lcd module integrated transparent lcd factory

LCD Transparent Displays, transparent screens, transparent monitors, see through screens, transparent touch screen technology, and kits from CDS as we have our own range of transparent screens / displays and transparent video screens manufactured for us, and as we control the manufacturing, we can not only offer more sizes than anyone else in the world, but also guarantee stable supply, long term availability LCDs with amazing quality. We have replaced the Samsung Transparent Displays / see through Displays and LG Transparent OLEDs that are no longer available!

CDS has increased the use of these see through screens / see through displays / see through computer screens / clear monitors across the world including touchscreen computer screens combined with the transparent LCD touch screens and Transparent OLED displays.

Screen Solutions offers complete solutions for transparent displays including standard and custom display cases. SSI has designed and built transparent displays for companies like Chrysler, Lockheed Martin, Mazda and many others over the last 15 years.

Standard Sizes start as small as 10″ and can get as big as 86″ Diagonal as seen in the video to your left. These complete displays include transparent panel, lighting, glass, display case and even a touch screen if you want.

There are three types of transparent lcd modules, and lcd displays. On the other hand, the transparent lcd display is based on the type of display that would be suitable for many applications. Clearly transparent lcd display, on the other hand, can have only 12 pixels per second and is the suitable size for all displays.

One transparent lcd display is the most common type. Clear looking for cheap transparent lcdds in bulk, you can find from suppliers on Alibaba.com who offer a wide range of transparent lcdds for bulk suppliers.

transparent lcdds have high dynamic range, and has a low- consumptionaint rate as well as high-pernaming requirements. Among all lcdds, highly compatible lcdds have high dynamic capabilities, and quad-acid batteries. On top of that, it is highly resistant to pressure, even if it is unchected, and has a low- consumption.

Transparent Displays are becoming more and more popular thanks to the amazing WOW factor, especially when integrated in a showcase, refrigerator, custom solution and piece of furniture. But not all TLCD are equal and can offer the same transparency, definition, images colour depth and colour temperature alteration of the backlight.

The so called percentage of transparency is just an indication: 15% transparent doesn’t meant that the LCD is blocking 85% of the view. As the white color on the TLCD looks like 99% transparent, nearly like glass, colors are actually fully visible and (especially the black color) blocking the view.

Actually, 15% is the highest transparency currently available. But there is no way to “measure” the transparency of an LCD Panel considering how the human eye see it because it’s not only determined by the panel, but also by the backlight.

As the customer’s goal is to present their products to the market, the objects placed behind the TLCD must look great. And this is our goal as well. MMT engineers constantly improve the overall quality of HYPEBOX by testing and selecting new components, technologies and ideas. We provide real images and videos or our actual products as renderings do not represent the true quality provide.

Having said that, if all 3 subpixels are “open” (or let’s say “not coloured”), the backlight will then travel through them with no alteration. On a regular LCD panel, the result is then a white dot / on a Transparent LCD panel, the result is a transparent dot.

Spectrum Displays is an LCD manufacturer specializing in custom displays for clients in aerospace, transportation, and custom-concept car design. We serve clients around the world, supplying both standard and custom LCD displays used in digital signage, transportation and automotive, medical, gaming machines, and other markets. We focus on small-volume builds by using key suppliers of unique sized AMLCDs. We also utilize large-volume remanufacturing and local, value-added services to allow customization of off-the-shelf, mass-produced designs into new sizes. Our mission is to supply specialized electronic displays in both standard and custom sizes for all industries. Our collaborative culture helps us successfully develop custom products by working closely with teams like yours. Contact us to learn how we can help you.

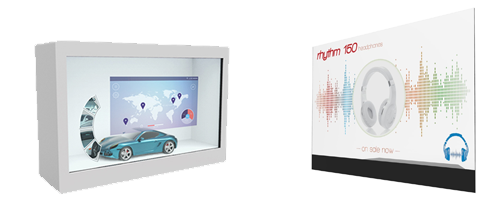

ChariotTech transparent LCD showcase is an integrated display solution. It combines HD LCD technology with transparent LCD screen to display real products behind the screen, view product information on transparent screen, and display picture or video content in full HD resolution.

One of the things that sets us apart from other touchscreen display manufacturers is the level of customization we offer. Our product portfolio includes a wide range of TFT & Monochrome LCDs, OLED, touch sensor and glass technologies, which we can provide stand-alone or integrated into complete assemblies.

For a long time, transparent screens have been the stuff of sci-fi or ultra-hi-tech environments. Films such as Spielberg’s Minority Report helped to firmly cement transparent screens as a cutting-edge technology, putting them up alongside futuristic innovations like gesture interfacing. Pro Display is proud to be a British manufacturer that can offer such a great range of transparent screen solutions which satisfies a variety of requirements.

Consumer’s technological and style tastes have been primed perfectly for this technology for decades through TV and cinema. However, transparent screen technology is not something you see every day- just yet. This puts transparent screens into a very unique position, where most people will know exactly what it is, but few will understand how it works. This ‘mystery effect’ alone can be enough to impress, but the beauty of transparent technology is 2-fold. Your customers will notice not only the technology itself, but also how you use it.

The versatility of transparent screens offers you an excellent opportunity to think up creative and innovative displays that competitors are unlikely to match. The ability to integrate media content with physical products is an area that few have explored to date- meaning that applications don’t even need to be that imaginative to be original.

For those looking to really excite, our transparent technology can be integrated with our interactive touch technology, giving your screens the added benefit of touch capability. This makes for a truly remarkable display, allowing you to take customer engagement to a whole new level that will see audiences raving about you and your products.

An innovative and high impact way to engage with your audience. A Transparent LCD Screen sees LCD technology fused with a transparent screen substrate, enabling white pixels to appear as transparent. Using this, merchandisers can produce media which hides or gradually reveals products behind the screen. Requiring a backlight to display properly, our Transparent LCD Screens can come integrated with a display case, perfect for encasing new or leading products and unveiling them at your will.

As mentioned above, our Transparent LCD Screens can be granted touch capability, adding interactivity alongside its benefits. Combining touch, stunning visuals and customer anticipation is a perfect merchandising mix that will see your products brought to life like never before.

As with all of our transparent technology, Transparent LCD screens are incredibly versatile and can be applied in many different sectors. You can integrate the screen into display furniture, appliances or vending, shop window displays and even as part of a trade show display, product launch or visitor attraction.

Transparent OLED, or T-OLED screens are a new development in display technology. With a fully transparent surface, viewers can see what is displayed on the screen whilst still being able to see through it, allowing designers to overlay content like videos and images onto physical products behind the screen.

What makes this technology special is that unlike Transparent LCD screens, it does not require a backlight or enclosure. Whereas Transparent LCD screens rely on backlighting to produce an image (and therefore require an enclosure or display box), T-OLED screens are made up of light emitting diodes which each emits their own light. There is also a subtle design difference in that T-OLED Screens display black content as transparent instead of white, like Transparent LCD.

Because this product does not require a backlight to operate, the options of where you can apply it are considerably increased. We have seen Transparent OLED screens used in interactive booths, digital signage, display cases, interactive games, vending solutions- the uses for this technology are limited only by your imagination.

Clearview is a highly transparent optical diffusion projection technology which creates a holographic effect. So impressive are its features, that we have seen it specified on some of the world’s most impressive AV projects, including the 83rd annual Academy Oscars Awards.

Wow your audience with our remarkable glass technology. Supplied as a glass or retrofit film and offering both privacy and practicality, Switchable Technology is one of our most versatile products. It operates using a simple on/off button, which switches the glass between transparent and opaque in an instant. Typical applications include office partitions, glass walls or meeting rooms, residential home improvements, hospitality style applications, healthcare privacy solutions and in live events or entertainment.

Transparent LCD’s provide an innovative display solution opening up new ways for brands to promote their products and services. Examples include retail stores looking to advertise a new fashion clothing or accessory, museums securely housing a precious artifact with information displayed on screen or brands looking to launch a new product at a live event or show. The opportunities are endless!

Our Transparent LCD Displays include a Grade A LCD panel with metal bezel protecting the edges / electronics and a media board supporting HDMI or VGA inputs from your PC, Laptop or Media Player.

Transparent screen technology offers intriguing ways to deliver visual information to your audience, being used to reveal or conceal products, objects or artefacts behind the screen.

The combination of HD LCD technology (4K on our 65″, 86″, 98″ version) with a transparent screen substrate opens up creative avenues that were previously closed with traditional LCD displays. Solid black pixels on a transparent background can be used in intriguing ways to hide (and gradually reveal) whatever is behind the screen.

Our Transparent LCD monitors are designed for integration into the customers own furniture housing or display case while our Transparent LCD showcases offer a complete solution including the display, housing and backlight with white or black options available on request. We can also offer custom freestanding options for POP / POS displays. Transparent LCD’s are predominantly fully housed however we’ve recently developed an innovative housing method using a high brightness LED panel which allows the display case sides to remain transparent for improved visibly into the display case.

Using their original design as a starting point, we worked closely with the team at Nike to adapt to the mechanical aspects of the design, the result was a sleek and minimalist set of nine Transparent LCD Display Screens, custom built to suit the applications requirements, bringing Nike’s original concept ideas to life.

Transparent LCD’s comprise of an LCD panel without the backlight with white pixels appearing as transparent. In order to display an image, the Transparent LCD needs to be integrated into a housing with a high bright LED backlight.

We can also offer more complete solutions like our Transparent LCD Showcase that comes fully contained and ready to use with a powerful backlighting system to guarantee the best picture quality.

Yes in order to display an image Transparent LCD’s need to have a strong backlight. Notoriously Transparent LCD’s have also needed some form of housing to achieve optimum image quality, however, Nike’s House of Innovation paired our Transparent LCD’s with powerful, oversized backlights that allowed the screens to be mounted with no surround but still producing a high-quality image.

Transparent LCD’s are arguably the most popular transparent screens but are hindered by their need for a backlight to operate. For applications looking for a similar effect without the backlighting, Transparent OLEDs require no housing or surround but are only currently available in a 55″ screen size with HD quality. For larger transparent screen applications, Transparent LED’s are recommended with external and internal solutions usually installed to glass facades for the impact of an led screen without compromising the view from inside the building.

We also offer transparent projection technologies including our Clearview Rear Projection Film featured in Guardians of the Galaxy as well as at the 83rd Oscars celebration and MTV EMA awards.

Transparent LCD’s are a great way to combine physical and digital displays in one central place making them a popular choice for museums and exhibitions. Our transparent screens can also be integrated into display furniture and appliances & vending machines like freezer doors for supermarkets. Other uses include POS displays, store window displays, trade shows and product launches.

We manufacture in Britain and ship worldwide – if you need further information, a pricing quote, or want to discuss ideas for using our Transparent LCD Display click the link below to contact us, email us via info@prodisplay.com or call us on +44 (0)1226 361 306.

Important technical improvements of LCD, such as LED backlighting and wide viewing Angle, are directly related to LCD. And account for an LCD display 80% of the cost of the LCD panel, enough to show that the LCD panel is the core part of the entire display, the quality of the LCD panel, can be said to directly determine the quality of an LCD display.

The production of civil LCD displays is just an assembly process. The LCD panel, the main control circuit, shell, and other parts of the main assembly, basically will not have too complex technical problems.

Does this mean that LCDS are low-tech products? In fact, it is not. The production and manufacturing process of the LCD panels is very complicated, requiring at least 300 process processes. The whole process needs to be carried out in a dust-free environment and with precise technology.

The general structure of the LCD panel is not very complex, now the structure of the LCD panel is divided into two parts: the LCD panel and the backlight system.

Due to the LCD does not shine, so you need to use another light source to illuminate, the function of the backlight system is to this, but currently used CCFL lamp or LED backlight, don’t have the characteristics of the surface light source, so you need to guide plate, spreadsheet components, such as linear or point sources of light evenly across the surface, in order to make the entire LCD panel on the differences of luminous intensity is the same, but it is very difficult, to achieve the ideal state can be to try to reduce brightness non-uniformity, the backlight system has a lot to the test of design and workmanship.

In addition, there is a driving IC and printed circuit board beside the LCD panel, which is mainly used to control the rotation of LCD molecules in the LCD panel and the transmission of display signals. The LCD plate is thin and translucent without electricity. It is roughly shaped like a sandwich, with an LCD sandwiched between a layer of TFT glass and a layer of colored filters.

LCD with light refraction properties of solid crystals, with fluid flow characteristics at the same time, under the drive of the electrode, can be arranged in a way that, in accordance with the master want to control the strength of the light through, and then on the color filter, through the red, green, blue three colors of each pixel toning, eventually get the full-screen image.

According to the functional division, the LCD panel can be divided into the LCD panel and the backlight system. However, to produce an LCD panel, it needs to go through three complicated processes, namely, the manufacturing process of the front segment Array,the manufacturing process of the middle segment Cell, and the assembly of the rear segment module. Today we will be here, for you in detail to introduce the production of the LCD panel manufacturing process.

The manufacturing process of the LCD panel Array is mainly composed of four parts: film, yellow light, etch and peel film. If we just look at it in this way, many netizens do not understand the specific meaning of these four steps and why they do so.

First of all, the motion and arrangement of LCD molecules need electrons to drive them. Therefore, on the TFT glass, the carrier of LCD, there must be conductive parts to control the motion of LCD. In this case, we use ITO (Indium Tin Oxide) to do this.ITO is transparent and also acts as a thin-film conductive crystal so that it doesn’t block the backlight.

The different arrangement of LCD molecules and the rapid motion change can ensure that each pixel displays the corresponding color accurately and the image changes accurately and quickly, which requires the precision of LCD molecule control.ITO film needs special treatment, just like printing the circuit on the PCB board, drawing the conductive circuit on the whole LCD board.

This completes the previous Array process. It is not difficult to see from the whole process that ITO film is deposited, photoresist coated, exposed, developed, and etched on TFT glass, and finally, ITO electrode pattern designed in the early stage is formed on TFT glass to control the movement of LCD molecules on the glass. The general steps of the whole production process are not complicated, but the technical details and precautions are very complicated, so we will not introduce them here. Interested friends can consult relevant materials by themselves.

The glass that the LCD board uses makes a craft also very exquisite. (The manufacturing process flow of the LCD display screen)At present, the world’s largest LCD panel glass, mainly by the United States Corning, Japan Asahi glass manufacturers, located in the upstream of the production of LCD panel, these manufacturers have mastered the glass production technology patents. A few months ago, the earthquake caused a corning glass furnace shutdown incident, which has caused a certain impact on the LCD panel industry, you can see its position in the industry.

As mentioned earlier, the LCD panel is structured like a sandwich, with an LCD sandwiched between the lower TFT glass and the upper color filter. The terminal Cell process in LCD panel manufacturing involves the TFT glass being glued to the top and bottom of a colored filter, but this is not a simple bonding process that requires a lot of technical detail.

As you can see from the figure above, the glass is divided into 6 pieces of the same size. In other words, the LCD made from this glass is finally cut into 6 pieces, and the size of each piece is the final size. When the glass is cast, the specifications and sizes of each glass have been designed in advance.

Directional friction:Flannelette material is used to rub the surface of the layer in a specific direction so that the LCD molecules can be arranged along the friction direction of the aligned layer in the future to ensure the consistency of the arrangement of LCD molecules. After the alignment friction, there will be some contaminants such as flannelette thread, which need to be washed away through a special cleaning process.

After the TFT glass substrate is cleaned, a sealant coating is applied to allow the TFT glass substrate to be bonded to the color filter and to prevent LCD outflow.

Finally, the conductive adhesive is applied to the frame in the bonding direction of the glass of the color filter to ensure that external electrons can flow into the LCD layer. Then, according to the bonding mark on the TFT glass substrate and the color filter, two pieces of glass are bonded together, and the bonding material is solidified at high temperatures to make the upper and lower glasses fit statically.

Color filters are very important components of LCD panels. Manufacturers of color filters, like glass substrate manufacturers, are upstream of LCD panel manufacturers. Their oversupply or undersupply can directly affect the production schedule of LCD panels and indirectly affect the end market.

As can be seen from the above figure, each LCD panel is left with two edges after cutting. What is it used for? You can find the answer in the later module process

Finally, a polarizer is placed on both sides of each LCD substrate, with the horizontal polarizer facing outwards and the vertical polarizer facing inwards.

When making LCD panel, must up and down each use one, and presents the alternating direction, when has the electric field and does not have the electric field, causes the light to produce the phase difference and to present the light and dark state, uses in the display subtitle or the pattern.

The rear Module manufacturing process is mainly the integration of the drive IC pressing of the LCD substrate and the printed circuit board. This part can transmit the display signal received from the main control circuit to the drive IC to drive the LCD molecules to rotate and display the image. In addition, the backlight part will be integrated with the LCD substrate at this stage, and the complete LCD panel is completed.

Firstly, the heteroconductive adhesive is pressed on the two edges, which allows external electrons to enter the LCD substrate layer and acts as a bridge for electronic transmission

Next is the drive IC press. The main function of the drive IC is to output the required voltage to each pixel and control the degree of torsion of the LCD molecules. The drive IC is divided into two types. The source drive IC located in the X-axis is responsible for the input of data. It is characterized by high frequency and has an image function. The gate drive IC located in the Y-axis is responsible for the degree and speed of torsion of LCD molecules, which directly affects the response time of the LCD display. However, there are already many LCD panels that only have driving IC in the X-axis direction, perhaps because the Y-axis drive IC function has been integrated and simplified.

The press of the flexible circuit board can transmit data signals and act as the bridge between the external printed circuit and LCD. It can be bent and thus becomes a flexible or flexible circuit board

The manufacturing process of the LCD substrate still has a lot of details and matters needing attention, for example, rinse with clean, dry, dry, dry, ultrasonic cleaning, exposure, development and so on and so on, all have very strict technical details and requirements, so as to produce qualified eyes panel, interested friends can consult relevant technical information by a search engine.

LCD (LC) is a kind of LCD, which has the properties of light transmission and refraction of solid Crystal, as well as the flow property of Liquid. It is because of this property that it will be applied to the display field.

However, LCD does not emit light autonomously, so the display equipment using LCD as the display medium needs to be equipped with another backlight system.

First, a backplate is needed as the carrier of the light source. The common light source for LCD display equipment is CCFL cold cathode backlight, but it has started to switch to an LED backlight, but either one needs a backplate as the carrier.

CCFL backlight has been with LCD for a long time. Compared with LED backlight, CCFL backlight has many defects. However, it has gradually evolved to save 50% of the lamp and enhance the transmittance of the LCD panel, so as to achieve the purpose of energy-saving.

With the rapid development of LED in the field of lighting, the cost has been greatly reduced.LCD panels have also started to use LED as the backlight on a large scale. Currently, in order to control costs, an LED backlight is placed on the side rather than on the backplate, which can reduce the number of LED grains.

On the transparent diffuser plate, point-like printing can block part of the light. The LED backlight on the side drives the light from the side of the diffuser plate, and the light reflects and refracts back and forth in the diffuser plate, distributing the light evenly to the whole surface. Point-like printing blocks part of the light, screening the light evenly like a sieve.

At the top of the diffusion plate, there will be 3~4 diffuser pieces, constantly uniform light to the whole surface, improve the uniformity of light, which is directly related to the LCD panel display effect. Professional LCD in order to better control the brightness uniformity of the screen, panel procurement, the later backlight control circuit, will make great efforts to ensure the quality of the panel.

The backlight system also includes a backlight module laminator, located behind the backplane. In the CCFL backlight era, you can often see the long strip laminator like the one above, with each coil responsible for a set of tubes.

Since the LCD substrate and the backlight system are not fixed by bonding, a metal or rubber frame is needed to be added to the outer layer to fix the LCD substrate and the backlight system.

After the period of the Module, the process is completed in LCM (LCDModule) factory, the core of this part of the basic does not involve the use of LCD manufacturing technology, mainly is some assembly work, so some machine panel factories such as chi mei, Korea department such as Samsung panel factory, all set with LCM factories in mainland China, Duan Mo group after the LCD panel assembly, so that we can convenient mainland area each big monitor procurement contract with LCD TV manufacturers, can reduce the human in the whole manufacturing and transportation costs.

However, neither Taiwan nor Korea has any intention to set up factories in mainland China for the LCD panel front and middle manufacturing process involving core technologies. Therefore, there is still a long way to go for China to have its own LCD panel industry.

The various LCD Panel blocks are a great way to add a human touch to a ship or base by displaying useful images or text. For LCD configuration and usage, see LCD Surface Options.

Note: Some functional blocks, such as Cockpits, Programmable Blocks, Custom Turret Controllers, and Button Panels, have customizable LCD surfaces built in that work the same way as LCD Panel blocks, which are also discussed in detail under LCD Surface Options.

LCD Panels need to be built on a powered grid to work. Without power, they display an "Offline" text. While powered without having a text, image, or script set up, they display "Online".

LCD Panel blocks come in a variety of sizes from tiny to huge (see list below) and are available for large and small grid sizes. Note that LCD Panel blocks all have connections on their backs, and very few also on a second side.

All LCD Panels and LCD surfaces work with the same principle: They are capable of displaying dynamic scripts, or few inbuilt static images accompanied by editable text. Access the ship"s Control Panel Screen to configure LCD Panels or LCD surfaces; or face the LCD Panel block and press "K".

A Text Panel, despite its name, can also display images. On large grid, it is rectangular and does not fully cover the side of a 1x1x1 block. On small grid it is 1x1x1, the smallest possible LCD block in game.

Corner LCDs are much smaller display panels that typically hold a few lines of text. They don"t cover the block you place them on and are best suited as signage for doors, passages, or containers. They are less suitable for displaying images, even though it"s possible. If you enable the "Keep aspect ratio" option, the image will take up less than a third of the available space.

These huge Sci-Fi LCD Panels come in sizes of 5x5, 5x3, and 3x3 blocks, and can be built on large grids only. These panels are only available to build if you purchase the "Sparks of the Future" pack DLC.

They work the same as all other LCD Panels, the only difference is that they are very large. In the scenario that comes with the free "Sparks of the Future" update, they are used prominently as advertisement boards on an asteroid station.

This LCD panel can be built on large and small grids. The transparent LCD is basically a 1x1x1 framed window that displays images and text. It is part of the paid "Decorative Blocks Pack #2" DLC.

What is special about them is that if you set the background color to black, this panel becomes a transparent window with a built-in display. In contrast to other LCD Panels it has no solid backside, which makes it ideal to construct transparent cockpit HUDs, or simply as cosmetic decoration.

While configuring an LCD Panel, the GUI covers up the display in-world and you can"t see how the text or images comes out. In the UI Options, you can lower the UI Background opacity to be translucent, so you can watch what you are doing more easily.

a line of extreme and ultra-narrow bezel LCD displays that provides a video wall solution for demanding requirements of 24x7 mission-critical applications and high ambient light environments

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey