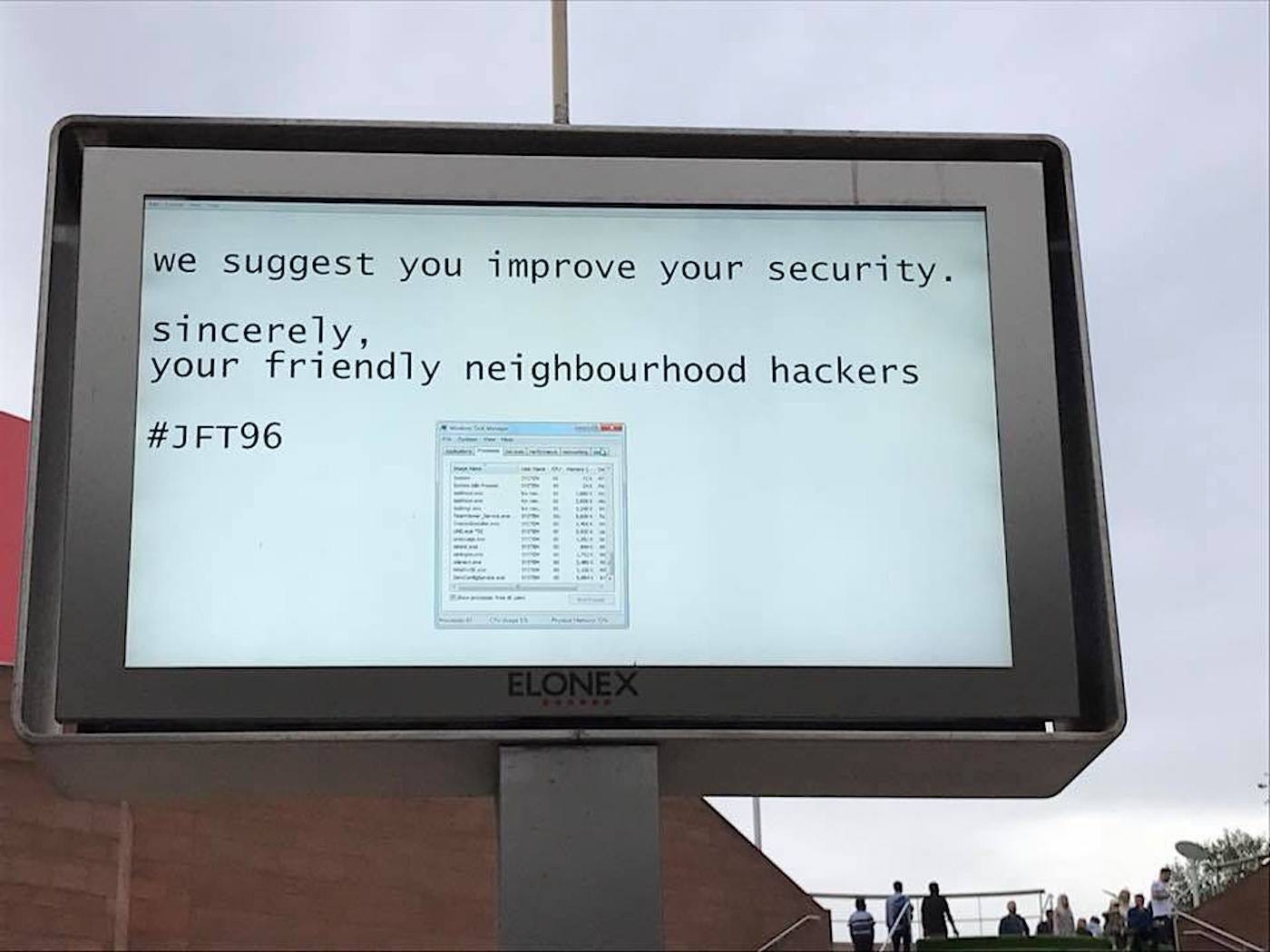

hacking lcd displays quotation

Luckily, all the digital devices in his 2012 Hyundai Genesis Coupe were connected using a fairly common standard — the “Controller Area Network bus” (or CAN bus). So Harin grabbed one of his Arduino’s — plus a cheap SPI CANBUS circuit board — and just started doing some experiments. When he first installed his Arduino circuit board into the dashboard, the LCD began showing the time of day — every ten milliseconds — and any new messages that he sent to the screen were simply being wiped out when the system re-transmitted. But Harin had already built up a strong motivation to keep moving forward, according to a recent write-up in Make: magazine, because “I hated that stupid little blue LCD. It would just sit there staring at me brightly with the words ‘AUX’…”

So he re-routed the LCD’s input. And fortunately, Harin’s other Raspberry Pi board could accommodate a WiFi dongle. By using an iPhone for connectivity, it was now able to draw down the funny Reddit quotes. And Make: also reported that his next project may be to install a router directly into his car.

Harin’s even mounted his Nexus 7 Android tablet into his car’s dashboard and is using it to play music. In the comments on his blog, he talks about one day transmitting the “now playing” information from the tablet to the LCD. Somewhere in the mix, there’s even an SQL database. “My main script retrieves the top post from Shower Thoughts and converts the characters to their hexadecimal equivalents, adds the message ID and row identifier, and stores it in an SQL database.”

There’re two more scripts just for retrieving the quote from the database and display it on the screen, which Harin says will be building blocks for more features down the road. “Eventually, I’ll be able to screen the messages intended for the LCD on the primary [CAN bus] network and add the ones I want to keep to the SQL database while removing the ones I don’t need anymore.”

PROJECT: I am looking to hack up an old used Pinephone and replace the LCD display panel with a smaller square"ish sized one. Something similar to attaching a Waveshare panel to a Raspberry pi, as per example: https://www.waveshare.com/product/2.8inch-dpi-lcd.htm

@Al Williams – I wonder how fast the opaque/transparent transition rate can be. I envisioned modulating a light beam with this (VLC or Visual Light Communications). However, I wanted to do so with a a high-wattage spotlight like a 18-million Candlepower Q-Beam Spotlight. Of course you could simply put a high-power TRIAC in line to the Q-Beam’s bulb and just drive (gate 12vdc) it directly with audio, Morse Code, or PCM (Pulse code modulation) digital data. But that would fatigue the bulb with too many off/on transitions.This method could put in front of the beam by a few feet to reduce overheating the LCD glass. The low-voltage AC signal could be applied to the glass causing it to interrupt the beam of light without damaging the spotlight’s bulb. You could use a low-power TRIAC (TRIAC’s are meant for gating low–to-moderate-voltage AC. You can also gate DC with a TRIAC. SCR’s latch and need to be reset. TRIAC’s don’t. But both can handle higher wattage).

We’ve seen a number of open source smart watches over the years, and while they’ve certainly been impressive from a technical standpoint, they often leave something to be desired in terms of fit and finish. Exposed PCBs and monochromatic OLED displays might be fine for a trip to the hackerspace, but it wouldn’t be our first choice for date night attire.

While getting our own code running on commercially produced smartwatches holds a lot of promise, the Open-SmartWatch is arguably the best of both worlds. The partnership with LILYGO brings professional fabrication to the open hardware project, and the GPLv3 licensed firmware is ripe for hacking. We’re very excited to see where the community takes this project, and fully expect to start seeing these watches out in the wild once we can have proper cons again.

By googling for hackable devices I found an interesting software hack that allow you to use a digital photo frame based on a Sintronix st2205u chipset as a usb LCD screen (1,5 inch, 128*128 pixels, with colors).

After changing the firmware it is possible to run lcd4linux : a program that displays information about computer system, or to run mplayer and display video on the DPF. It is even possible to use the DPF as linux terminal (with a computer and a keyboard of course).

There are many modded cases which had had simple LCD or VFD displays fitted to add an element of "coolness". These displays are generally somewhat limited in their capabilities and often consist of just a few lines of alphanumeric characters. Now you can go that extra mile and take "coolness" into the "chilly" realms by fitting a "real" graphic LCD display just like the one on your desktop, only smaller. I am talking about the add-on LCD screen for the Sony PSone Playstation games console. This display has a viewable area of approximately 5 inches, has a resolution of 640 x 480 and is a gift to modders everywhere. Here are a few features of this unit..."

The SoC GPU does have a DSI interface, and is used in many mobile phones world wide to drive the LCD. However, each LCD requires a new driver on the GPU, along with (often) very specific cabling etc. The DSI interface is available on the prototype, but I don"t think will be there on the Raspi Pi release board as no-one would be able to use it anyway as it would require recompiles of the binary blob. Also DSI is getting a bit old hat now.

But I still have a curious problem : on this ARM device the program lcd4linux display curious letters, as if it was an encoding (I mean like utf8 , in french we say "encodage", I hope it"s the good word) problem...

Pretty easy tbh if you don"t mind soldering a few things, just hook it up to the composite port of the RPi. There are hundreds of how-to"s explaining how to do composite->vga adaptors and you can easily find the psone lcd schematics.

Hey, a little cheap usb lcd screen would be great. You could use the little screen when using the device without a tv, and then plug it in to a tv when you get to one, but still have the lcd attached and working. It would be like a dual screened device.

The first step in the hack is to select a compatible LCD that’s also conveniently available. For various reasons related to how the flat panel display market works, LCDs are difficult to purchase in their raw form. Fortunately, Mouser Electronics has a fair selection of LCD modules available and in-stock, although the price is no where near wholesale. I found that the Microtips MTF-TV57NP721-AV was a good match; you can buy these directly from Mouser for $150.80 by ordering part number 668-MTF-TV57NP721-AV. This LCD module uses a compatible signal format, has an LED backlight that works with a slightly modified chumby backlight driver, and also features a 4-wire resistive touchscreen, which is exactly the technology used by the stock chumby device. While the datasheet for this display is not available for convenient download, the datasheet itself is not marked proprietary or confidential, so I was able to secure a copy with a phone call to the local Microtips sales representative.

The next step is to build an adapter board between the chumby and the LCD. The adapter board is necessary because the flat-flex connector used by the Microtips LCD has a different size and pinout from the existing chumby LCD connector. The design of the board doesn’t require many components, as it is just rewiring the signals between two connector formats, but getting the design right does require attention to detail. It’s particularly important to make sure you get the location of the connectors right, so as to minimize the stress on the flex cables, and you need to be aware of the pinout inversion that happens between the two sides of a flex cable mating to the same type of connector: pin 1 goes to pin 50, and vice versa. Here is a link to the schematic for the adapter board, and a link to the gerbers.

Since you won’t need the old LCD anymore, loosen the two long Philips screws on the wifi riser assembly and liberate the core from the LCD/bezel assembly by detaching the two flat flex cables that connect to the core board. Save the wifi riser assembly, screws, standoffs and cables. Also leave all the thermal pads in place; they will hold on their own if you do not peel them off of the circuit boards.

You will need to do some minor rework to the core circuit board of the chumby in order to beef up the backlight driver to work with the more power-hungry backlight of the larger LCD. The original chumby backlight is a 10.2 volt, 40 mA 3-LED backlight. The backlight inside the Microtips LCD is also a 10.2 volt backlight, but it requires 200 mA. Fortunately, the boost converter used to drive the chumby’s backlight has a current switch capable of handling that magnitude of current—the TPS65101 has a 2.3A switch in it. However, some of the external circuitry has to be upgraded. In particular, the catch diode D502 has a forward current rating of 0.5A. While the LCD only draws 200 mA, it is a boost converter so the amount of current going through the catch diode is going to be a bit bigger than the ratio of the output voltage to the input voltage times the average current. Therefore, D502 has to get an upgrade to a footprint-compatible but higher current version, such as the 1A-rated MBRX130TP by Micro Commercial, or the 1.5A-rated RB070M-30TR by Rohm. Finally, in order to actually increase the amount of current pumped into the LCD, the current sense resistor in the feedback network of the boost regulator has to be modified. R524 programs the backlight current in the “on” state of the backlight, though the following relationship: I = 1.146V / R524. Its stock value of 57.6 ohms yields a current near 20 mA; replacing this with a 5.6 ohm resistor will yield a current just over 200 mA.

Now that you’ve got all the bits and pieces, it’s time to put it all together. It’s good practice to mount the pieces so that they aren’t “floating”; the flat flex cables are fragile, and they will easily strain and break if you move the unit around too much. If you have access to a laser cutter, you can build the LCD mount using the designs presented below.

Next, cut a second protective bezel using 1/16” clear acrylic using the reverse bezel pattern. This pattern also has alignment markers on it, which are important for making sure the LCD’s active area is centered in the opening of the bezel. There is no need to treat the reverse bezel with paint because it is simply a protective layer to protect the painted front bezel from chipping and scratching.

A set of gaskets are applied to the outside of the LCD along the silvery circuitry area of the touchscreen panel in order to improve the touchscreen’s robustness against heat warpage of the acrylic that can cause the bezel to inadvertently touch down onto the screen. The gasket material in this case is Poron, but you may also use a couple layers of thin-cut pieces of masking tape to create a small offset between the bezel edge and the display.

Before screwing the backplate in place, attach the 33-pin flat flex cable (that you previously made by cutting down the 36-pin cable), and connect the other side to the adapter board; at this time, also connect the 4-pin touchpanel cable and the 50-pin cable for the LCD signals to the motherboard. Then, fold the adapter board assembly over and screw it in place using 4x M2x6mm socket cap screws.

You’re almost done! Flip the LCD assembly into the bezel, using the alignment pattern on the bezel as a guide, and glue the four LCD mounting corners in place, paying attention to ensure that the holes on the mounting corners line up with the holes on the back plate (you can accidentally put a mounting corner on upside down and have the holes end up on the wrong edge of the LCD). Standard super glue works well for this application. Allow the glue to dry for at least a half hour before proceeding.

The kernel contains the code that initializes the video frame buffer’s size, so the timing needs to be programmed into these registers by modifying the kernel source. Here is a patchfile that you can apply to the 1.5.0 kernel (build 565) that performs the appropriate initializations. The patch modifies one of the clock registers inside the MX21 to increase the frequency of the clock feeding the LCD controller, and it also modifies the LCD controller registers itself. It also patches code that handles copying the initial logo screen from a staging area in RAM to its final location. It’s more involved to get the bootloader to behave properly and show a more elegant startup screen; here is a link to the modified bootloader source. This code replicates the QVGA bitmaps stored in the bootloader four times over inside the VGA frame buffer for the chumby, and it handles some other corner cases during the hand-off between the bootloader and the kernel at higher resolutions as well.

Finally, reboot while holding down the touchscreen so that you enter the “Special Options” mode. When the selection screen comes up, you should be able to log in via the serial console and execute the command “update.sh USB”, which will overwrite the bootloader and the primary kernel with the code patches mentioned above. For safety reasons, the backup partitions’ kernel is not modified by the dongle, so you always have a safe partition to return to for re-flashing a broken chumby. The graphics on the screen will look funny in this mode, but it’s not harmful for the LCD.

June 28 (Reuters) - A federal judge on Tuesday said a former Uber Technologies Inc (UBER.N) security chief must face wire fraud charges over his alleged role in trying to cover up a 2016 hacking that exposed personal information of 57 million passengers and drivers.

The U.S. Department of Justice had in December added the three charges against Joseph Sullivan to an earlier indictment, saying he arranged to pay money to two hackers in exchange for their silence, while trying to conceal the hacking from passengers, drivers and the U.S. Federal Trade Commission.

U.S. District Judge William Orrick in San Francisco rejected Sullivan"s claim that prosecutors did not adequately allege he concealed the hacking to ensure that Uber drivers would not flee and would continue paying service fees.

The defendant was originally indicted in September 2020, and is believed to be the first corporate information security officer criminally charged with concealing a hacking.

In September 2018, the San Francisco-based company paid $148 million to settle claims by all 50 U.S. states and Washington, D.C. that it was too slow to reveal the hacking.

It is a fairly open secret that almost all system can be hacked, somehow. It is a less spoken of secret that such hacking has actually gone quite mainstream.Dan Kaminsky

I was addicted to hacking, more for the intellectual challenge, the curiosity, the seduction of adventure; not for stealing, or causing damage or writing computer viruses.Kevin Mitnick

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey