prusa i3 mk3 lcd screen made in china

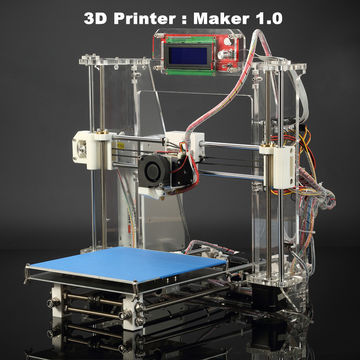

I just finished building my new Prusa i3 MK2. I have been waiting a long time for this machine. Just a bit of background: The first 3D printer I purchased was quite a while ago and it was an iteration of Prusa"s new MK2 design (new for that time). It went horribly wrong as the company was a Chinese manufacturer and everything about the product"s build was inferior with inferior support to boot! That turned me off from Prusa"s design for some time and thereafter I worked with makerbot/flashforge design printers exclusively due to the incredible ease of use. However, I hit a wall with what I could do and the Prusa was rated best printer. After some research, I found the many references to the original Prusa being far superior to the Chinese knock-offs. So I made my purchase.

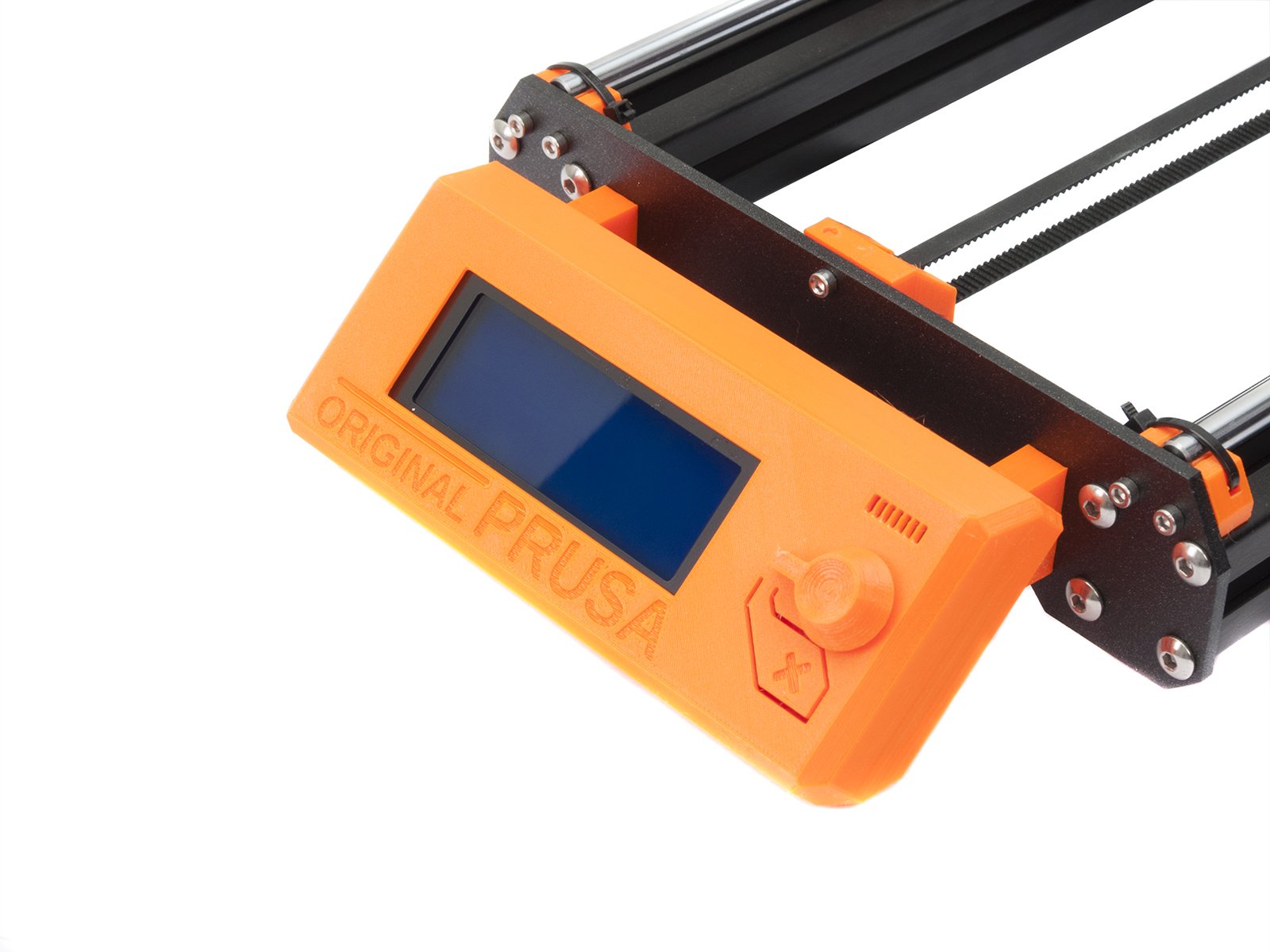

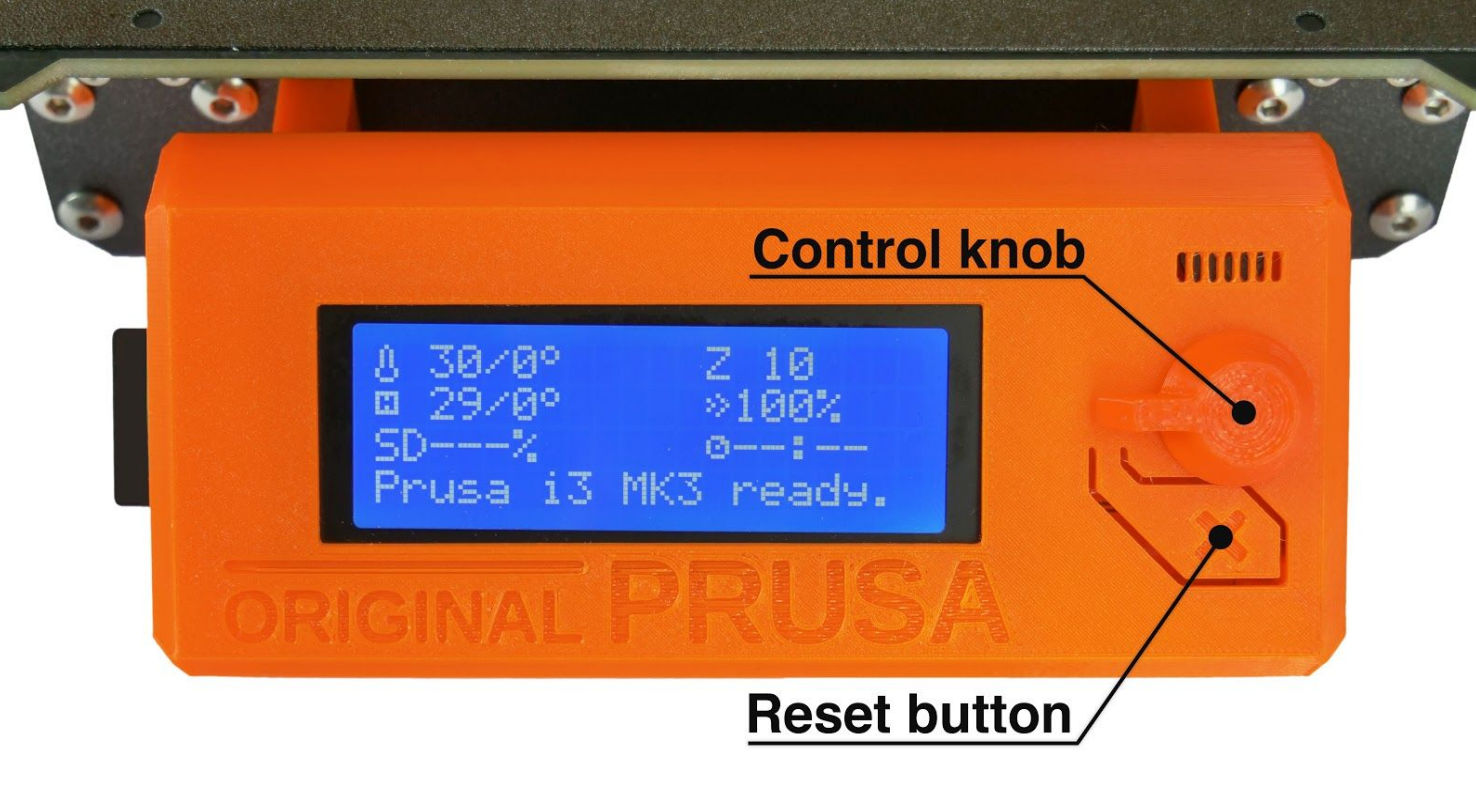

I received the original Received the printer about 5 weeks later, built it, now here I am. Everything looked great until I turned the machine on. The LCD panel displays language preference, click "English. Then the main "monitor" screen comes up. I click on the button and it goes to the menu. I turn the potentiometer to scroll and I start getting strange characters and/or white blocks where characters should be displayed. About 2 seconds later the LCD panel (and board) reset. Hoping this was just a small hiccup, I scrolled when the screen came on and it once again either showed blanks or strange characters.... then I started to have flashbacks to my Chusa (Chinese Prusa) and all the problems with it. Support from Prusa3D website was unhelpful. They gave me 4 different options for rewiring the 2 LCD cables, which took about 20 minutes to do because of the cramped space in the electrical box... the LCD panel did not turn on save for one of the options of wiring--the one I initially had (this is not my first rodeo!). Next, I flashed the board with a clean version of the 1.75_13a hex file from the Prusa website, and guess what happened...nothing! If nothing else, the LCD panel is consistent in its behavior. Same thing happened again, white blocks mostly, sometimes strange characters (a la pronterface console at the wrong baudrate), and within 1-3 seconds the board and LCD panel reset. I believe I may have had this problem with my Chusa as well, but I can"t remember... I remember I eventually did get the Chusa working--albeit with great difficulty and very bad print quality.

I"ve noticed a lot of people have had problems with the Prusa LCD panels on the web. However, very very few have this exact issue, and usually the issue is a simple one (loose connectors, incorrect positioning, etc.). I"ve checked everything over and over and found no issues, so I am putting it out to the forum to get some help. I had extremely high hopes for the Prusa from all the hype, so I can"t fault Joseph and his crew for the utter disappointment I feel. The quality of the printer"s parts is relatively exceptional. However, the only forum entry I found that might explain what is going on is that Prusa was once supplied with faulty LCD control boards which they sent out with their printers. I"m wondering if this might once again be the case...? Also, I should note that I don"t believe the SD card is working either as it lists nothing on the LCD monitor screen and there is nothing displayed within Pronterface.

I used to have the same issue with noise from the power supply getting onto the screen and even sometimes resetting my printer mid-print. I found that if I had my USB programming cable plugged in I never experienced the issue. I found that the issue was the noise from the power supply wasn"t not being drained to earth ground, and it was actually tripping the reset on the micro-controller. Part of that comes from the micro-controller and screen having to share their power, which is regulated down to 5v from the incoming 12v. The trick is to supply the micro controller with its own 5v while printing and drain the incoming noise off to earth ground. I modified the typical USB A-B cable to resolve this. As long as you still use the SD card to load the gcode you can occupy the programming port with this cable to supply the 5v.

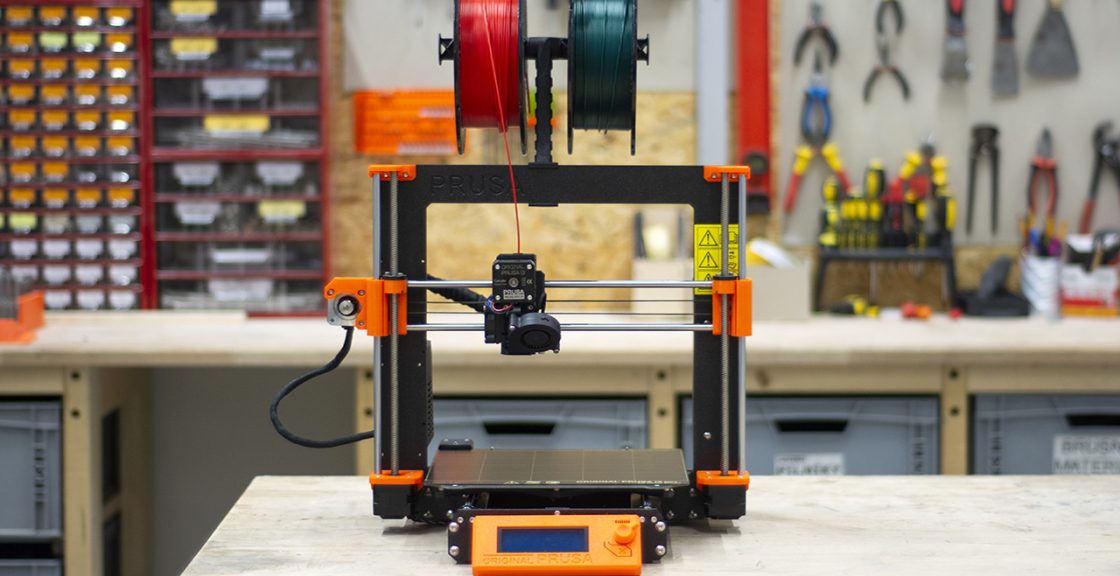

The Prusa i3 MK2 is an excellent 3D printer for people who want to start with 3D printing. It is most suited towards beginners as it is very user-friendly, but at the same time offers some advanced features as well. All in all, the Prusa i3 MK2 is an excellent choice for anyone looking to get into 3D printing. Yes, it has a higher upfront cost than some other 3D printers, but the time it will save you during setup and before printing is incalculable. Plus, with such a vast array of supported materials, you have unlimited potential for growth.

Today, we’re going to review a 3D printer that’s often imitated yet never surpassed. We’re talking, of course, about the Prusa i3 MK2. Now, before we begin, you should be aware that Prusa’s website is the only legitimate vendor of this product so don’t buy it from any other marketplace.

Simply, the i3 MK2 takes the hassle out of setting up a print. It comes with a heated bed and cold corner compensation, but what does this mean? Basically, filament tends to stick to cold surfaces and this feature ensures the bed remains at a constant temperature all over. That’s not bad, but there’s more.

The Prusa i3 MK2 features a built-in LCD display and SD card, controller. An 8GB SD card is also included to get you started but if you’re a heavy user, you’ll likely want to upgrade this in the future. It also uses cutting edge modern technology to stay as quiet as possible during the printing process – usually around 50dB, which is comparable to the noise from moderate rainfall.

We’ve all seen them: instructions that look like they’ve been translated into Chinese and back. They’re almost useless and unfortunately, all too common. In contrast, Prusa provides a thick instruction booklet with illustrated, concise directions on how to set up and configure your new 3D printer.

All in all, the Prusa i3 MK2 is an excellent choice for anyone looking to get into 3D printing. Yes, it has a higher upfront cost than some other 3D printers, but the time it will save you during setup and before printing is incalculable. Plus, with such a vast array of supported materials, you have unlimited potential for growth.

The Prusa i3 series consists of open-source fused deposition modeling 3D printers, manufactured by Czech company Prusa Research under the trademarked name Original Prusa i3. Part of the RepRap project, Prusa i3 printers were named the most used 3D printer in the world.

First conceived in 2009, RepRap Mendel 3D printers were designed to be assembled from 3D printed parts and commonly available off-the-shelf components (referred to as "vitamins," as they cannot be produced by the printer itself).leadscrews, smooth rods and bearings, screws, nuts, stepper motors, control circuit boards, and a "hot end" to melt and place thermoplastic materials.Cartesian mechanism with a movable flat bed and tool motion on two horizontal and two vertical rods permit placement of material anywhere in a cubic volume; this design has continued throughout development of the i3 series.

Průša streamlined his Mendel design, releasing "Prusa Iteration 2" in November 2011. Parts changes allowed for snap-fit assembly (no glue required); fewer tools were needed to construct and maintain this version. Although not required, fine-pitch manufactured pulleys and LM8UU linear bearings were recommended over printed equivalents for "professional" results.

In May 2012, Průša released a major redesign, focused on ease of construction and use, and no longer structured around the simplest available common hardware as previous RepRap printers were.water jet cut aluminium vertical frame to improve printing speed and accuracy; M10 threaded rods were still used in the base. It used a single piece, food safe stainless steel hot end called the Prusa Nozzle which printed with 3 mm filament, and used M5 threaded rods as lead screws instead of M8.

Three years later in 2015, Průša released an i3 full kit under the brand name "Original Prusa i3" after having realized that there was a market for 3D printer kits.

Průša released the Prusa i3 MK2 in May, 2016. It was the first hobby printer with mesh bed leveling and automatic geometry skew correction for all three axes. Features included a larger build volume, custom stepper motors with integrated lead screws, a non-contact inductance sensor for auto-leveling, and a rewritten version of the Marlin firmware.polyetherimide print surface, Rambo controller board and an E3D V6 Full hotend.Windows 10 Plug-and-Play USB ID.

In March 2017, Průša announced on his blog that the revised Prusa i3 MK2S would ship in place of the Prusa i3 MK2.cable ties had been used, higher quality bearings and rods, an improved mount for the inductance sensor, improved cable management, and a new electronics cover. An upgrade kit was offered to owners of the MK2 to add these improvements.

In September 2017, Prusa i3 MK3 was released, marketed as "bloody smart."extruder with dual Bondtech drive-gears, quieter fans with RPM monitoring, faster print speeds, an updated bed leveling sensor, a new electronics board named "Einsy", quieter stepper motors with 128 step microstepping drivers and a magnetic heatbed with interchangeable PEI-coated steel sheets.volt power supply. The printer also offers dedicated sockets to connect Raspberry Pi Zero W running a fork of the open source OctoPrint software for wireless printing.

In February 2019, Prusa i3 MK3S was released, along with the Multi Material Upgrade 2S (MMU2S), which allows selecting any of 5 different materials for printing together automatically.

Following the MK3S, Prusa introduced two unrelated models, the Prusa Mini (with a cantilever arm) and Prusa XL (using a Core XY method inside a full-frame structure). These printers are not iterations of the Mendel frame design.

The 3D Hubs Q3 2018 Trends report noted that the Prusa i3 MK2, MK2S and MK3 had been used to manufacture nearly 35% of all prints ordered through their fee-for-service business.

Like other RepRap printers the Prusa i3 is capable of creating many of its own parts. Formerly these were printed in ABS plastic; Prusa Research now uses mostly PETG instead.

In 2020, Prusa launched their own line of materials called Prusament, which are designed to be extremely consistent. Prusament materials come with a QR code which allows customers to view the exact specifications and test results from their spool.

When extruding the first layer, the print head must be a precise distance away from the build plate for proper adhesion. Many 3D printers rely on the user to complete this process by adjusting the height of the bed at several locations ("bed leveling"). To automate this process Prusa manufactures and sells an inductive sensor called the Pinda (Prusa INDuction Autoleveling sensor) which can be used to measure the exact height of the printbed at different locations, and then adjust for it when printing ("auto-leveling").

With all aspects of the design freely available under open source and open hardware terms, companies and individuals around the world have produced Prusa i3 copies, variants, and upgrades in assembled and kit form, with thousands offered for sale as early as 2015.

User "Scwimbush"; User "Prusajr" (April 12, 2011). "Prusa Mendel - RepRap". reprap.org. Retrieved October 9, 2020. |last1= has generic name (help)CS1 maint: url-status (link)

Sertoglu, Kubi (October 4, 2021). "Prusa showcases its new modular 3D printer farm at Dubai"s Expo 2020". 3D Printing Industry. Retrieved January 13, 2022.link)

The Prusa i3 is one of the most successful 3D printer designs in history. Because it’s an open-source design, dozens of manufacturers have sold their own versions. Sometimes those are exact clones, and sometimes they have small tweaks. But genuine Prusa i3 3D printers are consistently rated as the most reliable consumer printers on the market. That said, they have a pretty basic monochrome LCD screen.Dr. Scott M. Baker decided to swap that out for something a little more interesting, and chose a vintage VFD.

This mod was tested with the Prusa i3 Mk33D printer, but should work with earlier iterations and many clones. It essentially just replaces the boring monochrome LCD with a cyberpunk-style VFD (vacuum fluorescent display). VFDs used to be common in consumer electronics, because they produced clear, bright graphics. But they’ve fallen out of favor in recent years as LCD, LED, and OLED displays have become more affordable. There is no denying how cool they look though, which is why Dr. Baker performed this modification.

TheVFDitself is made by Noritake, and — very surprisingly — is almost an exact drop-in match for the LCD that comes with the Prusa i3 Mk3. The display is a little expensive at around $90, but it’s hard to beat the convenience. All you have to do is take apart your control panel and pull the PCB out. Then either desolder the original LCD or order a new PCB (available atprintedsolid.com). Next, just solder in the Noritake VFD and put the control panel back together. That’s it! It should just work. You can even use filters if you want to change the color of the VFD.

Though these 3D printers are similar in features and print quality, the Prusa MK3S+ comes at a substantially higher price tag than the Creality Ender 3 S1 Pro. While cost isn’t everything, it is definitely an important factor to consider when purchasing. The Ender 3 S1 Pro is priced in the $500-550 price range (Check the current price on Amazon), and includes free shipping from Amazon (or most other vendors). The Prusa$ MK3S+ starts at the $800-850 price point for the unassembled kit, and is over $1000 for the assembled version (Check prices on prusa3d.com). Shipping is not free, and will add $50-100 to the price tag depending on whether you purchase the kit or the fully assembled version.

Creality 3D printers are manufactured in China, while Prusa Research is located in the Czech Republic. Due to lower costs of labor and easier access to other manufactured parts, 3D printers manufactured in China cost less to produce and can support a lower price point. In addition, the Prusa MK3S+ uses 3D printed parts in the construction of the printer. This has a number of advantages for Prusa, such as the ability to iterate quickly on part updates, and is a way for Prusa to extensively test their printers when manufacturing these parts. However, 3D printing at scale is more expensive than traditional manufacturing methods such as injection molding.

For parts that they do not 3D print, Prusa focuses primarily on part quality with cost as a secondary consideration. For example, Prusa uses premium parts for the linear rail system and name-brand Bondtech and E3D components for the extruder and hot end. Creality takes a more balanced approach with the Ender 3 S1 Pro, and reduces cost by producing parts themselves, such as the CR-touch leveling sensor and a Creality branded power supply. Creality has historically focused on cost first, but we have seen that the higher-end printers like the Ender 3 S1 Pro do strike a good balance between quality and cost savings.

It is clear from the moment you open the MK3S+ that Prusa puts a lot of effort into testing and quality control. For our assembled unit, a checklist and test results sheet were included which showed all of the testing that they performed before shipping the unit. Additionally, the printer shipped with a completed test print on the bed, indicating that they run an actual print test on each unit they produce. Creality printers do not go through as rigorous of testing, and in some cases there will be small issues that require adjustment. In our experience of purchasing over 30 Creality printers at retail, we have noticed small QC issues on 10-15% of the printers.

Improved quality control is not free, and is likely a contributing factor in Prusa’s higher price point. The bottom line is that if you prefer to pay more to get a machine that will almost certainly work out of the box without any defects, the Prusa MK3S+ is more geared toward you.

In a similar vein, Prusa provides a much better support experience than Creality. After purchasing a printer, it is easy to get in touch with Prusa’s dedicated support team through their site, since you are buying directly from the manufacturer. With Creality, getting support is more difficult since you will be purchasing through a 3rd party like Amazon. If there are major defects with the printer, Amazon is very good about providing replacement units, however you will not be able to get assistance in repairing issues, and needing to do a full replacement can be a frustrating experience.

China"s first 8.5-generation TFT-LCD production line was launched in Bengbu, East China"s Anhui province, on June 18, 2019, representing a breakthrough in the production of high-definition LCD screen, Science and Technology Daily reported.

TFT-LCD, or Thin Film Transistor Liquid Crystal Display, is key strategic material of the electronic information display industry. The Gen 8.5 TFT-LCD production line, launched by the Bengbu Glass Industry Design and Research Institute of the China National Building Material Group, will produce high-definition LCD screens of 55 inches, the report said.

According to the Liquid Crystal Branch of the China Optics and Optoelectronics Manufactures Association, the demand for TFT-LCD in the Chinese mainland was about 260 million square meters in 2018, including 233 million square meters" Gen 8.5 TFT-LCD. However, the annual supply of domestically made TFT-LCD is less than 40 million square meters, with all of them Gen 6 or below, which cannot meet the demand in scale and quantity.

The association predicted that China"s market demand for Gen 8.5 TFT-LCD or above will exceed 300 million square meters by 2020, accounting for 49.6 percent of the total global demand.

The production and control precision of Gen 8.5 TFT-LCD is comparable to that of the semiconductor industry, representing a higher level of large-scale manufacturing of modern glass industry.

The institute in Bengbu, with 60 years of expertise in glass, has finally made a breakthrough in the production of Gen 8.5 TFT-LCD, and will provide key raw material guarantee for China"s LCD panel industry after it goes into mass production in September, the report said.

USE THESE INFORMATION AT YOUR OWN RISK. I am not responsible for any damage done to your printer or LCD when using these information. I hope you find them useful, I try to make them as accurate as possible but they may contain mistakes.

I have created ADVi3++, an alternative, better and open source firmware for Wanhao i3 Plus printers and clones. Thanks to supporters of this project on Patreon, I am able to continue the development of this firmware and write articles such as this article. More information about ADVi3++ on GitHub: https://github.com/andrivet/ADVi3pp. More information about supporting the project on Patreon: https://www.patreon.com/andrivet.

The Wanhao Duplicator i3 Plus 3D printer (and all its derivatives) is manufactured by Wanhao, a Chinese company in the town of Jinhua. It is sold by several resellers like Ultimate 3D Printing Store in the US, 3D Prima in Europe, but also Amazon, Aldi in Australia, etc.

There are today many different models with or without significant differences. I have open an issue on GitHub to reference all the different models and get input from the community: https://github.com/andrivet/ADVi3pp/issues/188. As far as I know, here are an exhaustive list of models derived from the Wanhao Duplicator i3 Plus:

No difference means that the model has no hardware difference compared to the original Wanhao Duplicator i3 Plus. It does not take into account differences like a different power plug or a firmware with a different boot animation.

There is also the case of the Wanhao Duplicator 9 (D9). In many aspects, it is similar to a Wanhao Duplicator i3 Plus. I may document it in a future update of this document.

Contrary to previous versions of Wanhao i3 printers (that were using a Melzi board), the Wanhao i3 Plus has a custom mainboard. The version is different between models:

The Wanhao Duplicator i3 Plus Mark II has an inductive proximity sensor for automatic bed leveling. Depending of when the printer was manufactured, the sensor is either blue or orange.

It is possible to upgrade the Wanhao Duplicator i3 Plus printers (non Mark II) with a BLTouch using an alternative firmware: ADVi3++ (I am the creator of this firmware).

The LCD Touch Screen is build around an ARM kernel and simplifies the development of user interfaces: the different screens are defined by a set of files (images, fonts, etc) stored in the flash memory of the panel and they can be customized using a graphical editor (part of DGUS SDK).

A set of resources, made by the manufacturer of the 3D printer (Wanhao, Monoprice, Coccon) or yourself. This component is often called "LCD firmware" even if it is wrong.

The last point is very important. The LCD (i.e. DGUS) is not able to handle other formats like top-down bitmaps. To convert images to the right format, you can use ImageMagick convert:

IMPORTANT: You have to use a microSD card with a maximum capacity of 8GiB. If you use a microSD card with a greater capacity, the results are unreliable (sometimes it flashes, sometimes not). This is a limitation of the LCD display itself.

Based on the Marlin GitHub history and the sources published by Wanhao (for version 2.1.8), the Wanhao i3 Plus fork is based on the commit ac74f45 (February 9, 2014) in the Marlin history and the fork for the MakerLab Maker. After this point, the sources have diverged and were never merged back into the Marlin history.

Most of the changes (such as for the second serial line or the Mini LCD) have nothing to do with the Wanhao i3 Plus, but deal with MakerLab Maker printer.

i3plus+ from Leo Lüker (Silverquark): a modified version of the Marlin 1.1.2 firmware for the WANHAO Duplicator i3 Plus 3d printer. Important: No more actively developed.

i3extra from Nemcsik Péter: a modified version of the Marlin 1.1.0-RC8 firmware and updated LCD resources. Important: this project is no more maintained.

- You"ll need an external power supply to power the module. Your MK3 runs on 24V and most laser modules run on 12V. It is possible to use a DC-DC step-down converter to make 12V out of the 24V but you"ll have to run the wiring from the main board (if you"re feeling inclined to go that route).

I designed a mount that attaches to the extruder motor of the MK3, which makes it possible to quickly swap between laser etching and printing without having to disassemble anything.

This step might get a bit challenging, depending on your skill level with a soldering iron and a Dupont crimping tool (if you decide to go that route). If you plan to do this mod on a different printer than the MK3, make sure there"s 5V flowing to the fans! Some printers will have 12V (or even 24V) and you"ll need to step that signal down to 5V, otherwise your laser"s control module will burn out.

Regardless of module, there will always be a power supply line and a TTL line. You want to make sure not to switch these since the voltages are different, and you wouldn"t want to damage your electronics (including your MK3 main board!). This is the reason behind using the male and female connectors, to reduce the likelihood of switching them up. You still have to pay attention to the polarity of each connector. For this, I laid out the connections so the housings are all facing the same way (the little square windows are all on the same side).

There"s a significant difference now between where your 0 point on the Y axis will be. The module is that much more offset from the extruder"s hotend. Luckily the MK3 has magnets on the bed and it"s fairly easy to move the sheet about 50mm or so towards the LCD screen and still be useful to place work items on it.

So, I came up with my own app that takes care of the vector engraving part by converting an SVG file into MK3-ready Gcode. My aim is to lower the threshold as much as possible so any beginner could jump in and start creating without much hassle.

In the next step I will guide you through an example of vector engraving with Adobe Illustrator and my app, which I named (true to Prusa tradition) Laribo (the Laser Haribo... get it?).

The work area is equal to the MK3"s bed area, 250mm width x 210mm height. The app expects an SVG file that is sized to the full area of the bed (again, 250x210).

- Think of your vector file as the bed of the MK3, same size, same orientation. For example, a 10mm circle in the top left corner of your atboard will be a 10mm etched circle on the top left of the print area when you face the printer.

You"ll probably have designs where areas need to be filled in, like the MK3 writing in my example design. The way to fill an area with a laser beam is by tracing lines close to each other. Just like the infill patterns in 3D printing where the extruder bounces inside the outlines of a shape until it"s filled in.

Enter LARIBO, the app I created to make it as simple as possible to convert SVG files to Gcode, which can then be copied to an SD card, plugged into the MK3, and laser etched!

Pop your SD card into your MK3, go to Print from SD and select your file. The printer will warn you that the file is incomplete (probably because we don"t do any mesh bed leveling, etc.) - ignore this and press Yes.

I tried to do similar mod on Prusa MINI+, but the laser never turns off. There is constant 2 volts between the ventilators +/- the whole time the printer is turned on. I tried also putting resistor as mentioned in the article, but didnt helped. Did anyone have the same issue?

ich habe mit meinem mk3s unsaubere Ergebnisse und kurze schwarze Striche beim lasern eines Bildes wie weiter unten schon beschrieben. Jetzt habe ich mir mal die Mühe gemacht und die Spannung am Lüfteranschluss ausgehend von 255 in 5er Schritten abwärts gemessen. Teilweise sind die Spannungen stabil, teilweise auch schwankend. Die Schwankungen stellen sich wie folgt dar: der min- Wert ist für ca.2 bis 3 Sekunden stabil, dann folgt ein kurzer Ausreisser auf den max. Wert. Das ganze wiederholt sich dann immer wieder zyklisch. Prusa sagt das wäre so normal. Jetzt meine Bitte an euch, kann bitte mal jemand an seinem Prusa mk3s die Spannung messen und mir hier mitteilen ob sich eure Meßergebnisse grob mit meinen decken oder ob ihr keine Schwankungen feststellen könnt, das wäre sehr hilfreich für mich. Mich würde nämlich brennend interessieren wo mein Problem liegt. Ist es der Laser oder liegt es an meinem mk3s?

Hallo Peter, ich denke, es liegt daran, dass die von Ihnen verwendete Software das "fan-blipping" nicht berücksichtigt - das auf Firmware-Ebene des MK3 auftritt. Laribo hat diesen "bug" behoben. Passiert das auch bei Laribo? Oder nur in Ihre Raster-App?0

Mit fan-blipping meinst du das Verhalten bei Prusa dass der Lüfter wenn er mit "M107" ausgeschaltet wird und mit "M106 S60" wieder mit reduziertem Speed laufen soll, erstmal hochgefahren wird und erst danach auf die geforderte Geschwindigkeit reduziert.

nachdem ich dieses Problem mit unterschiedlichen Programmen habe, denke ich das es an meinem mk3s bzw. am 1kOhm Widerstand liegen könnte den ich zwischen den beiden Lüfteranschlüssen geschaltet habe, damit der Laser nicht immer an ist wenn er an der Stromversorgung hängt (Eleksmakers-Laser). Mit einem 2,2kOhm Widerstand hat es nämlich nicht funktioniert, also liegt der optimale Widerstand irgendwo zwischen 1kOhm und 2,2kOhm. Ich bin wirklich kein Elektroniker und habe keine Ahnung von solchen Dingen, aber trotzdem würde ich gerne den 1kOhm Widerstand gegen einen Drehpotentiometer 0-2kOhm austauschen. Einfach um den Schaltpunkt genauer einstellen zu können. Es kann natürlich sein, dass sich ein Elektroniker jetzt die Haare rauft, aber im Rahmen meiner bescheidenen Möglichkeiten ist das alles was mir dazu einfällt.

The lower left corner represents the front left of your printbed, so if you only have 200x200 usable space, just don"t put anything past that area. Laribo is setup by default to handle the default size of the MK3, but it will work on any other size, as long as you keep the SVG file at 250x210 - even if you go over these bounderies, the Gcode will be generated no problem. Maybe one of these days I"ll do another round of updates so you can define your own printbed size.

Ich habe mich durch deinen Beitrag inspirieren lassen und meinen mk3s auch mit einem Laser ausgestattet. Nach anfänglichen Problemen funktioniert das System mittlerweile sehr gut.

Hello, I am trying to adapt the project to add laser capabilities to my Prusa MK2 printer (3.2.3 firmware). I am using a separate power supply for my Chinese 5W laser. I had to use a DC-DC (buck) converter to step down the Print Fan voltage from 12V to 5V. In Pronterface I use the M106 S## command to change the laser output but is seems that it"s always the same. I also tried a 3 kohm resistor between the laser TTL in and GND, no change.More CommentsPost Comment

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey