displays is of burning of pixels. After showing a specific image or colour for a longer period of time, the pixel can get burned. And if there is a problem with a single pixel it will affect the entire display.

Low outdoor visibility, usually the AMOLED Displays are quote not bright in direct sunlight and outdoor readability could be a problem for some devices but average screen brightness.

The LCD stands for “Liquid Crystal Display”, and this display produces colours a lot differently than AMOLED. LCD display uses a dedicated backlight for the light source rather than using individual LED components.

The LCD displays function pretty simply, a series of thin films, transparent mirrors, and some white LED lights that distributes lights across the back of the display.

As we have mentioned, an LCD display always requires a backlight and also a colour filter. The backlight must have to pass through a thin film transistor matrix and a polarizer. So, when you see it, the whole screen will be lit and only a fraction of light gets through. This is the key difference comparing AMOLED vs LCD and this is what differentiates these two display technologies.

The LCD displays are cheaper compared to the AMOLED as there is only one source of light which makes it easier to produce. Most budget smartphones also use LCD displays.

LCD displays have bright whites, the backlight emits lots of light through pixels which makes it easy to read in outdoors. It also shows the “Accurate True to Life” colours, which means it has the colours that reflect the objects of the real world more accurately than others.

LCDs also offer the best viewing angle. Although it may depend on the smartphone you have. But most high-quality LCD displays support great viewing angles without any colour distortion or colour shifting.

The LCD displays can never show the deep blacks like AMOLED. Due to the single backlight, it always has to illuminate the screen making it impossible to show the deep blacks.

The LCDs are also thicker than other displays because of the backlight as it needs more volume. So, LCD smartphones are mostly thicker than AMOLED ones.

Both of these display technologies have their own Pros and Cons. Taking them aside everything ends up with the user preferences as people might have different preferences among different colours and contrast profiles. However, a few factors might help you to decide which one fits perfectly for you.

Let’s start with the pricing. Most AMOLED display smartphones always cost more than an LCD smartphone. Although the trend is changing a bit. But still, if you want to get a good quality AMOLED display you have to go for the flagship devices.

The colors are also very sharp and vibrant with the AMOLED displays. And they look much better than any LCD display. The brightness is something where LCDs stood ahead of the AMOLED display. So using an LCD display outdoors gives much better results.

The last thing is battery consumption, and there is no one near the AMOLED displays in terms of battery. As of now, all smartphones feature a Dark Mode and most of the apps and UI are dark black with a black background. This dark UI on smartphones doesn’t require any other light, it gives the AMOLED displays a boost in battery performance.

Looking at all these factors and comparing AMOLED vs LCD displays, the AMOLED displays are certainly better than the LCDs. Also, the big display OEMs, like Samsung and LG are focusing more the OLED technologies for their future projects. So, it makes sense to look out for AMOLED displays. That being said, if we see further enhancements in the LCD technology in terms of battery efficiency and more, there is no point to cancel them at this moment.

Tried and trusted TFT technology works by controlling brightness in red, green and blue sub-pixels through transistors for each pixel on the screen. The pixels themselves do not produce light; instead, the screen uses a backlight for illumination.

By contrast the Active Matrix OLED (AMOLED) display requires no backlight and can light up or turn off each of their pixels independently. As the name suggests, they are made of organic material.

An AMOLED display has many other benefits which make it a superior looking display including exceptional vieiwng angles and a display that looks practically black when it is switched off.

So, why use a TFT display? Well, it is a mature technology meaning the manufacturing processes are efficient, yields high and cost much lower than AMOLED.

TFT displays also have a much longer lifespan than AMOLED displays and are available in a far greater range of standard sizes, which can be cut down to fit a space restricted enclosure for a relatively low cost adder.

Which type of display you choose really depends on your application, environment and users, so why not get in touch with us today to discuss your requirements.

What is difference between LCD and AMOLED? The biggest difference between AMOLED and LCD screens is that AMOLED generally has a wider color gamut, which can display more colors, and the displayed picture will be more pleasing. In addition, AMOLED screens have higher saturation when displaying blues and greens, so in the early days, AMOLED screens were often criticized for color inaccuracy and too bright colors. Compared to AMOLED screens, LCD screens typically overcompensate for red and suppress green. Although the color gamut of LCD screens is not as wide as that of AMOLED screens, it is actually closer to the standard RGB color gamut used for video and photo editing.

And if the AMOLED screen mobile phone and the LCD screen mobile phone are tested in detail, some differences can also be seen. It is not difficult to see that, in addition to the material of the screen itself, the adjustment of various manufacturers also affects the color of the screen. In addition to color gamut, color accuracy is also a very important evaluation indicator. From past tests, it can be found that the color accuracy of AMOLED screens has been very good, especially when it is actually displayed in white, while LCD screens are usually a bit blue or green. Of course, given that LCD screens typically use a blue backlight, this result is not surprising.

In addition, the LCD screen is not dominant in weight, because it uses a backlight layer, and the backlight layer cannot be completely closed, so there are some imperfections such as light leakage and low contrast. But AMOLED screens have different life cycles of RGB pixels and may experience color drift over time, while LCDs do not have this problem.

The world of mobile display technology is divided between those who prefer AMOLED screens and those who prefer LCD screens. OLED technology, closely related to AMOLED displays, is available on specific mobile devices. Since the two are based on fundamentally different technologies, distinct manufacturers will promote different advantages for their chosen display technology, AMOLED or LCD. AMOLED displays are becoming the standard for smartphones, whereas LCD screens are often kept for budget models.

First, let’s talk about AMOLED, similar to OLED displays but has a few more bells and whistles. One must be familiar with each of its three parts to grasp it fully. LED, short for “Light Emitting Diode,” is the first. The “O” in OLED refers to “organic,” which describes the material used to construct the device.

To put it another way, each LED has two conductors in which organic material is inserted to assist generate light. And the “AM” in AMOLED stands for Active Matrix, which may improve a pixel’s quality. High brightness and sharpness, improved battery life, accurate colour reproduction, etc., are all features shared by the AMOLED and OLED displays. A capacitor connects each LED in an AMOLED display to a thin film transistor (TFT).

TFT is used to control each pixel in an AMOLED screen. There are probably many benefits to this presentation, but because there are also some drawbacks, I’ll mention them.

The benefits of using best AMOLEDscreen include a higher contrast ratio and more vibrant colours, which contribute to a more satisfying video-viewing experience. Individual pixels may be activated or deactivated thanks to the included LEDs. The pixels in the black area of the picture will be disabled, revealing the most accurate black possible.

The use of individual LEDs improves the efficiency of the display. You may notice an increase in battery life as a result of the fact that specific pixels aren’t using any power at all.

LCD stands for “Liquid Crystal Display,” and its colour output differs from that of an AMOLED screen. Instead of employing separate LED lights for every pixel, an LCD screen has its own built-in backlight.

A backlight and colour filter are necessary components of every LCD panel, as we’ve discussed. A polarizer and a matrix of thin-film transistors are required stops for the backlight on its way to the display. This means that the whole screen will be illuminated, yet only a little amount of light will really reach the viewer. This is the main distinction between AMOLED and LCD, the two most common types of electronic displays now available.

Liquid crystal displays (LCDs) have lower production costs than AMOLEDs since they need less expensive light sources. LCD screens are also often seen in low-priced cell phones.

LCDs’ whites are so luminous because the backlight pumps so much illumination into each pixel that text on these screens can be read even in direct sunlight. Aside from that, it displays “Accurate True to Life” colours, which are most faithful to how things seem in the real world.

There are benefits and drawbacks to each of these presentation methods. Putting those aside, everything comes down to user choice, as different individuals have different tastes in colour schemes and contrast ratios. However, there are a few considerations that may aid you in selecting the one that is most suited to your needs.

Let’s talk about the cost to begin. The cost of a smartphone with an AMOLED screen is often higher than that of a smartphone with an LCD screen. This, is despite the fact that the tide is beginning to turn. Even still,thebest AMOLED screen of sufficient quality are now available on only the most expensive flagship handsets. AMOLED screens also provide very crisp and vivid colours. Additionally, they surpass the visual quality of any LCD screen. Compared to an LCD, an AMOLED screen isn’t nearly as bright. Therefore, an LCD screen performs much better when used in the open air.

Finally, we look at battery life, and no other display technology comes close to AMOLEDs in this regard. All modern smartphones include a “Dark Mode,” where the screen and app icons are black. There is no need for additional lighting while using this dark user interface, which is great for smartphones with AMOLED screens.

AMOLED screens are superior to LCD displays when compared using these criteria. In addition, major display original equipment manufacturers (OEMs) like Samsung and LG emphasise OLED technology for their next endeavours. Therefore, it is prudent to keep an eye out for AMOLED screens. However, if we witness more LCD technology improvements in battery economy and more, there is no need to cancel them at this time.

IPS (In-Plane Switching) lcd is still a type of TFT LCD, IPS TFT is also called SFT LCD (supper fine tft ),different to regular tft in TN (Twisted Nematic) mode, theIPS LCD liquid crystal elements inside the tft lcd cell, they are arrayed in plane inside the lcd cell when power off, so the light can not transmit it via theIPS lcdwhen power off, When power on, the liquid crystal elements inside the IPS tft would switch in a small angle, then the light would go through the IPS lcd display, then the display on since light go through the IPS display, the switching angle is related to the input power, the switch angle is related to the input power value of IPS LCD, the more switch angle, the more light would transmit the IPS LCD, we call it negative display mode.

The regular tft lcd, it is a-si TN (Twisted Nematic) tft lcd, its liquid crystal elements are arrayed in vertical type, the light could transmit the regularTFT LCDwhen power off. When power on, the liquid crystal twist in some angle, then it block the light transmit the tft lcd, then make the display elements display on by this way, the liquid crystal twist angle is also related to the input power, the more twist angle, the more light would be blocked by the tft lcd, it is tft lcd working mode.

A TFT lcd display is vivid and colorful than a common monochrome lcd display. TFT refreshes more quickly response than a monochrome LCD display and shows motion more smoothly. TFT displays use more electricity in driving than monochrome LCD screens, so they not only cost more in the first place, but they are also more expensive to drive tft lcd screen.The two most common types of TFT LCDs are IPS and TN displays.

Steven Van Slyke and Ching Wan Tang pioneered the organic OLED at Eastman Kodak in 1979. The first OLED product was a display for a car stereo, commercialized by Pioneer in 1997. Kodak’s EasyShare LS633 digital camera, introduced in 2003, was the first consumer electronic product incorporating a full-color OLED display. The first television featuring an OLED display, produced by Sony, entered the market in 2008. Today, Samsung uses OLEDs in all of its smartphones, and LG manufactures large OLED screens for premium TVs. Other companies currently incorporating OLED technology include Apple, Google, Facebook, Motorola, Sony, HP, Panasonic, Konica, Lenovo, Huawei, BOE, Philips and Osram. The OLED display market is expected to grow to $57 billion in 2026.

AMOLED (Active Matrix Organic Light Emitting Diode) is a type of OLED display device technology. OLED is a type of display technology in which organic material compounds form the electroluminescent material, and active matrix is the technology behind the addressing of individual pixels.

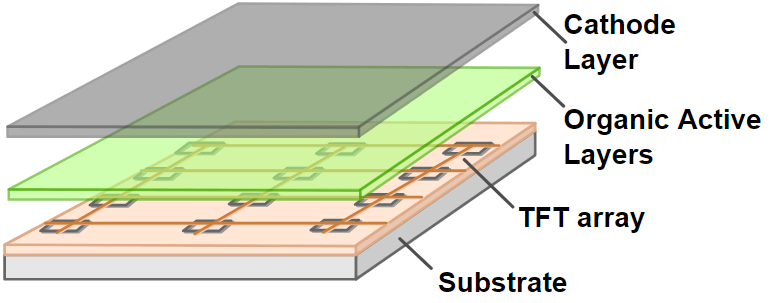

An AMOLED display consists of an active matrix of OLED pixels generating light (luminescence) upon electrical activation that have been deposited or integrated onto a thin-film transistor (TFT) array, which functions as a series of switches to control the current flowing to each individual pixel.

Typically, this continuous current flow is controlled by at least two TFTs at each pixel (to trigger the luminescence), with one TFT to start and stop the charging of a storage capacitor and the second to provide a voltage source at the level needed to create a constant current to the pixel, thereby eliminating the need for the very high currents required for PMOLED.

TFT backplane technology is crucial in the fabrication of AMOLED displays. In AMOLEDs, the two primary TFT backplane technologies, polycrystalline silicon (poly-Si) and amorphous silicon (a-Si), are currently used offering the potential for directly fabricating the active-matrix backplanes at low temperatures (below 150 °C) onto flexible plastic substrates for producing flexible AMOLED displays. Brightness of AMOLED is determined by the strength of the electron current. The colors are controlled by the red, green and blue light emitting diodes. It is easier to understand by thinking of each pixel is independently colored, mini-LED.

IPS technology is like an improvement on the traditional TFT LCD display module in the sense that it has the same basic structure, but with more enhanced features and more widespread usability compared with the older generation of TN type TFT screen (normally used for low-cost computer monitors). Actually, it is called super TFT. IPS LCD display consists of the following high-end features. It has much wider viewing angles, more consistent, better color in all viewing directions, it has higher contrast, faster response time. But IPS screens are not perfect as their higher manufacturing cost compared with TN TFT LCD.

Utilizing an electrical charge that causes the liquid crystal material to change their molecular structure allowing various wavelengths of backlight to “pass-through”. The active matrix of the TFT display is in constant flux and changes or refreshes rapidly depending upon the incoming signal from the control device.

LCD is an electronic display defined by liquid pixels. All electronic displays are composed of pixels arranged in a grid. When the pixels are illuminated, they form an image projected by the display device. However, LCDs contain pixels made of liquid organic matter. LCD is a liquid crystal display or other electronic modulation optical device, which has the light modulation characteristics combined with the polarizer. LCD cannot be directly lit, and can only project polychrome and monochrome images through backlight and reflection.

AMOLED is an electronic display technology similar to OLED. OLED is a display that uses organic liquid pixels, such as LCD. However, organic light emitting diodes and liquid crystal displays are completely different. In contrast, organic light emitting diodes (OLEDs) use organic liquid pixels, while liquid pixels in liquid crystal displays (LCDs) rely on backlighting.

In order to realize an ultrahigh resolution display, all elements of the system (backplane, frontplane, and driving) need to provide appropriate pixel density. On the frontplane side, several options for the light source can be chosen (Figure 2). OLED technology currently dominates the smartphone display industry not only with performance but also with the cost structure. In this case, the colors are defined by depositing separate device stacks for each color, which is typically referred to as side-by-side, red-green-blue (RGB) array. In OLED TVs, one common white OLED stack is combined with a color filter array (CFA). The limitation of the side-by-side RGB array is the pixel density, limited by the fine metal masking (FMM) technology, which uses deposition through a metal mesh. The white OLED array can achieve very small pixel pitch, which is only limited by the backplane and CFA resolution but imposes brightness loss due to CF transmission. Patterning multicolor OLEDs by photolithography can address the needs of ultralow pixel pitch for the future AR displays by realizing side-by-side OLED stacks with extreme density.

Patterning OLEDs by photolithography is an emerging, disruptive fabrication technique. The main challenge is the extreme chemical sensitivity of OLED materials with solvent, moisture, air, and temperature exposure responsible for performance degradation. The choice of appropriate photolithography chemistry is crucial, with fluorinated [6] or non-fluorinated systems [7] as the dominant options. Figure 3 shows the concept of using a negative-type photoresist to define patterns on top of OLED in a subtractive approach. First, the OLED stack is deposited as a plain layer over the entire substrate, on top of a pixel definition layer (PDL). This defines the active area of the light emitter. Second, photoresist is deposited on top of the entire substrate. Then, it is exposed through a lithography mask and developed to obtain the required pattern. Afterwards, the OLED layers that are not covered by the photoresist are etched away (typically with dry etching, such as reactive ion etch). In the end, the photoresist is stripped to achieve patterned OLED islands.

Photolithography allows pattern transfer beyond 1 μm resolution, enabling high-density lines and spaces. Transfer of small islands means that, with appropriate alignment (e.g., with an i-line stepper), a pixel density of a few thousand pixels per inch (ppi) can be realized. Transfer of openings means that pixel spacing can be minimized, resulting in a high aspect ratio. This is applicable for both TFT-based flat panel displays and CMOS-based microdisplays. Tests on patterning the OLED emission layer have shown that it is possible to achieve 1 μm pitch lines and spaces (Figure 4). Furthermore, the photoluminescence signal of the EML is maintained proving compatibility of this process with OLED material. 1 μm presented here is not a fundamental limit of the approach but rather a limit of the lithography mask design used in the experiment.

The achievable pixel density of the frontplane is limited not only by the photoresist used but also by the critical dimension (CD) and alignment/overlay accuracy of the litho tools used. In the i-line steppers typical for flat panel manufacturing, the achievable CD is 1.5 μm with an overlay between 0.25 and 0.5 μm. In contrast, CMOS fabs used for microdisplay manufacturing feature more advanced semiconductor nodes, with 248 nm KrF or 193 nm ArF light sources. Assuming a minimum PDL opening (defining the active area) of 500 nm, a 1.5 μm node imposes a density limit of 3500 ppi (for RGB) with an aperture ratio below 5%. Going to KrF steppers, the achievable density increases to 10,000 ppi while keeping the aperture ratio above 35%. This demonstrates the need of a tooling upgrade for future AR displays, both for the frontplane and the backplane. Denser and more efficient packing of pixels requires scaling down of the technology node, especially in FPD manufacturing.

OLED patterning by photolithography means that the deposition of the stack is interrupted (vacuum break) and the photoresist interacts with the organic materials. In the most simple case, the photolithography process is performed in a clean room in ambient atmosphere. The devices are loaded back into the glove box after the etch step for each color and after the photoresist strip when all colors are finished. This raises a serious challenge for the device lifetime. If the process is not optimized for compatibility with the stack, the current-voltage-luminance (IVL) curve shifts to the right (increased turn-on voltage) and to the bottom (reduced luminance). As a consequence, the brightness of the patterned OLED drops very fast and disappears even after a few minutes (Figure 5). Optimization of the photoresist system, of the OLED stack [8] and of the fabrication process, is needed to achieve OLED performance enabling implementation into devices. At imec, we demonstrated phosphorescent green OLED with T90 lifetime of >150 h at the starting brightness of 1000 nit. Efficiency remained above 85 cd/A before and after patterning. Current performance is considered an important step on the path to industrial technology readiness level, estimated to be T97 of at least 1000 h (for the green stack) [8].

Figure 6 shows an example comparison of unpatterned and patterned OLED lifetime curve at initial brightness of 1000 nit. The performance improvement can bring the two curves closer together.

OLED photolithography was used to fabricate passive displays with a 1400 × 1400 pixel array (almost 2 megapixels). 6 μm metal lines and 10 μm line pitch with SiN pixel definition layer (PDL) were used on glass substrate. Green and red OLED stacks were deposited by thermal evaporation in ultrahigh vacuum. After deposition of the first color (until above emission layer), photoresist was spin-coated, baked, exposed, and developed. Then, the OLED stack not covered by the photoresist was removed by dry etching. After that, the sample went back to the ultrahigh vacuum chamber for second color deposition, and the patterning process was repeated, this time finishing with stripping the photoresist. A semitransparent top contact stack was subsequently deposited, and the display was encapsulated with cavity glass. Both colors can be driven separately, and the PDL design allows for emission of a fixed image specified for each color (Figure 7). Subpixel pitch of 10 μm resulted in smooth edges and excellent feature representation. The device was tested for tens of hours with both colors on. No drop of brightness nor appearance of defects could be observed [9].

Passive 1250 ppi patterned OLED display with 1400 × 1400 pixels, 10 μm subpixel pitch, and independent color driving: general view (left) and detailed view for different color drivings (right).

This fabrication process is compatible with both CMOS backplanes and flexible TFT backplanes. The frontplane can thus be implemented in an active matrix display. Of course, photolithography can be used several times to realize more colors for a full-color display.

An organic light-emitting diode (OLED or organic LED), also known as organic electroluminescent (organic EL) diode,light-emitting diode (LED) in which the emissive electroluminescent layer is a film of organic compound that emits light in response to an electric current. This organic layer is situated between two electrodes; typically, at least one of these electrodes is transparent. OLEDs are used to create digital displays in devices such as television screens, computer monitors, and portable systems such as smartphones and handheld game consoles. A major area of research is the development of white OLED devices for use in solid-state lighting applications.

There are two main families of OLED: those based on small molecules and those employing polymers. Adding mobile ions to an OLED creates a light-emitting electrochemical cell (LEC) which has a slightly different mode of operation. An OLED display can be driven with a passive-matrix (PMOLED) or active-matrix (AMOLED) control scheme. In the PMOLED scheme, each row and line in the display is controlled sequentially, one by one,thin-film transistor (TFT) backplane to directly access and switch each individual pixel on or off, allowing for higher resolution and larger display sizes.

OLED is fundamentally different from LED which is based on a p-n diode structure. In LEDs doping is used to create p- and n- regions by changing the conductivity of the host semiconductor. OLEDs do not employ a p-n structure. Doping of OLEDs is used to increase radiative efficiency by direct modification of the quantum-mechanical optical recombination rate. Doping is additionally used to determine the wavelength of photon emission.

An OLED display works without a backlight because it emits its own visible light. Thus, it can display deep black levels and can be thinner and lighter than a liquid crystal display (LCD). In low ambient light conditions (such as a dark room), an OLED screen can achieve a higher contrast ratio than an LCD, regardless of whether the LCD uses cold cathode fluorescent lamps or an LED backlight. OLED displays are made in the same way as LCDs, but after TFT (for active matrix displays), addressable grid (for passive matrix displays) or indium-tin oxide (ITO) segment (for segment displays) formation, the display is coated with hole injection, transport and blocking layers, as well with electroluminescent material after the first 2 layers, after which ITO or metal may be applied again as a cathode and later the entire stack of materials is encapsulated. The TFT layer, addressable grid or ITO segments serve as or are connected to the anode, which may be made of ITO or metal.transparent displays being used in smartphones with optical fingerprint scanners and flexible displays being used in foldable smartphones.

André Bernanose and co-workers at the Nancy-Université in France made the first observations of electroluminescence in organic materials in the early 1950s. They applied high alternating voltages in air to materials such as acridine orange dye, either deposited on or dissolved in cellulose or cellophane thin films. The proposed mechanism was either direct excitation of the dye molecules or excitation of electrons.

In 1960, Martin Pope and some of his co-workers at New York University developed ohmic dark-injecting electrode contacts to organic crystals.work functions) for hole and electron injecting electrode contacts. These contacts are the basis of charge injection in all modern OLED devices. Pope"s group also first observed direct current (DC) electroluminescence under vacuum on a single pure crystal of anthracene and on anthracene crystals doped with tetracene in 1963volts. The proposed mechanism was field-accelerated electron excitation of molecular fluorescence.

Pope"s group reported in 1965exciton energy level. Also in 1965, Wolfgang Helfrich and W. G. Schneider of the National Research Council in Canada produced double injection recombination electroluminescence for the first time in an anthracene single crystal using hole and electron injecting electrodes,Dow Chemical researchers patented a method of preparing electroluminescent cells using high-voltage (500–1500 V) AC-driven (100–3000Hz) electrically insulated one millimetre thin layers of a melted phosphor consisting of ground anthracene powder, tetracene, and graphite powder.

The first Polymer LED (PLED) to be created was by Roger Partridge at the National Physical Laboratory in the United Kingdom. It used a film of poly(N-vinylcarbazole) up to 2.2 micrometers thick located between two charge-injecting electrodes. The light generated was readily visible in normal lighting conditions though the polymer used had 2 limitations; low conductivity and the difficulty of injecting electrons.

Research into polymer electroluminescence culminated in 1990, with J. H. Burroughes et al. at the Cavendish Laboratory at Cambridge University, UK, reporting a high-efficiency green light-emitting polymer-based device using 100nm thick films of poly(p-phenylene vinylene).plastic electronics and OLED research and device production grew rapidly.et al. at Yamagata University, Japan in 1995, achieved the commercialization of OLED-backlit displays and lighting.

In 1999, Kodak and Sanyo had entered into a partnership to jointly research, develop, and produce OLED displays. They announced the world"s first 2.4-inch active-matrix, full-color OLED display in September the same year.

Manufacturing of small molecule OLEDs was started in 1997 by Pioneer Corporation, followed by TDK in 2001 and Samsung-NEC Mobile Display (SNMD), which later became one of the world"s largest OLED display manufacturers - Samsung Display, in 2002.

The Sony XEL-1, released in 2007, was the first OLED television.Universal Display Corporation, one of the OLED materials companies, holds a number of patents concerning the commercialization of OLEDs that are used by major OLED manufacturers around the world.

On 5 December 2017, JOLED, the successor of Sony and Panasonic"s printable OLED business units, began the world"s first commercial shipment of inkjet-printed OLED panels.

A typical OLED is composed of a layer of organic materials situated between two electrodes, the anode and cathode, all deposited on a substrate. The organic molecules are electrically conductive as a result of delocalization of pi electrons caused by conjugation over part or all of the molecule. These materials have conductivity levels ranging from insulators to conductors, and are therefore considered organic semiconductors. The highest occupied and lowest unoccupied molecular orbitals (HOMO and LUMO) of organic semiconductors are analogous to the valence and conduction bands of inorganic semiconductors.

During operation, a voltage is applied across the OLED such that the anode is positive with respect to the cathode. Anodes are picked based upon the quality of their optical transparency, electrical conductivity, and chemical stability.electrons flows through the device from cathode to anode, as electrons are injected into the LUMO of the organic layer at the cathode and withdrawn from the HOMO at the anode. This latter process may also be described as the injection of electron holes into the HOMO. Electrostatic forces bring the electrons and the holes towards each other and they recombine forming an exciton, a bound state of the electron and hole. This happens closer to the electron-transport layer part of the emissive layer, because in organic semiconductors holes are generally more mobile than electrons. The decay of this excited state results in a relaxation of the energy levels of the electron, accompanied by emission of radiation whose frequency is in the visible region. The frequency of this radiation depends on the band gap of the material, in this case the difference in energy between the HOMO and LUMO.

As electrons and holes are fermions with half integer spin, an exciton may either be in a singlet state or a triplet state depending on how the spins of the electron and hole have been combined. Statistically three triplet excitons will be formed for each singlet exciton. Decay from triplet states (phosphorescence) is spin forbidden, increasing the timescale of the transition and limiting the internal efficiency of fluorescent devices. Phosphorescent organic light-emitting diodes make use of spin–orbit interactions to facilitate intersystem crossing between singlet and triplet states, thus obtaining emission from both singlet and triplet states and improving the internal efficiency.

Indium tin oxide (ITO) is commonly used as the anode material. It is transparent to visible light and has a high work function which promotes injection of holes into the HOMO level of the organic layer. A second conductive (injection) layer is typically added, which may consist of PEDOT:PSS,barium and calcium are often used for the cathode as they have low work functions which promote injection of electrons into the LUMO of the organic layer.aluminium to avoid degradation. Two secondary benefits of the aluminum capping layer include robustness to electrical contacts and the back reflection of emitted light out to the transparent ITO layer.

Experimental research has proven that the properties of the anode, specifically the anode/hole transport layer (HTL) interface topography plays a major role in the efficiency, performance, and lifetime of organic light-emitting diodes. Imperfections in the surface of the anode decrease anode-organic film interface adhesion, increase electrical resistance, and allow for more frequent formation of non-emissive dark spots in the OLED material adversely affecting lifetime. Mechanisms to decrease anode roughness for ITO/glass substrates include the use of thin films and self-assembled monolayers. Also, alternative substrates and anode materials are being considered to increase OLED performance and lifetime. Possible examples include single crystal sapphire substrates treated with gold (Au) film anodes yielding lower work functions, operating voltages, electrical resistance values, and increasing lifetime of OLEDs.

Single carrier devices are typically used to study the kinetics and charge transport mechanisms of an organic material and can be useful when trying to study energy transfer processes. As current through the device is composed of only one type of charge carrier, either electrons or holes, recombination does not occur and no light is emitted. For example, electron only devices can be obtained by replacing ITO with a lower work function metal which increases the energy barrier of hole injection. Similarly, hole only devices can be made by using a cathode made solely of aluminium, resulting in an energy barrier too large for efficient electron injection.

Balanced charge injection and transfer are required to get high internal efficiency, pure emission of luminance layer without contaminated emission from charge transporting layers, and high stability. A common way to balance charge is optimizing the thickness of the charge transporting layers but is hard to control. Another way is using the exciplex. Exciplex formed between hole-transporting (p-type) and electron-transporting (n-type) side chains to localize electron-hole pairs. Energy is then transferred to luminophore and provide high efficiency. An example of using exciplex is grafting Oxadiazole and carbazole side units in red diketopyrrolopyrrole-doped Copolymer main chain shows improved external quantum efficiency and color purity in no optimized OLED.

Organic small-molecule electroluminescent materials have the advantages of a wide variety, easy to purify, and strong chemical modifications. In order to make the luminescent materials to emit light as required, some chromophores or unsaturated groups such as alkene bonds and benzene rings will usually be introduced in the molecular structure design to change the size of the conjugation range of the material, so that the photophysical properties of the material changes. In general, the larger the range of π-electron conjugation system, the longer the wavelength of light emitted by the material. For instance, with the increase of the number of benzene rings, the fluorescence emission peak of benzene, naphthalene, anthracene,anthracenes, biphenyl acetylene aryl derivatives, coumarin derivatives,Ching W. Tang et al.Eastman Kodak. The term OLED traditionally refers specifically to this type of device, though the term SM-OLED is also in use.

Molecules commonly used in OLEDs include organometallic chelates (for example Alq3, used in the organic light-emitting device reported by Tang et al.), fluorescent and phosphorescent dyes and conjugated dendrimers. A number of materials are used for their charge transport properties, for example triphenylamine and derivatives are commonly used as materials for hole transport layers.perylene, rubrene and quinacridone derivatives are often used.3 has been used as a green emitter, electron transport material and as a host for yellow and red emitting dyes.

Because of the structural flexibility of small-molecule electroluminescent materials, thin films can be prepared by vacuum vapor deposition, which is more expensive and of limited use for large-area devices. The vacuum coating system, however, can make the entire process from film growth to OLED device preparation in a controlled and complete operating environment, helping to obtain uniform and stable films, thus ensuring the final fabrication of high-performance OLED devices.However, small molecule organic dyes are prone to fluorescence quenching

Polymer light-emitting diodes (PLED, P-OLED), also light-emitting polymers (LEP), involve an electroluminescent conductive polymer that emits light when connected to an external voltage. They are used as a thin film for full-spectrum colour displays. Polymer OLEDs are quite efficient and require a relatively small amount of power for the amount of light produced.

Vacuum deposition is not a suitable method for forming thin films of polymers. If the polymeric OLED films are made by vacuum vapor deposition, the chain elements will be cut off and the original photophysical properties will be compromised. However, polymers can be processed in solution, and spin coating is a common method of depositing thin polymer films. This method is more suited to forming large-area films than thermal evaporation. No vacuum is required, and the emissive materials can also be applied on the substrate by a technique derived from commercial inkjet printing.Langmuir-Blodgett film.

Typical polymers used in PLED displays include derivatives of poly(p-phenylene vinylene) and polyfluorene. Substitution of side chains onto the polymer backbone may determine the colour of emitted lightring opening metathesis polymerization.

The heavy metal atom at the centre of these complexes exhibits strong spin-orbit coupling, facilitating intersystem crossing between singlet and triplet states. By using these phosphorescent materials, both singlet and triplet excitons will be able to decay radiatively, hence improving the internal quantum efficiency of the device compared to a standard OLED where only the singlet states will contribute to emission of light.

a) Bottom-emitting and b) top-emitting OLED structures; c,d) Schematic diagrams based on bottom-emitting and top-emitting OLEDs with low and high contrast ratio, respectively.

The bottom-emission organic light-emitting diode (BE-OLED) is the architecture that was used in the early-stage AMOLED displays. It had a transparent anode fabricated on a glass substrate, and a shiny reflective cathode. Light is emitted from the transparent anode direction. To reflect all the light towards the anode direction, a relatively thick metal cathode such as aluminum is used. For the anode, high-transparency indium tin oxide (ITO) was a typical choice to emit as much light as possible.thin film transistor (TFT) substrate, and the area from which light can be extracted is limited and the light emission efficiency is reduced.

An alternative configuration is to switch the mode of emission. A reflective anode, and a transparent (or more often semi-transparent) cathode are used so that the light emits from the cathode side, and this configuration is called top-emission OLED (TE-OLED). Unlike BEOLEDs where the anode is made of transparent conductive ITO, this time the cathode needs to be transparent, and the ITO material is not an ideal choice for the cathode because of a damage issue due to the sputtering process.transmittance and high conductivity.

Since both electrodes are reflective in TEOLED, light reflections can happen within the diode, and they cause more complex interferences than those in BEOLEDs. In addition to the two-beam interference, there exists a multi-resonance interference between two electrodes. Because the structure of TEOLEDs is similar to that of the Fabry-Perot resonator or laser resonator, which contains two parallel mirrors comparable to the two reflective electrodes),

In the case of OLED, that means the cavity in a TEOLED could be especially designed to enhance the light output intensity and color purity with a narrow band of wavelengths, without consuming more power. In TEOLEDs, the microcavity effect commonly occurs, and when and how to restrain or make use of this effect is indispensable for device design. To match the conditions of constructive interference, different layer thicknesses are applied according to the resonance wavelength of that specific color. The thickness conditions are carefully designed and engineered according to the peak resonance emitting wavelengths of the blue (460 nm), green (530 nm), and red (610 nm) color LEDs. This technology greatly improves the light-emission efficiency of OLEDs, and are able to achieve a wider color gamut due to high color purity.

In "white + color filter method," red, green, and blue emissions are obtained from the same white-light LEDs using different color filters.uneven degradation rate of blue pixels vs. red and green pixels. Disadvantages of this method are low color purity and contrast. Also, the filters absorb most of the light waves emitted, requiring the background white light to be relatively strong to compensate for the drop in brightness, and thus the power consumption for such displays can be higher.

Color filters can also be implemented into bottom- and top-emission OLEDs. By adding the corresponding RGB color filters after the semi-transparent cathode, even purer wavelengths of light can be obtained. The use of a microcavity in top-emission OLEDs with color filters also contributes to an increase in the contrast ratio by reducing the reflection of incident ambient light.

Transparent OLEDs use transparent or semi-transparent contacts on both sides of the device to create displays that can be made to be both top and bottom emitting (transparent). TOLEDs can greatly improve contrast, making it much easier to view displays in bright sunlight.Head-up displays, smart windows or augmented reality applications.

Stacked OLEDs use a pixel architecture that stacks the red, green, and blue subpixels on top of one another instead of next to one another, leading to substantial increase in gamut and color depth,

In contrast to a conventional OLED, in which the anode is placed on the substrate, an Inverted OLED uses a bottom cathode that can be connected to the drain end of an n-channel TFT especially for the low cost amorphous silicon TFT backplane useful in the manufacturing of AMOLED displays.

The most commonly used patterning method for organic light-emitting displays is shadow masking during film deposition,photochemical machining, reminiscent of old CRT shadow masks, are used in this process. The dot density of the mask will determine the pixel density of the finished display.−5Pa. An oxygen meter ensures that no oxygen enters the chamber as it could damage (through oxidation) the electroluminescent material, which is in powder form. The mask is aligned with the mother substrate before every use, and it is placed just below the substrate. The substrate and mask assembly are placed at

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey