chi mei optoelectronics lcd panel manufacturer

CHIMEI Corporation (Chinese: 奇美實業; pinyin: Qíměi Shíyè; CMC) is a Taiwan-based performance materials company. It has long been known as the world’s largest vendor of ABS resins. It has factories in Tainan, Zhenjiang and Zhangzhou. It also produces advanced polymer materials, synthetic rubbers, and specialty chemicals.

CHIMEI Corporation is part of a privately held holding company called the CHIMEI Group, which has numerous subsidiaries. One of them is Chi Mei Optoelectronics (CMO), which was founded in 1997 as a subsidiary of Chi Mei Corporation. Chi Mei Group was the largest shareholder in publicly listed CMO. The new Chinese: 奇美電子, CMI) is the world"s No. 2 and Taiwan"s No. 1 largest maker of TFT-LCD panelsWestinghouse Digital Electronics. Though CEO Douglas Woo has maintained the confidentiality of the ownership of the private Westinghouse licensee, they admit a significant vertically integrated relationship exists between the two.

The company was founded by Shi Wen-long in 1960 as Chi Mei Industrial Company Ltd., the first acrylic sheet manufacturer in Taiwan; it was renamed CHIMEI Corporation in 1992.

In 2001, the CHIMEI Group along with IBM Japan set up International Display Technology, which it subsequently sold to Sony in 2005.price fixing conspiracy with respect to sales of TFT-LCDs between 2001 and 2006.

Established only in 1998, Chi Mei Optoelectronics Corporation (CMO) is one of the world"s leading manufacturers of thin-film transistor liquid crystal displays, better known as TFT-LCD flat-panel displays. The company produces more than 4.5 million flat-panel displays per year, and expects to top five million panels annually before 2006. CMO operates four LCM (liquid crystal display module) plants in Taiwan"s Southern Taiwan Science Park (STSP). That complex was subsidized by the Taiwanese government as part of its decision to make LCD displays one of the island"s key manufacturing areas. The company"s production operations include a 5.5G (generation) plant for production of 27-inch displays and a 6.0G plant for production of 32-inch displays. In 2005, CMO announced its intention to open an LCM plant in mainland China, in part because of a labor shortage in Taiwan. The opening of that plant will help CMO reclaim the industry"s top spot from chief rival AU Optronics. In addition to TFT-LCDs, CMO has been developing its own organic light-emitting diode (OLED) display capacity; the company also produces color filters. Chairman and founder Hsu Wen-lung, who suffered criticism from Beijing because of his support for Taiwan"s independence-minded government, stepped down from his position in 2005 as part of the company"s decision to enter the mainland. CMO is listed on the Taiwan Stock Exchange but remains controlled by Chi Mei Group, a petrochemicals conglomerate established by Hsu"s father in 1950.

Few companies so closely mirrored Taiwan"s evolution in the second half of the 20th century as Chi Mei Group and its publicly listed subsidiary Chi Mei Optoelectronics (CMO). Taiwan"s economy was virtually non-existent at the end of the 1940s, as the newly established government set out to convert itself from a predominantly agrarian base. The country turned toward the industrial sector, investing heavily to begin producing low-cost, and often low-quality, consumer items. With low wages and a vast workforce, Taiwan quickly became a source for discount goods the world over.

Chi Mei played a major role in this transition. The company originally focused on the retail sector, and was founded as a small children"s clothing store by Shu-Ho Shi in 1950. Shu chose the name Chi Mei, from the Chinese words for "Unique Beauty," for his store. Yet Chi Mei"s focus quickly expanded beyond retail sales.

A number of factors converged in the early 1950s to present a major opportunity for the company. Taiwan"s interest in developing its industrial sector, as well as the strong role the government played in directing the country"s economic and corporate policy, created a fertile environment for a new breed of entrepreneurs. At the same time, the development of new plastic technologies had opened up an extraordinarily large range of production possibilities. The timing for the new materials was perfect; the Western world was undergoing a period of sustained economic growth. The booming economies of the West not only created unprecedented levels of disposable income, but also steady advances in leisure time. Yet another factor came into play in the 1950s and 1960s: with more and more women joining the workforce, families began to shrink in size. Fewer children meant that parents were willing to spend more on each individual child, stimulating a surge in demand for children"s toys. Meanwhile, the use of plastics opened up a whole new range of potential shapes and colors, introducing one of the most creative eras of toy-making ever known.

Chi Mei entered the children"s toy market in 1953, setting up Chi Mei with its own manufacturing plant. The initial facility was quite modest, occupying just 26 square meters, manned by four employees. The company began producing toys and other household items, and the words "Made in Taiwan" quickly became ubiquitous throughout the Western world. Shu was joined by son Hsu Wen-lung, who became the driving force behind the company"s conversion into an industrial powerhouse.

By the late 1950s, however, Chi Mei had recognized a greater opportunity in producing the basic plastics materials themselves. In 1957, the company launched a research and development effort in order to establish its own methods for the production of acrylic sheets. This led to the creation of a new subsidiary, Chi Mei Industrial Co., led by Hsu Wen-lung. The company built a new industrial complex at Yen Chen Tainan, and launched production in 1960.

Chi Mei brought its acrylic sheets to the export market in 1963. Soon after the company launched production of one of its most successful products, Kibi Board, plywood sheets coated with decorative paper, sealed under a layer of polyester resin. By 1967, the company had developed a second, similar product, Mega Board, which differed from Kibi Board in that it was coated with an aminoalkyd resin. By then, too, the company also had begun to produce buttons, starting in 1964, and quickly became one of the world"s leading suppliers of buttons.

The success of its finished products enabled Chi Mei to begin its transformation into one of Taiwan"s leading petrochemicals groups toward the end of the 1960s. This effort began in 1965, with the creation of the company"s first technology transfer joint venture with Mitsubishi. The following year, Chi Mei launched a new research and development effort to build expertise in the production of expandable polystyrene (EPS). In 1968, Chi Mei turned to Mitsubishi again for technology, forming a new joint venture for the production of a larger range of polystyrene types, including general purpose polystyrene and high-impact polystyrene resins.

By the early 1970s, Chi Mei had established its first overseas plant, in the Philippines. The company"s polystyrene operations also became its largest component, topping its acrylic sheets sales by the middle of the decade. Through the next decade, the company continued to develop new plastics and petrochemicals capacity, becoming a leading producer of acrylic granulates and acrylic extrusion sheets. Into the 1990s, Chi Mei expanded its technology to include production of TPE rubber and other plastics. By then, the company had, in large part, exited its former finished goods production, dropping buttons in 1982 and both the Kibi and Mega Boards in 1985.

By the mid-1990s, however, Taiwan faced increasing competitive pressure from other emerging, low-cost markets. The country"s relatively high wages meant that it increasingly was unable to compete against the growing industrial strength of the developing markets. The gradual emergence of mainland China as a low-cost consumer goods producer especially promised to transform the industrial landscape on a global scale.

In recognition of the shifting situation, the Taiwanese government began encouraging the transformation of its economy toward higher-end technological sectors. Into the mid-1990s, the TFT-LCD market had becoming one of the most promising of the high-tech growth markets. The development of new generations of portable telephones, the promise of digital cameras, and the increasing development of portable computers as a consumer and even household appliance, but especially the development of the first generation of LCD-based televisions, encouraged the Taiwanese government to target that sector for its new technology initiatives.

Another factor played a role in Taiwan"s development as a center for world TFT-LCD production. Liquid crystals had been discovered as early as 1888 by Friedrich Reinitzer, a botanist in Austria. Yet the first practical application of liquid crystals did not take place until the late 1960s, when the United States" RCA launched the first display utilizing LCD technology. During the 1970s, however, the center of LCD technology shifted to Japan, and the country emerged as the global center for LCD production. The Japanese jealously guarded their technology, maintaining control of the market into the late 1990s.

Yet the collapse of the Japanese economy during the decade left the country"s TFT-LCD manufacturers cash-strapped just at a time when the world saw a surge in demand for TFT-LCD displays. In order to ensure the continued growth in production, the Japanese manufacturers began seeking joint ventures elsewhere, in South Korea and especially Taiwan. There, the Japanese companies found a ready list of cash-rich companies willing to enter TFT-LCD production.

Chi Mei decided to enter the market in 1997, setting up operations for the production of color filters, under Chi Mei Electronics (CME), and TFT-LCD displays, under Chi Mei Optoelectronics (CMO). By 1998, the company had signed on its first technology partner, Fujitsu, which entered into an alliance with CME. This was soon followed by the group"s first TFT-LCD partnership, again with Fujitsu. By 1999, CMO and Fujitsu had strengthened their partnership to include an agreement to co-develop new large-screen LCD technologies. Chi Mei also began production of LCD monitors, under a new subsidiary set up that year, Arch Technology Inc. By the end of that year, as well, CMO had succeeded in producing 14-inch TFT-LCD panels. This led the company to sign a new long-term development supply alliance with Dell Computer.

Mission Statement: Business as a Way to Pursue Fulfillment. Human Management and Harmony are the most important and have been the operating principles of the whole Chi Mei Group.

CMO took over the operations of CME in 2000 as the company geared up its vertical integration model, an important part of its strategy for its future display technologies growth. The company also was gaining expertise in large-sized panels, launching its first 18-inch display panel early the next year.

The year 2001 marked a new milestone for CMO"s development into one of the world"s leading producers of TFT-LCD panels. In August of that year, the company agreed to take over IBM of Japan"s Yasu Industrial Complex, acquiring not only its Japanese production capacity, but especially its technology. This acquisition led the company to focus on its panel display development, selling off the consumer-oriented Arch Technology.

By 2002, CMO had unveiled its first 30-inch TFT-LCD television display. In that year, CMO went public, the first member of the Chi Mei Group to do so. By then, CMO had become the motor for Chi Mei"s overall growth, serving as the group"s largest revenue generator.

The maturation of Taiwan"s LCD industry was clearly in place in the early 2000s. Not only had the island become the center of worldwide LCD production, boasting most of the world"s top five producers, the country also had emerged as a leading technological center. This development was highlighted by CMO"s announcement in 2003 that it had decided to develop its own color-filter technology for new generation display panels, becoming the first of the big six Taiwanese producers to set up its own color filter facilities.

CMO launched a new fifth-generation production facility in 2003, and began preparations to open a sixth generation and seventh generation plant at mid-decade. By 2005, the company had developed its expertise in the production of panels up to 32 inches in size. This led the company to reach an agreement with Sony Corporation to sell its 3G plant in Japan in 2004.

CMO remained the last of the major Taiwanese LCD producers to enter the mainland Chinese market, in part because of founder and Chairman Hsu Wen-lung"s open support for Taiwan President Chen Shui-ban. Yet difficulties in recruiting new workers, especially the lower wages of the Chinese mainland, left CMO in a vulnerable position vis-à-vis its competitors.

When CMO launched plans to develop production capacity in the mainland, however, it found itself in the middle of the political battle being waged between Beijing and Taiwan. After the Chinese government"s newspaper, the People"s Daily, branded Hsu as "a shameless anti-Chinese bigot," and further indicated that the country would not welcome "these sort of Taiwanese business people," Hsu conceded defeat and resigned from his post as chairman of CMO. Then in 2005, Hsu gave a speech in which he publicly stated that Taiwan and the mainland were part of "one" China. Soon afterward, CMO received permission to build its first LCD module plant in China. The move was expected to help the company reclaim its title as industry leader, which was captured by rival AU Optronics in August of that year. From toy maker to global technological leader, Chi Mei, with its publicly listed subsidiary CMO, had established itself as a quintessential member of Taiwan"s industrial community.

Key Dates:1950:Shu-Ho Shi sets up the Chi Mei retail store selling children"s clothing in Taiwan.1953:Chi Mei launches industrial production of plastic toys and household goods.1957:Under son Hsu Wen-lung, Chi Mei begins production of acrylic sheeting.1968:The company launches production of polystyrene.1997:The company announces its intention to begin production of TFT-LCD panels.1998:Chi Mei Optoelectronics (CMO) is created.1999:A technology transfer agreement is made with Fujitsu.2001:The company acquires an LCD fab in Japan from IBM.2004:Hsu Wen-lung steps down as chairman after the mainland Chinese government labels him "a shameless anti-Chinese bigot."2005:CMO receives approval to set up production facilities in mainland China.

Chi Mei Optoelectronics Corporation - Company Profile, Information, Business Description, History, Background Information on Chi Mei Optoelectronics Corporation

Mission Statement: Business as a Way to Pursue Fulfillment. Human Man agement and Harmony are the most important and have been the operatin g principles of the whole Chi Mei Group.

Established only in 1998, Chi Mei Optoelectronics Corporation (CMO) i s one of the world"s leading manufacturers of thin-film transistor li quid crystal displays, better known as TFT-LCD flat-panel displays. T he company produces more than 4.5 million flat-panel displays per yea r, and expects to top five million panels annually before 2006. CMO o perates four LCM (liquid crystal display module) plants in Taiwan"s S outhern Taiwan Science Park (STSP). That complex was subsidized by th e Taiwanese government as part of its decision to make LCD displays o ne of the island"s key manufacturing areas. The company"s production operations include a 5.5G (generation) plant for production of 27-inc h displays and a 6.0G plant for production of 32-inch displays. In 20 05, CMO announced its intention to open an LCM plant in mainland Chin a, in part because of a labor shortage in Taiwan. The opening of that plant will help CMO reclaim the industry"s top spot from chief rival AU Optronics. In addition to TFT-LCDs, CMO has been developing its o wn organic light-emitting diode (OLED) display capacity; the company also produces color filters. Chairman and founder Hsu Wen-lung, who s uffered criticism from Beijing because of his support for Taiwan"s in dependence-minded government, stepped down from his position in 2005 as part of the company"s decision to enter the mainland. CMO is liste d on the Taiwan Stock Exchange but remains controlled by Chi Mei Grou p, a petrochemicals conglomerate established by Hsu"s father in 1950.

Few companies so closely mirrored Taiwan"s evolution in the second ha lf of the 20th century as Chi Mei Group and its publicly listed subsi diary Chi Mei Optoelectronics (CMO). Taiwan"s economy was virtually n on-existent at the end of the 1940s, as the newly established governm ent set out to convert itself from a predominantly agrarian base. The country turned toward the industrial sector, investing heavily to be gin producing low-cost, and often low-quality, consumer items. With l ow wages and a vast workforce, Taiwan quickly became a source for dis count goods the world over.

Chi Mei played a major role in this transition. The company originall y focused on the retail sector, and was founded as a small children"s clothing store by Shu-Ho Shi in 1950. Shu chose the name Chi Mei, fr om the Chinese words for "Unique Beauty," for his store. Yet Chi Mei" s focus quickly expanded beyond retail sales.

A number of factors converged in the early 1950s to present a major o pportunity for the company. Taiwan"s interest in developing its indus trial sector, as well as the strong role the government played in dir ecting the country"s economic and corporate policy, created a fertile environment for a new breed of entrepreneurs. At the same time, the development of new plastic technologies had opened up an extraordinar ily large range of production possibilities. The timing for the new m aterials was perfect; the Western world was undergoing a period of su stained economic growth. The booming economies of the West not only c reated unprecedented levels of disposable income, but also steady adv ances in leisure time. Yet another factor came into play in the 1950s and 1960s: with more and more women joining the workforce, families began to shrink in size. Fewer children meant that parents were willi ng to spend more on each individual child, stimulating a surge in dem and for children"s toys. Meanwhile, the use of plastics opened up a w hole new range of potential shapes and colors, introducing one of the most creative eras of toy-making ever known.

Chi Mei entered the children"s toy market in 1953, setting up Chi Mei with its own manufacturing plant. The initial facility was quite mod est, occupying just 26 square meters, manned by four employees. The c ompany began producing toys and other household items, and the words "Made in Taiwan" quickly became ubiquitous throughout the Western wor ld. Shu was joined by son Hsu Wen-lung, who became the driving force behind the company"s conversion into an industrial powerhouse.

By the late 1950s, however, Chi Mei had recognized a greater opportun ity in producing the basic plastics materials themselves. In 1957, th e company launched a research and development effort in order to esta blish its own methods for the production of acrylic sheets. This led to the creation of a new subsidiary, Chi Mei Industrial Co., led by H su Wen-lung. The company built a new industrial complex at Yen Chen T ainan, and launched production in 1960.

Chi Mei brought its acrylic sheets to the export market in 1963. Soon after the company launched production of one of its most successful products, Kibi Board, plywood sheets coated with decorative paper, se aled under a layer of polyester resin. By 1967, the company had devel oped a second, similar product, Mega Board, which differed from Kibi Board in that it was coated with an aminoalkyd resin. By then, too, t he company also had begun to produce buttons, starting in 1964, and q uickly became one of the world"s leading suppliers of buttons.

The success of its finished products enabled Chi Mei to begin its tra nsformation into one of Taiwan"s leading petrochemicals groups toward the end of the 1960s. This effort began in 1965, with the creation o f the company"s first technology transfer joint venture with Mitsubis hi. The following year, Chi Mei launched a new research and developme nt effort to build expertise in the production of expandable polystyr ene (EPS). In 1968, Chi Mei turned to Mitsubishi again for technology , forming a new joint venture for the production of a larger range of polystyrene types, including general purpose polystyrene and high-im pact polystyrene resins.

By the early 1970s, Chi Mei had established its first overseas plant, in the Philippines. The company"s polystyrene operations also became its largest component, topping its acrylic sheets sales by the middl e of the decade. Through the next decade, the company continued to de velop new plastics and petro-chemicals capacity, becoming a leading p roducer of acrylic granulates and acrylic extrusion sheets. Into the 1990s, Chi Mei expanded its technology to include production of TPE r ubber and other plastics. By then, the company had, in large part, ex ited its former finished goods production, dropping buttons in 1982 a nd both the Kibi and Mega Boards in 1985.

By the mid-1990s, however, Taiwan faced increasing competitive pressu re from other emerging, low-cost markets. The country"s relatively hi gh wages meant that it increasingly was unable to compete against the growing industrial strength of the developing markets. The gradual e mergence of mainland China as a low-cost consumer goods producer espe cially promised to transform the industrial landscape on a global sca le.

In recognition of the shifting situation, the Taiwanese government be gan encouraging the transformation of its economy toward higher-end t echnological sectors. Into the mid-1990s, the TFT-LCD market had beco ming one of the most promising of the high-tech growth markets. The d evelopment of new generations of portable telephones, the promise of digital cameras, and the increasing development of portable computers as a consumer and even household appliance, but especially the devel opment of the first generation of LCD-based televisions, encouraged t he Taiwanese government to target that sector for its new technology initiatives.

Another factor played a role in Taiwan"s development as a center for world TFT-LCD production. Liquid crystals had been discovered as earl y as 1888 by Friedrich Reinitzer, a botanist in Austria. Yet the firs t practical application of liquid crystals did not take place until t he late 1960s, when the United States" RCA launched the first display utilizing LCD technology. During the 1970s, however, the center of L CD technology shifted to Japan, and the country emerged as the global center for LCD production. The Japanese jealously guarded their tech nology, maintaining control of the market into the late 1990s.

Yet the collapse of the Japanese economy during the decade left the c ountry"s TFT-LCD manufacturers cash-strapped just at a time when the world saw a surge in demand for TFT-LCD displays. In order to ensure the continued growth in production, the Japanese manufacturers began seeking joint ventures elsewhere, in South Korea and especially Taiwa n. There, the Japanese companies found a ready list of cash-rich comp anies willing to enter TFT-LCD production.

Chi Mei decided to enter the market in 1997, setting up operations fo r the production of color filters, under Chi Mei Electronics (CME), a nd TFT-LCD displays, under Chi Mei Optoelectronics (CMO). By 1998, th e company had signed on its first technology partner, Fujitsu, which entered into an alliance with CME. This was soon followed by the grou p"s first TFT-LCD partnership, again with Fujitsu. By 1999, CMO and F ujitsu had strengthened their partnership to include an agreement to co-develop new large-screen LCD technologies. Chi Mei also began prod uction of LCD monitors, under a new subsidiary set up that year, Arch Technology Inc. By the end of that year, as well, CMO had succeeded in producing 14-inch TFT-LCD panels. This led the company to sign a n ew long-term development supply alliance with Dell Computer.

CMO took over the operations of CME in 2000 as the company geared up its vertical integration model, an important part of its strategy for its future display technologies growth. The company also was gaining expertise in large-sized panels, launching its first 18-inch display panel early the next year.

The year 2001 marked a new milestone for CMO"s development into one o f the world"s leading producers of TFT-LCD panels. In August of that year, the company agreed to take over IBM of Japan"s Yasu Industrial Complex, acquiring not only its Japanese production capacity, but esp ecially its technology. This acquisition led the company to focus on its panel display development, selling off the consumer-oriented Arch Technology.

By 2002, CMO had unveiled its first 30-inch TFT-LCD television displa y. In that year, CMO went public, the first member of the Chi Mei Gro up to do so. By then, CMO had become the motor for Chi Mei"s overall growth, serving as the group"s largest revenue generator.

The maturation of Taiwan"s LCD industry was clearly in place in the e arly 2000s. Not only had the island become the center of worldwide LC D production, boasting most of the world"s top five producers, the co untry also had emerged as a leading technological center. This develo pment was highlighted by CMO"s announcement in 2003 that it had decid ed to develop its own color-filter technology for new generation disp lay panels, becoming the first of the big six Taiwanese producers to set up its own color filter facilities.

CMO launched a new fifth-generation production facility in 2003, and began preparations to open a sixth generation and seventh generation plant at mid-decade. By 2005, the company had developed its expertise in the production of panels up to 32 inches in size. This led the co mpany to reach an agreement with Sony Corporation to sell its 3G plan t in Japan in 2004.

CMO remained the last of the major Taiwanese LCD producers to enter t he mainland Chinese market, in part because of founder and Chairman H su Wen-lung"s open support for Taiwan President Chen Shui-ban. Yet di fficulties in recruiting new workers, especially the lower wages of t he Chinese mainland, left CMO in a vulnerable position vis-à-v is its competitors.

When CMO launched plans to develop production capacity in the mainlan d, however, it found itself in the middle of the political battle bei ng waged between Beijing and Taiwan. After the Chinese government"s n ewspaper, thePeople"s Daily, branded Hsu as "a shameless anti -Chinese bigot," and further indicated that the country would not wel come "these sort of Taiwanese business people," Hsu conceded defeat a nd resigned from his post as chairman of CMO. Then in 2005, Hsu gave a speech in which he publicly stated that Taiwan and the mainland wer e part of "one" China. Soon afterward, CMO received permission to bui ld its first LCD module plant in China. The move was expected to help the company reclaim its title as industry leader, which was captured by rival AU Optronics in August of that year. From toy maker to glob al technological leader, Chi Mei, with its publicly listed subsidiary CMO, had established itself as a quintessential member of Taiwan"s i ndustrial community.

"Originally established in 2003 and publicly listed in 2006. The company merged with Chi Mei Optoelectronics and Toppoly Optoelectronics in March 2010, in what was the largest merger in the flat panel display industry. Chimei Innolux Corporation was the successor company, and it initially preserved the Chimei name. In order to differentiate itself from the ChiMei brand, the company was renamed "Innolux Corporation" in December 2012...

As a supplier of TFT-LCD panels, Innolux Corporation has contributed greatly to enhancing the quality and product performance through its innovations in technology and production processes. Innolux is committed to enhancing life"s visual pleasures and to developing aesthetically designed display products."

Innolux Corporation (Chinese: 群創光電股份有限公司; pinyin: Qúnchuàng Guāngdiàn Gǔfèn Yǒuxiàn Gōngsī) is a company producing TFT LCD panels, established in 2003 and located in Taiwan.

Innolux Display Corp., following its merger with Chi Mei Optoelectronics and TPO Displays Corp., began operating under the name Innolux Corporation (INX) in March 2010.

With products spanning the full range of TFT-LCD panel modules and touch panels, including TV panels, desktop monitors and notebook computer panels, AV & mobile panels, Innolux is a TFT-LCD supplier to information technology and consumer electronics product makers worldwide.

Originally established in 2003 and publicly listed in 2006, Innolux merged with Chi Mei Optoelectronics and Toppoly Optoelectronics in March 2010, in what was the largest merger in the flat panel display industry. Chimei Innolux was the successor company and it initially preserved the Chimei name. In order to differentiate itself from the ChiMei brand, the company was renamed Innolux in December 2012. Based in Taiwan, Innolux produces a full range of large, medium and small LCD panels and touch-control screens. It has 58,000 employees and production sites and sales locations worldwide.

Originally established in 2003 and publicly listed in 2006. The company merged with Chi Mei Optoelectronics and Toppoly Optoelectronics in March 2010, in what was the largest merger in the flat panel display industry. Chimei Innolux Corporation was the successor company, and it initially preserved the Chimei name. In order to differentiate itself from the ChiMei brand, the company was renamed "Innolux Corporation" in December 2012.

Innolux"s 14 plants possess a complete range of 3.5G, 4G, 4.5G, 5G, 6G, 7.5G, and 8.5G-8.6G production line, making it the world"s total display solutions provider offering a full range of large/medium/small LCD panels and touch-control screens.Innolux offers advanced display integration solutions employing innovative, differentiated technology, including 4K2K ultra-high resolution, 3D naked eye, IGZO, LTPS, AMOLED, OLED, and touch-control solutions. Innolux is active in drafting specifications, and is a market trend leader. Its all-inclusive product lines span the full range of TFT LCD panel modules and touch panels, including TV panels, desktop monitors, notebook computer panels, small and medium-sized panels, and medical and automotive panels. The world"s leading manufacturer of TFT-LCD displays, Innolux supplies customers that include many of the world"s leading information and consumer electronics manufacturers.

Chi Mei EL Corporation (CMEL), founded by the R&D team at Chi Mei Optoelectronics (CMO) in 2004, is fully devoted to the R&D, design, production, and sales of OLED panels.

CMEL currently focuses on small and medium-sized OLED panel production. Their largest panel available is 7.6" AMOLED. The company has over 210 employees and is fully owned by Chi Mei Optoelectronics.

Innolux Corporation (Innolux), formerly Chimei Innolux Corporation, is a Taiwan-based company primarily engaged in research, development, manufacture and distribution of thin film transistor liquid crystal display (TFT-LCD) panel modules and LCD monitors. The company will be strong enough to challenge the leading CMI was formed in March 2010 following the merger of LCD monitor maker Innolux Display, Chi Mei Optoelectronics (CMO), and handheld device panel supplier TPO Display.position of AUO Optronics and becoming the world No. 3 liquid-crystal-display (LCD) panel maker.

The Company"s major products include LCD television panels, monitor panels, notebook computer display panels, audio/video (AV) and mobile display panels, medical display panels and special-application panels. Its products are applied in mobile communication products, information product and household electrical appliances. The Company operates international divisions in Japan, the United States, Holland, England, Germany and Singapore. The Company has production facilities in Jhunan and Tainan(Taiwan), Ningbo, Zhejiang Province, and Foshan, Guangdong province in China.

The Company"s major products include LCD television panels, monitor panels, notebook computer display panels, audio/video (AV) and mobile display panels, medical display panels and special-application panels. Its products are applied in mobile communication products, information product and household electrical appliances. The Company operates international divisions in Japan, the United States, Holland, England, Germany and Singapore. The Company has production facilities in Ningbo, Zhejiang Province, and Foshan, Guangdong province, China. It distributes its products principally in Taiwan, Japan, the United States, Europe and Mainland China.

Chi Mei Corporation established Chi Mei Optoelectronics (CMO) in 1998. Company shares began trading on the Taiwan Stock Exchange in August of 2002. Our main products are LCD TV panels and LCD panel displays for desktop and notebook computers, delivered to IT and home electronics vendors worldwide. CMO is a global industry leader in TFT- LCD manufacturing. In its perseverance to promote LCD TV and LCD panels in universal applications, CMO has earned the industry"s trust and respect as a first-rate manufacturer with world-class display technology. With production facilities are based in Southern Taiwan Science Park, we are currently operating one 3.5G, 4G, 5.5, 6G, and G7.5 plant each, as well as two 5G plants. Besides producing LCD panels for nearly every specification on the market, capacity on all production lines can be easily adjusted to meet customer requests. Long-term global technology exchanges have boosted our R&D efforts and ensured a leading position. Product quality has been applauded by customers and industry peers alike. CMO"s remarkable product development is manifested in its 56-inch LCD TV panel, launched in 2005. The panel"s image resolution is unbeatable: 3840x2160 to be exact. CMO has maintained a significant lead by being the first to establish specifications for 19 and 22-inch wide-screen panels, a move that has stimulated new buying interest on the wide-screen panel market. CMO really begins to show off its superior technology in special-application products, most notably avionic displays. Both weather and shock- resistant, CMO"s line of avionic displays come standard with ultra high resolution and a wide viewing angle. CMO"s medical panels provide ultra high resolution, high brightness and high contrast. The cluster solution is important to the optoelectronics sector as an effective way to sharpen competitive edge. CMO understands its duties as a vital link in the global optoelectronics supply chain. At CMO we firmly believe that, aside from pursuing profits, human interests and values are what really make a company succeed. By providing the most enjoyable visual experience possible and strengthening the influence of Taiwan"s display manufacturing sector on the global market, CMO hopes to contribute to the advancement of society as a whole. Combining technology with the arts and humanities, CMO is striving to make a better life for all of us.

Chi Mei Optoelectronics Corp (奇美電子), the nation’s No. 2 liquid-crystal-display (LCD) panel maker, said yesterday it hoped to close a three-way merger with panel makers Innolux Display Corp (群創光電) and TPO Displays Corp (統寶光電) in March, one month earlier than scheduled.

The share-swap merger came amid the LCD panel industry’s rapid recovery from last year’s slump as consumers resume spending on electronics because of the improving global economy, led mostly by Asian countries like China.

Chi Mei Optoelectronics chairman Frank Liao (廖錦祥) told shareholders that the merger would have a synergistic effect in terms of capacity, capital, customers and raw material suppliers. Liao said the three companies were complementary to each other in terms of flat-panel manufacturing technologies. Early integration would maximize the effect, he said.

Innolux said at the time that it would issue 2.95 billion common shares to Chi Mei Optoelectronics and 528 million to TPO Displays. The resultant company will be named Chimei Innolux Corp.

Shareholders of Innolux and TPO yesterday gave their go-ahead to the plan, which will create the nation’s biggest LCD panel maker, unseating AU Optronics Corp (友達光電).

The companies yesterday also gave positive forecasts for the LCD industry. Innolux chairman Tuan Hsing-chien (段行建) said demand was better than he had expected last month and that inventory was healthy.

The positive outlook is reflected in plans to hike prices aggressively for PC monitor and TV panels in the first half of this month as demand looks stronger than expected, market researcher DisplaySearch said in a report released on Tuesday.

“TV brands are continuing to stock more panels for the sales planned for the next one to two months, especially since the demand from China TV brands remains firm in January, which shifts power to the panel sell-side,” DisplaySearch said in the report.

The price for mainstay 19-inch PC monitor panels rose 2.7 percent, or US$2, to US$77 per unit for the first two weeks of this month from the previous two weeks, the report showed. Prices for 32-inch TV panels may climb nearly 1 percent to US$205 per unit, it said.

A wide variety of chimei lcd panels options are available to you, You can also choose from original manufacturer, odm and agency chimei lcd panels,As well as from tft, ips, and tn.

It offers television, desktop monitors and notebook computer, audio and video, and mobile panels. It also offers glass, film, and one glass capacitive touch panels. Originally established in 2003 and publicly listed in 2006. The company merged with Chi Mei Optoelectronics and Toppoly Optoelectronics in March 2010, in what was the largest merger in the flat panel display industry. Chimei Innolux Corporation was the successor company, and it initially preserved the Chimei name. In order to differentiate itself from the ChiMei brand, the company was renamed "Innolux Corporation" in December 2012.

Innolux"s 14 plants in Taiwan possess a complete range of 3.5G, 4G, 4.5G, 5G, 6G, 7.5G, and 8.5G-8.6G production line, making it the world"s total display solutions provider offering a full range of large/medium/small LCD panels and touch-control screens.Innolux offers advanced display integration solutions employing innovative, differentiated technology, including 4K2K ultra-high resolution, 3D naked eye, IGZO, LTPS, AMOLED, OLED, and touch-control solutions. Innolux is active in drafting specifications, and is a market trend leader. Its all-inclusive product lines span the full range of TFT LCD panel modules and touch panels, including TV panels, desktop monitors, notebook computer panels, small and medium-sized panels, and medical and automotive panels. The world"s leading manufacturer of TFT-LCD displays, Innolux supplies customers that include many of the world"s leading information and consumer electronics manufacturers.

After its creation in a three-in-one merger, in order to increase its integration and synergy, Innolux has made in Taiwan its R&D center, is training core technical manpower, and is increasing its capacity in order to better serve the needs of its many customers worldwide. Compared with conventional panel manufacturers only bearing responsibility for panel production, Innolux provides access to an integrated product manufacturing and supply chain, and provides customers complete solutions based on its panel expertise, vertical integration, and innovative business methods. Apart from its extensive TFT-LCD experience and superlative quality, Innolux is applying its advanced management skills to the perfection of process technologies and components.

Innolux"s employees worldwide number more than 56,000, and its production sites and sales locations span the globe. With its major TFT plants located in Zhunan and Tainan, both in Taiwan, Innolux has also established overseas module plants in the Chinese cities of Ningbo, Nanjing, Foshan, and Shanghai. Innolux"s extensive global presence allows it to quickly provide a full range of services to its customers, reducing logistics and manpower costs, while achieving the environmental objectives of energy conservation and reduced carbon emissions. Innolux"s unique intelligent management platform has not only enhanced the company"s management capabilities, but also provides customers with prompt, accurate delivery information. This is just one of the ways we are constantly striving to boost customer satisfaction.

Innolux is rooted in Taiwan, but has global ambitions. As a leader in the global optoelectronics industry chain, Innolux has many responsibilities and duties. It is actively recruiting and training R&D talent in order to consolidate its prominent status in the industry. Innolux is striving to realize the apex in human visual enjoyment, and relies on its "inimitable competitiveness" to ensure corporate sustainability and provide the greatest possible satisfaction and benefit to shareholders, customers, employees, and all of society.

SmarterGlass is honored to provide Innolux displays. Innolux is a vast display manufacturer covering all verticals including, industrial, consumer, and automotive. Trust us to find the panel that fits your project.

Innolux merged with Chi Mei Optoelectronics (CMO) and Toppoly Optoelectronics in 2010. The resultant company was named Chimei Innolux (CMI). They renamed the company Innolux in 2012. We can source CMO, CMI, Toppoly, and Innolux panels. Contact us so we can source the displays you need today.

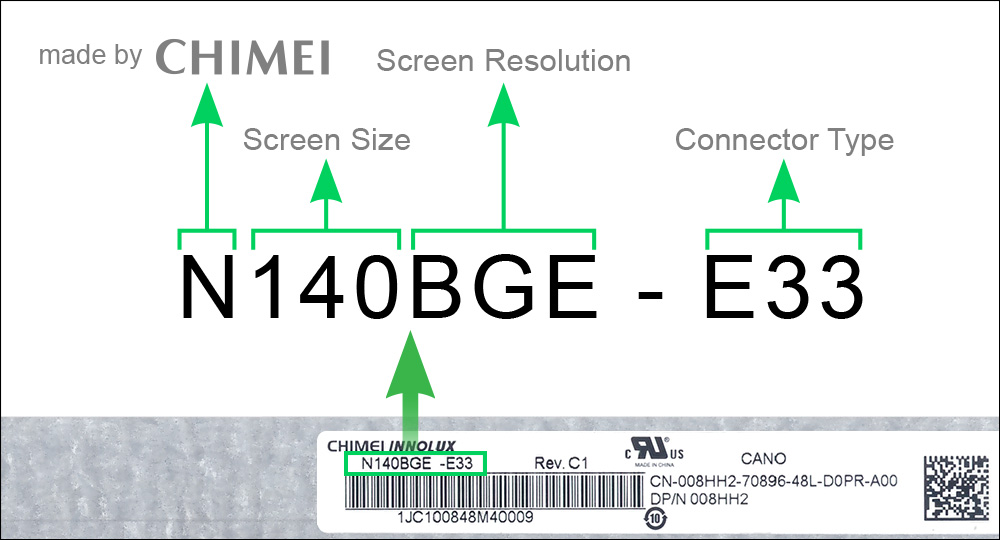

Chi Mei Optoelectronics (CMO)Location: There is a label on the back of the display with “Chi Mei Optoelectronics” written. The part number is on the label above the barcode.

Toppoly Optoelectronics (TPO)Location:There is a label on the back of the display with a bar code. The part number is on the label on the left above the bar code.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey