tft lcd fritzing made in china

I don’t think inkscape is quirky, I get along with it quite well considering I am a newbie at it. I think the inkscape to Fritzing interaction needs work and I think most of the problems can be solved on the inkscape side of things.

This is slightly misleading in that copper1 is actually under copper0 not silkscreen, but the order should be silkscreen, copper1 with copper0 as a group under copper1 (at present copper1 and copper0 are reversed.) I don’t know of any problem this causes other than Fritzing will prefer to select silkscreen if it is the lowest group (thus a warning rather than an error.)

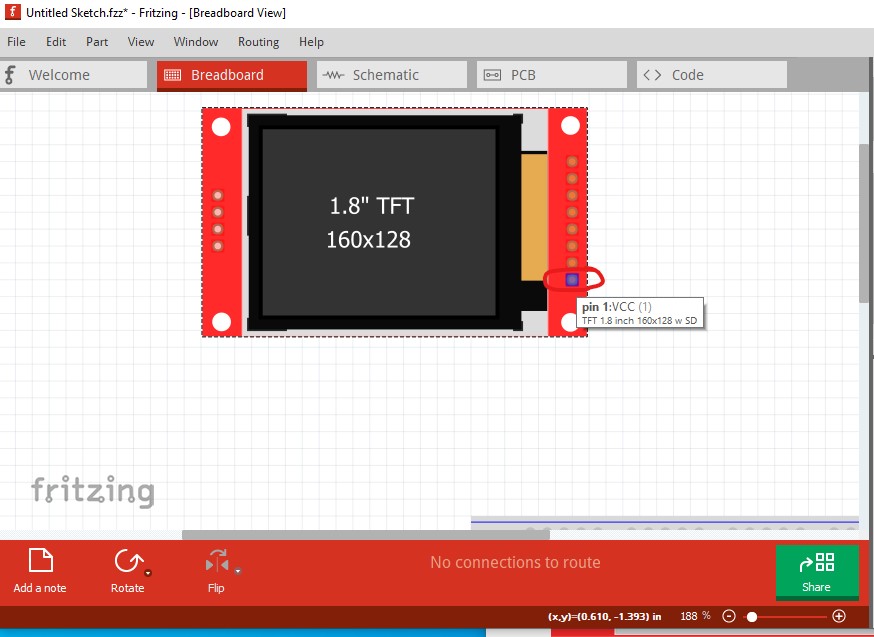

While this shows as an error (because in schematic it likely is one), in this case it is ignorable, because Fritzing will use the center of the pin as the termination point as was intended. Technically you can and should remove the connectorxterminal elements in breadboard, but it won’t hurt anything. repeats for all the pins on breadboard.

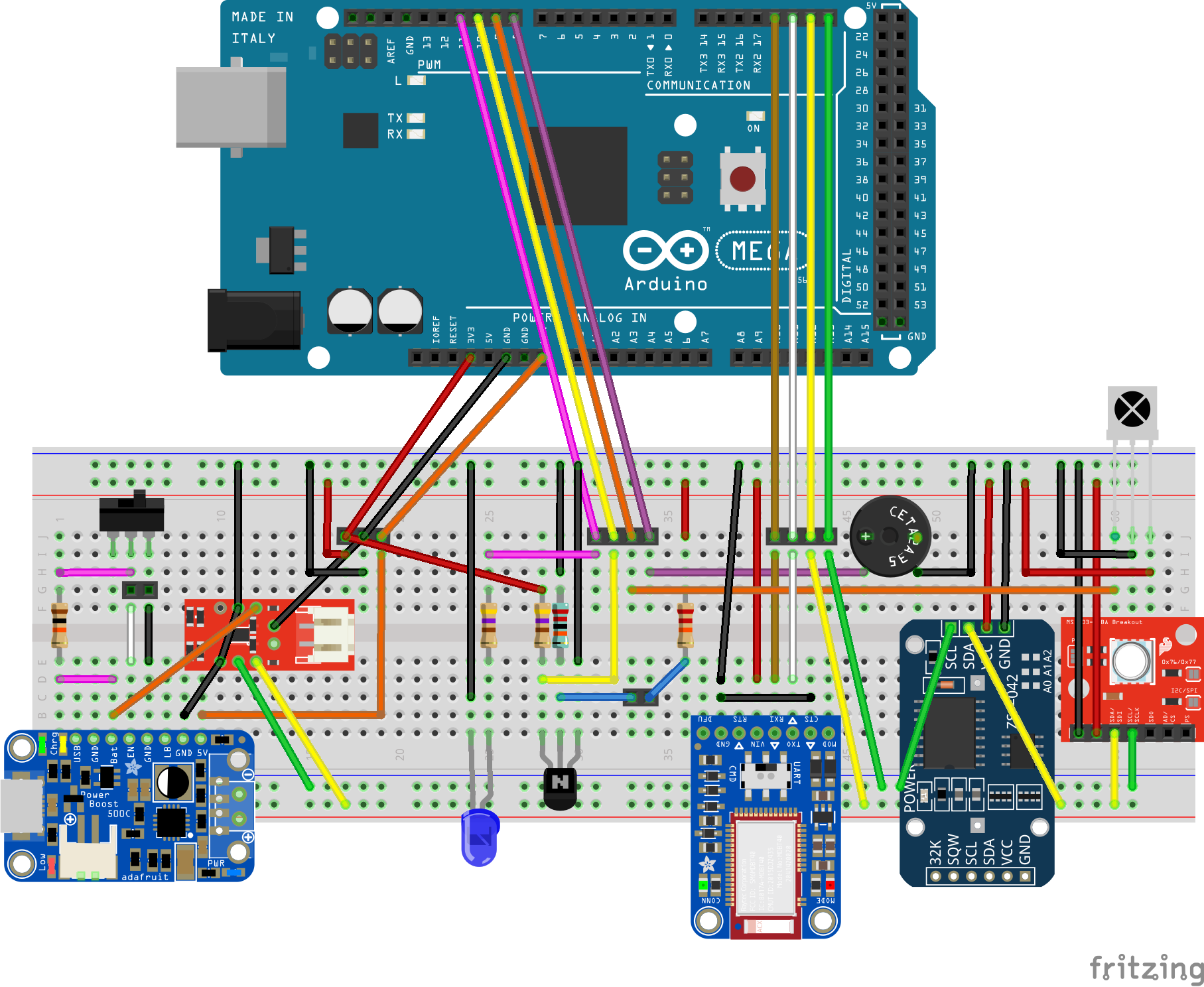

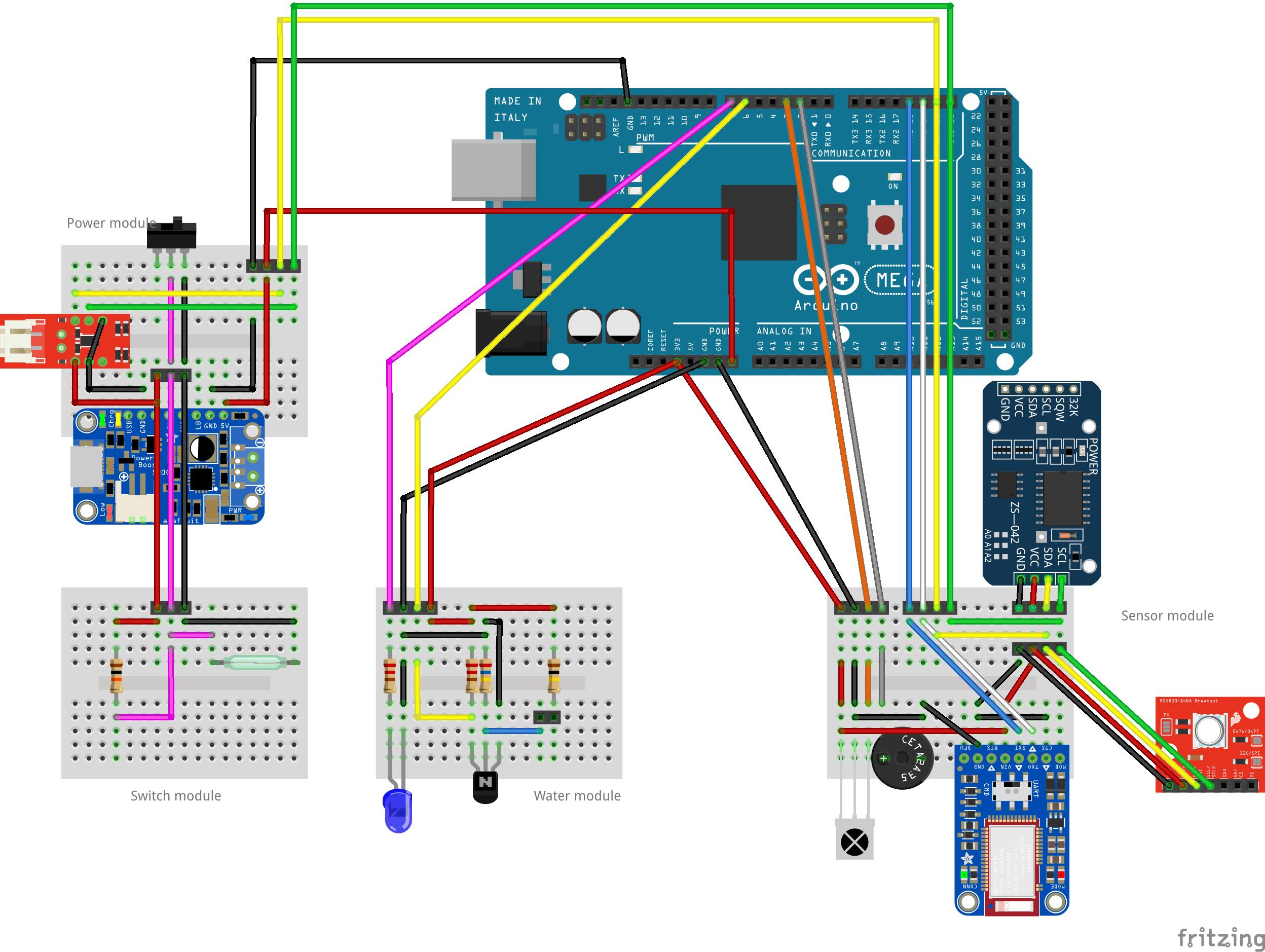

With that done and no major problems, load the part in to Fritzing and test it. This is to catch errors that the script can not (such as a terminalId existing but being in the wrong place). Here is a sketch of a typical test:

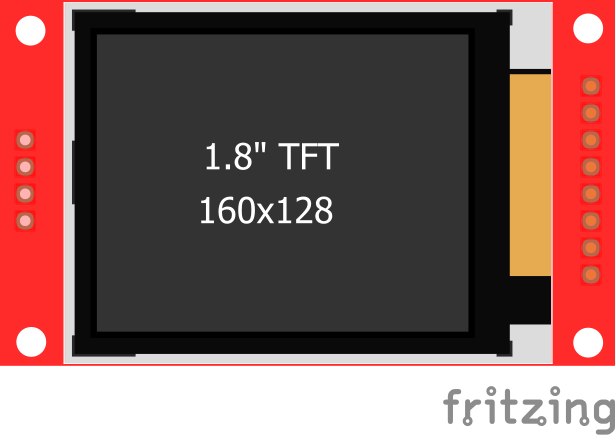

Resize and rescale to the proper scale. Copied in the connectors from pcb view via copy/ paste in Inkscape. Resized the tft display to fit inside the connectors (In real life it doesn’t but the connectors won’t work in breadboard that way). Added a rectangle as the underlying board. Resize regroup save and done.

Ungroup, resize rescale. Changed the pin designations to match the board and arrange them to match breadboard. Run the part through the part checking script to catch any typos or errors, zip it to an fzpz and test it in Fritzing (including generating and checking the gerber output). Looks fine, so post it.

In our last episode, I introduced Fritzing — a novice-friendly hardware design package that we are using to design a real time clock shield for an Arduino. We saw how we can use Fritzing to design the prototype for it on a breadboard. This time, we"ll see how to take that breadboard prototype and generate a schematic design. Then — still using Fritzing — we’ll convert it into a printed circuit board (PCB) layout that we will have manufactured for us by SparkFun’s BatchPCB service.

One thing to remember while going through all this is that Fritzing is but one among many open source hardware design tools that let you draw schematics and generate PCB files. However, Fritzing is unique (as far as I know) in that it also lets you draw the circuit first on a breadboard that then automatically generates the schematic and PCB drawings.

For those of us who prototype with breadboards, this gives us not only an intuitive entry into the design, but it produces excellent drawings that we can use for documenting our projects. You’ll see lots of Arduino projects on the Internet that use Fritzing for documentation. It is the clarity that the Fritzing drawings give that make this tool so popular.

So, I waited 10 minutes hoping the microspirits would work some magic ... but nothing. I removed the battery to reset it and after taking forever to completely reboot, I got the message in Figure 10 suggesting the Fritzing may have crashed.

I clicked on the .fzz file and followed the suggestions. I renamed the file just in case, and as luck would have it I was able to recover the work. (Yeah!) It took a while to get back in business, but again the price is right and frankly I’m having fun with Fritzing. One thing I noticed when recovering the file is that for some strange reason it was saving my work in the Windows downloads directory, so I created a new directory under C:\Fritzing\mySketches and moved my files there. (I had to leave again, but this time I closed Fritzing before closing my laptop.)

Fritzing has an auto-router, but we won’t use it since this is a very small board and I find routing is fairly intuitive. You just click on a pin and move the wire to the next connection and release it. Figure 16 shows what happened when I wired the VCC, GND, and crystal pins.

Well, let’s hope what Fritzing is showing us isn’t what it generates for the final PCB file. So, click on the ‘Export for PCB’ and the ‘Etchable (PDF)’ as shown in Figure 18.

Okay, I’m used to being able to set the pad and trace dimensions, but Fritzing doesn’t seem ready for that. Let’s reroute the troubling traces on the opposite side and see what we get.

I have to say that making a board with all that free space and the entire upper row of Arduino pins gives me the creeps — so much wasted space. Since we are making an Arduino shield we actually need all those pins so that we can — theoretically — mount another shield on top of the one we are making. [BTW, I found that you can — in fact — change the wire size in Fritzing! Just highlight the trace in question and you can change the width in the Inspector window Width dropdown box to 16, 24, 32, or 48 mils.]

Fritzing has a feature that lets you get your board fabricated in Europe. For an Arduino shield, it costs $38 + shipping. Frankly, I’d like to see these guys get rewarded for their efforts (which would also give them incentive to improve their product), but I know there are much less expensive options for those of us in the US, so let’s take a look at one: SparkFun’s BatchPCB. Of course, there is always a down side for every choice. BatchPCB is cheaper but it takes longer to get the board (to the US, 3-10 days for Fritzing; 3+ weeks for BatchPCB).

PCB fab houses require files in certain specific formats. We’ll use the Gerber format supported by Fritzing. Notice that the Fritzing ‘Export for PCB’ has an ‘Extended Gerber (RS-247X)...’ option, so let’s go with that. This generates the following files:

You can get Viewplot for free at www.viewplot.com. Click ‘File’ and ‘Load files,’ then navigate to the Gerber files in your Fritzing directory and load them.

These two parts of the Fritzing tutorial show you how to design and build your own DS1307 based real time clock, but if you just want one to play with, you can purchase Nuts & Volts webstore, which contains all the parts you’ll need including a PCB (better than the one we designed here) that we discussed in workshop 48.

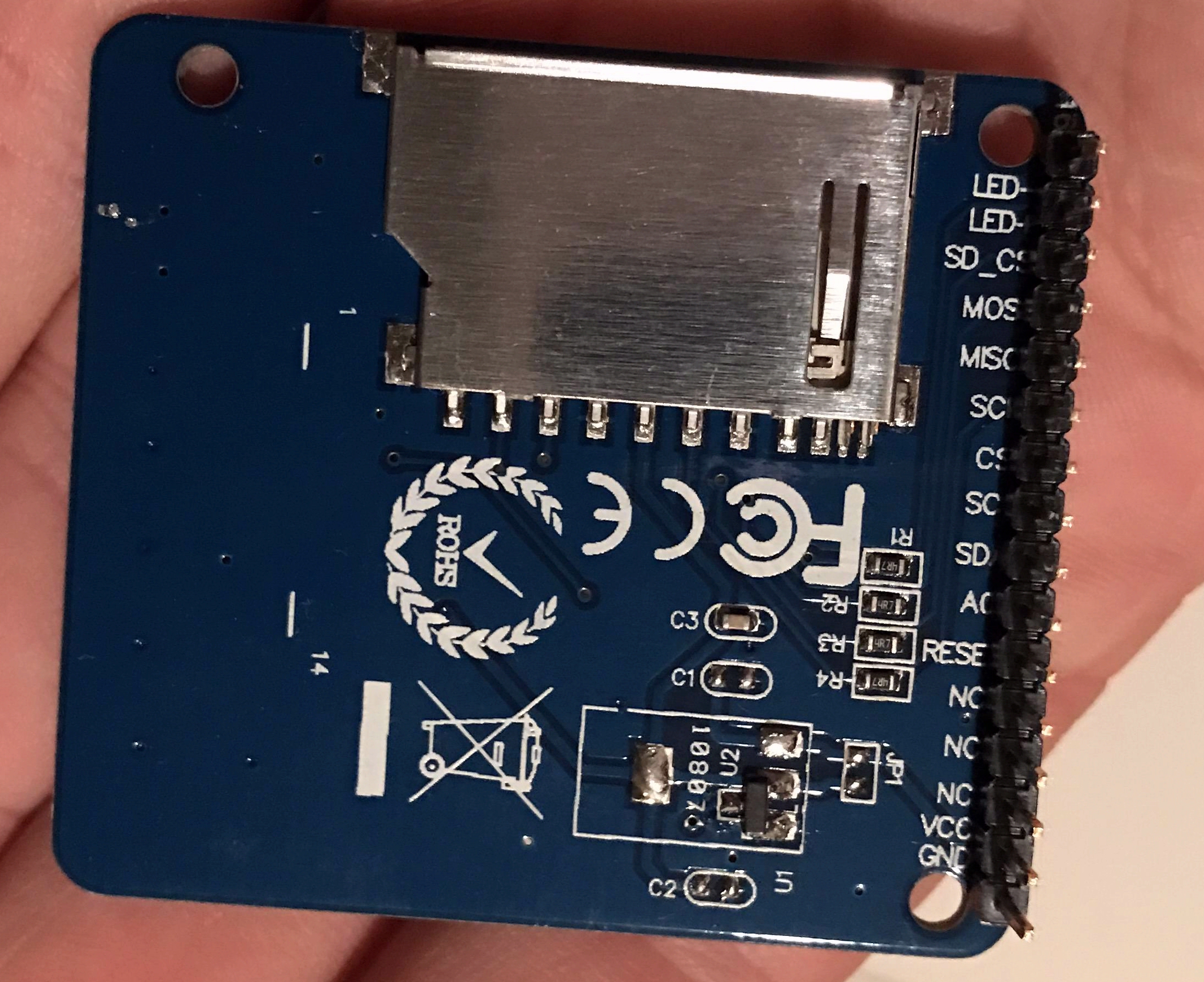

I"m trying to get an off-brand (REXQualis) Arduino Nano to display anything at all to a cheap 1.8" SPI TFT display, as seen here. As far as I can tell, the Nano has a pinout identical to the official branded ones.

Sometimes it is handy to have a small screen in your Arduino project. The 0.96 inch IPS color diplay is perfect for this. You can get the original Adafruit Color TFT display with SD card readerfor this for $20 (excluding shipping costs), but you can also find a clone on Chinese reseller websites or eBay. Mine did not include a SD card reader, but it was $3 (including shipping).

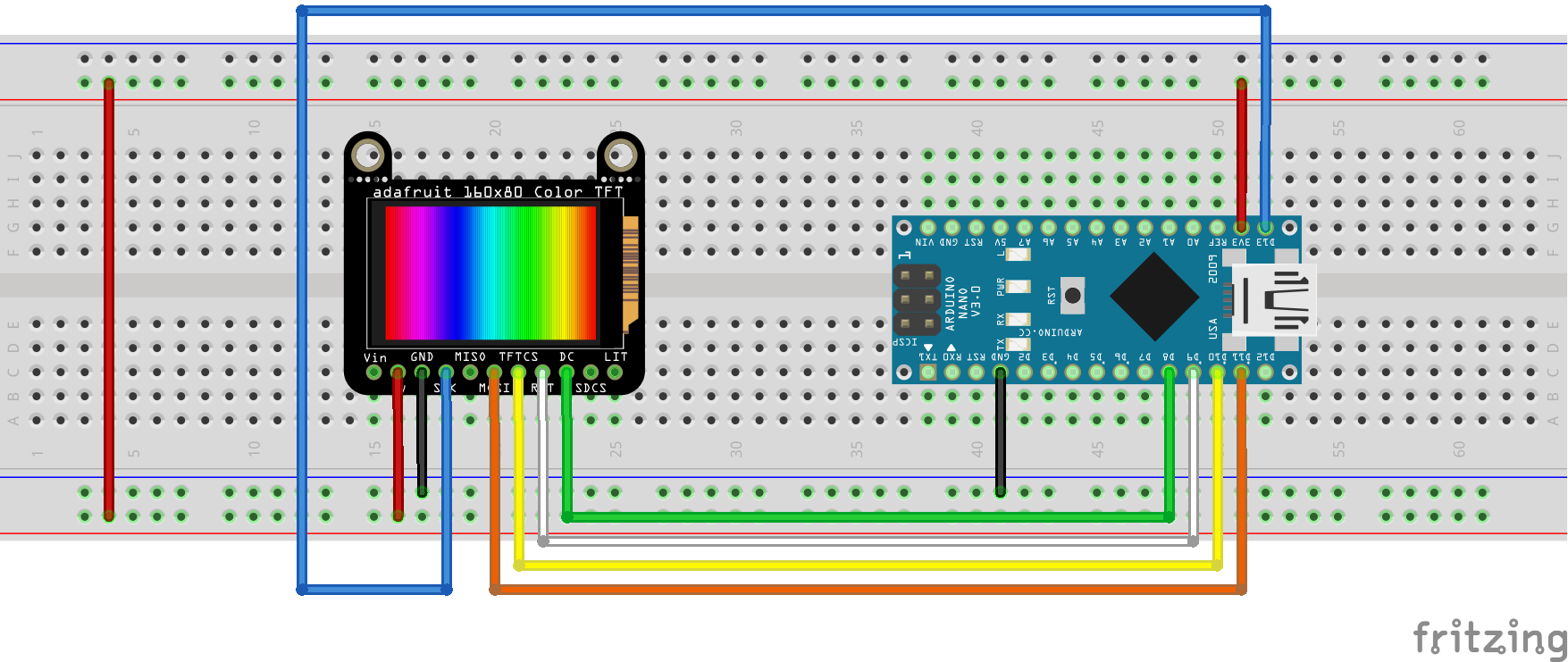

To make your project better to understand, you can also add board diagrams. This can be done using Fritzing. Just download the version supported by your OS. I have used the Windows 64-bit version and just needed to unzip it and start Fritzing.exe.

In my case I also needed a part that was not in the Fritzing database. Luckily there is a community that submits parts. It is located on the forum page. Adafruit also has parts on their Github page. To import the part just click the icon in the Parts frame and select Import...

I was now able to create the breadboard diagram. Below you see the breadboard diagram created with Fritzing app of how to connect the display to Arduino Nano.

The display part is Adafruit based, but I have created a table on how to translate the Original Adafruit 0.96" 160x80 Color TFT Display to Chinese Clone IPS 0.96 inch 7P SPI ST7735 module

As you are used to, I always illustrate my projects with ascheme made in Fritzing. The standard components are usually present in the default software. But often enough there are components not present. I then make these components myself. Because I have added a whole series again, I wanted to share my own new library, and here they are.

I decided a couple of months ago to run with the RF remote control project as a test-bed to try to learn how to lay out a custom PCB and have it manufactured. I had tried taking Chris’s class in EagleCAD and had found the interface to be pretty annoying and difficult. Chris had suggested looking at another tool, called Fritzing, but it took me a couple of months and seeing a couple of articles online about it before I finally downloaded the (free) software and tried it out: Bingo!

Fritzing is a very easy to use tool that let’s you capture (or design up-front) a breadboard circuit. With a breadboard, you just stick jumpers in holes to make connections; no soldering needed, easy to make changes until you get it working right. Fritzing lets you just drag wires into place with your mouse, on a graphic display that looks just like your breadboard:

[I actually used two different Arduinos during this project: the Boarduino version is very handy for breadboard work, as it plugs right into a breadboard for quick & easy prototyping. For the actual PCB, I wanted to make an Arduino shield, so in Fritzing I used a standard Arduino Uno. Plus, Fritzing doesn’t have a predefined part definition for the Boarduino…]

Fritzing includes predefined parts definitions for hundreds of common parts, including multiple Arduino versions and most of the parts in the the Sparkfun catalog. It also provides a “mystery” chip feature (the black box with the question-mark above) that lets you define the number and names of an arbitrary set of pins.

I was overjoyed to even get this far: just using Fritzing to document a breadboard design is incredibly valuable. I had been struggling to find some easy way to capture and document projects; Fritzing meets that need beautifully, even if you never need the schematic or board-layout features.

This shows my final design, omitting some intermediate steps. Fritzing has an “auto-route” feature that tries to lay out all the traces on the board so that they don’t overlap each other, using a double-sided board design if you need it (as this one did). Most likely it will fail to find a workable route for a few of the connections, but easily allows you to manually shift things around until you get a workable design. It can feel kind of like doing Rubic’s Cube at first, but with a little practice it isn’t too hard, at least for relatively simple circuits. Plus, Fritzing has a “check design rules” feature that validates nothing’s crossed and things are far enough apart to actually build and function properly.

I identified two leading vendors: one in Germany (http://fab.fritzing.org/fritzing-fab) would make me one (1) PCB for 28 Euros. The other in China (http://iteadstudio.com/) would make me ten (10) PCBs for $26. I couldn’t convince myself to spend more money for 10% as many boards, so I emailed my Gerber files off to China on New Years morning. And 22 days later, the mailman had me sign for a small box of PCBs.

Fritzing is an open-source initiativeCAD software for the design of electronics hardware, intended to allow designers and artists to build more permanent circuits from prototypes. It was developed at the University of Applied Sciences Potsdam.free software under the GPL 3.0 or later license, with the source code available on GitHub and the binaries at a monetary cost, which is allowed by the GPL.

Fritzing can be seen as an electronic design automation (EDA) tool for non-engineers: the input metaphor is inspired by the environment of designers (the breadboard-based prototype), while the output is focused on accessible means of production. As of December 2, 2014 Fritzing has made a code view option, where one can modify code and upload it directly to an Arduino device.

Fritzing allows for creation of printed circuit boards. Fritzing provides access to a commercial service known as ‘FritzingFab’ to order PCBs created with designs made on the Fritzing software.

Open up your vector graphics editor and create a new file. The image size of the file should be the same size of your board. The SparkFun T5403 Barometer Breakout size is 1" x 0.650". You are going to want to save the file with a good naming convention, since you are going to end up needing 3 different svg files when creating your Fritzing part.

To compare the different layers and groups, you can open up the Fritzing BreadboardViewGraphic_Template.svg file found in the Fritzing Fonts and Template folder you downloaded earlier. You can also open the example SparkFun T5403 Barometer Breakout breadboard SVG template file from the SparkFun Fritzing Parts Github repo.

The great thing with Fritzing is you can make your board as simple or as complex as you want. Since SparkFun is always trying to make our products better with revisions and have a lot of boards, it is easier and faster for us to not included certain details, like traces or every component, on our boards. That way if there is a new change with the board, like a resistor value change, we don"t have to go in and change that resistor in the Fritzing part. Focusing more on the important components, like ICs, might be a better way to spend your time. It will still look nice, but less work!

If you need an SMD LED on your board that is already in Fritzing, go ahead and use it! This will save you time and keep the all the Fritzing parts having the same look and feel. If you create a custom board with components that others can use, you can share them on the Fritzing site, so others can use too! Make sure to organize the component graphics nicely in the vector graphics editor you are using, so the parts are easy to find when using on future boards.

Stick with the Fritzing fonts to kept all Fritzing parts looking alike. It is suggested that the standard font size is 5pt. However, there will be times you won"t have space for smaller boards. You won"t want to go lower then 3pt, because it starts to become harder to see without zooming in. On the Fritzing site they mention using black as the font color. Whatever your silkscreen color is tends to look better. For this example we are using white, since that is the breakout board"s silkscreen color and it is easier to read against a red background.

Inkscape Users: For those using Inkscape, you will still create a rectangle using the rectangle tool. Set a color for the Fill: while leaving the Stroke: as Unset. Select the layers for the rectangle and board in the "Objects" tab with the Ctrl key. Next, go to Path -> Difference. The two layers will combine into one layer with the see through holes. You should see the same effect as if you were designing the board in Fritzing. For more information, check out the Inkscape tutorial using the Boolean operations.

Step 1 Gather Materials Before we begin, lets gather the components required for the build. You will need the following electronic components and PCBs:Raspberry Pi A+ 256MBAdafruit FONA uFL Version3.5in PiTFT AssembledRaspberry Pi Camera 5MPPowerboost 500 BasicGSM Antenna 1W 8 ohm Metal SpeakerUSB Wifi AdapterElectret Microphone 1200mah Lithium Ion Battery4-40 x 3/8in screws M2.5 x 5mm screws M2.5 x 20mm screws M2 x 5mm screws Slide SwitchWire

Step 3 Wire the Power Circuit Now lets start wiring everything together. In the Fritzing diagram, there is a Raspberry Pi. Instead of connecting to the Raspberry Pi, connect your wires to the 26 pin male header on the PiTFT. Now that we have that out of the way, lets start making connections.Connect "bat" on the Adafruit FONA to "bat" on the Power Boost. Solder a wire from GND on the FONA to GND on the Power Boost. Solder a wire from GND on the power boost to one terminal on a slide switch. Also connect the GND pin on the power boost to a ground pin on the PiTFT (Same Pinout as the first 26 pins on a Raspberry Pi, notice the arrow and "1" indicating pin 1, which is 3v3) Connect the 5V line on the Power Boost to a 5v pin on your PiTFT. Solder a wire from the middle terminal of your slide switch to the "EN" pin (Enable) on the Power Boost.

Solder a wire from the "KEY" pin on the FONA to Pin 40 (GPIO 21) on the Raspberry Pi. (Changed on commit acd5c08) Place the PiTFT over your Raspberry Pi A+ Double check your connections WHILE TESTING, MAKE SURE YOU DO NOT PLUG IN A 5V MICRO USB. THE PI IS ALREADY BEING POWERED BY THE LITHIUM ION BATTERY

If you slide the slide switch the LEDs on the Power Boost should illuminate and the Raspberry Pi should power up. The PiTFT backlight should also turn on. If you have a PiTFT image on your Pi"s SD card the screen should also boot up. Otherwise, it will just stay solid white, which is just fine for now. Most likely, no LEDs will illuminate on the FONA. To turn on the FONA, hold in the Key button on the device for two seconds or pull GPIO 18 on the Raspberry Pi high for two seconds. If you can power the Pi, TFT, and FONA from the battery and turn it all off from a switch, you are ready for the next step.

Step 4 Finish Wiring Now that power connection are done, we can continue on to wiring up the UART to the Raspberry Pi, the speakers, and the microphone. Lets get started.Solder the 8 ohm speaker to "spk +" and "spk -" on the FONA. The polarity doesn"t matter. Solder the red wire on the electret microphone to the Mic + pin on the FONA. Solder the black wire on the electret microphone to the Mic - pin on the FONA. Connect the "RI" (Ring indicator) pin on the Adafruit FONA to pin 7 (GPIO 4) on the PiTFT. Connect TX on the FONA to pin 10 (RX) on the PiTFT. Solder RX on the

FONA to pin 8 (TX) on the PiTFT. Solder Vio on the FONA to bat, also on the FONA. If you want, you could also use a 3v3 line on the Raspberry Pi. Snap the uFL antenna onto the uFL connector on the FONA. Double check your connections.

hardware wired up, we can setup the Raspberry Pi to communicate with it. Start by flashing the latest version of the PiTFT OS onto a micro SD card for your Raspberry Pi. You will want to use the latest PiTFT image, which can be downloaded here. Install the image to the SD card by following these instructions. Once your SD card is prepared, insert it into your Pi and power it on. You should get the raspi-config utility on your PiTFT. It may be small but it will do for now. There are a few things you must set up it raspi-config:Expand filesystem is a must. Enable Camera Disable serial port. This is so the Raspberry Pi can communicate with the FONA Enable SSH. This is essential because the A+ only has one USB port.

End setup and reboot your Pi. By typing startx the Raspberry Pi will enter LXDE on the PiTFT. To enter LXDE over the HDMI port typeFRAMEBUFFER=/dev/fb0 startx

Start X and see if the touchscreen is working properly. If the mouse is not in the correct spot when you tap, you will need to calibrate the touchscreen. Run this command to do so:sudo adafruit-pitft-touch-cal The script will calibrate the touchscreen to work with the new orientation.

microphone it the their slots. Using the M2 screws, screw in the Raspberry Pi camera. Route the ribbon cable so it is out of the way of any other electronics. Using M2.5 screws, screw the Raspberry Pi A+ with SD card and USB Wifi down into the case. Connect the Pi camera ribbon cable to the Pi with the blue facing the camera. Also using M2.5 screws, screw the FONA SIM card up into the case. Organise the wiring making sure it does not interfere with any of the other electronics. Wrap the Power Boost in electrical tape to prevent a short. Sandwich the Power Boost and battery between the Raspberry Pi and PiTFT. Hot glue the slide switch into the switch slot on the top part of the case. Using 4-40 screws, screw the top and bottom halves of the case together. Test everything out.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey