tft lcd 2 nodemcu arduino code supplier

Hi. First time poster and first time arduino"r. Might be wrong subforum? Please let me know if I should address this somewhere else. I was hoping for some assistance with better understanding the layout of these 2 pieces I received from Amazon. I bought the following pack:

I"ve been doing some research and trying to understand how to connect these 2 pieces. The video tutorial found on the amazon page is pretty good, but the LCD display"s pins are a little bit different:

I"ve also been looking for documentation and I find it very difficult, I believe the ESP8266 is this ESP8266 ESP-12E NodeMCU, but I can"t quite figure out the Display. The pins don"t line up to:

Any help or guidance would be great. Just looking to connect these before I even dive into the coding aspect. Again, first time arduino attempter (probably should have bought a real kit rather than some Amazon "kit" too. bleh). Please let me know if I need to supply additional information. Thanks!

Pins D5 (GPIO14) and D7 (GPIO13) are hardware SPI module pins of the ESP8266EX microcontroller respectively for SCK (serial clock) and MOSI (master-out slave-in).

The first library is a driver for the ST7735 TFT display which can be installed from Arduino IDE library manager (Sketch —> Include Library —> Manage Libraries …, in the search box write “st7735” and install the one from Adafruit).

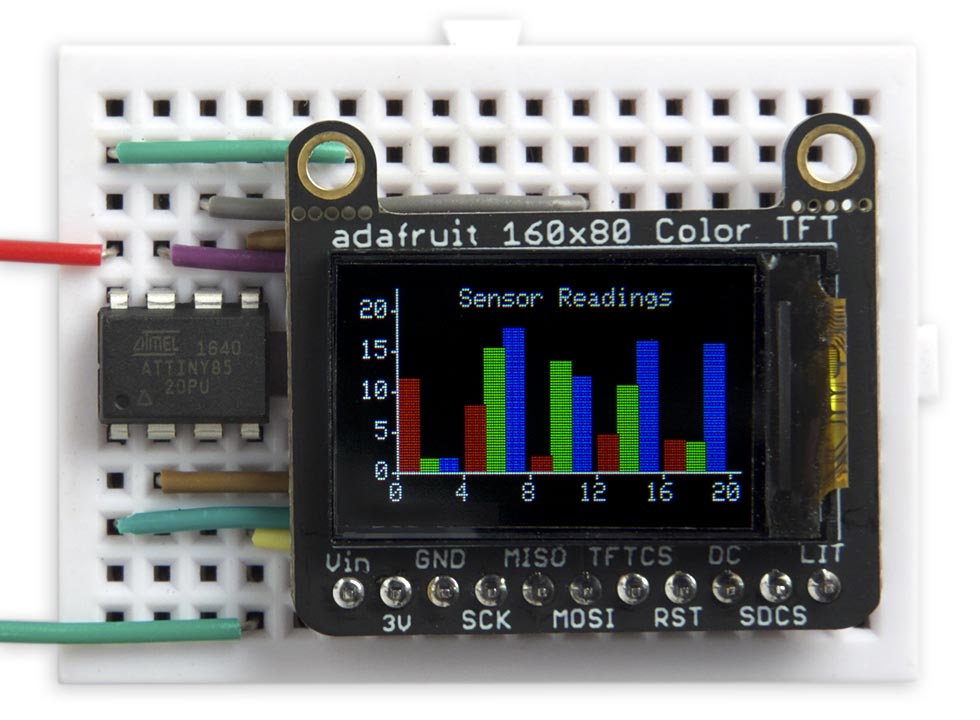

The Arduino code below is the Adafruit test example for the ST7735 display (comes with Adafruit ST7735 library) with few modifications in order to work with the circuit schematic shown above.

Project hardware circuit should give the same result as the one shown in the following video where Arduino UNO board is used (NodeMCU is much faster than Arduino UNO):

ILI9341 is a 262,144-color single-chip SOC driver for a-TFT liquid crystal display with resolution of 240RGBx320 dots, comprising a 720-channel source driver, a 320-channel gate driver, 172,800 bytes GRAM for graphic display data of 240RGBx320 dots, and power supply circuit. ILI9341 supports parallel 8-/9-/16-/18-bit data bus MCU interface, 6-/16-/18-bit data bus RGB interface and 3-/4-line serial peripheral interface (SPI). The moving picture area can be specified in internal GRAM by window address function. The specified window area can be updated selectively, so that moving picture can be displayed simultaneously independent of still picture area.

You can find ILI9341-based TFT displays in various sizes on eBay and Aliexpress. The one I chose for this tutorial is 2.2″ length along the diagonal, 240×320 pixels resolution, supports SPI interface, and can be purchased for less than $10.

Note that we will be using the hardware SPI module of the ESP8266 to drive the TFT LCD. The SPI communication pins are multiplexed with I/O pins D5 (SCK), D6 (MISO), and D7 (MOSI). The chip select (CS) and Data/Command (DC) signal lines are configurable through software.

For ILI9341-based TFT displays, there are some options for choosing the library for your application. The most common one is using Bodmer. We will use this library in this tutorial. So go ahead and download the

The library contains proportional fonts, different sizes can be enabled/disabled at compile time to optimise the use of FLASH memory. The library has been tested with the NodeMCU (ESP8266 based).

The library is based on the Adafruit GFX and Adafruit ILI9341 libraries and the aim is to retain compatibility. Significant additions have been made to the library to boost the speed for ESP8266 processors (it is typically 3 to 10 times faster) and to add new features. The new graphics functions include different size proportional fonts and formatting features. There are a significant number of example sketches to demonstrate the different features.

Configuration of the library font selections, pins used to interface with the TFT and other features is made by editting the User_Setup.h file in the library folder. Fonts and features can easily be disabled by commenting out lines.

Now you are all set to try out tons of really cool built-in examples that come with the library. The following output corresponds to the TFT_Pie_Chart example.

My favorite example is TFT terminal, which implements a simple “Arduino IDE Serial Monitor” like serial receive terminal for monitoring debugging messages from another Arduino or ESP8266 board.

The ESP8266 is a well performing microcontroller chip that is fully Arduino compatible. Its WiFi capability makes boards with this chip easy implementable as IOT devices. Here we wire two representative ESP8266 boards: NodeMCU and Wemos D1 mini to a single-row 14-pin header, 320*240 TFT display that uses the four-wire SPI interface.

Here we connect a 320240 ILI9341 TFT display that has a SPI pin-out. This breakout board has 3.3V controller logic while power supply and background illumination operate on either 3.3V and 5V. ESP8266 microcontroller boards support displays with up to 320480 pixels

The display shown in figure 1 has a touch screen. It has a single row of 14 pins (figure 1; see also figure 3). The pins supporting ‘touch’ as well as those associated with the SD card reader are not connected: we concentrate on displaying text, variables, graphics and fast sequences of memory-loaded bitmaps (‘image frames”). The ILI9341 controller is fast and, in combination with an ESP8266, performs excellently.

Figure 3 shows a Wemos D1 mini board mounted on a prototyping breadboard together with a 2.8 inch ILI9341 SPI TFT display according to the wiring diagram shown in Figure 2. The ESP8266 is running a demo adapted for the “Adafruit_GFX.h” and “Adafruit_ILI9341.h” libraries from Bodmer’s ‘Clock’ example for his TFT_eSPI library.

— ESP8266_ILI9341_Adafruit_Bodmers_clock.ino, a real time analog clock example adapted from Bodmer’s TFT_eSPi library examples (display visible in figure 3).

This tutorial shows how to use the I2C LCD (Liquid Crystal Display) with the ESP32 using Arduino IDE. We’ll show you how to wire the display, install the library and try sample code to write text on the LCD: static text, and scroll long messages. You can also use this guide with the ESP8266.

Additionally, it comes with a built-in potentiometer you can use to adjust the contrast between the background and the characters on the LCD. On a “regular” LCD you need to add a potentiometer to the circuit to adjust the contrast.

Before displaying text on the LCD, you need to find the LCD I2C address. With the LCD properly wired to the ESP32, upload the following I2C Scanner sketch.

After uploading the code, open the Serial Monitor at a baud rate of 115200. Press the ESP32 EN button. The I2C address should be displayed in the Serial Monitor.

Displaying static text on the LCD is very simple. All you have to do is select where you want the characters to be displayed on the screen, and then send the message to the display.

In this simple sketch we show you the most useful and important functions from the LiquidCrystal_I2C library. So, let’s take a quick look at how the code works.

The next two lines set the number of columns and rows of your LCD display. If you’re using a display with another size, you should modify those variables.

Scrolling text on the LCD is specially useful when you want to display messages longer than 16 characters. The library comes with built-in functions that allows you to scroll text. However, many people experience problems with those functions because:

The messageToScroll variable is displayed in the second row (1 corresponds to the second row), with a delay time of 250 ms (the GIF image is speed up 1.5x).

In a 16×2 LCD there are 32 blocks where you can display characters. Each block is made out of 5×8 tiny pixels. You can display custom characters by defining the state of each tiny pixel. For that, you can create a byte variable to hold the state of each pixel.

In summary, in this tutorial we’ve shown you how to use an I2C LCD display with the ESP32/ESP8266 with Arduino IDE: how to display static text, scrolling text and custom characters. This tutorial also works with the Arduino board, you just need to change the pin assignment to use the Arduino I2C pins.

We hope you’ve found this tutorial useful. If you like ESP32 and you want to learn more, we recommend enrolling in Learn ESP32 with Arduino IDE course.

I am using the 1.8″ color ST7735 TFT display a lot. The reason for that is that this display is very easy to use, it costs less than $5 and it offers color! At the back, the display has an SD card slot.A brief summary of the pins (adapted from Adafruits thorough summary):

RST – this is the TFT reset pin. Connect to ground to reset the TFT! Its best to have this pin controlled by the library so the display is reset cleanly, but you can also connect it to the Arduino Reset pin, which works for most cases.CS – this is the TFT SPI chip select pinD / C – this is the TFT SPI data or command selector pinDIN – this is the SPI Master Out Slave In pin (MOSI), it is used to send data from the microcontroller to the SD card and / or TFTSCLK – this is the SPI clock input pinVcc – this is the power pin, connect to 5VDC – it has reverse polarity protection but try to wire it right!LED – this is the input for the backlight control. Connect to 5VDC to turn on the backlight.GND – this is the power and signal ground pinNow that we know what we’re dealing with it’s time to start wiring!

As you all know the are a few variants of the 1.8" TFT on the internet. With the genuine Adafruit lcd-s there are usually no problems. But when using fake ones(usually from Aliexpress) you have to make some adjustments.

Bodmers TFT_eSPI library is very awsome and rich funcionality. And the best part is that he made it to handle the pixel offsets depending on wich kind of 1.8" TFT you are using.

Then uncomment the tft height an width. And then in my case(REDTAB) uncomment for eg: #define ST7735_REDTAB. After this save it for the moment and compile sketch and upload to board. To be sure i have defined the parameters in the sketch too.This is a bit long procedure, cause you have to compile and upload the sketch every time to board untill the offset is gone, but it is worth the experimenting. For editing the h. files i strongly suggest Wordpad. Images included.

by Floris Wouterlood – The Netherlands – May 2, 2021 — IntroductionThe ESP8266 is a well performing microcontroller chip that is fully Arduino compatible. Its WiFi capability make…

In this article, you will learn how to use TFT LCDs by Arduino boards. From basic commands to professional designs and technics are all explained here.

There are several components to achieve this. LEDs, 7-segments, Character and Graphic displays, and full-color TFT LCDs. The right component for your projects depends on the amount of data to be displayed, type of user interaction, and processor capacity.

TFT LCD is a variant of a liquid-crystal display (LCD) that uses thin-film-transistor (TFT) technology to improve image qualities such as addressability and contrast. A TFT LCD is an active matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven LCDs with a few segments.

In Arduino-based projects, the processor frequency is low. So it is not possible to display complex, high definition images and high-speed motions. Therefore, full-color TFT LCDs can only be used to display simple data and commands.

There are several components to achieve this. LEDs, 7-segments, Character and Graphic displays, and full-color TFT LCDs. The right component for your projects depends on the amount of data to be displayed, type of user interaction, and processor capacity.

TFT LCD is a variant of a liquid-crystal display (LCD) that uses thin-film-transistor (TFT) technology to improve image qualities such as addressability and contrast. A TFT LCD is an active matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven LCDs with a few segments.

In Arduino-based projects, the processor frequency is low. So it is not possible to display complex, high definition images and high-speed motions. Therefore, full-color TFT LCDs can only be used to display simple data and commands.

After choosing the right display, It’s time to choose the right controller. If you want to display characters, tests, numbers and static images and the speed of display is not important, the Atmega328 Arduino boards (such as Arduino UNO) are a proper choice. If the size of your code is big, The UNO board may not be enough. You can use Arduino Mega2560 instead. And if you want to show high resolution images and motions with high speed, you should use the ARM core Arduino boards such as Arduino DUE.

In electronics/computer hardware a display driver is usually a semiconductor integrated circuit (but may alternatively comprise a state machine made of discrete logic and other components) which provides an interface function between a microprocessor, microcontroller, ASIC or general-purpose peripheral interface and a particular type of display device, e.g. LCD, LED, OLED, ePaper, CRT, Vacuum fluorescent or Nixie.

The display driver will typically accept commands and data using an industry-standard general-purpose serial or parallel interface, such as TTL, CMOS, RS232, SPI, I2C, etc. and generate signals with suitable voltage, current, timing and demultiplexing to make the display show the desired text or image.

The LCDs manufacturers use different drivers in their products. Some of them are more popular and some of them are very unknown. To run your display easily, you should use Arduino LCDs libraries and add them to your code. Otherwise running the display may be very difficult. There are many free libraries you can find on the internet but the important point about the libraries is their compatibility with the LCD’s driver. The driver of your LCD must be known by your library. In this article, we use the Adafruit GFX library and MCUFRIEND KBV library and example codes. You can download them from the following links.

You must add the library and then upload the code. If it is the first time you run an Arduino board, don’t worry. Just follow these steps:Go to www.arduino.cc/en/Main/Software and download the software of your OS. Install the IDE software as instructed.

By these two functions, You can find out the resolution of the display. Just add them to the code and put the outputs in a uint16_t variable. Then read it from the Serial port by Serial.println(); . First add Serial.begin(9600); in setup().

First you should convert your image to hex code. Download the software from the following link. if you don’t want to change the settings of the software, you must invert the color of the image and make the image horizontally mirrored and rotate it 90 degrees counterclockwise. Now add it to the software and convert it. Open the exported file and copy the hex code to Arduino IDE. x and y are locations of the image. sx and sy are sizes of image. you can change the color of the image in the last input.

Upload your image and download the converted file that the UTFT libraries can process. Now copy the hex code to Arduino IDE. x and y are locations of the image. sx and sy are size of the image.

In this template, We just used a string and 8 filled circles that change their colors in order. To draw circles around a static point ,You can use sin(); and cos(); functions. you should define the PI number . To change colors, you can use color565(); function and replace your RGB code.

In this template, We converted a .jpg image to .c file and added to the code, wrote a string and used the fade code to display. Then we used scroll code to move the screen left. Download the .h file and add it to the folder of the Arduino sketch.

In this template, We used sin(); and cos(); functions to draw Arcs with our desired thickness and displayed number by text printing function. Then we converted an image to hex code and added them to the code and displayed the image by bitmap function. Then we used draw lines function to change the style of the image. Download the .h file and add it to the folder of the Arduino sketch.

In this template, We added a converted image to code and then used two black and white arcs to create the pointer of volumes. Download the .h file and add it to the folder of the Arduino sketch.

In this template, We added a converted image and use the arc and print function to create this gauge. Download the .h file and add it to folder of the Arduino sketch.

while (a < b) { Serial.println(a); j = 80 * (sin(PI * a / 2000)); i = 80 * (cos(PI * a / 2000)); j2 = 50 * (sin(PI * a / 2000)); i2 = 50 * (cos(PI * a / 2000)); tft.drawLine(i2 + 235, j2 + 169, i + 235, j + 169, tft.color565(0, 255, 255)); tft.fillRect(200, 153, 75, 33, 0x0000); tft.setTextSize(3); tft.setTextColor(0xffff); if ((a/20)>99)

while (b < a) { j = 80 * (sin(PI * a / 2000)); i = 80 * (cos(PI * a / 2000)); j2 = 50 * (sin(PI * a / 2000)); i2 = 50 * (cos(PI * a / 2000)); tft.drawLine(i2 + 235, j2 + 169, i + 235, j + 169, tft.color565(0, 0, 0)); tft.fillRect(200, 153, 75, 33, 0x0000); tft.setTextSize(3); tft.setTextColor(0xffff); if ((a/20)>99)

In this template, We display simple images one after each other very fast by bitmap function. So you can make your animation by this trick. Download the .h file and add it to folder of the Arduino sketch.

In this template, We just display some images by RGBbitmap and bitmap functions. Just make a code for touchscreen and use this template. Download the .h file and add it to folder of the Arduino sketch.

The speed of playing all the GIF files are edited and we made them faster or slower for better understanding. The speed of motions depends on the speed of your processor or type of code or size and thickness of elements in the code.

This 2.0”LCD display adopts T7789V driver chip and has 320*240 color pixels (RGB565). It uses IPS TFT display and can display 18-bit color(16-bit is basically used). The module performs excellently in displaying color bitmap. Besides, there is an onboard MicroSD card slot for displaying more pictures. There are two connection ways for this module: pin headers and GDI. Only one fpc cable is needed when working with main-cotnrollers with GDI, which greatly reduces the complexity of wiring.

This is an example of commonly-used icons. 1. We use GIMP2 to convert these icons into codes for better display. 2. We provide some icons for you, Click here to find more"Click here to find more").

For an upcoming new project I wanted a colour (UK spelling) LCD screen (ideally OLED), 256×256 (or greater) resolution and nice and cheap. It was not an easy 2 minute task. There were no OLED screens offering what I wanted (that I could see at the time). So compromises were made, in the end I purchased a 128×128 pixel screen (none OLED) for around $3.50 (£3.20, 3.50 Euro). Not as cheap as I thought I might get one for but the cheapest I could find. There were a lot of sellers offering this screen and it’s shown below.

For my new project (after the Space Invaders one, see https://www.xtronical.com/programming-series-space-invaders-on-arduino/), I wanted a screen where I could directly port the Arcade graphics and screen layout without too much messing about re-designing graphics. But for the price point I wanted this proved impossible. Most arcade games of the early 80’s did not go above 256 pixels in any give direction so porting the graphics should be easy I thought. At half the resolution I hope that transferring the graphics will not be too tedious and that in most cases I can simply reduce the number of pixels in each image by half.

Due to the planned game being more advanced than Space Invaders I needed a processor with more memory and speed than the Arduino could offer. Enter the ESP8266 processors which offer faster speeds and lots and lots more memory. Wifi is also available but will not be required for this project unless we implemented a World High Score Table perhaps! There are newer versions, ESP32, available with even more power but are more expensive and we don’t need that level of performance for this project. I’m using a NodeMCU from Lolin, which is basically a breakout board for the ESP8266 so that you can use it easily on breadboards or small production runs using through hole.

Connections – very careful now!Looking at the back we can see +3v3 (this screen can be powered from 5v as well), several grounds (Gnd) and SCL/SDA. This shouldmean that this device is an I²C device and can be easily connected to our Arduino. Err… Think again. This screen gave me no end of problems as connecting it to the I²C connections and running any demo I could find on the internet did not get anything on the display. I went back and looked at the listing for this device, it stated SPI Bus not I²C ! So it began to become apparent that this screen had an SPI interface. SCL and SDA would logically seem to be SPI clock and data (MOSI) respectively but other pin labels didn’t match normal SPI protocol labels. Reading several resources for other different screens and looking at the source code for the examples in the Arduino IDE Examples library lead me to find the correct connections to power and use this screen.

Power is self explanatory. LED adds a little extra brightness to the screen but it does still work if not connected. I’ve seen resistors added in series here and even variable ones to vary the brightness but I’ve ran it directly connected on this screen with no issues and wouldn’t want it dimmer as its not ultra bright. It is actually on even when not connected giving adequate brightness in my opinion. SCL is the SPI clock and goes to the NodeMCU’s hardware SPI pin (pin D5). SDA is actually the SPI MOSI connection and goes to the NodeMCU’s SPI MOSI pin (D7). RS is a Regsiter Select pin for ST7735 driver chips, this maps to a variable called TFT_DC in the Adafruitcode (explained later) that I was using for testing. This controls whether we are sending a command to the ST7735 chip or actual data. I think that Adafruit call it DC meaning Data Control, but I’m not sure. On some boards it may even be referred to as A0. For our purposed we connect it to D4. RST is the screen reset and and is connected to pin D3. These last two can connect to any NodeMCU pins that are not used for other functions. CS is Chip Select (usually referred to as Slave Select in the SPI protocol) and again can connect to any pin but I use D2. If this is pulled low then this device can receive or send data on the SPI bus. If only one device in your design you could pull this low permanently and not use D2.

Driver CodeWhen presented with this board (as mentioned above) it was difficult to work out where wires should go and what driver software I needed for the display. Looking at the solitary chip on the board and Googling revealed nothing. So I went back to the sellers listing and found buried deep in a sub-page description the phrase “7735 drive”. Googling this revealed Adafruit had written some drivers for this chip for a board they had created (which also had an SD card slot on it as well). It was not surprising I didn’t find the 7735 chip on the board as this chip is designed to by embedded onto the back of the screen. It was being armed with this source code and other web pages dealing with different chip sets but similar displays that I managed to work out (with a little trial and error) the connections talked about previously above. Initially I used the Adafruit driver code but gave issues with this screen (as it was designed to work with the one they sell). Look below.

Fixing the ST7735 driver to work with this screen.So we have some work to do still to make this work well with our display. The driver we have used to get this up and running was not designed for this display exactly. Things appear clipped and off screen. There were other issues with colour (i.e. red was blue and blue was red amongst other colour problems) and other graphics routines were not correct. I won’t bore you with all the tiny re-writes I did but just supply you with the new driver for this particular display. This driver is very specific, i.e. only targeting this display and resolution but it may well work with many other similar displays. At the time of writing I have no other displays to test with but will be expanding the driver code as and when required. The full driver code is available from the link below, add it into your Arduino in the usual manner (Adding libraries to the Arduino IDE.)

Load up the example code that should now be available at “Files->Examples->XTronical ST7735 Library->GraphicsTestESP8266”. This is basically the Adafruit example with just some tiny changes (It goes through all the tests for each rotational position of the screen) so that it uses the new driver file and slightly altered initialisation routine.

There is an issue with the line drawing routine within the Adafruit GFX library, so this part of the original demo was removed. Basically it forces the NodeMCU to reset. As I’m not going ot be using this I’ve decided for now to ignore this issue.

As a 2inch IPS display module with a resolution of 240 * 320, it uses an SPI interface for communication. The LCD has an internal controller with basic functions, which can be used to draw points, lines, circles, and rectangles, and display English, Chinese as well as pictures.

The 2inch LCD uses the PH2.0 8PIN interface, which can be connected to the Raspberry Pi according to the above table: (Please connect according to the pin definition table. The color of the wiring in the picture is for reference only, and the actual color shall prevail.)

The example we provide is based on STM32F103RBT6, and the connection method provided is also the corresponding pin of STM32F103RBT6. If you need to transplant the program, please connect according to the actual pin.

The LCD supports 12-bit, 16-bit, and 18-bit input color formats per pixel, namely RGB444, RGB565, and RGB666 three color formats, this demo uses RGB565 color format, which is also a commonly used RGB format.

For most LCD controllers, the communication mode of the controller can be configured, usually with an 8080 parallel interface, three-wire SPI, four-wire SPI, and other communication methods. This LCD uses a four-wire SPI communication interface, which can greatly save the GPIO port, and the communication speed will be faster.

2.We use Dev libraries by default. If you need to change to BCM2835 or WiringPi libraries ,please open RaspberryPi\c\Makefile and modify lines 13-15 as follows:

Write Chinese string: in the image buffer, use (Xstart Ystart) as the left vertex, write a string of Chinese characters, you can choose character font, font foreground color, font background color of the GB2312 encoding

2. The module_init() function is automatically called in the INIT () initializer on the LCD, but the module_exit() function needs to be called by itself

Python has an image library PIL official library link, it do not need to write code from the logical layer like C, can directly call to the image library for image processing. The following will take 1.54inch LCD as an example, we provide a brief description for the demo.

The first argument is a tuple of four elements. (20,10) is the coordinate value in the upper left corner of the rectangle, and (70,60) is the coordinate value in the lower right corner of the rectangle. Fill =" WHITE" means BLACK inside, and outline="BLACK" means the color of the outline is black.

The first parameter is a tuple of 2 elements, with (40, 50) as the left vertex, the font is Font2, and the fill is the font color. You can directly make fill = "WHITE", because the regular color value is already defined Well, of course, you can also use fill = (128,255,128), the parentheses correspond to the values of the three RGB colors so that you can precisely control the color you want. The second sentence shows Micro Snow Electronics, using Font3, the font color is white.

After two theory-loaded blog posts about handling data array-like in strings (Strings, arrays, and the less known sp(lit)str(ing) function and Strings & arrays - continued) which you are highly recommended to read before continuing here, if you haven"t already, it"s big time to see how things work in practice! We"ll use a string variable as a lookup lookup table containing data of one single wave period and add this repeatedly to a waveform component until it"s full.A few weeks ago, I wrote this article about using a text variable as an array, either an array of strings or an array of numbers, using the covx conversion function in addition for the latter, to extract single elements with the help of the spstr function. It"s a convenient and almost a "one fits all" solution for most use cases and many of the demo projects or the sample code attached to the Nextion Sunday Blog articles made use of it, sometimes even without mentioning it explicitly since it"s almost self-explaining. Then, I got a message from a reader, writing: "... Why then didn"t you use it for the combined sine / cosine lookup table in the flicker free turbo gauge project?"105 editions of the Nextion Sunday blog in a little over two years - time to look back and forth at the same time. Was all the stuff I wrote about interesting for my readers? Is it possible at all to satisfy everybody - hobbyists, makers, and professionals - at the same time? Are people (re-)using the many many HMI demo projects and code snippets? Is anybody interested in the explanation of all the underlying basics like the algorithms for calculating square roots and trigonometric functions with Nextion"s purely integer based language? Are optimized code snippets which allow to save a few milliseconds here and there helpful to other developers?Looking through the different Nextion user groups on social networks, the Nextion user forum and a few not so official but Nextion related forums can be surprising. Sometimes, Nextion newbies ask questions or have issues although the required function is well (in a condensed manner for the experienced developer, I admit) documented on the Nextion Instruction Set page, accessible through the menu of this website. On top of that, there is for sure one of my more than 100 Sunday blog articles which deals not only with that function, but goes often even beyond the usual usage of it. Apparently, I should sometimes move away from always trying to push the limits and listen to the "back to the roots!" calls by my potential readers...Do you remember the (almost) full screen sized flicker free and ultra rapid gauge we designed in June? And this without using the built-in Gauge component? If not, it"s time to read this article first, to understand today"s improvements. The June 2022 version does its job perfectly, the needle movement is quick and smooth, and other components can be added close to the outer circle without flickering since there is no background which needs constantly to be redrawn. But there was a minor and only esthetic weak point: The needle was a 1px thin line, sometimes difficult to see. Thus, already a short time after publishing, some readers contacted me and asked if there were a way to make the needle thicker, at least 2 pixels.Recently, when playing with a ESP32 based NodeMCU 32S and especially with its WiFi configuration, I did as (I guess) everybody does: I loaded an example sketch to learn more about the Wifi library. When you set up the ESP32 as an access point, creating its own wireless network, everything is pretty straightforward. You can easily hard code the Wifi name (SSID) and the password. But what about the client mode ? Perhaps one needs to use it in different environments. And then, a hard coded network name and password are definitively not the best solution. Thus, I thought, why not use a Nextion HMI for a dynamic WiFi setup functionality?

Arduino has always helped to build projects easily and make them look more attractive. Programming an LCD screen with touch screen option might sound as a complicated task, but the Arduino libraries and shields had made it really easy. In this project we will use a 2.4” Arduino TFT LCD screen to build our own Arduino Touch Screen calculator that could perform all basic calculations like Addition, Subtraction, Division and Multiplication.

Before we actually dive into the project it is important to know, how this 2.4” TFT LCD Module works and what are the types present in it. Let us take a look at the pinouts of this 2.4” TFT LCD screen module.

As you can see there are 28 pins which will perfectly fit into any Arduino Uno / Arduino Mega Board. A small classification of these pins is given in the table below.

As you can see the pins can be classified in to four main classifications such as LCD Command Pins, LCD Data Pins, SD Card Pins and Power Pins, We need not know much about the detailed working of these pins since they will be take care by our Arduino Library.

You can also find an SD card slot at the bottom of the module shown above, which can be used to load an SD card with bmp image files, and these images can be displayed in our TFT LCD screen using the Arduino Program.

Another important thing to note is your Interface IC. There are many types of TFT modules available in the market starting from the original Adafruit TFT LCD module to cheap Chinese clones. A program which works perfectly for your Adafruit shield might not work the same for Chinese breakout boards. So, it is very important to know which types of LCD display your are holding in hand. This detail has to be obtained from the vendor. If you are having a cheap clone like mine then it is most probably using the ili9341 driver IC.You can follow this TFT LCD interfacing with Arduino tutorial to try out some basic example programs and get comfortable with the LCD screen. Also check out our other TFT LCD projects with Arduino here:

If you planning to use the touch screen function of your TFT LCD module, then you have to calibrate it to make it work properly. A LCD screen without calibration might work unlikely, for instance you might touch at one place and the TFT might respond for a touch at some other place. These calibrations results will not be similar for all boards and hence you are left on your own to do this.

The 2.4” TFT LCD screen is a perfect Arduino Shield. You can directly push the LCD screen on top of the Arduino Uno and it will perfectly match with the pins and slid in through. However, as matters of safety cover the Programming terminal of your Arduino UNO with a small insulation tape, just in case if the terminal comes in contact with your TFT LCD screen. The LCD assembled on UNO will look something like this below.

We are using the SPFD5408 Library to get this arduino calculator code working. This is a modified library of Adafruit and can work seamlessly with our LCD TFT Module. You can check the complete program at the end of this Article.

Now, open Arduino IDE and select Sketch -> Include Librarey -> Add .ZIP library. A browser window will open navigate to the ZIP file and click “OK”. You should notice “Library added to your Libraries” on the bottom-left corner of Arduino, if successful. A detailed guide to do the same is given in the Interfacing Tutorial.

Now, you can use the code below in your Arduino IDE and upload it to your Arduino UNO for the Touch Screen Calculator to work. Further down, I have explained the code into small segments.

We need three libraries for this program to work; all these three libraries were given in the ZIP file you downloaded from the above provided link. I have simply included them in the code as shown below.

As said earlier we need to calibrate the LCD screen to make it work as expected, but don’t worry the values given here are almost universal. The variables TS_MINX, TS_MINY, TS_MAXX, and TS_MAXY decide the calibration of the Screen. You can toy around them if you feel the calibration is not satisfactory.

As we know the TFT LCD screen can display a lot of colours, all these colours have to be entered in hex value. To make it more human readable we assign these values to a variable as shown below.

The final step is to calculate the result and display them on TFT LCD Screen. This arduino calculator can perform operation with 2 numbers only. These two numbers are named as variables “Num1” and “Num2”. The variable “Number” gives and takes value from Num1 and Num2 and also bears the result.

When Equal is pressed the value in Number will be sent to Num2 and then the respective calculation (in this case addition) will be made and the result will be again stored in the variable “Number”.

The working of this Arduino Touch Screen Calculator is simple. You have to upload the below given code on your Arduino and fire it up. You get the calculator displayed on your LCD screen.

Now, you can enter any number and perform your calculations. It is limited to only two operand and only operator for now. But, you can tweak the code to make it have lots of option.

"Upper layer" main development board contains ESP32-PICO-D4 SiP, battery connector & charger circuit with LiPo charge status LEDs, Reset & pull-up IO0 buttons, and a green LED on GPIO4.

Clone of the SparkFun ESP32 Thing board. Compact ESP32 based development board with battery connector, and the typical development board component accoutrements.

Similar to, but slightly different than, Heltec Automation"s WIFI LoRa 32 board. Notably, it uses a planar inverted-F antenna (shaped metal) for Wi-Fi.

Version 2.0 of this board (1) corrected polarity labeling on bottom silk-screened battery symbol and (2) changed the LiPo battery connecter direction.

Development board/module with ESP-WROOM-32 module, USB-to-UART, Reset & Boot (IO0) buttons, Li-ion battery connector & charger, two Grove connectors, LED on IO2, and three indicator LEDs.

The ESP32-LyraTD-MSC Audio-Mic HDK (hardware development kit) combines the ESP32-LyraTD-MSC ("audio-mic development board") with a secondary "top" board.

The ESP32 touch sensor development kit, ESP32-Sense Kit, is used for evaluating and developing ESP32 touch sensor system. ESP32-Sense Kit consists of one motherboard and multiple daughterboards. The motherboard contains a display unit, a main control unit and a debug unit. The daughterboards have touch electrodes in different combinations or shapes, such as linear slider, wheel slider, matrix buttons and spring buttons, depending on the application scenarios. Users can design and add their own daughterboards for special usage cases.

Features an xBee socket with switchable VCC voltage (3.3 V or 5 V), so 2G (SIM800) and 3G (SIM5360) xBee modules will work on it to provide cellular network access.

ESP-WROOM-32 based development board with SH1106 OLED display (128×64 pixels), RJ-45 Ethernet connector, CAN-bus connector, Micro USB connector, USB-to-UART bridge, LiPo battery connector and charging circuit.

ESP32 development board with ePaper display, TI PCM5102A DAC, ICS43434 MEMS Microphone, CP2102N USB-to-UART bridge, microSD card slot, and LiPo charger.

Circular board with ESP-WROOM-32 module, Ethernet (LAN8720A), stereo audio CODEC (WM8978), microphone, 3.5 mm audio receptacle, USB-to-UART bridge (CP2104), Micro USB connector, and SD card slot.

2× Ethernet (optional), 1× Serial Port RS-232/485, OLED 0.96″ 128×64 (optional), power supply with UPS (optional), U.FL (I-PEX) antenna mount(s), and ExCard extension modules support.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey