waterproof lcd display arduino free sample

I am to the point where I want to start making the thing fancy. Earlier I had decided that it would cost about the same or less to use an Arduino with a cheap GPS receiver to report speed than to buy a new speed indicator (The old one was all busted up), and now I am expanding on that idea. I want my little speed reporting computer to also take care of everything else onboard the boat. I am buying a 128 x 64 LCD display and want to mount it into the dash behind the steering wheel.

In the Google Drive share I put at the top I have my project files, my eagle files, and picture etc... I plan on keeping it updated as I work on my little project, but before I get more side-tracked, the question I came here for: What is the best way to weatherproof this display? A boat is constantly exposed to moisture, and it is stored outdoors, so it has to endure the cold and the hot as well. I mainly stick to freshwater, but saltwater is not out of the question. I came up with an idea of how I might do it, but I had not found any examples of how other people have done something similar before. Here is what I was thinking: plan.png - Google Drive and here is the dash: Display Location.jpg - Google Drive

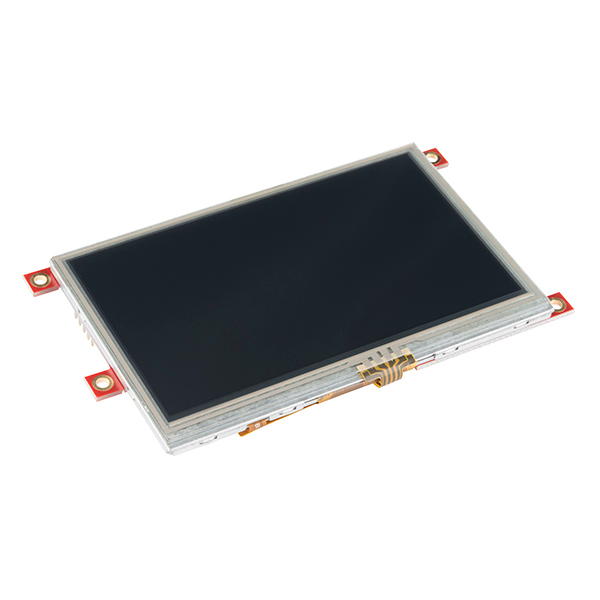

I was basically going to try cutting a window through the dash (it is basically a sheet of fiberglass on top of a sheet of wood) and leaving a bit of a lip to silicone a bit of plexiglass in place, and then screw the display in from the other side (the screen is from here: 3.5 Inch TFT Color Screen Module for Arduino UNO R3 / Mega2560 - Free shipping - DealExtreme). To keep water from leaching in I would put a thin layer of silicone on the exposed wood and finish it off with a plastic box of some sort attached to the back with connectors filled with dielectric grease. It might be better to have everything in one container that slides into a hole, but I am not sure where to get/how to make something like that. Anybody here have any experience with this kind of thing?

I"m looking for an enclosure for a project that will include one of the 2x8 character LCDs from seeedstudio and should have an IR panel and battery enclosure.

but accoring to the datasheet, the internal dimension is 60mm wide and according to seeedstudio, the LCD is 58mm wide. I"m worried I"ll have trouble fitting the LCD because it"s cutting too close, or in the best case the aesthetics will suffer because the display will be too far off center (it doesn"t look centered on its own PCB).

I"m working with a similar sized LCD but it"s going behind a panel rather than in a box. I am lucky that I can make my own cutout and fit the LCD into it. I"m not real sure how I"m going to protect the LCD though - it will be exposed to the elements.

oh, by the way, I have one of the Seeed modules in my hand and I would say the LCD face is pretty well centered on the board. It"s not EXACT but no more than a couple of mm further from the backlight end of the board than the connector end.

I have the seeedstudio LCD too. It was my original request that he stock them ;). I"m thinking a few mm off will look pretty crappy in the box though.

What trouble are you having getting it to work? It"s working for me, but I had to modify the time delays in the arduino liquidcystal library (the problem was with the library, not the display). I had a horribly frustrating time where it would work once in a while, but 95% of the time would never initialize.

I am having trouble with the 60mm red-green 8x8 matrix display though. I"ve only tested by directly connecting to the LEDs, through a resistor of course, and the brightness is very, very dim.

What trouble are you having getting it to work? It"s working for me, but I had to modify the time delays in the arduino liquidcystal library (the problem was with the library, not the display). I had a horribly frustrating time where it would work once in a while, but 95% of the time would never initialize.

I would get either blank or sometimes the black character boxes showing (I now know) that it was getting power. This was the first LCD module I bought and I had not yet learned about the liquidcrystal library so i was working just from the datasheet. The problem could have been my wiring or my code. I have it out now and I"ll try it again. What timing did you have to change?

In terms of centering, I just don"t believe I could detect the offset, maybe mine is not quite the same. How are you going to make the cutout for the LCD and attach it?

it looks better now since ive taped the sides but it was impossible to cut a perfect rectangle witha dremel, nor a box cutter, so i had to sand and sand, and, ofcourse, i over sanded and ended up with huge, awkward gaps between the sides of the lcd screen and the box...

it looks better now since ive taped the sides but it was impossible to cut a perfect rectangle witha dremel, nor a box cutter, so i had to sand and sand, and, ofcourse, i over sanded and ended up with huge, awkward gaps between the sides of the lcd screen and the box...

exactly what I"ve been worrying about. I foolishly expected there would be readily available plastic/chrome bezels that would fit neatly around stock-sized LCDs, no luck yet though.

One thing I"ve used is a shadow box. It"s like a picture frame but instead of holding a flat page it"s got an internal compartment to hold and display 3D objects. I paid around $10 at a crafts store for a 5x7 with about 2 inches inside. It came with a glass front and a felt-lined pressboard back. I made all the holes in the back board.

I got a couple of sample boxes like the one below from pactec. They have a wide variety on their web site. In this case the end is separate but probably too small for the LCD and the sides of the cases just leave you with the same issue of cutting your own hole and finishing it.

If waterproofing/dustproofing is not important, you can just sandwich your project (PCB, LCD etc) between 2 sheets of acrylic, with long screws and spacers.

I"m still surprised that there aren"t more readily available LCD mounting options. In my case I need something really weatherproof because I"m mounting on an exposed motorcycle surface but I haven"t see anything that would help finish off a project.

I think it is amazing that there isn"t already on the market a simpe palstic box with rectangular holes the size of the screens on LCD"s, which are all pretty standard.

Mike, I don"t think there is a single standard. I have three 16x2 LCD panels and all require different size cutouts. My 16x1 and 16x4 panels are different sizes again.

For your weatherproof project, why not use florinc"s suggestion of a pelikan or otterbox? They"re expensive, but very weatherproof and available with clear tops for the display. For the interface if needed, you can rig up something IR so you don"t have to comprimise the weatherproofing.

I"ve seen the same need to provide enclosures for Arduino, and other DIY projects, and have started working on a couple of things. They are a few months off, so don"t really solve any problems now, but I"m trying to get a couple of manufacturers to work with me on a more modular enclosure design that would work better for the type of projects that Arduino, and other hobby projects seem to need.

The driver used in this LCD is GC9A01, with a resolution of 240RGB×240 dots and 129600 bytes of GRAM inside. This LCD supports 12-bits/16-bits/18-bits data bus by MCU interface, which are RGB444, RGB565, RGB666.

For most LCD controllers, the communication method of the controller can be configured, they are usually using 8080 parallel interface, 3-line SPI, 4-line SPI, and other communication methods. This LCD uses a 4-line SPI interface for reducing GPIO and fast speed.LCD

If you are wondering which point is the first pixel of the screen (because the screen is round), you can understand it as a square screen with an inscribed circle drawn in it, and it only displays the content in this inscribed circle. The pixels in other locations are simply discarded (just like most round smartwatches on the market)

This guide shows how to use the DS18B20 temperature sensor with the Arduino board. You’ll learn how to wire the sensor, install the required libraries and get temperature from one or multiple DS18B20 sensors.

The DS18B20 temperature sensor is a one-wire digital temperature sensor. This means that it just requires one data line (and GND) to communicate with the Arduino.

Each DS18B20 temperature sensor has a unique 64-bit serial code. This allows you to wire multiple sensors to the same data wire. So, you can get temperature from multiple sensors using just one Arduino digital pin.

To show you how the sensor works, we’ll build a simple example that reads the temperature from the DS18B20 sensor with the Arduino and displays the values on the Arduino Serial Monitor.

You can read the temperature of more than one sensor at the same time using just one Arduino digital pin. For that, you just need to wire together all the sensors data pins to an Arduino digital pin.

After installing the needed libraries, upload the following code to your Arduino board. This sketch is based on an example from the Dallas Temperature library.

After uploading the code, open the Arduino IDE Serial Monitor at a 9600 baud rate. You should get the temperature displayed in both Celsius and Fahrenheit:

The DS18B20 temperature sensor communicates using one-wire protocol and each sensor has a unique 64-bit serial code, so you can read the temperature from multiple sensors using just one single Arduino digital Pin.

The DS18B20 temperature sensor is a one-wire digital sensor. To use this sensor with the Arduino, you need the OneWire and the DallasTemperature libraries. You can use one sensor or multiple sensors on the same data line because you can identify each sensor by its unique address.

Crystalfontz has a wide variety of LCD display products. Including ePaper, OLED, TFT and accessories. Watch our LCD videos below to see our display solutions in action.

Not sure how the difference between transflective and transmissive affects sunlight readability? Here is a video that takes you from pitch black to full sunlight, showing how the transflective CFAF480640A-035T compares to a transmissive TFT display module.

In this video, we"re demonstrating driving a 800x480 5" TFT with an Seeeduino (Arduino UNO Clone with 3.3v / 5v switch) and the help of our CFA10100 EVE accelerated board.

Awesome little transparent OLED display. Its a 128x56 pixels and 1.51 inch diagonal. Super-bright, monochrome (light blue). We powered it up with a Seeeduino for this demonstration.

This is a quick video showing our new 1.3 inch TFT LCD. This is a small, full-color TFT. It"s controlled via 4-wire SPI. It has a ST7789H2 controller. This display runs off a single 3.3v supply which controls the logic and backlight.

Ever wonder what will happen if you submerge an OLED display in water? Well we tried it, we also tried coating the components with various sealants to see if we can help protect them in high humidity, or high-water level scenarios.

This is a 2.4" IPS TFT designed for embedded systems. This wide viewing angle IPS display can be used in any orientation--landscape or portrait. The backlight is 850 nits (cd/m2) so it can be used in most lighting conditions.

This is a Capacitive Touch 2.4" IPS TFT designed for embedded systems. This wide viewing angle IPS display can be used in any orientation--landscape or portrait. The backlight is 730 nits (cd/m2) so it can be used in most lighting conditions.

Check out this small, low power transflective LCD display. Available in many options including with and without a backlight, breakout board, or a complete development kit.

Arduino is a popular open-source development board used by engineers, hobbyists and makers to develop electronic projects and prototypes in an easy way. The Arduino platform consists of many development boards like Arduino UNO, Arduino Nano, Arduino Mega, Arduino Pro Mini etc.. all of which are based on the series of AVR microcontrollers.

The below list consist of a large collection of free Arduino Projects from Circuit Digest, including basic LCD interfacing, sensor interfacing projects to advanced Bluetooth and Wi-Fi project. All projects consist of neatly illustrated Arduino circuit diagram and detailed explanation, the relevant Arduino code is also provided for a complete do-it-yourself tutorial.

NeoPixel LEDs are individually addressable LEDs. Only one data line is connected to all the LEDs. All the LEDs in the strip are connected in series. Each LED will have a small logic IC which will understand the incoming data, process it and light up the RGB LEDs accordingly. It is quite a fascinating idea which is now a globally called FastLEDs or NeoPixel LEDs, but basically, all these are individually addressable LEDs.

- Copy the code of your NeoPixel project.

- Make a note of the number of LEDs and number of the Arduino pin to which the data line of the LED is connected to

- I will also pick a random example from the internet

- I choose adafruit link to take a sample code for our test

- I changed the pin number of Arduino from 0 (from the code) to 6.

- I changed the number of LEDs from 24 to 8

- Below is the screenshot of the running simulation in action

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey