tft display construction and working price

Get rich colors, detailed images, and bright graphics from an LCD with a TFT screen. Our standard Displaytech TFT screens start at 1” through 7” in diagonal size and have a variety of display resolutions to select from. Displaytech TFT displays meet the needs for products within industrial, medical, and consumer applications.

TFT displays are LCD modules with thin-film transistor technology. The TFT display technology offers full color RGB showcasing a range of colors and hues. These liquid crystal display panels are available with touchscreen capabilities, wide viewing angles, and bright luminance for high contrast.

Our TFT displays have LVDS, RGB, SPI, and MCU interfaces. All Displaytech TFT LCD modules include an LED backlight, FPC, driver ICs, and the LCD panel.

We offer resistive and capacitive touch screens for our 2.8” and larger TFT modules. Our TFT panels have a wide operating temperature range to suit a variety of environments. All Displaytech LCDs are RoHS compliant.

We also offer semi-customization to our standard TFT screens. This is a cost-optimized solution to make a standard product better suit your application’s needs compared to selecting a fully custom TFT LCD. Customizations can focus on cover glass, mounting / enclosures, and more - contact us to discuss your semi-custom TFT solution.

Focus Displays offers a wide range of standard full color TFT displays. 64 million unique colors, high brightness, sharp contrast, -30C operating temperature, and fast response time are all good descriptions of a TFT display. This is why TFT technology is one of the most popular choices for a new product.

Thin Film Transistor (TFT) display technology can be seen in products such as laptop computers, cell phones, tablets, digital cameras, and many other products that require color. TFT’s are active matrix displays which offers exceptional viewing experiences especially when compared to other passive matrix technologies. The clarity on TFT displays is outstanding; and they possess a longer half-life than some types of OLEDs and range in sizes from less than an inch to over 15 inches.

Cold-Cathode Fluorescent Lamp (CCFL) is an AC driven backlight that requires an inverter to convert DC to AC. The AC signal and inverter may generate EMI (Electromagnetic interference) and arcing; Arcing must be eliminated for Intrinsically Safe products.

CCFL’s are still available, but are becoming a legacy (obsolete) component. TFT displays equipped with a CCFL require higher MOQs (Minimum Order Quantities) than displays with LED backlights.

Red, Green and Blue (RGB) backlights are built with either a single LED that produces red, green and blue colors or with three separate Red, Green or Blue LEDs.

RGB backlights require a controller to regulate the different intensities of each color. The controller’s function is to combine unique levels of Red, Green and Blue to produce any of 64M different colors.

Backlight brightness (Luminance) is measured in nits. A nit being the amount of light that one candle delivers in a 1 square meter box. The intensity of the LED backlight can be critical when operating in low light or in direct sun light and is usually controlled by adjusting the DC voltage. In many applications this is accomplished through pulse-width modulation (PWM)

The majority of TFT displays contain a touch panel, or touch screen. The touch panel is a touch-sensitive transparent overlay mounted on the front of the display glass. Allowing for interaction between the user and the LCD display.

Some touch panels require an independent driver IC; which can be included in the TFT display module or placed on the customer’s Printed Circuit Board (PCB). Touch screens make use of coordinate systems to locate where the user touched the screen.

Resistive touch panels are the lowest cost option and are standard equipment on many TFT modules. They are more common on smaller TFT displays, but can still be incorporated on larger modules.

Resistive touch panels are constructed using flexible materials with an air gap between and are coated with a resistive layer. When an object applies pressure to the top layer, it makes contact with microdots located on the bottom layer. This allows the touch screen to find the location of the touch using X and Y coordinates.

Custom resistive touch screens are an option if the customer requires a seal or gasket to be in contact with the glass and not in contact with the touch panel.

They also have the added advantage of operating in a wide temperature range and environments, including anything from the arctic cold of Alaska to the extreme heat of Death Valley.

Capacitive touch panels have become popular with such software as Windows 8®, Android® and Apple®. Additionally it is used in products such as cell phones and tablets, where multi-touch and zoom capabilities are important.

Contrast ratio, or static contrast ratio, is one way to measure the sharpness of the TFT LCD display. This ratio is the difference between the darkest black and the brightest white the display is able to produce. The higher the number on the left, the sharper the image. A typical contrast ratio for TFT may be 300:1. This number ratio means that the white is 300 times brighter than the black.

TFT LCD displays are measured in inches; this is the measurement of the diagonal distance across the glass. Common TFT sizes include: 1.77”, 2.4”, 2.8”, 3”, 4.3”, 5”, 5.7”, 5.8”, 7”, 10.2”, 12.1 and 15”.

As a general rule, the larger the size of the glass the higher the cost of the display, but there are exceptions to this rule. A larger display may be less expensive than a smaller display if the manufacture produces higher quantities of the larger displays. When selecting your color display, be sure to ask what the cost is for one size smaller and one size larger. It may be worth modifying your design requirements.

TFT resolution is the number of dots or pixels the display contains. It is measured by the number of dots along the horizontal (X axis) and the dots along the vertical (Y axis).

The higher the resolution, the more dots per square inch (DPI), the sharper the display will look. A higher resolution results in a higher cost. One reason for the increase in cost is that more driver chips are necessary to drive each segment.

Certain combinations of width and height are standardized and typically given a name and a letter representation that is descriptive of its dimensions. Popular names given to the TFT LCD displays resolution include:

Transmissive displays must have the backlight on at all times to read the display, but are not the best option in direct sunlight unless the backlight is 750 Nits or higher. A majority of TFT displays are Transmissive, but they will require more power to operate with a brighter backlight.

Transflective displays are readable with the backlight off provided there is enough ambient light. Transflective displays are more expensive than Transmissive also there may be a larger MOQ for Transflective. However, Transflective displays are the best option for direct sunlight.

Drivers update and refresh the pixels (Picture Elements) of a display. Each driver is assigned a set number of pixels. If there are more pixels than a single driver can handle, then an additional drivers are added.

A primary job of the driver is to refresh each pixel. In passive TFT displays, the pixel is refreshed and then allowed to slowly fade (aka decay) until refreshed again. The higher the refresh frequency, the sharper the displays contrast.

The controller does just what its name suggest. It controls the drivers. There is only one controller per display no matter how many drivers. A complex graphic display with several thousand pixels will contain one controller and several drivers.

The TFT display (minus touch screen/backlight) alone will contain one controller/driver combination. These are built into the display so the design engineer does not need to locate the correct hardware.

Response Time is the measurement of time it takes for a pixel/segment to change from black (OFF state) to white (ON state) and then back to black again. In other words, how fast the picture can be changed. A slow response time can result in the blurring of the picture in games, movies and even cad type programs.

If you do not see a Thin Film Transistor (TFT) Display module that meets your specifications, or you need a replacement TFT, we can build a custom TFT displays to meet your requirements. Custom TFTs require a one-time tooling fee and may require higher MOQs.

Ready to order samples for your TFT design? Contact one of our US-based technical support people today concerning your design requirements. Note: We can provide smaller quantities for samples and prototyping.

In illustrated steps he connects the RIoTboard up to a Thin Film Transistor (TFT) LCD display, covers such things as the RIoTboard LVDS interface, board pin outs and selecting an In-Plane Switching panel, and solders the display to the breakout board…

The circuit at the heart of the system manages two power supplies: one to drive the panel, and another for the backlight (the two voltages will vary depending on the panel chosen). He writes:

The circuit has lots of ‘do not fit’ resistor locations that can be experimented with if it is desired to run the entire circuit and the RIoTboard from a single supply source.

Shabaz acknowledges that there are pre-built displays you could use with for the RIoTboard, but a “build-it-yourself” approach is more in the spirit of Gadget Master!

There are loads of details, step by step guides, lots of pics, the full circuit diagram, a parts list with order codes and plot (Gerber) files for the PCB…

LCD is the abbreviation for liquid crystal display. An LCD basically consists of two glass plates with a special liquid between them. The special attribute of this liquid is that it rotates or “twists” the plane of polarized light. This effect is influenced by the creation of an electrical field. The glass plates are thus each coated with a very thin metallic film. To obtain polarized light, you apply a polarization foil, the polarizer, to the bottom glass plate. Another foil must be applied to the bottom glass plate, but this time with a plane of polarization twisted by 90°. This is referred to as the analyzer.

In the idle state, the liquid twists the plane of polarization of the incoming light by 90° so that it can pass the analyzer unhindered. The LCD is thus transparent. If a specific voltage is applied to the metallic film coating, the crystals rotate in the liquid. This twists the plane of polarization of the light by another 90°, for example: The analyzer prevents the light getting through, and the LCD thus becomes opaque.TN, STN, FSTN, blue mode, yellow-green mode

Liquids that twist the plane of polarized light by 90° are referred to as TN (Twisted Nematic). STN (Super Twisted Nematic) liquids twist the plane of polarized light by at least 180°. This gives the display improved contrast. However, this technology does color the display to a certain extent. The most common colors are referred to as yellow-green and blue mode. There is also a gray mode, which in practice is more blue than gray, however.

In order to counteract the undesired color effect, the FSTN technology uses an additional foil on the outer side, but this causes a loss of light and means that this technology is only effective with lit displays.

However, the different colors occur only in displays that are either not lit or that are lit with white light. If there is any color in the lighting (e.g. yellow-green LED lighting), it overrides the color of the display. A blue-mode LCD with yellow-green LED lighting will always appear yellow-green.Static or multiplex driving method

Small displays with a small viewing area are generally statically driven. Static displays have the best contrast and the largest possible angle of view. The TN technology fulfills its purpose to the full here (black and white display, reasonably priced). The bigger displays get, however, the more lines become necessary in static operation (e.g. graphics 128x64=8192 segments =8192 lines). Since there is not enough space on either the display or a driver IC for so many lines, multiplexing is used. The display is thus divided up into rows and columns, and there is a segment at each intersection (128+64=192 lines). Scanning takes place row by row (64x, in other words a multiplex rate of 1:64). Because only 1 row is ever active at any one time, however, the contrast and the angle of view suffer the higher the multiplex rate becomes. This makes it essential to use STN.Angle of view 6°°/12°°

Every LCD has a preferred angle of view at which the contrast of the display is at its optimum. Most displays are produced for the 6°° angle of view, which is also known as the bottom view (BV). This angle corresponds to that of a pocket calculator that is lying flat on a desktop.

12°° displays (top view, TV) are best built into a table-top unit. All displays can be read vertically from the front.Reflective, transflective, transmissive

However, the lighting also determines the optical impression made by the display, and the display mode; blue or yellow-green – does not always have an influence. Below you can see the EAP162-3N display with different types of lighting by way of example:Lighting

Standard LCDs have a temperature range of 0 to +50°C. High-temperature displays are designed for operation in the range from -20 to +70°C. In this case, however, additional supply voltage is generally required. Since the contrast of any LCD is dependent on the temperature, a special temperature-compensation circuit is needed in order to use the entire temperature range, and this is particularly true for high-temperature displays (-20 to +70°C). Manual adjustment is possible but rather impractical for the user.

However, the storage temperature of a display should never be exceeded under any circumstances. An excessively high temperature can destroy the display very quickly. Direct exposure to the sun, for example, can destroy an LCD: This is because an LCD becomes darker (in positive mode) as it gets hotter. As it gets darker, it absorbs more light and converts it to heat. As a result, the display becomes even hotter and darker... In this way, temperatures of over 100°C can quickly be reached.Dot-matrix, graphics and 7-segment displays

The first LCDs were 7-segment displays, and they are still found today in simple pocket calculators and digital watches. 7 segments allow all of the digits from 0 to 9 to be displayed.

Text displays require what is known as a dot matrix, an area consisting of 5x7=35 dots, in order to display all of the letters in the alphabet as well as various special characters. Graphics displays have a similar structure to text displays. In this case, however, there are no spaces between the lines and characters.Display drivers and controllers

The semiconductor industry now offers a very large range of LCD drivers. We generally distinguish between pure display drivers without intelligence of their own, controllers with a display memory and possibly a character set, and micro-controllers with integrated LC drivers.

Pure display drivers work in a similar way to a shift register. They generally have a serial input. They require an external pulse, and in multiplex operation with high frequency they require new display data continuously in order to achieve a refresh frequency that is as high as possible (MSM5219, UPD7225, HD44100, LC7942, etc.). An example of a genuine controller is theHD44780 for dot-matrix displays: Once it has received the ASCII code, the controller manages its character set, memory and multiplexing entirely on its own. The following controllers are widely used for graphics displays: HD61202/3, HD61830, SED1520, SED1330, T6963.

Many ask themselves, "What is the difference between an LCD display and a TFT-display?" or "What is the difference between a TFT and an OLED display?". Here are these 3 sometimes extremely different display technologies briefly explained. LCD vs. TFT vs. OLED (comparison).

- The LCD (Liquid Crystal Display) is a passive display technology. The operation and the structure are described above. Passive means that an LCD can only darken or let out light. So it always depends on ambient light or a backlight. This can be an advantage because the power consumption of a LCD display is very, very low. Sometimes even less than the accumulated power consumption of an E-paper display, which in static operation requires absolutely no energy to maintain the content. To change the contents, however, a relatively large amount of power is required for an E-paper display.

LCDs can also be reflective, so they reflect incident light and are therefore legible even at maximum brightness (sunlight, surgical lighting). Compared to TFT and also OLED, they have an unbeatable advantage in terms of readability and power consumption :; the "formula" is: Sunlight = LCD.

- A TFT-display (of Thin-Film Transistor) is usually a color display (RGB). From the construction and the technology it corresponds to the LCD. It is also passive, so it needs a backlight. This is in any case necessary except for a few, very expensive constructions. However, a TFT needs much more light than the monochrome relatives, because the additional structures on the glass as well as the additional color filters "swallow" light. So TFTs are not particularly energy-efficient, but can display in color and at the same time the resolution is much higher.

- OLED displays (by Organic-Light-Emitting-Diode) are as the name implies active displays - every pixel or sign generates light. This achieves an extremely wide viewing angle and high contrast values. The power consumption is dependent on the display content. Here OLEDs to TFTs and LCDs differ significantly, which have a nearly constant power consumption even with different display contents. Unfortunately, the efficiency of converting the electric current into light energy is still very poor. This means that the power consumption of OLEDs with normal content is sometimes higher than that of a TFT with the same size. Colored OLEDs are increasingly used in consumer devices, but for the industry, due to their availability and lifetime, currently only monochrome displays are suitable (usually in yellow color).

In the reaction time, the OLEDs beat each TFT and LCD by worlds. Trise and Tfall are about 10μs, which would correspond to a theoretical refresh rate of 50,000 Hz. Possibly an advantage in very special applications.

Finally the question "What is better, LCD, OLED or TFT?" Due to the physical differences you can not answer that blanket. Depending on the application, there are pros and cons to each individual technology. In addition to the above differences, there are many more details in the design and construction that need to be individually illuminated for each device. Write us an e-mail or call us: we have specialists with some 20- and 30-year experience. We are happy to compare different displays together with you.AACS and IPS technology

A TFT LCD, or a thin film transistor liquid crystal display, is one of the fastest growing forms of display technology today. The thin film transistor (TFT) is a type of semiconductor device used in display technology to enhance efficiency, compactness, and cost of the product. In conjunction with its semiconductor properties, the TFT LCD is an active matrix display, controlling pixels individually and actively rather than passively, furthering the benefits of this semiconductor device.

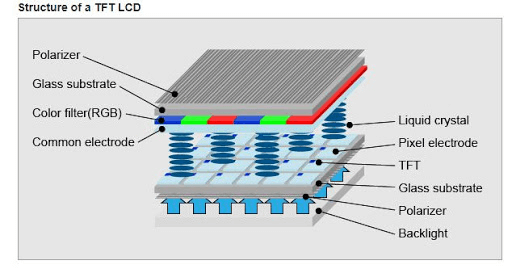

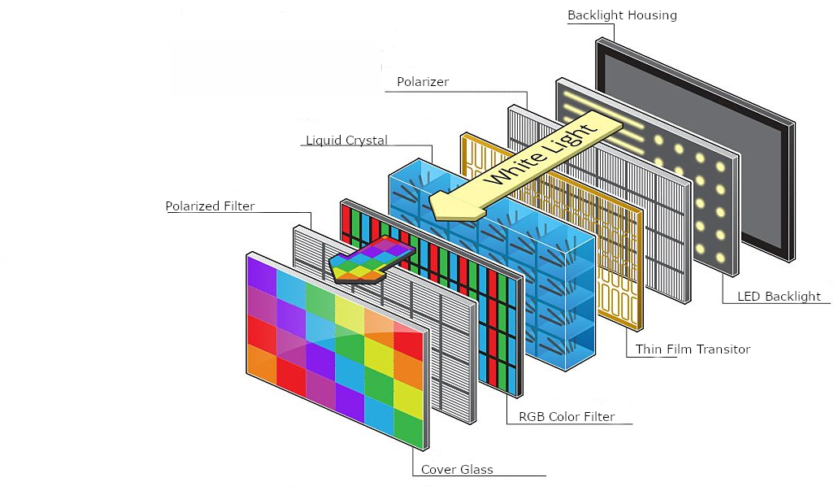

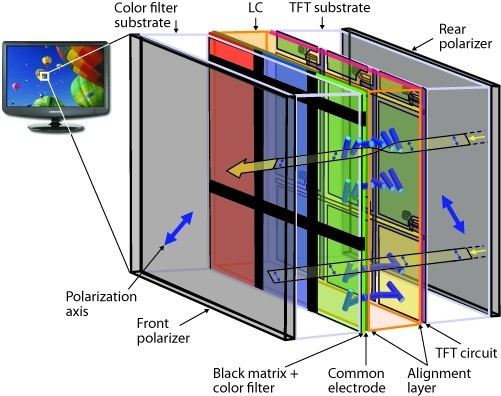

The TFT LCD is built with three key layers. Two sandwiching layers consist of glass substrates, though one includes TFTs while the other has an RGB, or red green blue, color filter. The layer between the glass layers is a liquid crystal layer.

The Architecture of a TFT Pixelbelow) from the other substrate layer of the device and control the amount of voltage applied to their respective sub-pixels. This layer also has pixel electrodes between the substrate and the liquid crystal layer. Electrodes are conductors that channel electricity into or out of something, in this case, pixels.

On the surface level is the other glass substrate. Just beneath this glass substrate is where the actual pixels and sub-pixels reside, forming the RGB color filter. In order to counteract the electrodes of the previously mentioned layer, this surface layer has counter (or common) electrodes on the side closer to the liquid crystals that close off the circuit that travels between the two layers. In both these substrate layers, the electrodes are most frequently made of indium tin oxide (ITO) because they allow for transparency and have good conductive properties.

Between the two substrate layers lie liquid crystals. Together, the liquid crystal molecules may behave as a liquid in terms of movement, but it holds its structure as a crystal. There are a variety of chemical formulas available for use in this layer. Typically, liquid crystals are aligned to position the molecules in a certain way to induce specific behaviors of passing light through the polarization of the light waves. To do this, either a magnetic or electric field must be used; however, with displays, for a magnetic field to be usable, it will be too strong for the display itself, and thus electric fields, using very low power and requiring no current, are used.

Before applying an electric field to the crystals between the electrodes, the alignment of the crystals is in a 90 degree twisted pattern, allowing a properly crystal-polarized light to pass through the surface polarizer in a display’s “normal white” mode. This state is caused by electrodes that are purposely coated in a material that orients the structure with this specific twist.

However, when the electric field is applied, the twist is broken as the crystals straighten out, otherwise known as re-aligning. The passing light can still pass through the back polarizer, but because the crystal layer does not polarize the lights to pass through the surface polarizer, light is not transmitted to the surface, thus an opaque display. If the voltage is lessened, only some crystals re-align, allowing for a partial amount of light to pass and creating different shades of grey (levels of light). This effect is called the twisted nematic effect.

Fig. 2: On the left is the twisted liquid crystal layer in which polarized light passes freely; on the right is after the electric field is charged into the layer, completely re-aligning the molecule orientations so that light is not polarized and cannot pass through the surface polarizer.

The twisted nematic effect is one of the cheapest options for LCD technology, and it also allows for fast pixel response time. There are still some limits, though; color reproduction quality may not be great, and viewing angles, or the direction at which the screen is looked at, are more limited.

Fig. 3:The top row characterizes the nature of alignment in using IPS as well as the quality of viewing angles. The bottom row displays how the twisted nematic is used to align the crystals and how viewing angles are affected by it.

The light that passes through the device is sourced from the backlight which can shine light from the back or the side of the display. Because the LCD does not produce its own light, it needs to use the backlight in the OLED) have come into use as well. Typically white, this light, if polarized correctly, will pass through the RGB color filter of the surface substrate layer, displaying the color signaled for by the TFT device.

Within an LCD, each pixel can be characterized by its three sub-pixels. These three sub-pixels create the RGB colorization of that overall pixel. These sub-pixels act as capacitors, or electrical storage units within a device, each with their own independent structural and functional layers as described earlier. With the three sub-pixels per pixel, colors of almost any kind can be mixed from the light passing through the filters and polarizer at different brightness based on the liquid crystal alignment.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Take your design to the next level with our range of TFT Displays including latest IPS TFT, circular and bar shape as well as large size TFT. With or without touch, these are fully customisable to your system requirements.

TFT-LCD technology is now fairly mature. As a result, manufacturing processes are efficient and production yields are high, leading to very competitive unit prices. Upgrading from a monochrome display to a TFT is now an affordable way to give your product an uplift.

Users of industrial display devices are wanting the same experience they have come to expect from a consumer device with all-round viewing angles. Switching to a superior IPS TFT display has become very cost effective as production increases and unit prices decrease.

Choosing a circular display for your next product design could really set you apart from your competition. Models are available from 1" to 4.2"in TFT, PMOLED and AMOLED, we have something to suit every application.

It is now possible to transform from a monochrome display to a colour display in space constrained systemsby using a letterbox shaped display. These ultra-wide displays are ideal for applications with restricted build height such as rack mount systems or landscape format front panels.

Large TFT display systems are increasingly being used for transportation information, retail signage and vending machines and kiosks. We can supply a large range of TFT solutions up to 65" diameter and in bar-style, square or rectangular configurations.

Anders have partnered with world leading brand Kastus®to offer a globally patentedantimicrobial & antiviralsurface coating which has a proven kill rate of up to 99.99% against harmful bacteria, fungi and antibiotic-resistant superbugs, which makes it particularly useful for products including glass and ceramics. This year, an independent testing report found Kastus to be effective against human Coronavirus on screens.

We are now offering increasing cover lens customisation options and processes to make your TFT LCD user interface truly stand out! Anders’ experienced marketers and engineers work with our manufacturing partners around the world to keep informed of the latest innovations, including mirrored glass,tinted glass, spot-facing, three dimension glass, and many more!

Here at Anders we don"t just strive to design a best in class display solution for your product, but we also want to make sure the display is driven with the right embedded system. We can help achieve a hardware solution that ensures your display works perfectly within your application. Hardware solutions include:

Get started quickly on your new user interface with our HMI development kits. The display, the processor and the OS work together out of the box with optimised QT GUI images. We"ll then optimise the kit to meet exactly your system requirements with our design services.

At Anders we understand that no two customers are the same, which is why we specialise in custom display solutionsand offer unique productstailored to your end application.

See below our range of TFT Displayswith sizes ranging from0.96" to 64.5" and including circular and bar type shape. All our displays can be tailored to suit your application antimicrobial coating technology,

We aim to offer reliable and long-term solutions to our B2B customers. If you are a business and would like to discuss your display and/or embedded system requirements please contact us below

A TFT display is a form of Liquid Crystal Display with thin film transistors for controlling the image formation. The TFT technology works by controlling brightness in red, green and blue sub-pixels through transistors for each pixel on the screen.

There are many display technologies, but do you know which one would be better for your application? Particularly when considering optimum viewing angle and contrast. We discuss 2 of the best options.

Compare IPS vs TFT displays - the TFT display is the display of choice for industrial designs, but it can have its limitations. A newer technology called IPS (in plane switching) offers better viewing angles and colours, but is it really the best choice - we discuss benefits and negatives of both types of TFT display.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

When it comes to choosing what to use for your displays, going with the standard can get you farther ahead than thinking outside the box. TFT LCD display gives you an edge for your advertising needs, television screens, or even phone screens.

A thin-film transistor (TFT) is one of the technologies commonly used for building LCDs. With this technology, your LCD is guaranteed a sharp, clear, and full-color display and high-quality performance.

When a signal sent to a pixel also affects the pixels next to it, crosstalk This runs the risk of distorting the quality of your image. With TFT, crosstalk is significantly reduced with the TFT layer integrated into the screen itself. With every pixel corresponding to the signals meant only for them, you are guaranteed the best resolution and image quality.

In the LCD industry, the most popular kinds of displays are manufactured and innovated the most. Unlike other types of LCD technologies, the TFT module is available in different sizes, ranging from cellphone sizes to larger TV sizes, to suit your needs.

All LCD displays have a determined number of hours of use before they become half as bright than when they were turned on for the first time. This is called half-life. Although research is still ongoing regarding half-life, TFT displays are said to have more than 14,000 hours of half-life.

Compared to CRTs, TFT LCD modules have lower heat release. Moreover, they emit lower electromagnetic emissions which significantly decrease visual fatigue. This means that TFTs are ideal for devices and displays that require an audience’s prolonged attention, such as cell phones and television screens.

While the TFT’s power consumption is significantly lower than OLEDs in white displays, there are also emerging TFT displays in the market that integrate smart technologies that can save up to 50% energy on battery-operated devices.

One of the notable disadvantages of TFTs, however, is its cost. The characteristics detailed in the previous section, however, must be considered worthy of investment. Moreover, as the number of TFTs floods the LCD display market, the price for TFTs are decreasing by the day.

At Microtips Technology USA, we only provide you with the best among the best of TFT modules. Our TFT LCD displays assure only full RGB brilliance with up to 16.7 million colors, better picture quality with high resolutions and IPS technology, and affordability.

The worlds of high-end Color LCD Modules are taken over. As our world evolved and embedded devices becoming more, and more sophisticated and prevalent, we tend to look at the art of design. Steve Jobs sums it up just right. “Design is not just what it looks like and feels like. Design is how it works.” TFT LCD modules are a type of variant of an LCD which uses thin film, appliances such as: TV, computer monitors, kindles, mobile phone, and navigation system. The construction of a color LCD module or TFT LCD is quite extraordinary because of the circuit layout process; this form of layout is similar to the layout of a semiconductor product. Even though as we observe the TFT LCD display we came across few pros and cons which are most needed for this discussion. The advantages of TFT LCD are as follows: less energy consumption, visibility is sharper in other words has superb quality, physical design, response time, and less eye strain etc… With every great product there are few disadvantages associated, such as, cost and viewing angles.

TFT LCD displays are very convenient because of the energy consumption associate with this display, knowingly in today’s society saving energy is a number one priority to reduce greenhouse gas and ensure a better future generations. Due to the construction of TFT structures Pixel like materials does not consume much energy to begin with except this material consume far less power than a comparable CRT monitor. The images of a TFT display does not rely on the scanning of electron beams instead they are free from flicker and has a crisp image, with no geometric distortion. The physical design of TFT display are space savors which can be position anywhere in ones office, or house with a rotations mechanism in place for less constrains on space.

As mention before TFT LCD has few disadvantages, due to the nature of the design TFT LCD display may cost a little more than a regular monochrome display. Other disadvantages may arise when the viewing the display at the 6 0’clock direction but in fact the optimal viewing is at the 12’oclock direction this may also lead to inversion which or common in situation like this; however TFT displays are superior and will be in production for years to come.

If you are TFT LCD module users, we will provide you with the most suitable TFT LCD products, including the selection of control board, accessories, testing, maintenance and a series of services.

If you have special requirements for product application, we will provide the best customization solutions, in the most economical and efficient way, to meet all your personalized needs.

Pacer offers an extensive range of colour TFT LCD panels from 1.8″ through the popular 3.5″ and 5.7″ sizes to 82″. Our range includes sunlight readable panels from 5.6″ to 70″, bar cut panels, and SMART TFT displays with built-in control. We offer TFT displays with high brightness, high contrast ratio, wide viewing angle, wide temperature operation, longer lamp life, and lower power consumption.

TFT displays are used extensively in many industrial, commercial and scientific applications, including ATMs, POS terminals, kiosks, security systems, lottery and gambling gaming machines, medical equipment, factory automation, digital advertisement signage, transportation information, and marine equipment.

TFT technology is being used to replace Mono LCD in many applications, and Raystar Optronics now offers a 5.2″ TFT module designed specifically to fit the footprint of the industry standard RG24064-series 240×64 mono graphic STN LCD. The RFS520A can replace traditional STN displays of 8×2 or 16×2 format as it shares the same 16 pin footprint.

Our TFT modules are fully supported with a variety of options including wide operating temperatures, high brightness and contrast, built-in DC-DC and temperature compensation circuitry and most with white LED backlights. Resistive Touchscreens and Projected Capacitive Touchscreens are available for most models. Many panels can be configured as a kit – see our Interface Kits page for more details.

IMPORTANT ANNOUNCEMENT – Mitsubishi has decided to end production of TFT-LCD modules, as the company is no longer able to maintain the products’ competitiveness after significant price falls in the global market. Production of TFT-LCD modules is scheduled to end in June 2022 with a Last Time Buy date of June 2021. Please contact us as soon as possible to discuss last time buy or identification of suitable alternative displays.

Raystar is a professional TFT (Thin Film Transistor) module manufacturer. Whether you need a TFT display with control board, high brightness, wide viewing angle, monochrome or bar type, we have TFT active matrix display models for you to choose from.

Mitsubishi’s Electric Diode InfraRed sensor (MelDIR) is a thermal sensor for applications in the fields of security, surveillance, crime prevention, people counting, heating, ventilation and air conditioning (HVAC) and smart buildings.

LITEMAX® Industrial Display solution provide a wide range of reliable displays from 5.7″ to 85″ including LCD panel modules, open frame LCD displays, outdoor displays, and panel mount monitors. LITEMAX have developed and focused on LCD display technologies such as high brightness technology, optical bonding solutions, and color enhancement technology that bring more add-on value to enhance their products.

Display screen is everywhere nowadays. Do you still remember the TVs or computer monitors 20 years ago? They were quadrate, huge and heavy. Now let’s look at the flat, thin and light screen in front of you, have you ever wondered why is there such a big difference?

Actually, the monitors 20 year ago were CRT (Cathode Ray Tube) displays, which requires a large space to run the inner component. And now the screen here in your presence is the LCD (Liquid Crystal Display) screen.

As mentioned above, LCD is the abbreviation of Liquid Crystal Display. It’s a new display technology making use of the optical-electrical characteristic of liquid crystal.

Liquid crystal is a state of substance that has both the characteristics of liquid and solid crystal. It don’t emit light itself, but it can let the light pass perfectly in specific direction. Meanwhile, liquid crystal molecule will rotate under the influence of a electric field, and then the light goes through it will rotate too. That said, liquid crystal can be a switch of light, which is the key in display technology.

STN LCD: STN is for Super-twisted Nematic. The liquid crystal in STN LCD rotate more angles than that in TN LCD, and have a different electrical feature, allowing STN LCD to display more information. There are many improved version of STN LCD like DSTN LCD (double layer) and CSTN LCD (color). This LCD is used in many early phones, computers and outdoor devices.

TFT LCD: TFT is for Thin Film Transistor. It’s the latest generation of LCD technology and has been applied in all the displaying scenario including electronic devices, motor cars, industrial machines, etc. When you see the word ‘transistor’, you may realize there’s integrated circuits in TFT LCD. That’s correct and the secret that TFT LCD has the advantage of high resolution and full color display.

In a simple way, we can divide TFT LCD into three parts, from bottom to top they are: light system, circuit system and light and color control system.In manufacturing process, we’ll start from inner light and color control system and then stretch out to whole module.

It’s accustomed to divide TFT LCD manufacturing process into three main part: array, cell and module. The former two steps are about the production of light and color control system, which contains TFT, CF (color filter) and LC (liquid crystal), named a cell. And the last step is the assembly of cell, circuit and light system.

First, let me introduce a crucial material, ITO, to you. ITO, abbreviation of Indium tin oxide, has the characteristic of electrical conductivity and optical transparency, as well as can be easily deposited as a thin film. Thus it’s widely used to create circuit on glass.

Now let’s turn to the production of TFT and CF. Here is a common method called PR (photoresist) method. The whole process of PR method will be demonstrated in TFT production.

◇ Use glue to build a boundary for LC on both glass. And on CF glass, apply one more layer of conductive adhesive. This enable LC molecule link to the control circuit.

◇ Put the diffuser film and prism film on light source in turn. Together with reflector film, these two films are used to turn the point light from light source into area light and enhance light intensity.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey