lcd display schematic diagram manufacturer

Important technical improvements of LCD, such as LED backlighting and wide viewing Angle, are directly related to LCD. And account for an LCD display 80% of the cost of the LCD panel, enough to show that the LCD panel is the core part of the entire display, the quality of the LCD panel, can be said to directly determine the quality of an LCD display.

The production of civil LCD displays is just an assembly process. The LCD panel, the main control circuit, shell, and other parts of the main assembly, basically will not have too complex technical problems.

Does this mean that LCDS are low-tech products? In fact, it is not. The production and manufacturing process of the LCD panels is very complicated, requiring at least 300 process processes. The whole process needs to be carried out in a dust-free environment and with precise technology.

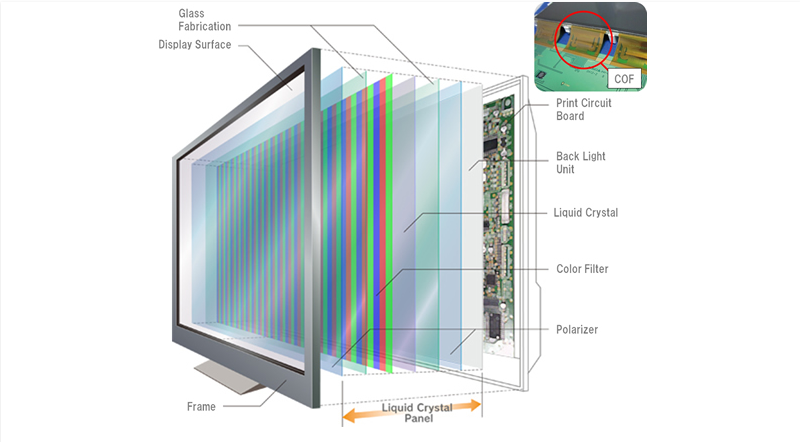

The general structure of the LCD panel is not very complex, now the structure of the LCD panel is divided into two parts: the LCD panel and the backlight system.

Due to the LCD does not shine, so you need to use another light source to illuminate, the function of the backlight system is to this, but currently used CCFL lamp or LED backlight, don’t have the characteristics of the surface light source, so you need to guide plate, spreadsheet components, such as linear or point sources of light evenly across the surface, in order to make the entire LCD panel on the differences of luminous intensity is the same, but it is very difficult, to achieve the ideal state can be to try to reduce brightness non-uniformity, the backlight system has a lot to the test of design and workmanship.

In addition, there is a driving IC and printed circuit board beside the LCD panel, which is mainly used to control the rotation of LCD molecules in the LCD panel and the transmission of display signals. The LCD plate is thin and translucent without electricity. It is roughly shaped like a sandwich, with an LCD sandwiched between a layer of TFT glass and a layer of colored filters.

LCD with light refraction properties of solid crystals, with fluid flow characteristics at the same time, under the drive of the electrode, can be arranged in a way that, in accordance with the master want to control the strength of the light through, and then on the color filter, through the red, green, blue three colors of each pixel toning, eventually get the full-screen image.

According to the functional division, the LCD panel can be divided into the LCD panel and the backlight system. However, to produce an LCD panel, it needs to go through three complicated processes, namely, the manufacturing process of the front segment Array,the manufacturing process of the middle segment Cell, and the assembly of the rear segment module. Today we will be here, for you in detail to introduce the production of the LCD panel manufacturing process.

The manufacturing process of the LCD panel Array is mainly composed of four parts: film, yellow light, etch and peel film. If we just look at it in this way, many netizens do not understand the specific meaning of these four steps and why they do so.

First of all, the motion and arrangement of LCD molecules need electrons to drive them. Therefore, on the TFT glass, the carrier of LCD, there must be conductive parts to control the motion of LCD. In this case, we use ITO (Indium Tin Oxide) to do this.ITO is transparent and also acts as a thin-film conductive crystal so that it doesn’t block the backlight.

The different arrangement of LCD molecules and the rapid motion change can ensure that each pixel displays the corresponding color accurately and the image changes accurately and quickly, which requires the precision of LCD molecule control.ITO film needs special treatment, just like printing the circuit on the PCB board, drawing the conductive circuit on the whole LCD board.

This completes the previous Array process. It is not difficult to see from the whole process that ITO film is deposited, photoresist coated, exposed, developed, and etched on TFT glass, and finally, ITO electrode pattern designed in the early stage is formed on TFT glass to control the movement of LCD molecules on the glass. The general steps of the whole production process are not complicated, but the technical details and precautions are very complicated, so we will not introduce them here. Interested friends can consult relevant materials by themselves.

The glass that the LCD board uses makes a craft also very exquisite. (The manufacturing process flow of the LCD display screen)At present, the world’s largest LCD panel glass, mainly by the United States Corning, Japan Asahi glass manufacturers, located in the upstream of the production of LCD panel, these manufacturers have mastered the glass production technology patents. A few months ago, the earthquake caused a corning glass furnace shutdown incident, which has caused a certain impact on the LCD panel industry, you can see its position in the industry.

As mentioned earlier, the LCD panel is structured like a sandwich, with an LCD sandwiched between the lower TFT glass and the upper color filter. The terminal Cell process in LCD panel manufacturing involves the TFT glass being glued to the top and bottom of a colored filter, but this is not a simple bonding process that requires a lot of technical detail.

As you can see from the figure above, the glass is divided into 6 pieces of the same size. In other words, the LCD made from this glass is finally cut into 6 pieces, and the size of each piece is the final size. When the glass is cast, the specifications and sizes of each glass have been designed in advance.

Directional friction:Flannelette material is used to rub the surface of the layer in a specific direction so that the LCD molecules can be arranged along the friction direction of the aligned layer in the future to ensure the consistency of the arrangement of LCD molecules. After the alignment friction, there will be some contaminants such as flannelette thread, which need to be washed away through a special cleaning process.

After the TFT glass substrate is cleaned, a sealant coating is applied to allow the TFT glass substrate to be bonded to the color filter and to prevent LCD outflow.

Finally, the conductive adhesive is applied to the frame in the bonding direction of the glass of the color filter to ensure that external electrons can flow into the LCD layer. Then, according to the bonding mark on the TFT glass substrate and the color filter, two pieces of glass are bonded together, and the bonding material is solidified at high temperatures to make the upper and lower glasses fit statically.

Color filters are very important components of LCD panels. Manufacturers of color filters, like glass substrate manufacturers, are upstream of LCD panel manufacturers. Their oversupply or undersupply can directly affect the production schedule of LCD panels and indirectly affect the end market.

As can be seen from the above figure, each LCD panel is left with two edges after cutting. What is it used for? You can find the answer in the later module process

Finally, a polarizer is placed on both sides of each LCD substrate, with the horizontal polarizer facing outwards and the vertical polarizer facing inwards.

When making LCD panel, must up and down each use one, and presents the alternating direction, when has the electric field and does not have the electric field, causes the light to produce the phase difference and to present the light and dark state, uses in the display subtitle or the pattern.

The rear Module manufacturing process is mainly the integration of the drive IC pressing of the LCD substrate and the printed circuit board. This part can transmit the display signal received from the main control circuit to the drive IC to drive the LCD molecules to rotate and display the image. In addition, the backlight part will be integrated with the LCD substrate at this stage, and the complete LCD panel is completed.

Firstly, the heteroconductive adhesive is pressed on the two edges, which allows external electrons to enter the LCD substrate layer and acts as a bridge for electronic transmission

Next is the drive IC press. The main function of the drive IC is to output the required voltage to each pixel and control the degree of torsion of the LCD molecules. The drive IC is divided into two types. The source drive IC located in the X-axis is responsible for the input of data. It is characterized by high frequency and has an image function. The gate drive IC located in the Y-axis is responsible for the degree and speed of torsion of LCD molecules, which directly affects the response time of the LCD display. However, there are already many LCD panels that only have driving IC in the X-axis direction, perhaps because the Y-axis drive IC function has been integrated and simplified.

The press of the flexible circuit board can transmit data signals and act as the bridge between the external printed circuit and LCD. It can be bent and thus becomes a flexible or flexible circuit board

The manufacturing process of the LCD substrate still has a lot of details and matters needing attention, for example, rinse with clean, dry, dry, dry, ultrasonic cleaning, exposure, development and so on and so on, all have very strict technical details and requirements, so as to produce qualified eyes panel, interested friends can consult relevant technical information by a search engine.

LCD (LC) is a kind of LCD, which has the properties of light transmission and refraction of solid Crystal, as well as the flow property of Liquid. It is because of this property that it will be applied to the display field.

However, LCD does not emit light autonomously, so the display equipment using LCD as the display medium needs to be equipped with another backlight system.

First, a backplate is needed as the carrier of the light source. The common light source for LCD display equipment is CCFL cold cathode backlight, but it has started to switch to an LED backlight, but either one needs a backplate as the carrier.

CCFL backlight has been with LCD for a long time. Compared with LED backlight, CCFL backlight has many defects. However, it has gradually evolved to save 50% of the lamp and enhance the transmittance of the LCD panel, so as to achieve the purpose of energy-saving.

With the rapid development of LED in the field of lighting, the cost has been greatly reduced.LCD panels have also started to use LED as the backlight on a large scale. Currently, in order to control costs, an LED backlight is placed on the side rather than on the backplate, which can reduce the number of LED grains.

At the top of the diffusion plate, there will be 3~4 diffuser pieces, constantly uniform light to the whole surface, improve the uniformity of light, which is directly related to the LCD panel display effect. Professional LCD in order to better control the brightness uniformity of the screen, panel procurement, the later backlight control circuit, will make great efforts to ensure the quality of the panel.

Since the LCD substrate and the backlight system are not fixed by bonding, a metal or rubber frame is needed to be added to the outer layer to fix the LCD substrate and the backlight system.

After the period of the Module, the process is completed in LCM (LCDModule) factory, the core of this part of the basic does not involve the use of LCD manufacturing technology, mainly is some assembly work, so some machine panel factories such as chi mei, Korea department such as Samsung panel factory, all set with LCM factories in mainland China, Duan Mo group after the LCD panel assembly, so that we can convenient mainland area each big monitor procurement contract with LCD TV manufacturers, can reduce the human in the whole manufacturing and transportation costs.

However, neither Taiwan nor Korea has any intention to set up factories in mainland China for the LCD panel front and middle manufacturing process involving core technologies. Therefore, there is still a long way to go for China to have its own LCD panel industry.

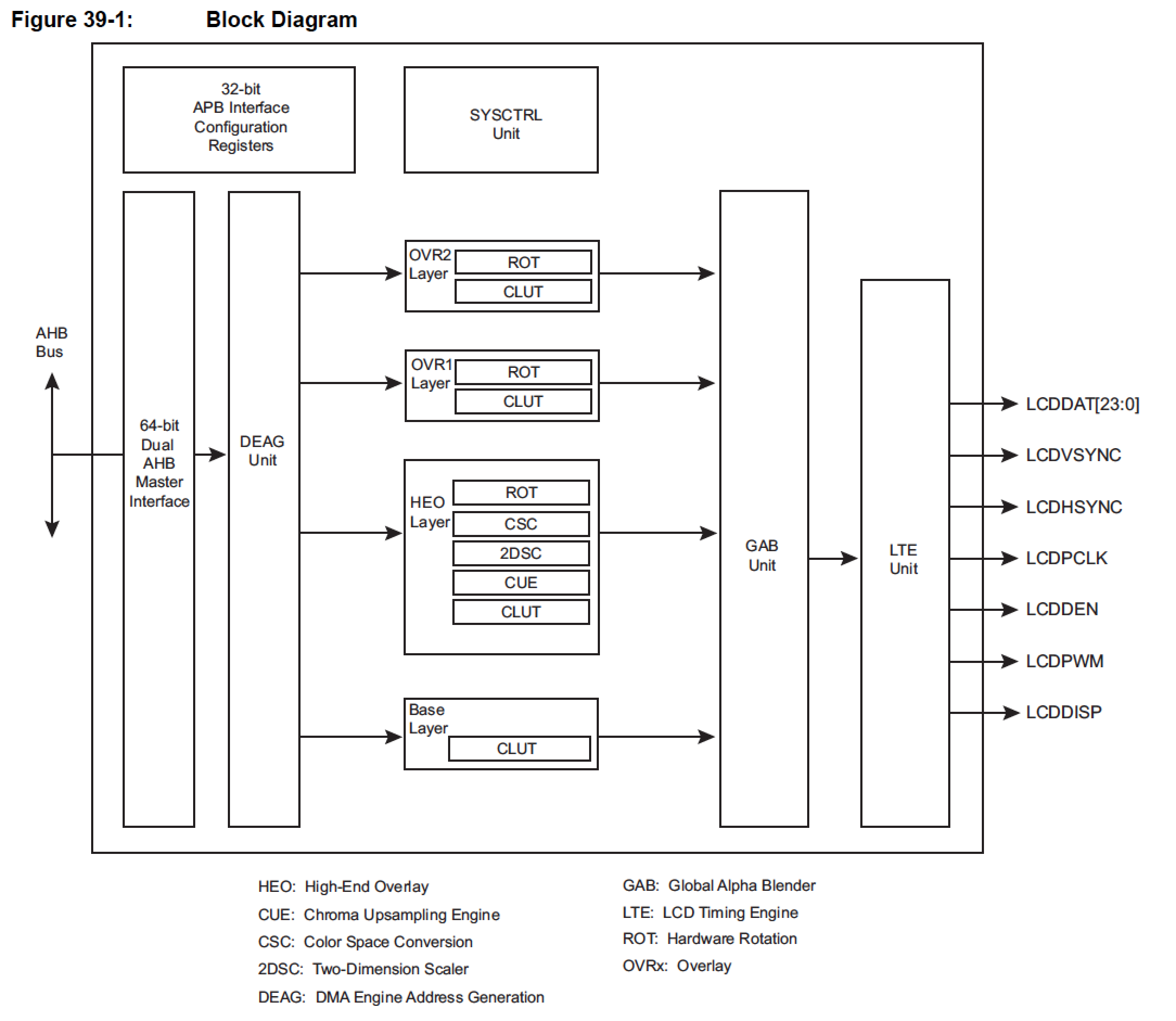

Benq FP 757/767The archive is a schematic diagram of electric LCD Monitors Benq FP 757/767:1) Input Interface2) voltage regulator 1.8 V3) Graphics Controller PW135. Interface LCD panel4) Memory ROM and EEPROM5) The control and display panel interface6) Power source7) DC / AC-converter supply backlight CCFL-lamps (inverter)8) Power...

20 "LCD monitors. Manufacturer - TPV, IC - TEA1530AT, OZT1060GNThe archive is a schematic diagram of an electric power supply (Power + Inverter) 20 "LCD monitors -TPV manufacturer, IC -. TEA1530AT, OZT1060GN.1) Main Power2) Power Inverter backlight CCFL-lamp LCD panel

Samsung SyncMaster 172N/192NThe archive is a schematic circuit diagram of the main board of the monitor "Samsung SyncMaster 172N / 192N" (chassis BB17A)

Samsung SyncMaster 540N/B, 740N/B/T, 940B/Be/T/NThe archive shows the circuit LCD Monitor Samsung SyncMaster 540N / B, 740N / B / T, 940B / Be / T / N: 1) Schematic diagram of the power supply 2) The electrical circuit. Inverter backlight 3) The electrical circuit. BIS SE556M? LF. EEPROM. Voltage regulators. Interface connectors D? SUB and DVI

SONY SDM-50N (chassis ST5)The archives are located schemes LCD Monitor SONY SDM-50N (chassis ST5): 1) Block diagram. U Fee 2) Block diagram. Fee A 3) Block diagram. Fee in 4) Block diagram. Fee H 5) The electrical circuit. A fee (P1) 6) The electrical circuit. Fee A (P2) 7) The electrical circuit. Fee A (RE) 8) The electrical circuit. Fee B (...

Acer AL532The archives are available concepts LCD-monitor Acer AL532:1) VGA-Interface2) Graphics Controller MASCOTV3) LVDS interface4) The microcontroller5) Power Supply6) Sound Processor7) Inverter DC / AC

Text: indicates where to find the appropriate schematic diagram . Diagram - Page System Block Diagram - Page B - , Schematic Diagram B.Schematic Diagrams AC-IN, 1.8V, 0.9VS - Page B - 30 VCORE - Page B - 31 12VS - , Diagram Sheet 1 of 38 Schematic Diagram CLEVO L295N/L297N System Block Diagram Yonah/Merom PROCESSOR , Preface LCD Computer L295N/L297N Series Service Manual Preface I Preface Notice , Lists Appendix B, Schematic Diagrams Preface III Preface Related Documents You may also

Abstract: schematic diagram of lga775 cpu socket v320b1-l01 PC intel 945 MOTHERBOARD CIRCUIT diagram 2.1 surrounding amplifer subwoofer circuit B154EW01 lg crt tv circuit diagram QD17EL07 W83627EHG-A SLB9635

Text: 11-8 Index Board Support Package Software Solution 12-2 Daughter Boards 12-3 LCD , Desktop +12V +5V 0-11 Medical Solutions MTP-1201 Medical Touch Panel PC · 12" TFT LCD , functionality. Conventional 4:3 LCD or Wide Screen 16:9 LCD , Touch function. Gigabit LAN, Optional Wireless , Evaluation Specification Development t · Schematic · PCB Placement / Layout / Assembly · Design , successful qualification in August 2005. The report verifies the facts that Avalue is capable to monitor

Abstract: transistor 34N nx smv r010 schematic diagram lcd monitor samsung 370HR net eN8 schematic diagram lcd monitor advance 17 DISPLAYTECH ML550 SMV-R005-1.0 5 mOhm

Text: schematic for connections to the display. Figure 3-4 shows a block diagram of the display, and Figure 3-5 , Monitor header in Figure 1-1, page 13. Added note to Table 3-2, page 21. Changed fuse in Figure 3-7, page 29. Added "Power Monitor Connector" section. Revised LVDS_DATAOUT_1, Pin 47 and Pin 49, in Table , System Monitor and Power Monitor Support," page 34 to Chapter 3. ML550 Networking Interfaces Platform , Hardware Schematic Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Abstract: schematic LG lcd power supply unit LG lcd monitor power supply circuit diagram lg lcd monitor circuit diagram top246 RL205 equivalent TOP246 equivalent LG monitor lcd power supply schematic diagram LG lcd transformer for top246

Text: intended to power a 17" LCD monitor . The document contains the power supply specification, schematic , -27 48W LCD Monitor Supply March 30, 2004 3 Schematic Figure 1 Schematic . Page 5 of 22 , -27 48W LCD Monitor Supply March 30, 2004 7 Transformer Specification 7.1 Electrical Diagram , 10 of 22 DER-27 48W LCD Monitor Supply March 30, 2004 7.4 Transformer Build Diagram 8 , : 100 265 VAC Output: 5V/1.8A, 13V/3A Application LCD Monitor Author Power Integrations

Abstract: schematic lcd inverter samsung schematic diagram lcd monitor chimei Epson ca22 acer Notebook lcd inverter schematic circuit diagram of epson t13 printer 71-P500R-003 acer lcd monitor power board schematic HT15X11-200 z0123

Text: Schematic Diagrams .B-1 System Block Diagram , -P5006-031 71-P500R-003 Schematic Diagrams B - 1 Schematic Diagrams Diagram - Page Diagram - , - 1 Schematic Diagram System Block Diagram - Page B - 3 NorthWood 845 1 of 2 - Page B - 4 , Preface LCD Computer L285P Service Manual Preface I Preface Notice The company , information for servicing and/or upgrading components of the LCD PC. The following information is included

Abstract: SCHEMATIC DIAGRAM monitor adapter 12v 5A lg lcd monitor circuit diagram free sck053 ceramic LG lcd monitor power supply circuit diagram lg lcd monitor circuit diagram sck053 thermistor sck053 LG monitor lcd power supply TOP246

Text: VAC Output: 5 V / 2 A, 12 V / 3 A Application LCD Monitor Author Power Integrations , 408 414 9201 www.powerint.com DER-94 LCD Monitor Internal Supply September 12, 2005 , DER-94 LCD Monitor Internal Supply September 12, 2005 Important Notes: Although this board , 9200 Fax: +1 408 414 9201 www.powerint.com DER-94 LCD Monitor Internal Supply September 12 , monitor internal power supplies The document contains the power supply specification, schematic , bill of

Abstract: FAN7317B tv lcd Schematic Power Supply schematic diagram inverter lcd monitor backlight inverter circuit diagram SOIC127P1030X265-20L schematic diagram lcd monitor EFD2126 lcd monitor circuit diagram 21 inch Lcd tv circuit schematic diagram

Text: in a 20-pin SOIC package. Applications LCD TV LCD Monitor Ordering Information Part Number , Inverter Drive IC Typical Application Circuit ( LCD Backlight Inverter) Application 22-Inch LCD Monitor , . Transformer Schematic Diagram Figure 56. Transformer Schematic Diagram 3. Core & Bobbin Core , FAN7317B - LCD Backlight Inverter Drive IC January 2010 FAN7317B LCD Backlight Inverter , The FAN7317B is a LCD backlight inverter drive IC that controls P-N full-bridge topology using a new

Text: § LCD TV LCD Monitor Ordering Information Part Number FAN7317BM FAN7317BMX Operating , Number of Lamps 22-Inch LCD Monitor FAN7317B 13±10% 4 1. Features 20 19 18 17 , . Transformer Schematic Diagram Figure 56. Transformer Schematic Diagram 3. Core & Bobbin ï§ ï§ ï , FAN7317B LCD Backlight Inverter Drive IC Features Description ï§ ï§ ï§ ï§ ï§ ï§ ï§ ï§ ï§ ï§ ï§ ï§ ï§ ï§ ï§ ï§ The FAN7317B is a LCD backlight inverter drive

Abstract: schematic diagram inverter lcd monitor tv lcd Schematic Power Supply LCD 20pin LCD INVERTER SERVICE INFORMATION lcd inverter SCHEMATIC schematic diagram lcd monitor schematic diagram ac inverter backlight inverter circuit diagram schematic diagram ac to ac inverter

Text: Lamps 22-Inch LCD Monitor FAN7317B 13±10% 4 1. Features 20 19 18 17 16 , through Protection Functions Figure 55. Typical Application Circuit 2. Transformer Schematic Diagram Figure 56. Transformer Schematic Diagram 3. Core & Bobbin Core: EFD2126 Material: PL7 Bobbin , FAN7317B LCD Backlight Inverter Drive IC Features Description The FAN7317B is a LCD backlight , external components. The FAN7317B is available in a 20-pin SOIC package. Applications LCD TV LCD

Abstract: digital blood pressure circuit diagram samsung lcd monitor power supply circuit diagram MPS-3117-006G schematic diagram lcd monitor samsung digital blood pressure monitor circuit diagram blood pressure circuit schematic samsung lcd monitor circuit diagram MPS 3117 blood pressure circuit schematic and block diagram

Text: .21 LCD Function Diagram and External Driving Circuit , 1 OVERVIEW OF ARM BLOOD PRESSURE MONITOR 1.2 System Block Diagram Note of BPM System Block BT , User Button System Block Diagram 1.3 Principles of Electronic Blood Pressure Monitor Typically , Figure 2-1 shows a schematic diagram of the Analog Board. VCC_+5V R1 4.7K ohm R2 Q1 9012 R3 , is +5V, 1/4 duty, and 1/3 bias. Figure 2-11 LCD Function Diagram and External Driving Circuit

Text: block diagram of the evaluation board. CL-PS7111 EVAL BOARD LCD 240*100 320*240 480*320 , kit. System Requirements The preloaded debug monitor requires a PC running the symbolic debug monitor PC (DOS or Windows ® 95). Contact ARM at www.arm.com or Cirrus Logic to order the ARM toolkit , . 9 LCD , Start Up Sequence Using Preinstalled Debug Monitor (DEMON) . 12 Configure the ARM

Abstract: schematic diagram video converter rca to vga vhdl code for codec WM8731 3 digit seven segment 11 pin display schematic diagram vga to tv pin configuration of seven segment usb video player circuit diagram

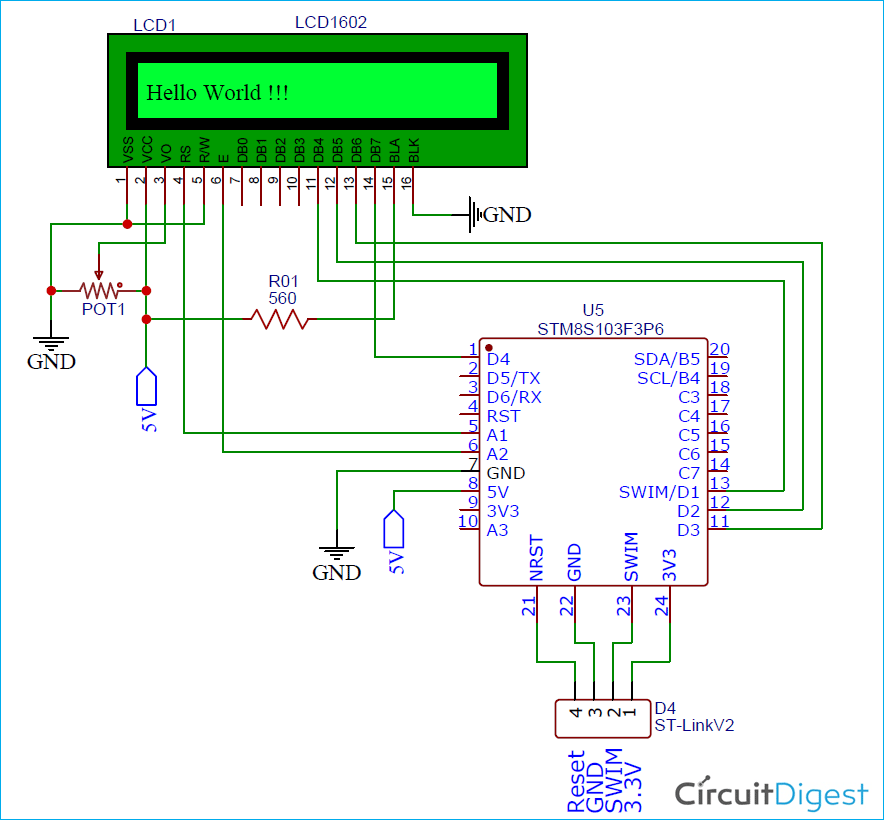

Text: Datasheet folder on the DE2 System CD-ROM. A schematic diagram of the LCD module showing connections to the , User Manual Figure 4.9. Schematic diagram of the LCD module. Signal Name FPGA Pin No , the pin low turns it off. A schematic diagram that shows the pushbutton and toggle switches is given in Figure 4.4. A schematic diagram that shows the LED circuitry appears in Figure 4.5. A list of , , respectively. Figure 4.4. Schematic diagram of the pushbutton and toggle switches. 27 DE2 User Manual

Abstract: mp3 altera de2 board altera de2 board sd card VHDL audio codec ON DE2 altera de2 board vga connector de2 altera Schematic LED panel display tv de2 video image processing altera vhdl code for rs232 receiver altera schematic diagram pc vga to tv rca converter

Text: the DE2 System CD-ROM. A schematic diagram of the LCD module showing connections to the Cyclone II , Manual Figure 4.9. Schematic diagram of the LCD module. Signal Name FPGA Pin No. Description , . A schematic diagram that shows the pushbutton and toggle switches is given in Figure 4.4. A schematic diagram that shows the LED circuitry appears in Figure 4.5. A list of the pin names on the , . Figure 4.4. Schematic diagram of the pushbutton and toggle switches. 27 DE2 User Manual Figure

Abstract: TOP257EN lg lcd monitor circuit diagram free LG monitor lcd power supply lg lcd monitor circuit diagram LG lcd monitor power supply circuit diagram ALG220 3M1350F-1 schematic LG lcd power supply unit AIP-0156 Ef25 core

Text: of 32 24-Jun-08 DER-187 35 W LCD Monitor , TOP257EN 13 V Output Supply 3 Schematic , Input; 13 V, 2.69 A Output Application LCD Monitor Author Applications Engineering Department , 9200 Fax: +1 408 414 9201 www.powerint.com Page 2 of 32 24-Jun-08 DER-187 35 W LCD Monitor , TOP257EN 13 V Output Supply 1 Introduction This engineering report describes an LCD monitor power , 408 414 9200 Fax: +1 408 414 9201 www.powerint.com DER-187 35 W LCD Monitor , TOP257EN 13 V

Abstract: NC-2H Nicera schematic LG lcd power supply unit YC2504 lg lcd monitor circuit diagram free TOP266E LG lcd monitor power supply circuit diagram TOP266 LG monitor lcd power supply DER-235

Text: VAC Input; 5 V, 2.5 A and 14.5 V, 1 A Outputs Application LCD Monitor Author Applications , -235 27 W LCD Monitor Supply 22-Jan-10 2 Power Supply Specification The table below represents the , 50 o C Free convection, sea level Page 4 of 35 22-Jan-10 DER-235 27 W LCD Monitor , www.powerint.com DER-235 27 W LCD Monitor Supply 22-Jan-10 4 Circuit Description The power supply , www.powerint.com Page 6 of 35 22-Jan-10 DER-235 27 W LCD Monitor Supply located and share the same

Text: connect to an LCD monitor . This cable or adapter is not provided with the BeagleBone DVI-D Cape. A , SYSTEM BLOCK DIAGRAM , BeagleBone DVI-D Cape High Level Block Diagram . 21 BeagleBone DVI-D Cape , (2.2) 2. Modified block diagram due to pin change of signal DVI_PDn Date By 12/14/2011 BBT , boards. This board features a standard HDMI connector, which can be connected to a DVI-D monitor using a

Abstract: schematic diagram inverter lcd monitor lcd inverter board schematic lcd tv inverter board schematic ccfl lcd inverter schematic lcd monitor inverter board schematic lcd tv inverter schematic lcd inverter schematic LCD TV backlight power inverter lcd backlight inverter 7 pin

Text: Reel www.fairchildsemi.com FAN7313 LCD Backlight Inverter Drive IC September 2006 Application Lamps Input Voltage 19-inch LCD Monitor 4 13V 1. Schematic F1 FUSE C1 220u , "s characteristics. 20-SOIC Applications LCD TV LCD Monitor Ordering Information Part Number Package , Schematic Diagram Supported by Namyang electronics (http://www.namyangelec.co.kr). FAN7313 Rev. 00 , FAN7313 LCD Backlight Inverter Drive IC Features Description High-Efficiency Single-Stage

Abstract: schematic diagram lcd monitor advance 17 schematic diagram tv monitor advance 17 lcd tv inverter board schematic CFL inverter circuit schematic diagram lcd monitor inverter board schematic schematic diagram tv monitor advance CFL 12v inverter circuit schematic schematic diagram of lcd inverter board 2 lamps lcd inverter schematic

Text: Application Lamps Input Voltage 19-inch LCD Monitor 4 13V 1. Schematic F1 FUSE C22 220u , "s characteristics. The FAN7311B uses a new patent-pending phaseshift control. 20-SOIC Applications LCD TV LCD Monitor Ordering Information Package Pb-Free FAN7311BM Part Number 20-SOIC Yes , . Transformer Schematic Diagram - Supported by Namyang electronics (http://www.namyangelec.co.kr) FAN7311, FAN7311B LCD Backlight Inverter Drive IC Features Description High-Efficiency Single-Stage

Abstract: Wavecom Q2403 AT Command Wavecom 16 port sms modem AT Command for imei number change wismo pac Wavecom PLUS gprs modem Wavecom Q2403 Wavecom 16 port sms modem AT Command wavecom GSM Modem Q2403 Wavecom modem circuit diagram wismo

Text: 3: Equivalent schematic , the components must be defined Proper antenna matching is essential for , section (audio amplifier, filter), and LCD circuit. If there is no more space to separate these circuits , - ch_imei .001 - ch_imei .002 - user_name.bat1 - user_name.cfg1 1- See before starting paragraph , under the folder where is located the IMEI downloading program ch_imei.exe: For example: ch_imei gsm

Text: .3 2.2. FPGA Schematic , .9 Figures Figure 1: Interface Block Diagram .1 Figure 2: Interface Schematic .3 Figure 3: FPGA Schematic , solution for LCD projectors and displays. Some systems and applications require the reduction scaling

Text: Consumption 8 4 Display Expansion Board Design 9 4.1 Block Diagram 9 4.2 Schematic , have the schematic side by side when reading this chapter. 4.1 Block Diagram The block , Expansion Board Block Diagram 4.2 Schematic Walkthrough 4.2.1 Page 2 J1 is the interface , board that is connected and initialize the MCU LCD controller and control the Display Expansion board , / monitor /tv that has identical resolution as the intended end-application. If the exact same resolution

Abstract: CG1626-SGR1 Diode zener smd u53 DS22192 PIC18f14 "power factor measurement" schematic PIC Microcontroller CC0603KRX7R9BB104 CC0603KRX7R9BB fema lcd MCP3901

Text: . 22 A.2 Board Schematic Microcontroller and LCD . , Power Monitor firmware. · Appendix A. "Schematics and Layouts" Shows the schematic and board layouts , in the appendix, A.1 "Board Schematic Analog and Power". The MCP3901 Power Monitor Reference , from the PC to the power monitor . The pulse output LED stops blinking for a few seconds, and the LCD , monitor . The the pulse output LED is forced ON for a few seconds, while the LCD shows "Calibrating for

Abstract: altera DE2-70 board connect usb in vcd player circuit diagram 16X2 LCD vhdl CODE schematic diagram tv monitor advance 17 schematic diagram lcd monitor advance 17 de2 video image processing altera altera de2 board DE2-70 usb vcd player circuit diagram

Text: values displayed on 7-segment and LCD displays, monitor buttons/switches status, read/write the SDRAM , high logic level turns the LED on, and driving the pin low turns it off. A schematic diagram that shows the pushbutton and toggle switches is given in Figure 5.4. A schematic diagram that shows the LED , ] SLIDE SW Figure 5.4. Schematic diagram of the pushbutton and toggle switches. 33 SLIDE SW SW13 , LED25 LED26 LEDR Figure 5.5. Schematic diagram of the LEDs. Signal Name FPGA Pin No

Text: LCD Monitor 3 Schematic Figure 4 â Circuit Schematic . Page 7 of 56 Power Integrations , Flyback Supply for LCD Monitor Transformer Build Diagram : Figure 8 â Transformer Build Diagram , Title Reference Design Report for a 17 W Dual Output Flyback Converter for LCD Monitor Using , Application LCD Monitor Author Applications Engineering Department Document Number RDR , -321 17 W Dual Output Flyback Supply for LCD Monitor 28-Sep-12 Table of Contents 1Â 2Â 3Â 4Â

Abstract: lg lcd monitor circuit diagram free schematic LG lcd power supply unit lg lcd monitor circuit diagram NC-2H efd25 TNY380 NC-2H Nicera efd25 bobbin LG lcd monitor power supply circuit diagram LG monitor lcd power supply

Text: W Low Standby LCD Monitor Supply Using TNY380PN 17-Aug-09 3 Schematic Figure 2 Schematic , LCD Monitor Author Applications Engineering Department Document Number DER-229 Date , www.powerint.com DER-229 27 W Low Standby LCD Monitor Supply Using TNY380PN 17-Aug-09 Table of Contents , of 39 17-Aug-09 DER-229 27 W Low Standby LCD Monitor Supply Using TNY380PN Important Note , 414 9200 Fax: +1 408 414 9201 www.powerint.com DER-229 27 W Low Standby LCD Monitor Supply Using

6. To form usable thin film transistors, it is necessary to repeat the process of cleaning, coating, photoresist, exposure, development, etching, and photoresist removal. Generally speaking, to manufacture TFT-LCD, it is necessary to repeat 5 to 7 times.

1. After completing the thin-film transistor glass substrate, we will proceed to the combination of the liquid crystal module. The liquid crystal panel is composed of the transistor glass substrate and the color filter. First, we must clean the glass first, and then proceed The next step. The entire manufacturing process of TFT-LCD must be in a clean room, so that there will be no impurities in the display.

4. Before combining the two glass plates, we must first evenly cover the spherical-like gaps at a fixed interval to prevent the two glass plates from bending inward after the liquid crystal display is combined. Usually, when the liquid crystal panel is assembled, one or two gaps are left to facilitate the subsequent filling of the liquid crystal, and then the edge of the two pieces of glass is sealed with frame glue and conductive glue, thus completing the glass assembly.

5. After sealing the frame, place the LCD panel in the vacuum chamber, and drain the air from the LCD panel through the gap just reserved, and then pour the liquid crystal with the help of atmospheric pressure, and then close the gap. The liquid crystal is a kind of The compound substance between solid and liquid has the characteristic of regular molecular arrangement.

3. The light of the LCD module is emitted from the backlight. Before assembling the backlight, we will first check whether the assembled LCD panel is perfect, and then assemble the backlight. The backlight is the source of light behind the LCD panel.

6. The best quality products can be packaged and shipped. In this way, the liquid crystal module undergoes many inspection and testing procedures to deliver the most perfect product to the customer, and this is the real completion of the entire liquid crystal display manufacturing process.

Liquid Crystal Displays or more commonly known as LCDs are one of the most common electronic components which help us interact with an equipment or a device. Most personal portable equipment and even gigantic industrial equipment utilize a custom segment display to display data. For many portable consumer electronics, a segment LCD display is one of the biggest contributors to the overall cost of the device, hence designing a custom segment display can drive the cost down while also utilizing the display area in the most optimum manner. These displays have the lowest cost per piece, low power requirements, and a low tooling fee too.

At first thought, designing a custom segment LCD might look like a Herculean task, but trust me that it is easier than it seems. In this article, we have summarised and compared the display types and available technologies which are required to construct a custom segment LCD. We have also provided a flowchart that can act as a step-by-step guide while you design your own custom LCD. We have also provided the process we followed, a require gathering sheet we used for communicating our needs to the manufacturer, and a few other data and the quotation we received from the manufacturer.

Icons: A silhouette of any shape can be placed on the glass which enhances the ability to display data. For example, a symbol of a heart can be made to denote heart rate or an icon for a low battery to show that the battery needs to be charged. Icons are counted as a single pixel or segment and can give a lot more details than similar-sized text.

LCD Bias– It denotes the number of different voltage levels used in driving the segments, static drives (explained later in this article) only have 2 voltage levels or 2 bias voltage while multiplex drives have multiple voltage levels. For example, 1/3 will have 4 bias voltages.

LCDs utilizes the light modulating properties of liquid crystals which can be observed by using polarizing filters. Polarizing filters are special materials that have their molecules aligned in the same direction. If the light waves passing through polarisers have the same orientation as the filter, then the molecules of lights are absorbed by the filter, hence reducing the intensity of light passing through it, making it visible.

A custom LCD is important for maximizing the efficiency of the display area by adding custom symbols and characters. It also helps in reducing the cost and improving energy efficiency of the product. A higher number of custom symbols and specified placement of numerical and alphanumerical characters make the display more informative and readable for the user. This makes it look better than the plain old boring displays we get in the market. Furthermore, we can specify the viewing angle, contrast, and other specifications which can increase durability or give a better value for money for our intended usage. A typical Custom Segment display is shown below, we will also show you how to design and fabricate the same further in the article.

The LCD display doesn’t emit any light of its own, therefore it requires an external source of illumination or reflector to be readable in dark environments.

While designing a custom segment LCD display, we have the leverage of choosing a lot of parameters that affect the final product. From the color of the display to the illumination technique and color of illumination as well as the type of input pins. Some important considerations we need to take while designing a custom 7 segment display are - the type of display, i.e. positive or negative, illumination method, driving technique, polarising type, and connection method. All these design criteria are explained below:

Positive and negative displays can be easily distinguished by the colour of the background and characters. Some common differences between the positive and negative displays are:

So, which one should you choose? When the displays are to be used in areas with higher ambient light, we should select positive segment LCD display as it has better visibility than negative segment LCD displays without using a backlight.

As we know that LED displays don’t emit any light, hence to illuminate it and make it visible in a dark environment, we can use different methods of illumination. The most common LCD Illumination methods are compared below:

For displays that need to be used for budget-friendly devices that should be small and rugged, LED lights are preferred for the displays due to the high durability and low cost of operations. For high brightness, CCFL and Incandescent lights can be used.

A polarizer film is the most important component of an LCD display, which makes it possible to display characters by controlling the light. There are 3 types of polarizers that can be used in the LCD display, the properties and difference are given below:

Displays can be categorized into two types, passive displays, and active display, passive displays are simpler to construct as they have 2 connections at each segment, the conductors comprise of an Indium Tin Oxide to create an image, whereas the active displays use thin-film transistors (TFT) arranged in a grid. The name is due to its ability to control each pixel individually.

If your displays have fewer segments, then static LCD drive is preferred as it is easier to control and cheaper to construct, and has a better contrast ratio. But let’s say that if the number of segments in the display are more than 30-40 then a multiplex LCD drive should be preferred as it has multiple common pins, hence reducing the total number of pins required to drive the display.

Choosing a connector type!!! For the prototyping phase or if you need to connect your LCD display on a Microcontroller directly, a pin type connector is the best and most economical option you have. If you need to connect your LCD display in a final product with a high volume of production which also requires to be extremely durable, but at the same time should not take up a lot of space, a Flex type LCD Connector will work best for you

LCDs have limited viewing angles and when seen from an angle they lose contrast and are difficult to be observed. The viewing angle is defined by the angles perpendicular to the center of the display towards its right, left, up, and down which are denoted by the notations 3:00, 9:00, 12:00, and 6:00 respectively. The viewing angle of LCD can be defined as the angle w.r.t. to the bias angle at which the contrast of segments is legible.

To improve the viewing angle in an LCD, a Bias is incorporated in the design which shifts the nominal viewing angle with an offset. Another technique is to increase the Voltage, it affects the bias angle, making the display crisper when viewed from a direction.

For example, the viewing angle of a TN type TFT LCD is 45-65 degrees. Extra-wide polarising film (EWP) can increase the viewing angle by 10 degrees, using an O film polariser can make the viewing angles 75 degrees but these come at a cost of reduced contrast.

LCD Control chip or LCD driver chips can be mounted on the flex cable, display, or externally on a PCB. The placement of LCD control chip can affect the cost and size of the display. The 2 most common methods of chip placement are-Chip of Board (COB)and Chip on Glass(COG) which are described below:

We planned to design an air quality monitoring system for which we needed a custom segment LCD panel for an air quality monitoring device. Our product needs to display the following data: 2.5-micron and 10-micron particulate matter (PM) suspended in the air; the units should be in parts per million (PPM). CO2 in the air in PPM along with total volatile organic compounds present in the air in parts per billion (PPB). To make the product more usable, we included time in 24-hour format, Temperature in ºC, Battery status, loudspeaker status, Bluetooth status, and Wi-Fi status. And for some personal touch, we also added how good the air quality in the room is by using 3 different smileys.

We realized that it was impossible to provide all these data in a generic LCD available in the market, thus decided to build a custom LCD for our project.

A step-by-step flowchart is shown below to walk you through each and every step of selecting components and getting your custom segment LCD manufactured.

We started by listing down our requirements and drew a mock-up of the display on paper. After finalizing the placement of all the segments and icons on the prototype sketch of the display, we then decided which all icons and segments have to be kept on for the whole time and which needs to be driven. Realizing that there are too many segments, characters and icons, hence we selected a multiplex drive with 8 common pins which helped us bring down the total pins from an estimated 180 pins to less than 40 pins.

Since the device was meant to be used inside houses and offices, which are more often than not well lit and protected from environmental conditions, we opted for a positive mode display. For superior contrast ratio and better viewing angle, we chose a Film Super Twisted Nematic Display (FSTN) with a drive condition of 1/8 Duty and bias of 1/4.

Usually, the displays are mounted at a height of 4.5 feet from the ground, thus the viewing direction was selected to be 12"O clock with an operating frequency of 64Hz. We selected a Transmissive polarizer for the front glass and a reflective polarizer for the rear glass so that the natural light can pass through the front panel and the display can achieve the maximum contrast without the need for backlighting and we opted for the pin type connectors as they are easy for prototyping and are suitable for harsh environment with a lot of vibrations and shocks which best suited our purpose.

In the above image of a custom display design, we sent to the manufacturer, the red lines over multiple characters indicate that all these are considered as a single segment. For the sake of simplicity, we added test like T, S, U, B to denote Text, Symbols, Units, and Battery respectively. These characters were followed by numbers to simplify communication between us and the manufacturer. For example, if we needed any particular text or symbol to remain on, we can easily specify that to the manufacturer by using the corresponding text for that segment.

We mailed our requirements to multiple LCD manufacturers, (you will find a lot of LCD manufacturers on the Internet). Most LCD manufacturers have competitive pricing, and reply within a week. A sample requirement sheet is shown above which a customer needs to fill to specify all the details to the manufacturer.

This is a sample Custom Segment LCD quotation we got from one of the manufacturers. As you can see, the cost is based on the quantity. Higher the quantity, lower the cost. Apart from the cost per quantity, there is one more component called tooling fees. Tooling fee is a one-time fee charged by the manufacturer. It is for the technical design, support, and customization of the product. Customization of PCB or tooling of LCD can drive the tooling price higher or lower.

A custom segment LCD can help you personalize your product while also saving the overall cost of your product. The whole process will take you around 2-3 months, which will include the designing phase, prototyping phase, and getting your custom segment LCDs delivered to your doorstep. Higher ordering quantity will reduce the cost per piece of each unit, thus driving down the cost of your final product.

SmartDraw"s schematic diagram software is easy to use. It includes thousands of templates and examples to help you get started quickly. Select from a huge library of vector schematic diagram symbols that scale easily without quality degradation.

SmartDraw is more than just easy—it is also an incredibly powerful tool. Create professional-looking diagrams in less time than you"ll spend with other programs.

Whether your needs are in electrical circuit design, mechanical design, or component and industrial design, SmartDraw can help you create all of your engineering schematics.

In addition to custom LCD displays, we provide custom PCB assemblies and turnkey solutions for products that feature a Displaytech LCD. As a display manufacturer, our engineering and production staff are experienced in handling the design and manufacturing of printed circuit board assemblies for front panels, rack mount equipment, handheld devices and many other products.

At present, we look liquid crystal displays (LCDs) everywhere; however, they didn’t develop immediately. It took so much time to develop from the development of the liquid crystal to a large number of LCD applications. In the year 1888, the first Liquid crystals were invented by Friedrich Reinitzer (Austrian botanist). When he dissolved a material like a cholesteryl benzoate, then he observed that it initially it turns into a cloudy fluid & cleared up as its temperature rose. Once it is cooled, then the fluid became blue before lastly crystallizing. So, the first experimental liquid crystal display was developed by the RCA Corporation in the year1968. After that, the manufacturers of LCD have gradually designed ingenious differences &developments on the technology by taking this display device into an incredible range. So finally, the developments in the LCD have been increased.

A liquid crystal display or LCD draws its definition from its name itself. It is a combination of two states of matter, the solid and the liquid. LCD uses a liquid crystal to produce a visible image. Liquid crystal displays are super-thin technology display screens that are generally used in laptop computer screens, TVs, cell phones, and portable video games. LCD’s technologies allow displays to be much thinner when compared to a cathode ray tube (CRT) technology.

Liquid crystal display is composed of several layers which include two polarized panel filters and electrodes. LCD technology is used for displaying the image in a notebook or some other electronic devices like mini computers. Light is projected from a lens on a layer of liquid crystal. This combination of colored light with the grayscale image of the crystal (formed as electric current flows through the crystal) forms the colored image. This image is then displayed on the screen.

An LCD is either made up of an active matrix display grid or a passive display grid. Most of the Smartphone’s with LCD technology uses active matrix display, but some of the older displays still make use of the passive display grid designs. Most of the electronic devices mainly depend on liquid crystal display technology for their display. The liquid has a unique advantage of having low power consumption than the LED or cathode ray tube.

The liquid crystal display screen works on the principle of blocking light rather than emitting light. LCDs require a backlight as they do not emit light them. We always use devices which are made up of LCD’s displays which are replacing the use of cathode ray tube. Cathode ray tube draws more power compared to LCDs and is also heavier and bigger.

The principle behind the LCDs is that when an electrical current is applied to the liquid crystal molecule, the molecule tends to untwist. This causes the angle of light which is passing through the molecule of the polarized glass and also causes a change in the angle of the top polarizing filter. As a result, a little light is allowed to pass the polarized glass through a particular area of the LCD.

Thus that particular area will become dark compared to others. The LCD works on the principle of blocking light. While constructing the LCDs, a reflected mirror is arranged at the back. An electrode plane is made of indium-tin-oxide which is kept on top and a polarized glass with a polarizing film is also added on the bottom of the device. The complete region of the LCD has to be enclosed by a common electrode and above it should be the liquid crystal matter.

Next comes the second piece of glass with an electrode in the form of the rectangle on the bottom and, on top, another polarizing film. It must be considered that both the pieces are kept at the right angles. When there is no current, the light passes through the front of the LCD it will be reflected by the mirror and bounced back. As the electrode is connected to a battery the current from it will cause the liquid crystals between the common-plane electrode and the electrode shaped like a rectangle to untwist. Thus the light is blocked from passing through. That particular rectangular area appears blank.

An LCD TV monitor utilizes the sunglasses concept to operate its colored pixels. On the flip side of the LCD screen, there is a huge bright light that shines out in the direction of the observer. On the front side of the display, it includes the millions of pixels, where each pixel can be made up of smaller regions known as sub-pixels. These are colored with different colors like green, blue, and red. Each pixel in the display includes a polarizing glass filter at the backside and the front side includes at 90 degrees, so the pixel looks dark normally.

Generally, every consumer doesn’t have much information regarding the different kinds of LCDs available in the market. So before selecting an LCD, they collect all the data like features, price, company, quality, specifications, service, customer reviews, etc. The truth is that promoters tend to get the benefit from the truth that most of the customers conduct extremely minimum research before purchasing any product.

In an LCD, motion blur can be an effect of how long a picture takes to switch and display on the screen. However, both of these incidents change very much among an individual LCD panel in spite of primary LCD tech. Selecting an LCD based on underlying technology must be more regarding price vs. preferred difference, viewing angles & reproduction of color than estimated blur otherwise other gaming qualities. The highest refresh rate, as well as response time, must be planned in any specifications of the panel. Another gaming tech like strobe will turn ON/OFF the backlight rapidly to decrease resolution.

The TN (Twisted Nematic) LCDs production can be done most frequently and used different kinds of displays all over the industries. These displays most frequently used by gamers as they are cheap & have quick response time as compared with other displays. The main disadvantage of these displays is that they have low quality as well as partial contrast ratios, viewing angles & reproduction of color. But, these devices are sufficient for daily operations.

These displays allow quick response times as well as quick refresh rates. So, these are the only gaming displays which are available with 240 hertz (Hz). These displays have poor contrast & color because of the not accurate otherwise precise twist device.

IPS displays are considered to be the best LCD because they provide good image quality, higher viewing angles, vibrant color precision & difference. These displays are mostly used by graphic designers & in some other applications, LCDs need the maximum potential standards for the reproduction of image & color.

The vertical alignment (VA) panels drop anywhere in the center among Twisted Nematic and in-plane switching panel technology. These panels have the best viewing angles as well as color reproduction with higher quality features as compared with TN type displays. These panels have a low response time. But, these are much more reasonable and appropriate for daily use.

The structure of this panel generates deeper blacks as well as better colors as compared with the twisted nematic display. And several crystal alignments can permit for better viewing angles as compared with TN type displays. These displays arrive with a tradeoff because they are expensive as compared with other displays. And also they have slow response times & low refresh rates.

AFFS LCDs offer the best performance & a wide range of color reproduction as compared with IPS displays. The applications of AFFS are very advanced because they can reduce the distortion of color without compromising on the broad viewing angle. Usually, this display is used in highly advanced as well as professional surroundings like in the viable airplane cockpits.

The Passive-matrix type LCDs works with a simple grid so that charge can be supplied to a specific pixel on the LCD. The grid can be designed with a quiet process and it starts through two substrates which are known as glass layers. One glass layer gives columns whereas the other one gives rows that are designed by using a clear conductive material like indium-tin-oxide.

In this display, the rows otherwise columns are linked to ICs to control whenever the charge is transmitted in the direction of a particular row or column. The material of the liquid crystal is placed in between the two glass layers where on the external side of the substrate, a polarizing film can be added. The IC transmits a charge down the exact column of a single substrate & the ground can be switched ON to the exact row of the other so that a pixel can be activated.

The passive-matrix system has major drawbacks particularly response time is slow & inaccurate voltage control. The response time of the display mainly refers to the capability of the display to refresh the displayed image. In this type of display, the simplest way to check the slow response time is to shift the mouse pointer fast from one face of the display to the other.

Active-matrix type LCDs mainly depends on TFT (thin-film transistors). These transistors are small switching transistors as well as capacitors which are placed within a matrix over a glass substrate. When the proper row is activated then a charge can be transmitted down the exact column so that a specific pixel can be addressed, because all of the additional rows that the column intersects are switched OFF, simply the capacitor next to the designated pixel gets a charge.

A horizontal polarizing filter ahead of the light will block all the light signals apart from those horizontally vibrate. The pixel of the display can be switched off by a transistor by allowing the flow of current throughout its liquid crystals which makes the crystals sort out & the light supplies through them will not change.

Both the displays like plasma and an LCD are similar, however, it works in a different way totally. Every pixel is a microscopic fluorescent lamp that glows through the plasma, whereas plasma is an extremely hot type of gas where the atoms are blown separately to make electrons (negatively charged) & ions (positively charged). These atoms flow very freely and generate a glow of light once they crash. The designing of the plasma screen can be done very bigger as compared with ordinary CRO (cathode-ray tube) TVs, but they are very expensive.

Thus, this is all about an overview of LCD and the structure of this from the backside to the front side can be done using backlights, sheet1, liquid crystals, sheet2 with color filters & screen. The standard liquid crystal displays use the backlights like CRFL (cold cathode fluorescent lamps). These lights are consistently arranged backside of the display to deliver reliable lighting across the panel. So the brightness level of all the pixels in the picture will have equal brightness.

I hope you have got a good knowledge of liquid crystal display. Here I leave a task for you. How is an LCD interfaced to a microcontroller? furthermore, any queries on this concept or electrical and electronic project Leave your answer in the comment section below.

4. #Press the LCD glass side of the panel, if the vertical lines disappear or reappear, it can be judged that the cause of poor contact, OM checking should be able to find the poor contact.

5. #If there is no display change in pressing, confirm whether ITO is damaged under the OM microscope, or pin signal waveform corresponding to needle COF.

The above is the full text of LCD screen failure repair guide, we hope it is helpful to you. If you need to buy LCD and find a reliable LCD supplier, we suggest you to read our other great blog – How to find a reliable LCD supplier.

Founded in 2014, VISLCD is a professional LCD supplier. We provide LCD modules, touch LCD and customized LCD in various sizes with stable quality and competitive price. Welcome to contact us for any LCD demand, thank you.

A well-crafted circuit design can offer clarity to an otherwise confusing system and provide a handy visual reference. Whether you’re building a simplified pictorial circuit diagram or a schematic circuit diagram for technically advanced employees, our circuit diagram maker can help. With drag-and-drop shapes and easily formatted lines and arrows, you can save time drawing out technical processes and create easy-to-read circuit drawings for any audience in minutes.

Our circuit drawing software lets you easily construct any type of circuit diagram with dedicated shape libraries. With dozens of industry-standard shapes to choose from, you can create schematics, circuit diagrams, wiring diagrams, and other electrical diagrams. Choose from electrical, power sources, transistors, relays, logic gates, and other standard symbols. Lucidchart also allows you to add and manage custom shapes for your team to use and further standardize your processes.

Already have diagrams from other platforms? Use our import/export feature to upload your existing visuals into our circuit builder. Anyone can use Lucidchart to view imported documents from other programs, while users with Pro, Team, and Enterprise accounts can continue editing circuit drawings on the Lucidchart canvas. These users can even export their circuit designs back to Visio, so you can still collaborate with Visio users who haven’t yet made the switch.

Present your circuit design to collaborators, stakeholders, and decision-makers in just a few clicks with our in-editor Presentation Mode. Whether you’re presenting a pictorial or schematic circuit diagram, our circuit design software lets you present your designs and your audience can clearly visualize and understand each part of your circuit. Use Presentation Mode to display a sweeping overview of your circuit diagram or zoom in on key points of your circuit drawing for added clarification.

Share and collaborate on your circuit diagrams online within the programs you and your team use every day thanks to our dynamic integrations. Lucidchart is fully integrated with today’s most popular applications, including Confluence, Jira, MS Office, and G Suite, so you and your team can easily insert your circuit designs as you please. You can also download your circuit diagrams into a PDF, PNG, JPEG, or SVG file type for easy viewing and sharing.

Glass substrate with ITO electrodes. The shapes of these electrodes will determine the shapes that will appear when the LCD is switched ON. Vertical ridges etched on the surface are smooth.

A liquid-crystal display (LCD) is a flat-panel display or other electronically modulated optical device that uses the light-modulating properties of liquid crystals combined with polarizers. Liquid crystals do not emit light directlybacklight or reflector to produce images in color or monochrome.seven-segment displays, as in a digital clock, are all good examples of devices with these displays. They use the same basic technology, except that arbitrary images are made from a matrix of small pixels, while other displays have larger elements. LCDs can either be normally on (positive) or off (negative), depending on the polarizer arrangement. For example, a character positive LCD with a backlight will have black lettering on a background that is the color of the backlight, and a character negative LCD will have a black background with the letters being of the same color as the backlight. Optical filters are added to white on blue LCDs to give them their characteristic appearance.

LCDs are used in a wide range of applications, including LCD televisions, computer monitors, instrument panels, aircraft cockpit displays, and indoor and outdoor signage. Small LCD screens are common in LCD projectors and portable consumer devices such as digital cameras, watches, digital clocks, calculators, and mobile telephones, including smartphones. LCD screens are also used on consumer electronics products such as DVD players, video game devices and clocks. LCD screens have replaced heavy, bulky cathode-ray tube (CRT) displays in nearly all applications. LCD screens are available in a wider range of screen sizes than CRT and plasma displays, with LCD screens available in sizes ranging from tiny digital watches to very large television receivers. LCDs are slowly being replaced by OLEDs, which can be easily made into different shapes, and have a lower response time, wider color gamut, virtually infinite color contrast and viewing angles, lower weight for a given display size and a slimmer profile (because OLEDs use a single glass or plastic panel whereas LCDs use two glass panels; the thickness of the panels increases with size but the increase is more noticeable on LCDs) and potentially lower power consumption (as the display is only "on" where needed and there is no backlight). OLEDs, however, are more expensive for a given display size due to the very expensive electroluminescent materials or phosphors that they use. Also due to the use of phosphors, OLEDs suffer from screen burn-in and there is currently no way to recycle OLED displays, whereas LCD panels can be recycled, although the technology required to recycle LCDs is not yet widespread. Attempts to maintain the competitiveness of LCDs are quantum dot displays, marketed as SUHD, QLED or Triluminos, which are displays with blue LED backlighting and a Quantum-dot enhancement film (QDEF) that converts part of the blue light into red and green, offering similar performance to an OLED display at a lower pr

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey