lcd panel ribbon repair quotation

This instructable came about from a broken LCD control module out of a modern VW Camper Van. The LCD module is part of a control unit which was virtually unreadable and a replacement for a new unit was £400+. It really was a no lose option, either have a go at fixing it or end up buying a new unit.

The fault of the LCD was that it only displayed a couple lines of output on the LCD. The symptoms are caused by poor location of the LCD ribbon in manufacture and also the poor position of the whole module in the vehicle which exposes it to heat and is subject to vibration within the vehicle. This causes the ribbon to fail eventually and is a known common fault.

The ribbon in this display actually controls the Rows of the LCD matrix and the Columns were handled by a rubber standoff connection on the longest side of the LCD. There were no problems with the rubberized connection.

Some re-work on the LCD ribbon had already been tried with a little improvement but the poor registration of the ribbon pushed me to try a new attachment.

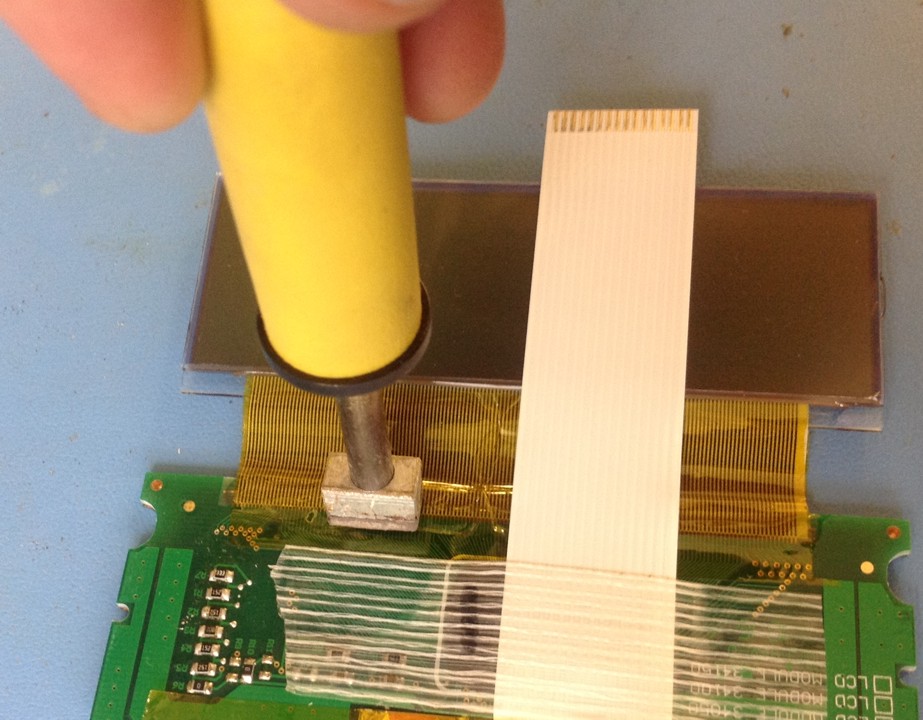

From the photos below you can see the LCD control unit and the state of the LCD ribbon before repair. You can just make out the offset placement and poor registration of the ribbon before repair.

Do not under estimate the patience required for this repair as some delicate and nimble work is required and i cannot stress how important it is to take your time and not rush. You may only get one chance with this sort of repair.

The registrations of the LCD ribbon in this repair was difficult. It took me and my friend 20 minutes just to line up the ribbon for re-attachment. The ribbon in this case is sub 1mm pitch OR less than 25.4 thousands of an inch. You may want to try a simpler ribbon repair on an old LCD clock for example before jumping in head first with fine pitch.

Also the removal of the LCD ribbon is a delicate process as you do not want to tear what is a good ribbon or damage the carbon printed lines. Also the PCB must be respected to avoid introducing other faults and the the re-attachment may need an extra pair of hands.

You may also want to review the last step for results and lessons learned from this instructable before jumping in head first but i believe this will give a you a good insight to some important factors of LCD ribbons and possible success.

Other favorites of reworking the LCD connection that i have read here are the tinfoil on a heat gun. This has good temperature management but not so good in tight spaces. The solder iron with flat blade and tin foil is more precise but a 25 Watt iron can be too brutal on the ribbon.

1. Do you have enough spare ribbon to detach and re-attach? The more ribbon you have the more goes you may get but watch out for the mechanical caveat below.

2. Will you be mechanically constrained if you cut the ribbon. This is a tough one as some shortening of the ribbon may make it impossible to re-assemble the device!!

3. Is the Ribbon continuity visibly good, by that i mean the carbon connection lines are continuous and unbroken - Do check otherwise you may be wasting your time.

In the photos below you can see the available ribbon length was generous enough but do watch for mechanical constraints. In some cases you could find yourself not being able to lay down the LCD back down as it is too tight a radius to sit down.

The ribbon removal needs careful thought depending on your device. It would be difficult to write a complete panacea solution for every device so please use some careful judgement on your device.

You do not want to pull at the ribbon as you will most likely damage what you already have. In my instance it was best to cut the ribbon free as close to the PCB pads as possible.I used a scalpel to slice parallel to the PCB board to remove the ribbon. Do make a good job of this as you may need to preserve as much extra ribbon to re-attach the LCD module.

The LCD assembly was lifted off and put in safe place to avoid damage. The ribbon was then gently lifted and peeled back with tweezers to remove the bulk. You must not use force to remove the remainder ribbon especially if your PCB is off a cheap quality OR single sided cardboard type variety. The PCB pads can come off with the ribbon! If you have a double sided PCB of FR4

For either connection style you need to remove any old glue from the ribbon and remaining carbon debris from the pads. I used isopropanol on a cotton wool bud. Do not flood the PCB with cleaning fluidas you may effect electro-mechanical elements in close proximity such as switches and other items on the PCB which are not sealed against cleaning!

From the photos you can see that ribbon was trimmed with a rounded scalpel blade. The ribbon also had extra green tape which adhered to the original heel of the PCB pad connection. This gave extra mechanical stability for the ribbon but has to be peeled off to allow for re-connection. Later in this instructable i will mention about putting back extra mechanical stability for ribbon support.

If you have a fine pitch ribbon like i had this will cause you the most trouble. I needed an extra steady pair of hands to help and some patience before i got the the ribbon aligned. It took twenty minutes of nudging the PCB and ribbon to get a precise alignment. Our alignment was actually better than the original which was slightly skewed to one side.

The trick to get good alignment is to allow some the gold pad fingers toes of the PCB to be visible just beyond the carbon lines of the ribbon. You then get the pads toes to line up with the carbon lines of the LCD ribbon.

Do not continue until you have excellent alignment of the black carbon lines of the ribbon to the PCB pads. The finer the pitch of the ribbon the better registration is required.

The photos below show how i handled the PCB and LCD and clamped the ribbon in place. The LCD display is being held by a plastic clamp above the PCB assembly. The PCB below which has components both sides is laying on some foam (try polystyrene). This allowed me to nudge the PCB under the ribbon into position. The plastic ruler acts as a LCD ribbon clamp. When you have got the registration get a steady handed friend to hold the ruler as a ribbon clamp in place so you can then apply the heat to stick the ribbon back down.

You may want to skip forward to the next step to see the re-attached picture of the ribbon and to see how the alignment was achieved. You should see the gold PCB pad finger toes in line with the carbon of the ribbon

1. Do not apply so much heat you obliterate the ribbon. Yes it sounds stupid but i over cooked one side of my ribbon and got away with it. You may want to test on the bit you trimmed off elsewhere to get correct amount of heat.

2. Only tack the ribbon down my pressing the heated tip down vertically and stroking from the heel to the toe. That is to say in the same line that the carbon lines flows.

Again Do not apply heat to the ribbon in one broad stroke. Work from the heel of the ribbon to the toe Or work by dabbing. By dabbing I mean hitting one spot on the ribbon with the heated tip and then lifted vertically again cooling the tip with the wet sponge before each dab.

The second photo in this step is the actual ribbon re-attached. You can see that the left hand side of the ribbon has not worked out as well as the right. I had too much heat in the solder iron. This is how i ended up cooling the solder iron with the wet sponge before applying heat.

In our case the LCD ribbon was not only glued to the PCB pads but there was some additional tape at the heel of the ribbon to hold the ribbon in place. By holding at the heel the ribbon you get some good extra mechanical support.

I did not go further with more re-work as the VW LCD module was considered a good enough result and some other time pressures intervened. It was concluded that we could read the display well enough and operate items from the controller. It was also considered as one of those quit while your ahead things!

For some people this may not be good enough but i hope that some of the steps i have listed will get people going in the correct direction when considering this. I do believe with a little more time a 100% is achievable. I took two hours to dismantle and remove the ribbon, Most of this was thinking things through... and another two hours to re-register and re-attach ribbon.

The technique for LCD ribbon removal and re-attachment are achievable certainly on simpler ribbons and fine pitch ribbons with careful preparation and thought. I hope this instructable is comprehensive enough for people to get some good results.

The ribbon is know as a "Heat Seal Connection" OR "HSC". In the industry heat and pressure are used to make this type of connection. The material comes from a family of "Anisotropic Conductive Films" OR "ACF".

The material bonds at 180 DegreeC. Direct Ribbon connection is used for economy (i.e. no fancy connectors) and for the number of connections its offers in a small footprint which would not be possible through traditional connectors.

The other end of the ribbon that joins to the LCD is terminated on the glass on Indium tin oxide (ITO) which is one of the most widely used transparent conducting oxides.

If you want more information there are many different types of LCM assemby (LCD Display plus it driving chips) to look at but these are the main ones (increasing in density):

In manufacture of these modules a machine is used for assembly which would compress HSC to the LCD Or the PCB and then apply the correct amount of heat.

very nice and complicated work but...my question is, where can I find a ribbon cable like this? I have a keyboard Technics KN2000 with a display not working because the cable was disconnected from both the glass display and the circuit board. Thank You!

I am attempting to fix a TV with vertical lines in it. Actually it was showing a black screen. I cleaned the ribbon connections and now I get an image with some multicolored vertical lines. ( good progress) . When I looked at the ends of the cable some of them were "missing" the last 1 - 2 mm of gold plating? do you think the method you used of slicing the ribbon to even the pads up is a good method? Or is there a way of replating/tinning the missing portions?

These graphite ribbon cables appear to have a layer of clear tape on either side of the graphite paths. To expose a new area of graphite paths for reconnection should the original path be damaged, the tape on one side needs to be peeled back. In my case, when I attempted to peel back the tape some of the paths fragmented and went with the peeled back tape. I suspect that in the case at hand, the peel back was not necessary and heat was used to reattach the previously exposed paths.0

My flat ribbon seems to have a plastic covering on both sides but looks just like your pictures. Must I remove the plastic covering on the attachment side before applying heat to make the connection or does the plastic stay in place and somehow act as a glue when hot?0

Attached is a picture of a screen from a Brookstone clock. I think it may be an LCD. The black pads show where a ribbon cable was connected and I see not transmission paths from the pads into the screen. How does this work? Is it really an LCD?

Are the paths in this ribbon cable covered on both sides as mine is and can you adhere the ribbon without removing any covering by applying heat? And what do I do on the LCD side where there appears to be no pads on the LCD but the ribbon cable was apparently applied in this manner?0

I have two items to add, kapton tape and sil-pads used to isolate heat-sinks from semiconductor devices. With kapton tape it brings the means to secure the ribbon to the board, place the tape over the whole connection area, and kapton resists heat very well, ( try and melt it with your soldering iron). This means an average soldering iron turned down will allow heat to be applied to each joint. With experience a rework can be done in a few minutes. The bond can also be renewed on the LCD glass as well, kapton also works here. Sil-pads allow heat to be passed to the joint with some pressure applied at the same time. The sil-pad can be dragged up and down all the ribbon connections allowing uniform heating. Once the bond is resurrected the sil-pad is discarded. http://goo.gl/mpZNkm0

I just thought the same way, adding aLCD flat connector... then you can swap chinese or VDO oem screens. Seems the VDO LCD(as for Audi A3-Vw golf/jetta4) have 50 pins and the ribbons is 48mm width. Then you have to look to modify the metal bracket to avoid pressure on ribbon.

i would not rule out a connector fix totally but its nice if you can fix for zero cost if possible. Also you then have to manage the mechanical constraints as well as choosing a suitable connector. Usually only the semi flexi PCB circuits ribbons go into connectors not the carbon screen printed sort so may not be so desirable.0

I simply lifted the clear tape off from the top of the ribbon, then slowly stroked the ribbon contacts in turn a couple of times with the hot glue gun tip. Not hot enough to cause any damage.

In the photo i am only using a soldering iron covered in tin foil to heat the plastic ribbon. There is no solder used in this setup. The tin foil is there only to provide a better surface to apply heat to the ribbon (does not stick to the ribbon!!).

Actual Electrical connectivity is provided by carbon lines which are printed in the ribbon. The carbon lines only make contact via the adhesion of the ribbon.

The solder iron method technique is actually too hot and so i dip the solder iron in a sponge to cool it down before pressing down on the ribbon. If you have a temperature controlled soldering iron it would be much better.

i have an alarm clock which doesn"t have a ribbon, but instead some sort of rubbery contact strip against which the display should be pressed. You can find pics of it on google images for "lcd rubber contact strip", it seems to be called a zebra rubber. Any idea on how to glue/solder the display to that rubbery contact strip?More CommentsPost Comment

Try using lcd ribbon cable repair found on Alibaba.com to make many types of production jobs faster and easier. Each model can be filled with different types of liquid and quickly dispensed into containers. Use lcd ribbon cable repair to fill paint cans with speed and precision. Other compatible fluids include resin or glue, making such devices suitable for manufacturing all kinds of helpful products.

All lcd ribbon cable repair are built to be easy to operate, reducing labor and training times needed. Some versions can pour food-grade liquids such as beer or milk into bottles for future sealing. Most units work automatically so workers can program them and stay back as they work on their own. When installed on a factory floor, they offer greater efficiency to help save time and costs.

Shop for lcd ribbon cable repair at Alibaba.com to find many helpful suppliers with a wide range of options that can be ordered. Choose just the right size to fit the intended workspace. Pick a wattage level that promises good speed and power without using too much electricity and driving up costs. Certain designs can dispense products in the form of powder or granules into nearby containers. Use these to package particular powdered food and pharmaceutical ingredients.

Search for lcd ribbon cable repair on Alibaba.com and enjoy lower costs when working with various liquids or powders. Whether for use in food manufacturing or building materials, there are plenty of options to browse. Find a satisfactory brand that will improve efficiency for better overall quality in each final product.

I suspect I already know the answer to this, but if I don"t ask I"ll never be sure. I"m a beginner, only rudimentary soldering skills. I"ve got an old Acer Aspire laptop, a little while ago it developed a flickering screen fault and after a little googling we determined it was the backlight, and I put it to one side. The laptop works fine on an external monitor, and the backlight would sometimes appear to be fine for a few minutes until the machine warmed up, sometimes altering the angle between screen and keyboard would cause it to show fine (or go completely black) etc. You can get replacement lcd cables on eBay for a few quid, if it were just the lcd cable I"d have replaced it in a heartbeat.

I opened it up tonight just as a change of project, and after a little gentle exploration (and some googling) I confirmed it was a torn/degenerated backlight ribbon cable within part of the overall LCD display - there"s a ribbon that runs from inside the panel, along the outside to a connector that is still on the panel (rather than in the laptop). Putting very gentle pressure with a plastic spudger would cause the display to light up (or go black) etc etc. It looked like the kind of ribbon cable where you just push it into a connector so I gently tried to undo it with a view to trying to reseat it - and predictably it fell apart. :-)

I just want to confirm that this isn"t something I can fix by soldering some ribbon cable onto the bit left on the panel. I mean, the iron would probably melt the ribbon anyway, even if I could source some more ribbon, and I guess that introducing even very thin gauge wiring would be almost impossible to do...?

But if there"s a slim chance that someone might say, "oh, you can do this (insert clever trick here) and it might work" then I"ll give it a go - I gave the laptop up as a lost cause, it owes me nothing and it really doesn"t warrant the £70 or so for a replacement lcd panel, but if it can be repaired then it"s something my young daughter can play with until it breaks for good.

The attachments here show the cable, how it was originally bent over itself to make a 90 degree turn, and where it goes into the socket. Also you can see where the other end of it bends off into the innards of the panel.

The term ‘flat screen’ applies to a wide range of TV types, from LCDs to the latest 4K and Smart models. A flat screen means the TV’s screen surface is flat rather than convex like older models. There can be several different types of flat-screen TVs, from older LCD to the newest Smart and 4K TVs. The type impacts the repair costs because more advanced and expensive TVs have more costly components to replace or fix. In addition, some TV repairs may not always be possible on that type. For example, it is not possible to replace the screen on a plasma TV if it cracks and begins to leak. The table below shows common television types and average repair costs for each:

Repairs for LCD TVs cost between $60 and $400. LCD televisions are one of the most popular options on the market, available in a wide range of sizes and styles. They use an LCD (liquid crystal display) with backlights to produce images. The backlights, screen, and other components may get damaged over time and need repairing.

LED TV repairs range from $60 to $400, depending on the scale of the problem. LED televisions are a specific type of LCD TV that use LED backlights to illuminate the liquid crystal display. These TVs usually produce more colorful and vibrant images and are more energy-efficient, but the LED backlights may need to be repaired or replaced over time.

4K TV repairs range from $100 to $275. A 4K television provides some of the clearest and most detailed images because of the very high resolution of its screen, providing more engaging viewing experiences. There are different types of 4K TVs, including some that use LED and others that use OLED. Basically, a television is considered 4K if it has ultra high definition. These models can be expensive to purchase and repair, but in many cases, repairs may not be possible on these units. So, their overall repair costs may be lower simply because some repairs may not be offered.

OLED TV repairs cost between $100 and $400 on average. They are the next step up from a standard LED TV, with OLED standing for organic light-emitting diodes. OLED televisions can achieve deeper blacks and higher contrast compared to standard LED screens. However, they can be very expensive to purchase and repair.

Plasma TV repairs average $100 to $400. These televisions are made up of pixels filled with gas that light up when an electrical current is applied. They are less popular today, and most companies have stopped making them. But they can still be found in many homes and are subject to problems like screen burn and distorted colors. While some repairs on these TVs are possible, many issues cannot be repaired due to their design.

Smart TV repairs cost between $100 and $400. These TVs have Smart technology and connect with your home’s WiFi network to download updates and access apps and the internet. They are more advanced than other TVs but still have various components that can break and require repairs. Many Smart TVs can have basic components. So even though they may be more expensive to purchase, they are not necessarily the most expensive to repair. That comes down to how the television is made and what makes it Smart.

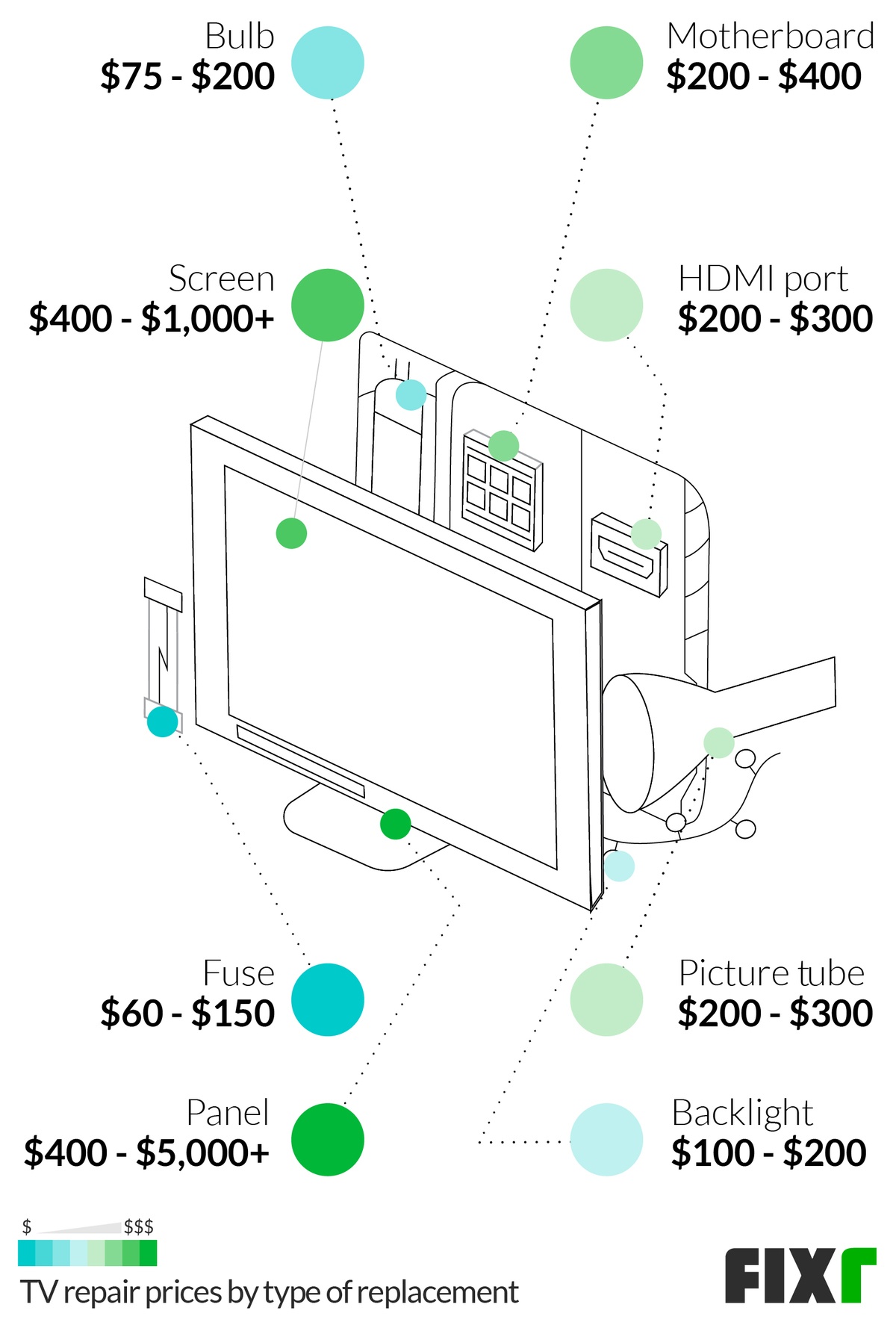

TVs are made up of various parts and components, all working together to produce lights, colors, pictures, and sounds for your entertainment. Over time, accidents may happen that damage these parts, or they might just wear down over the years through repeated use. The table below shows common TV repairs and the costs for each.

HDMI port repairs for a TV costs between $60 and $250. Sometimes, HDMI ports fall out of position and may simply need to be repositioned. In other cases, one might stop working due to a more serious fault and require technical repair work.

TV speaker repairs range from $75 to $250, depending on the type and damage done to the speaker. Faulty speakers may simply need rewiring or minor adjustments, or they could need to be cleaned or replaced, so the exact costs and amount of work vary.

Backlight repairs average $100 to $150. The backlight is what illuminates the display of your television, providing the brightness and color. It may be in the form of LED light strips or fluorescent lights, depending on which television type you have. If these lights develop a problem, a repairman must open it up and make adjustments to get them functioning again.

TV inverter repairs cost between $100 and $200 each. The inverter powers up the backlights for your television, and they can stop working if their capacitors break down. Repairs are made by fitting new capacitors in place.

Water damage repairs on a TV range from $150 to $400. In some cases, if too much water has gotten into the TV, it may be beyond repair. In less severe situations, a repairman will take the television apart, dry it out, and put it back together successfully, repairing any damaged components.

TV screen repairs cost between $200 and $400, but in many cases, repairing the screen is not possible. Since the screen is usually the most expensive part of the television and one of the most sensitive to impacts and other damage, an expert may advise you to simply buy a new television instead of having it repaired. It is worth getting a diagnosis if the screen issue is not too severe because issues like flashing pixels or distorted colors may be fixable.

TV panel repairs average $200 to $400 in some cases, but some panels cannot be repaired. For this reason, many companies do not offer panel repair. So if your television gets a crack in the panel, you may be better off buying a new unit instead.

Power board repairs cost between $200 and $400. The power supply board allows it to turn on and function, and if it breaks down in any way, it may simply stop turning on. Often, a repairman can replace some of the capacitors and make other adjustments to repair a faulty board, rather than having to replace it entirely.

In some cases, your TV components may not be able to be repaired, or it might be more cost-effective to replace them with new ones. The repair price includes the cost of new parts, plus the labor required to fit them into place and remove the broken components. While some components can be replaced, they may be extremely expensive or cost-prohibitive to do so. This is mainly in the case of panels and screens because they often contain too many parts to replace on their own. The table below shows average costs for a variety of common replacements:

Fuse replacement in a TV costs between $60 and $150 and is one of the easier replacement jobs for a repairman. Glass and ceramic fuses on your TV’s power supply board may blow in certain situations and need replacing. To replace a fuse, the repairman opens the TV to access the power panel and swaps out the fuse.

Replacing a TV capacitor is inexpensive, starting at $60 up to $200. If more than one capacitor needs replacing, it is usually less expensive to replace the entire board. Capacitors cannot be repaired, so replacement is the only option.

TV bulb replacement costs average $75 to $200. Bulbs are usually found only in older models of LCD TVs or projection TVs. They are used to illuminate the display so that the picture can be seen. Bulbs are relatively easy to replace, but the material costs are a little higher with bulbs when compared to other components, leading to varied replacement prices from model to model.

Picture tube replacements range from $200 to $300 on average. Picture tubes, also known as cathode ray tubes or CRTs, are only used in older TVs. So, this is not a replacement job you need to worry about with an LED or LCD TV.

TV motherboard replacements average $200 to $400. Often when a problem occurs with a motherboard, it needs to be completely replaced rather than repaired. The motherboard controls the TV’s functions and features, and a broken motherboard makes your television completely unusable.

TV screen replacement costs at least $400 to $1,000 and often much more. The screen is the most expensive part of a TV. So usually, the cost of replacing it is higher than just buying a new unit. In some cases, this is because the screen cannot be replaced without also replacing most of the other components, particularly for TVs like LED, LCD, or plasma. Most professional repair companies do not offer screen or panel replacement as a service.

TV panel replacement costs a minimum of $400 to $5,000 and often a lot more on some of the high-end 4K and Smart screen displays. Because the cost of a replacement panel is so high, it is usually more cost-effective to simply purchase a new television. Like the screen, this is due to the number of components involved. Therefore, most repair places will not offer panel replacement as a service.

You might not know exactly which part of your TV is broken or damaged at first. The symptoms of a broken television vary from vertical colored lines across the screen to audio issues, power problems, and even situations where the television starts normally but then turns itself off. For this reason, most repairs start with a diagnostic so that the problem can be found and a plan made for repair. For some repairs to be made, the part will need to be replaced, while in other cases, repair or replacement of that part may not be possible. The table below shows common problems and average repair costs for each.

Repairing a TV that will not turn on costs between $60 and $400 because there are many potential causes. It might be something as simple as a blown fuse, which can be replaced quite cheaply. Or, it could be a motherboard or power supply issue, which is more costly to fix.

Damaged cables on your TV can be repaired for between $75 and $200 in most cases. Over time, cables can get frayed, twisted, or broken, but professionals can cut away the damaged parts, add in new connectors and repair the damage, or simply replace the bad cables with new ones.

Expect to pay between $75 and $400 to repair a television with no sound. There are various reasons why your TV’s sound stopped working. It is most likely a fault with a speaker, which can be repaired or replaced. Or, it could be a deeper issue associated with the motherboard, which may also need fixing or replacing.

Repairs for this problem cost between $100 and $200. If your TV’s picture appears for a moment and then vanishes, it is most likely an issue with the inverter. A repairman will open it up, diagnose the issue, and decide on the most efficient solution.

Repairing vertical lines on the screen averages $150 to $400. This is usually an issue associated with your TV’s control board or motherboard, which may be damaged and need to be either repaired or replaced. It could also be caused by a loose cable, but it will need to be opened up to diagnose the issue and repair it.

Repairing horizontal lines on your TV costs between $150 and $400. It might be an issue with the motherboard, or it could be a problem with loose cables between the panel and the control board. To fix this issue, the television needs to be opened up and analyzed by a professional repairman.

Repairing a cracked TV screen costs from $400 to $1,000 or even more. Cracked screens cannot be repaired, they can only be replaced, and they are very expensive, sometimes exceeding the cost of a new TV. For this reason, if you have a cracked screen, it will probably have to be replaced entirely.

There are many different brands and companies that make TVs. Some brands specialize in certain types, while others make a wider range of products. It is common for the brand to impact the cost of repair because there may be specific issues or costs related to that brand.

While you may choose a specific brand based on the technology, cost, or resolution, keep in mind that brands may also have varying costs for repairs and the repairs types that may be available. Regardless of brand, most TV repairs fall between $60 and $400, although some repairs may be higher.

To fix your TCL TV blank screen, you should expect to pay about $60 to $400. One characteristic repair of the TCL brand is a black screen with no picture. This can be a fuse that has blown, or it may require a major change, such as a new main board.

Damaged cables can cause a TV to flicker or grow dim. Repair prices for damaged cables are $75 to $200. Samsung TV owners cite this flickering or dimming of the screen as a common issue with this brand. Sometimes the settings for the eco sensor1 or the energy-saving feature create this problem. Turning either of those off may fix the issue.

Some of the most common issues with this brand are banding at a repair cost of $100 to $200 or sound with a cost of $150 to $400. Color problems may be related to adjustment and can be fixed for a low cost of $75 to $100, HDMI connections are often fixed at the cost of $200 to $300, and streaming problems may be corrected with a software update. Software updates can be done by the owner, but a repairman will most likely charge a minimum fee of $75 to $100. Banding presents as sections of bands where it should be smooth. Sound and color can go out over time in the LG brand. HDMI and streaming can become difficult as technology emerges and changes.

Panasonic TV owners often experience the power clicking on and off and may need a new main board at the cost of $200 to $400. The reset button may help. The repairman will need to replace the motherboard of the TV if that fails.

Labor costs for TV repair vary depending on whether you have the television repaired in your home or drop it off at a repair center. Having someone come to your home will have higher costs than taking it to a technician.

A television repair technician has earned a career certificate or Associate’s degree in electronics technology or a related field. Expect to pay between $40 and $60 per hour in labor for someone to fix your television. Some technicians have minimum costs for some repairs, particularly if they travel to you. In this case, you may find that even if the repair only takes an hour, you may need to pay a minimum of two hours of work.

The amount of time to repair your TV depends on what the problem is and the availability of parts. Most jobs can be completed in 1 to 3 hours when the parts are on hand.

Most technicians charge you a diagnostic fee upfront. This fee is for determining what the problem is and can run between $75 and $150. The cost is often waived if you allow the shop’s technicians to make the repairs for you.

Often, you must decide whether it is worth repairing your TV because in many situations, the cost of repairs is higher than the price of a new TV. For example, when screens are cracked or damaged, the cost of replacing a panel is usually much higher than simply buying a new TV.

Consumer Reports recommends replacing electronics whenever the cost of repairs equals or exceeds half the cost of a new purchase. It is also recommended that you replace your television if the new version is less than $200, or if your screen is smaller than 32”. For example, it costs around $150 for a new motherboard in an LG Model 24LF452B 24” TV, which takes around one hour to repair. As a result, you would pay between $190 and $210 to repair your old set, while it is possible to purchase a new one for less.

If you invested a lot of money in your television, the costs of repairing an inverter or getting new backlights may be far cheaper than replacing it. This is why it is often best to ask a professional to diagnose the problem and give you a quote for the repair work. Then, you can compare the price of repairs against the cost of a new TV and decide what makes sense. If your TV breaks down repeatedly, you have multiple repair bills over the course of a year. It might be time for a new television even if a single repair does not seem too expensive.

To minimize repairs and help your TV stay in working order for as long as possible, take care of it as well as you can. Here are some useful TV maintenance tips:Do not leave the TV on if you are not actually watching it. They can run for tens of thousands of hours, but there is no need to waste those hours. So, avoid leaving it on in the background, and make sure to turn it off when you leave the room.

Additional Considerations and CostsDIY. In some cases, television repair can be performed as a DIY project. There are numerous how-to videos available that are easy to watch and understand. Parts for most sets are also available online. However, if you are not comfortable with the process, always call a technician rather than attempting the repair yourself.

DIY issues. While DIY repair is often possible, it is not frequently recommended. There is some risk of electrocution, and you might also damage the TV even more by improperly installing a t-con board or ribbon connectors. If you are in doubt, it is best to leave this job to a professional.

Obvious solutions. Before seeking repairs, first look for the obvious. If your set will not power on, it could be a problem with your outlet and not your TV. Try plugging your television into a different outlet to see if that resolves the problem. If that does not fix it, ensure you have not tripped a breaker, and check that the power cord is fully seated.

Warranty. When purchasing a new television, buying an extended warranty can spare you the unwanted expense of repair bills in some cases. An extended warranty is largely based on the price of your television. Expect to spend between 10 and 20 percent of your set’s cost on an extended warranty to help cover damage. Ordinary warranties only cover manufacturer’s defects and, therefore, cannot be used to pay for damage due to neglect or accidents.

Warranty repairs. When having warranty repairs made, drop the set off at a local shop whenever possible or have them come to you. If you need to ship the television off, get a tracking number so that you can locate your set if it gets lost.

Scams. Television repair scams are quite common. Before hiring someone to fix your set, find out what experience and training that person has. Check references and online reviews as well.

In-shop repairs. In-shop TV repair services may involve a pick-up and delivery charge if you do not take it in yourself. While some may do this for free, others charge between $40 and $75 to pick-up and deliver the TV back to you. Additionally, customers that live in rural areas may have to ship the television. If you do this, make sure you obtain a tracking number and proof of delivery. The repair service will contact you with the list of recommended repairs and the cost and request a debit or credit card to pay for the repairs before completing them.

Television repair costs vary widely, but the average consumer pays between $100 and $300. Prices depend on the make, model, and size of your set, as well as the availability of parts. It is generally more expensive to repair an older model than it would be to replace it. New televisions are becoming more affordable every year, but the price of parts remains steady or even increases as older parts become rarer.Can a flat-screen TV be fixed?

Not all TV screens can be fixed or replaced. Certain types have components behind the screen that can be damaged by its removal. However, if you choose to proceed, remove all external cables, unplug your set, and lay it face down on a flat, soft surface. Remove any screws holding the frame in place and then gently remove the frame and set it aside. Put your new screen in place and reconnect the internal cables in the same manner you disconnected them. It is usually best to get a professional to handle TV repairs, and the cost of replacement screens is often very high. So, it may be more cost-effective to get a new TV.How many years will a flat-screen TV last?

display problems with your vehicle entertainment system (VES) DVD or Blu-ray monitor, despair no longer. We have a cost-effective ribbon repair kit for VES, DVD, and Blu-ray monitors in 2007-2016 Chrysler, Dodge and VW Routan vehicles that will help protect your patience during the next road trip.

(VES) monitors are blank or has a split screen. If you have taken the time to get a quote to repair your system, you may have been shocked by a quote in the range of $1200-$1700. Fortunately, the cause of the problem is almost certainly the failure of a simple ribbon cable internal to the monitor. A recent comment from a happy customer exclaimed, "After a $1,200.00 estimate from Chrysler dealer to replace the TV module in our 2014 Town & Country this $39.99 kit and instruction Video WAS PERFECT!!"

DIY VES ribbon cable replacement kit includes all that you need to repair your entertainment system without depleting your summer vacation fund. We offer two VES repair kit solutions depending upon whether your vehicle is equipped with DVD only playback or DVD + Blu-ray capability. All of our repair kits include ribbon cables for both front and rear screens. The repair kit for DVD only vehicles include 2007 through 2012 models of Chrysler Town & Country, Dodge Caravan, Durango, and Volkswagen Routan. The second repair kit is for 2013 through 2016 Chrysler, Dodge and VW Blu-ray player equipped models. Our VES repair kit comes with new ribbon cables and a pry tool that helps remove the overhead monitors. We include two replacement cables in this kit so that you can upgrade both screens if your vehicle has two displays. Below you will find an easy to follow video that shows how to remove and replace the ribbon cable that is causing the issue. A 1-year guarantee backs our VES repair kit, which comes with free shipping options via US Postal Service and ships the same business day (Monday - Friday) for any orders placed by 3:00 PM EST. If you have any questions, we would love to hear from you at 800-547-2049 or by contacting us through our website.

TV repair costs between $60 and $350 with most spending $207 on average for LCD, LED, plasma, and 4K TVs; costs are higher if repairing older DLP, projection, and HD TVs. TV problems like display issues, powering-on problems, or sound issues can be fixed. Pickup and delivery fees may apply.

The cost to repair a TV will include the price of parts and labor costs, plus other associated costs. Additional charges include a trip fee for a technician to come to your home, a fee to transport your TV to and from a repair shop, and the diagnostic fee to determine what needs to be replaced.

The cost to repair a TV screen can be significantly more than the cost of purchasing a new TV. For this reason, replacing or repairing a broken TV screen is not considered feasible.

For example, the price of a new Samsung 40-inch LED TV is about $400, yet the cost of a replacement display panel for this model is about $380. This price is only for the replacement part and does not cover diagnostic costs, labor costs, or travel or shipping fees.

Broken TV screen repair is not a service offered by most TV or electronics repair companies. For example, BestBuy"s 90-day warranty, does not list broken TV screen repair as one of the problems they service.

Unless you are trying to fix a TV from the ’80s or earlier, cracked TV screen repair is not feasible; the entire display panel must be replaced instead. The cost of a replacement TV display panel is more than the cost of buying a new TV, and that’s before labor and other service costs.

TV manufacturers do keep replacement TV screen panels on hand to support products under warranty in case the screen malfunctions, due to manufacturer defect.

If you still want to replace a damaged or malfunctioning TV screen, your best option is to find a used replacement panel or a broken TV of the same model on which the screen is still functional. You might find one on eBay, and you can hire a technician to change out the panel.

The cost of a used replacement TV panel ranges from $50 to $350 or more, excluding shipping, depending on the brand and size. Note that the chances of finding exactly the part you need in excellent condition are slim, and the cost excludes the cost of installation by a repair shop.

Whether your TV is LCD, LED, plasma screen, or 4K (Ultra HD), the cost to fix common problems ranges from $60 to $350, depending on the repair type and the brand of TV being repaired.

These repair problems could have more than one possible source, so a technician should take time to narrow down the exact problem. TVs are repaired by replacing faulty components.

A TV inverter repair costs $104 to $171, including parts and labor, with an average cost of $138 for a TV with one inverter board or $178 for two. Parts range from $7 to $74, and the average labor cost for TV inverter repair is $97 per hour.

When an inverter component goes bad, it is usually replaced rather than repaired. In some cases, the capacitors on a converter board fail, and a technician can fix it by replacing the capacitors rather than replacing the entire inverter component. However, if an entire inverter board replacement is not available for the model of TV being repaired, replacing the capacitors may be the only option for TV inverter repair.

If an older model LCD TV or projection TV powers on and has sound but no picture, this may be due to lamp burnout, which is both common and expected. In this case, replacing the bulb will fix the problem. An experienced technician should be able to replace the bulb quickly and easily.

TV backlight repair costs $100 to $122, including replacement parts and labor, at a repair shop. In-house repair costs are more due to trip fees. The price of backlight replacement parts averages around $2.50for each LED and between $20 and $25 for each CCFL strip.

A new inverter may be needed to power the LEDs, costing between $7 and $74before labor, or an average of $40. In some cases, a repair shop can convert a CCFL backlight to LED without installing a new inverter.

Repairing a TV power supply board costs $23 to $234 for parts alone. Completely replacing the power supply board costs $250 for parts and labor. If one capacitor has failed, the cost for replacement capacitors is low. However, it’s more cost-effective for the technician to replace the entire board rather than spend time trying to diagnose and replace faulty capacitors one by one.

TV capacitor repair costs $60 to $129, including parts and labor. The cost for the replacement part ranges from $0.06 to $14, with the labor portion ranging from $60 to $125 per hour. TV capacitors protect the circuit from getting too much power, filter signals, and facilitate changing channels.

Flat screen replacement glass is not available. The only option for flat-screen TV glass repair is to try optical glass glue, which costs $1.70 for a 5-ml. tube. This may be an option for TV glass repair if the crack is only a few inches or less. TV panels are built as one unit at the factory, with the glass adhered to the display panel.

In-home CRT repair ranges from $199 to $249. The cost of repairing a CRT picture tube ranges from $199 for a TV that is 27 inches or smaller to $249 for a TV that is 28 inches or larger.

A TV fuse repair costs between $61 and $136, with most spending $99 on average. The cost of the replacement fuse itself is $1.50 to $11, while labor ranges from $60 to $125 per hour. Additional fees may apply.

LCD flat-panel repair is not considered cost-effective. If the glass is cracked or the display is physically damaged, it is cheaper to replace the entire TV than to repair or replace the display panel.

Estimating TV repairs costs by brand is not something TV repair shops offer, however, there are general prices by type. When looking for specific repair costs for your TV, you’ll find them in the common repairs price list above. Pricing applies to brands such as Samsung, LG, Sanyo, TCL, Insignia, HiSense, Sony, Toshiba, Pioneer, and Vizio.

More popular TVs are usually less expensive to repair because repair shops order replacement parts for them in bulk, which allows them to buy those parts at a lower cost.

The cost of flat-screen TV repair ranges from $42 to $359. You cannot fix a broken screen, but the price of a new flat-panel TV starts from around $249 for a 1080-mp (non-4K) LED TV from LG to as much as $14,999 for an 85-inch 8K LED TV from Samsung. A TV referred to as a “flat TV” or “flat-screen” TV might be any of the following:

LCD TV repair typically costs $60 to $85 for diagnostics testing, and $200 to $300 to perform repairs. LCD TVs use backlighting, which may fail. Newer LCD TVs use LED strips for backlighting. Older ones might use CCFL. If CCFL backlighting fails, a technician can replace it with LED backlighting.

An LED TV is just an LCD TV that uses LED backlighting, which all newer models do (older models use CCFL backlighting). The cost to replace one LED backlighting strip ranges from $100 to $122, including parts and labor.

The cost to replace the motherboard, inverter, or LED"s in a 4K TV ranges from $100 to $275 or more depending on the brand and model. The cost for screen repair for a 4K TV is irrelevant because it cannot be fixed or replaced at a cost that is lower than the cost of a new 4K TV.

Digital light processing (DLP) TVs are also known as projection TVs. DLP big screens have not been made since 2012, and DLP TV repair is usually not worth the cost except for a lamp burnout, in which the bulb can be replaced. The cost to replace bulbs ranges from $60 to $115.

TV repair shops charge an average $60 to $125 per hour, or a flat rate of $50 to $250, which includes the diagnostic fee. Additional costs after that depend on the repairs needed and the brand and type of TV. However, most stores will have a minimum charge of about $90.

Best Buy TV repair is provided through the Geek Squad TV & home theater service. Geek Squad TV repair starts at a base cost of $100 for a diagnostic fee. TV repair is covered under Best Buy’s protection plan, which costs $280 per year when you purchase a TV from Best Buy at the time of purchase, or within the return period printed on your receipt.

The brand and model of your TV will dictate the final repair cost, with more expensive brands and larger TVs costing more to repair. Consider the remaining lifespan of the TV before paying for repairs. You can now buy bigger TVs with more features and better displays for a TV that won’t need repairs for a while and probably comes with a warranty.

The cost of labor to fix a TV ranges from $60 to $125 per hour, or a flat rate of $90 to $299. If the work is performed in your home, the cost ranges from $25 to $125 per hour plus the trip fee. Most TV repairs take 1 to 3 hours if the repair specialist has the parts already.

If you live in a remote area, you may need to ship your TV to a repair facility, costing $99 to $175. Be sure to choose a delivery service that allows you to track the shipment and confirm delivery. When sending your TV into a service center for repair, you will be contacted regarding the associated costs and asked to process payment before the repair is completed, which usually takes two weeks including the shipping time.

Many TV repair shops charge a diagnostic fee that ranges from $20 to $60, depending on whether it is done in your home or the repair shop. Some shops charge a flat fee that ranges from $50 to $250that covers both the diagnostic cost and labor cost. In many cases, the initial diagnostic fee will be applied to the repair cost if you have the shop do the repair.

The more expensive a TV is, the more sense it makes to purchase an additional warranty to defray the potential for costly repairs. Best Buy offers an $89 five-year extended warranty for entry-level TVs. On larger TVs such as the 85-inch Samsung QLED 8K TV, which costs $14,998, the five-year warranty from Geek Squad costs an additional $1,699—11.33% of the cost of the TV.

With modern TVs, repair entails component replacement or replacement of capacitors, for which high levels of certification are not necessary. Generally, TV repair shops will let you know if their employees have certification.

Satellite dish repair is either covered by your satellite service company or the cost for a technician to fix it ranges from $80 to $150. Repairs may also be billed at an hourly rate of $50 to $65.

There are various ways you might be able to save money on TV repair. These include transporting your TV to a repair shop, using a shop that charges in 15- or 30-minute increments, diagnosing the problem yourself, using salvaged parts, and doing the repair work on your own.

You can also consider the cost of TV repair when purchasing a new TV. More popular TV models are less expensive to repair because repair shops buy parts for the most common TVs in bulk and are therefore able to get them at lower prices.

Circuit breaker - Check the circuit breaker for the power outlet that the TV plugs into. You can check the breakers by opening the door to your breaker panel and looking for circuit breakers that are in the OFF position.

Lamp burnout -In a projection TV or older LCD TV, no picture may be caused by lamp burnout. In this case, a technician can replace the bulb quickly and easily.

The primary way to save money on TV repair would be to perform the work yourself. This may require you to purchase and get familiar with various tools such as soldering tools, and methods for replacing a capacitor or some other component.

The right parts - It can be complicated to determine which component of a TV is failing and causing the TV not to work correctly. If you buy a replacement part and perform the repair yourself, the TV may still not work, either because you replaced the wrong part, the part was old and not working properly to begin with, or you did not perform the work correctly. Buying multiple replacement parts can become costly.

The cost of repairing a TV could be as much as $500 if multiple repairs are needed. Consumer Reports recommends not to spend more than 50% of the cost of a new TV repairing the old one.

If you have a newer TV that cost thousands of dollars, having it repaired would most likely be cost-effective. If the TV only cost a few hundred dollars to begin with, replacing the TV is more likely to be the best option.

In most cases, a flat-screen TV can be fixed. The exception is a physically damaged display panel or screen. Most other issues including failing speakers, backlights, or power supply. Burned out fuses and damaged input ports can also be repaired.

If the screen is not physically damaged but is not showing a picture or is displaying “snow’” or vertical or horizontal lines, a technician can repair the TV by replacing failed components. If the screen is physically damaged, it cannot be repaired.

If you live in a remote area, you may need to ship your TV to a repair facility, costing $99 to $175. Be sure to choose a delivery service that allows you to track the shipment and confirm delivery.

Degradation of the fine ribbon cable in older TI graphing calculators is a familiar problem, manifesting as missing rows and columns in the LCD. Otherwise perfectly functional calculators are put to waste over two relatively short-lived ribbon cables, one of which is unreplaceable, with long-term repair methods elusive.

As the LCD is integral to the very purpose of the calculator, I was interested in correcting this common issue for the sake of correcting it. Something as trivial as "exercising" missing lines in the display would often reinvigorate them for about a day, which prompted me to investigate a more reliable repair.

Though TI does not specify the assembly method actually used, many similar ribbon cables are applied by hot press. While this entails expensive, specialized equipment, I learned to imitate the hot press process using inexpensive, readily-available components through a video on automobile instrument panel repair. Note that I modified the method since we are not able to install a new cable.

I have applied the method to seven graphing calculators exhibiting fine ribbon cable failure. In the 20 days between the repair and this writing, I observed a high degree of success across the calculators repaired.

Before continuing, check whether the fine ribbon cable is culprit. Missing or intermittently functioning lines are prime indicators of fine ribbon cable degradation. If the contents of the screen are garbled or corrupted, the coarse ribbon cable will need to be repaired first:

These are available on eBay for about US $7. The point of this is to distribute heat and pressure along the ribbon cable connection in a similar manner to a hot press. If given a choice between a tip for 30W, 45W, 60W, etc. choose 30W unless using a larger unregulated iron.

Remove the circuit board from the calculator. Locate where the fine ribbon cable connects to the edge of the LCD glass. If there is foam padding attached, gently peel it off and set it aside. Be sure NOT to tear the ribbon cable off either end, which will ruin the chances of a successful repair.

Locate where the fine ribbon cable connects to the board. Set the LCD face down on a flat, non-abrasive surface and place the iron flat on the connection as such:

Make two passes across the connection as before. The edge of the LCD may change color as heat is applied, but if it is turning a dark or purplish blue, move the iron faster to prevent overheating.

Now reassemble the calculator and test if the display looks good. If any defects remain, do another pass over the cable connections. There is the possibility, however, that some lines do not resolve even on the second or third attempts. These, unfortunately, will remain unrepairable.

Note: From my testing, the silicone pad is necessary to distribute heat and pressure along the cable. It will also wear out when used multiple times. Replace it when it no longer slides smoothly over the ribbon cable connection.

The TI-85 and 86 feature two ribbon cables, one on top responsible for vertical columns and one on the side for horizontal rows. Determine which one needs repair and move the side ribbon cable out of the way if necessary. I have yet to attempt a repair on the side ribbon cable, which appears more challenging to access than the top cable.

One TI-82 has one column that will start working once something is displayed on it. Despite two repair attempts, this column would not stay put when the calculator was powered off for a longer period of time.

Ideally, an economical, readily-available replacement LCD assembly without such a flawed ribbon cable would be available to prolong the useful life of TI graphing calculators. This is currently in the works as we see with KermMartian"s Surget. In the absence of a finished replacement LCD, this currently is the most effective method I have found to breathe new life into aging calculators, restoring the majority of, though not all, missing LCD lines.

Across a sample of seven calculators over 20 days, each LCD line that was repairable and repaired remained functional. The long-term viability of this repair method remains to be discovered, though it is one that vaguely emulates a common method of LCD ribbon cable assembly at the factory. In the meantime, I will take note of and post any significant changes that I notice on the calculators I have repaired using this method.

No further repairs were attempted. Hopefully the repairs on the TI-82s and the TI-85 will continue to last a while more. I"d say this was a rather fun experiment and I will continue posting any significant developments.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey