oled vs lcd touch screen design manufacturer

If you’re designing a display application or deciding what type of TV to get, you’ll probably have to choose between an OLED or LCD as your display type.

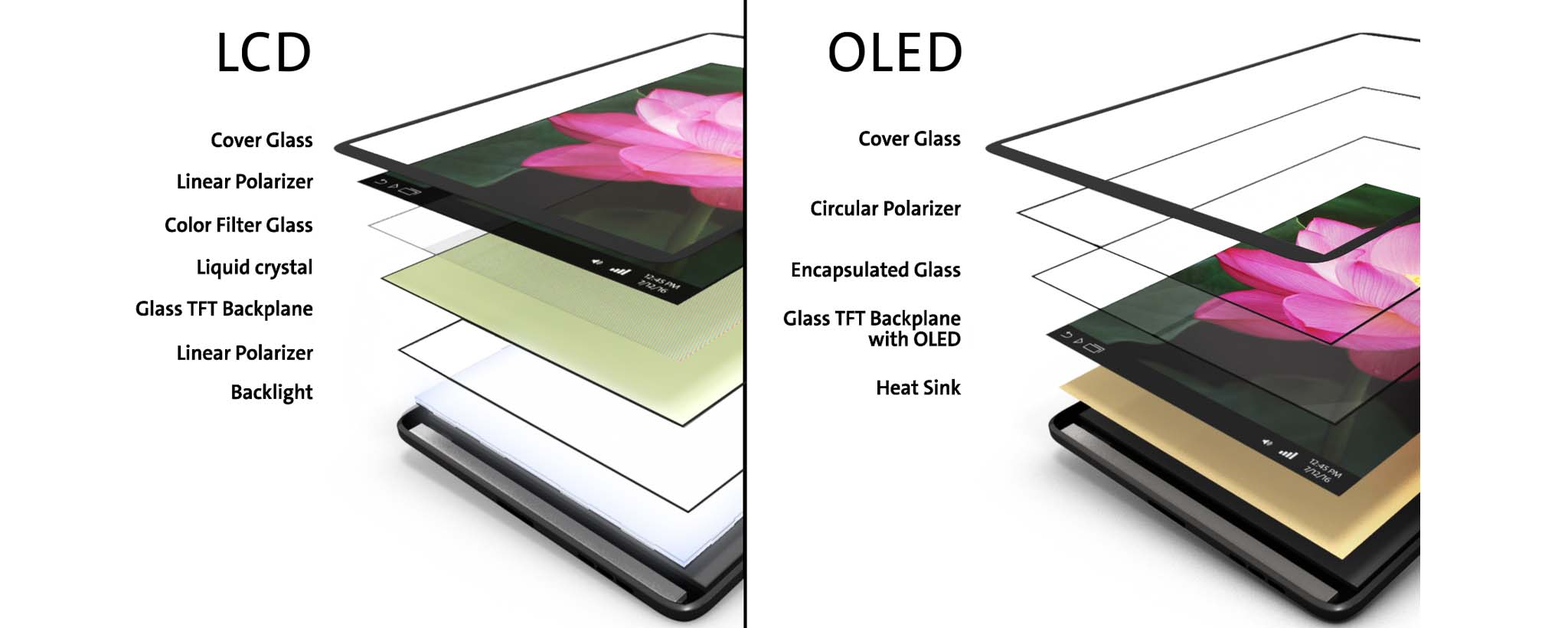

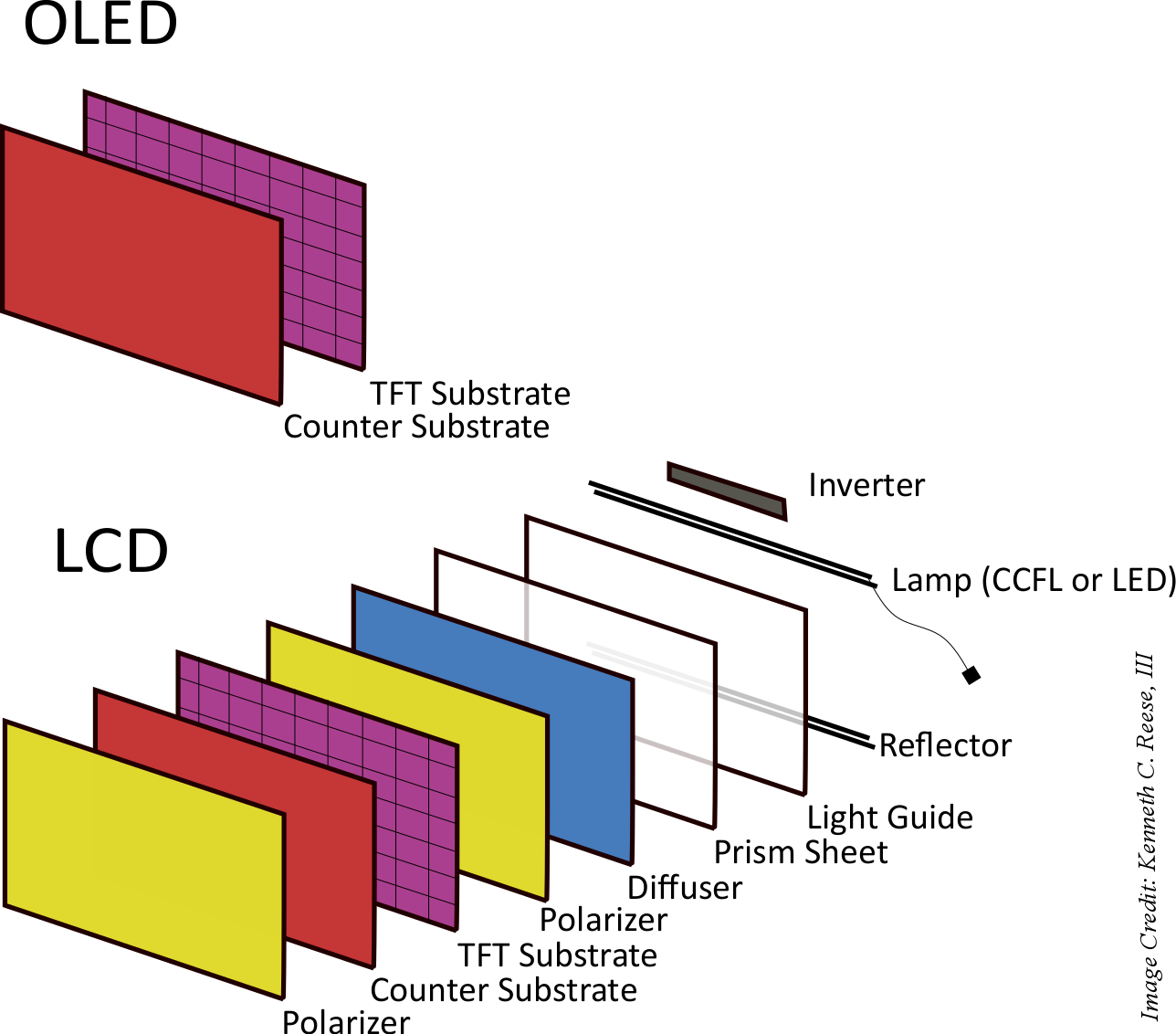

LCDs utilize liquid crystals that produce an image when light is passed through the display. OLED displays generate images by applying electricity to organic materials inside the display.OLED and LCD Main Difference:

graphics and images visible. This is the reason you’re still able to see light coming through on images that are meant to be dark on an LCD monitor, display, or television.

OLEDs by comparison, deliver a drastically higher contrast by dynamically managing their individual pixels. When an image on an OLED display uses the color black, the pixel shuts off completely and renders a much higher contrast than that of LCDs.OLED vs LCD - Who is better at contrast?

Having a high brightness level is important if your display is going to be used in direct sunlight or somewhere with high ambient brightness. The display"s brightness level isn"t as important if it’s going to be used indoors or in a low light setting.OLED vs LCD - Who is better at Brightness?

Have you ever looked at a screen from an angle and noticed that the images became washed out or shadowy? The further away you get from the “front and center” view, the worse the image appears to be. This is an example of viewing angles in action – the wider the viewing angle, the better the images on screen will appear as you view them from different vantage points.

This means the display is much thinner than LCD displays and their pixels are much closer to the surface of the display, giving them an inherently wider viewing angle.

You’ll often notice images becoming distorted or losing their colors when tilting an LCD or when you view it from different angles. However, many LCDs now include technology to compensate for this – specifically In-Plane Switching (IPS).

LCDs with IPS are significantly brighter than standard LCDs and offer viewing angles that are on-par with OLEDs.OLED vs LCD - Who is better at Viewing Angles?

LCDs have been on the market much longer than OLEDs, so there is more data to support their longevity. On average LCDs have proven to perform for around 60,000 hours (2,500) days of operation.

With most LCDs you can expect about 7 years of consistent performance. Some dimming of the backlight has been observed but it is not significant to the quality of the display.

OLEDs are a newer technology in the display market, which makes them harder to fully review. Not only does OLED technology continue to improve at a rapid pace, but there also hasn’t been enough time to thoroughly observe their performance.

You must also consider OLED’s vulnerability to image burn-in. The organic material in these displays can leave a permanent afterimage on the display if a static image is displayed for too long.

So depending on how your OLED is used, this can greatly affect its lifespan. An OLED being used to show static images for long periods of time will not have the same longevity as one displaying dynamic, constantly moving images.OLED vs LCD - Which one last longer?

There is not yet a clear winner when it comes to lifespans between LCD and OLED displays. Each have their advantages depending on their use-cases. It’s a tie!

For a display application requiring the best colors, contrast, and viewing angles – especially for small and lightweight wearable devices – we would suggest an OLED display.

There are plenty of new and confusing terms facing TV shoppers today, but when it comes down to the screen technology itself, there are only two: Nearly every TV sold today is either LCD or OLED.

The biggest between the two is in how they work. With OLED, each pixel provides its own illumination so there"s no separate backlight. With an LCD TV, all of the pixels are illuminated by an LED backlight. That difference leads to all kinds of picture quality effects, some of which favor LCD, but most of which benefit OLED.

LCDs are made by a number of companies across Asia. All current OLED TVs are built by LG Display, though companies like Sony and Vizio buy OLED panels from LG and then use their own electronics and aesthetic design.

So which one is better? Read on for their strengths and weaknesses. In general we"ll be comparing OLED to the best (read: most expensive) LCD has to offer, mainly because there"s no such thing as a cheap OLED TV (yet).

At the other side of light output is black level, or how dark the TV can get. OLED wins here because of its ability to turn off individual pixels completely. It can produce truly perfect black.

The better LCDs have local dimming, where parts of the screen can dim independently of others. This isn"t quite as good as per-pixel control because the black areas still aren"t absolutely black, but it"s better than nothing. The best LCDs have full-array local dimming, which provides even finer control over the contrast of what"s onscreen -- but even they can suffer from "blooming," where a bright area spoils the black of an adjacent dark area.

Here"s where it comes together. Contrast ratio is the difference between the brightest and the darkest a TV can be. OLED is the winner here because it can get extremely bright, plus it can produce absolute black with no blooming. It has the best contrast ratio of any modern display.

One of the main downsides of LCD TVs is a change in picture quality if you sit away from dead center (as in, off to the sides). How much this matters to you certainly depends on your seating arrangement, but also on how much you love your loved ones.

A few LCDs use in-plane switching (IPS) panels, which have better off-axis picture quality than other kinds of LCDs, but don"t look as good as other LCDs straight on (primarily due to a lower contrast ratio).

OLED doesn"t have the off-axis issue LCDs have; its image looks basically the same, even from extreme angles. So if you have a wide seating area, OLED is the better option.

Nearly all current TVs are HDR compatible, but that"s not the entire story. Just because a TV claims HDR compatibility doesn"t mean it can accurately display HDR content. All OLED TVs have the dynamic range to take advantage of HDR, but lower-priced LCDs, especially those without local-dimming backlights, do not. So if you want to see HDR content it all its dynamic, vibrant beauty, go for OLED or an LCD with local dimming.

In our tests comparing the best new OLED and LCD TVs with HDR games and movies, OLED usually looks better. Its superior contrast and lack of blooming win the day despite LCD"s brightness advantage. In other words LCD TVs can get brighter, especially in full-screen bright scenes and HDR highlights, but none of them can control that illumination as precisely as an OLED TV.

OLED"s energy consumption is directly related to screen brightness. The brighter the screen, the more power it draws. It even varies with content. A dark movie will require less power than a hockey game or ski competition.

The energy consumption of LCD varies depending on the backlight setting. The lower the backlight, the lower the power consumption. A basic LED LCD with its backlight set low will draw less power than OLED.

LG has said their OLED TVs have a lifespan of 100,000 hours to half brightness, a figure that"s similar to LED LCDs. Generally speaking, all modern TVs are quite reliable.

Does that mean your new LCD or OLED will last for several decades like your parent"s last CRT (like the one pictured). Probably not, but then, why would you want it to? A 42-inch flat panel cost $14,000 in the late 90"s, and now a 65-inch TV with more than 16x the resolution and a million times better contrast ratio costs $1,400. Which is to say, by the time you"ll want/need to replace it, there will be something even better than what"s available now, for less money.

OLED TVs are available in sizes from 48 to 88 inches, but LCD TVs come in smaller and larger sizes than that -- with many more choices in between -- so LCD wins. At the high end of the size scale, however, the biggest "TVs" don"t use either technology.

You can get 4K resolution, 50-inch LCDs for around $400 -- or half that on sale. It"s going to be a long time before OLEDs are that price, but they have come down considerably.

LCD dominates the market because it"s cheap to manufacture and delivers good enough picture quality for just about everybody. But according to reviews at CNET and elsewhere, OLED wins for overall picture quality, largely due to the incredible contrast ratio. The price difference isn"t as severe as it used to be, and in the mid- to high-end of the market, there are lots of options.

There are two main competing display technologies in the market today: LCD and OLED. The mature and dominant technology is the Liquid Crystal Display (LCD), while the up-and-coming challenger is the Organic Light Emitting Diode Display (OLED display). The main difference between LCD and OLED displays is how they create the light and the colors of the image being displayed. This leads to application dependent strengths and weaknesses of either technology.

OLEDs operate via a solid-state technology, where the individual pixels can emit light in various colors and intensity without the need for an additional light source or color filter. The light-emitting portion of an OLED display is comprised of multiple layers of very specific organic semiconductor materials which can be adjusted to emit light in specific wavelengths. These organic layers have a typical thickness in the order of 100nm. In addition, no backlight is required, allowing for a very thin display module.

The organic layers beginning on the cathode side of the device consist of several electron transport layers, a recombination layer and end with a hole transport layer on the anode side. The electron transport layers in the OLED stack-up allow movement of electrons from the cathode toward holes supplied from the anode. The electrons and holes recombine in the emissive recombination layer of the film stack-up. This recombination relaxes the energy levels of the electrons, which produces an emission of light. The wavelength of the emitted light is dependent on the chemical composition of the organic materials used in the recombination layer. The intensity of the light is controlled by the amount of current flowing through the OLED’s organic layers. In OLEDs, the individual pixels can emit red, green, or blue light, or – alternatively – they emit white light, which must then pass through color filters.

There are two main varieties of OLED screens: active-matrix and passive-matrix. The difference lies in how the pixels are generated. In the passive-matrix version, each pixel is created by the intersection of two wires, through which electrical current is passed to create a different color. In an active-matrix setup, each pixel has its individual transistor, which allows for faster refresh times and creates smoother motion and transitions in the picture.

In LCD display technology, the individual pixels modulate light. An applied voltage changes the orientation of liquid crystal molecules that – in conjunction with a pair of polarizers – function as a light shutter by either blocking or allowing light to pass through. LCD displays, therefore, require an additional light source, either from reflected ambient light or more commonly from a “backlight” (an array of LEDs arranged behind or next to the LCD panel). LCD color can be created by adding color filters to the individual pixels. Because OLED displays don’t require the additional backlight, polarizers, or color filter components of an LCD module, they can be made much thinner than LCD displays of equivalent size and resolution.

OLED display technology can offer power-saving advantages over LCDs, which is important, especially for battery-powered applications such as mobile phones. An OLED’s power consumption will vary with image content and brightness, as light is generated only at the individual pixels needed to display the image. A dark image or a graphic on a black background will consume much less power than bright images or graphics. In contrast, LCD backlights must be ON while the display operates. It’s possible to control individual zones of the backlight separately to save power, but this added complexity is usually only applied in larger displays.

OLEDs can achieve a much higher contrast ratio if reflections from the front surface are carefully controlled. If no current flows through an OLED pixel, it does not emit any light. In contrast the shutter effect of an LCD pixel does not block 100% of the light. Depending on the specific LCD technology used and the angle of observation, a small percentage of the light generated in the backlight can escape. This can wash out dark areas of an image. It is possible but expensive to limit this light leakage to a point where the contrast of an LCD and OLED display become perceptually equivalent.

RGB OLEDs naturally generate a narrow bandwidth of light. This leads to very saturated primary colors and a wide color gamut. This enables OLED technology to display colors which are not easily accessible to LCDs unless RGB backlights or quantum dots are used. Often OLED colors are used “as is”, however, for very high image color fidelity, such high color saturation needs to be electronically ‘tuned down’, to match the color bandwidth of the rendering chain.

LCDs offer an advantage over OLEDs in applications where a continuous static image is required. The light emitting materials in OLEDs are affected by luminance decay as a function of the total amount of current that has passed through the pixel. This decay differs for red, green and blue. The dimming effect is subtle, but when adjacent pixels are illuminated at the same time it can become noticeable as an undesired brightness variation or color shift. LCDs don’t suffer from this dimming effect, which makes them a more suitable solution for applications with static images or images with static elements.

Another advantage of LCD technology is the wide variety of different variations to choose from. Depending on the application certain trade-offs can be very attractive. An example is much lower cost for a laptop display compared to a tablet. This is achieved by allowing poor image performance when viewed from the direction the is usually blocked by the keyboard. In a tablet where good viewing performance is required from any direction, much higher cost LCDs or OLEDs must be used.

OLEDs offer an excellent solution for a variety of applications: Glucometers, thermometers, fitness trackers, professional audio equipment, Wi-Fi hotspots, radar detectors, dive computers, biometric transaction devices, and military communications equipment.

They can be used to replace old TN LCDs or add dynamic push buttons on industrial equipment. They can be customized to various resolutions, FPC configurations, colors, custom shaped OLED displays (e.g. octagonal, round, etc.) and can even be made into flexible and transparent displays. Thanks to their versatility, OLED display panel suppliers can offer some exciting capabilities for their customers – things that were previously impossible with LCDs.

As an experienced LCD and OLED panel supplier, New Vision Display can help you find the right technology for your application. Contact us via the below form to discuss your project.

Ready to get started or learn more about how we can help your business? Call us at +1-855-848-1332 or fill out the form below and a company representative will be in touch within 1 business day.

Tech observers and investors revel in lively discussions about the latest, greatest gadget and whose bottom line will get the greatest bounce. They enjoy debating the intricacies and details of materials that contribute to these devices, and the related trends and developments. For us at Corning, materials innovators for 165 years, it’s been great to see a recent uptick in discussions about OLED versus LCD display panel technology - a genuine #GlassAge debate.

Corning.com staff sat down with Mike Kunigonis, business director for Corning’s High Performance Displays Group, to understand key differences between OLED and LCD display technology.

Corning.com: Thanks for your time today, Mike. Let’s start with a key question: In the context of display panels, how does OLED technology work and what are the main differences between it and LCD technology?

MK: OLED stands for Organic Light-Emitting Diode, or Organic LED. It’s an alternative to LCDs for consumer electronic devices that range in size from wearable to TVs. Like LCD, OLED is a type of panel that enables the displays on device screens. An OLED display picture is generated by turning on and off millions of tiny individual LEDs, each forming the individual pixels of a display. Compare this to LCD, where an always-on backlight projects light through a liquid crystal, sandwiched between two pieces of glass. When the liquid crystal is excited by an electrical current, it lets the light of an individual pixel pass through like a shutter. LCD and OLED display panels both excel at delivering vibrant consumer displays, each in its own unique way.

Corning.com: We’ve heard industry analysts with varying opinions on the benefits an OLED device offers. So why would a consumer prefer a device with an OLED display over an LCD display?

MK: Adoption of OLED displays on smaller, mobile devices is the driver behind most of today’s OLED industry growth, so let me focus on that. A handheld OLED display is attractive to consumers because of the industrial design and display attributes that this technology can support. For example, OLED displays can be curved, or be thinner, or have narrower bezels – or no bezels at all – or flex and bend. Plus, an OLED display will be a great solution for virtual reality applications because it can provide high resolution and superior response time and latency.

A new form of display technology called Organic Light-Emitting Diode (OLED) is sweeping the display world today. Let’s take a look at what TFT display VS OLED display and how it stacks up to TFTs.

OLED display uses a light-emitting diode (LED) that features an organic compound as its emissive electroluminescent layer. Electric current is applied to the diode, activating the organic compound film and giving off light as a result. The organic compound film is typically situated between two electrodes, one of which is transparent.

OLEDs are mostly used in smartphones and limited releases of high-end smart televisions. It can also be used in computer monitors and handheld game consoles.

OLED displays naturally emit light, so using them on a display panel doesn’t require a backlight. Meanwhile, LCDs need backlights because the liquid crystals cannot create light on their own. OLED’s natural light emission also paves the way for creating lighter screen devices than those using TFT LCD display.

LCD displays are brighter than OLED. This is due to the LCD’s use of backlights that can brightly light up the entire screen. While OLEDs emit good brightness levels from their light, they can never match the brightness that LCD backlights have.

OLED wins in the black levels feature. It’s because OLEDs can perfectly turn off a pixel, causing it to become completely black. LCDs can’t create perfect black screens even with their full-array local dimming feature. LCDs are also prone to blooming, where a bright part spoils the darkness of an adjacent black area.

OLED screens have better viewing angles than LCDs display. Some LCDs improve their viewing angles by using in-plane switching panels (IPS). However, the clarity of images and videos can’t match that of OLEDs when viewed from extreme side angles. This is because LCDs inherently block light due to their filtering layers, and that creates added depth which makes LCD viewing angles limited.

LCD displays are a bit more energy-efficient than OLEDs. Energy consumption in OLED displays depends on the screen brightness. Less brightness used means lower power consumption, but this may not be ideal because the contrast ratio will suffer when brightness is reduced. This is not ideal if, for instance, you’re using an OLED smartphone under bright sunlight.

Meanwhile, the backlights form the bulk of power consumption in TFT displays. Putting the backlight to a lower setting significantly improves the energy efficiency of TFT displays. For instance, reducing the backlight brightness of an LCD TV with a LED backlight won’t affect the picture quality but will draw less power consumption than an OLED TV.

Both OLED and LCD create high-quality images with a wide color gamut on a screen. OLED display wins over TFT display regarding blackness levels and viewing angle. However, the TFT display takes the cake for brightness and energy efficiency.

AMOLED is another emerging display technology lately. It stands for Active Matrix Organic Light-Emitting Diodes. AMOLED is a type of OLED display used in several smartphones, digital cameras, televisions, and media players.

AMOLED displays have better color accuracy than LCDs. What makes the color more accurate in AMOLED displays is largely due to the precise pixel control achieved by AMOLED panels.

Whites and blacks appear perfect in AMOLED displays. Whites produced by LCDs may carry a bluish tint due to the backlight. Blacks don’t completely appear dark in LCDs, too.

AMOLED provides a greater color gamut than LCDs. AMOLEDs (and all OLED displays in general) have additional blue and green saturation. While these hues greatly widen AMOLED’s color options, some people find the resulting colors a bit unnatural to look at.

Meanwhile, LCDs have subdued greens and quite compelling red hues. Its color gamutmay not be as wide as AMOLED’s, but many people still find it satisfying. That’s because LCD’s color range closely matches the Standard RBG color gamut profile, the one most utilized in videos and images.

LCD’s backlights help maintain the color balance of the entire screen. The backlights ensure that color balance remains consistent across the display. Meanwhile, AMOLED tends to suffer from very slight color balance drifts because of variances in the diodes’ light-emitting capacity over time.

LCDs often have a lower contrast ratio and are prone to light bleeds. That’s due to the backlights remaining open even if light has been blocked and the pixels are supposed to show black color. This is not a problem with AMOLED displays because the panel can simply switch off the pixel to create a pure black color. AMOLEDs have a better contrast ratio as exhibited by their pure black and white levels.

Since AMOLED displays do not require filtering layers and backlights, they’re more suited for use in handheld mobile devices such as smartphones and gaming consoles. LCD may be used in mobile devices as well, but the filtering layers and backlights tend to add a slight bulk to the device. Hence, many manufacturers are now switching to thinner and lighter AMOLED displays.

To sum up this part, AMOLED displays fare better than LCDs in terms of color gamut, accuracy, contrast, and mobile device suitability. However, LCDs have the potential for longer lifespans and carry a better color balance across the display device.

If you compare color LCD vs Display P3, you’ll find a significantly wider color range in Display P3 than the typical sRGB used in color LCDs. LCD monitors, especially those used in computers and laptops, are configured to accurately represent the sRGB gamut as precisely as possible. Meanwhile, Display P3 has been consistently used in Apple products since 2015, starting with the iMac desktop.

That’s all the basic information you need to know about LCD display screens. And the difference between TFT Display VS OLED Display. Now, you know How LCD Works, its possible lifespan, components, and how it compares to other display technologies.

Armed with this information, you can better appreciate and take care of your LCD display devices. And in case you’re planning to add display devices to your business, the information you’ve learned will help you make educated choices regarding the display technologies you’ll utilize.

In market, LCD means passive matrix LCDs which increase TN (Twisted Nematic), STN (Super Twisted Nematic), or FSTN (Film Compensated STN) LCD Displays. It is a kind of earliest and lowest cost display technology.

LCD screens are still found in the market of low cost watches, calculators, clocks, utility meters etc. because of its advantages of low cost, fast response time (speed), wide temperature range, low power consumption, sunlight readable with transflective or reflective polarizers etc. Most of them are monochrome LCD display and belong to passive-matrix LCDs.

TFT LCDs have capacitors and transistors. These are the two elements that play a key part in ensuring that the TFT display monitor functions by using a very small amount of energy without running out of operation.

Normally, we say TFT LCD panels or TFT screens, we mean they are TN (Twisted Nematic) Type TFT displays or TN panels, or TN screen technology. TFT is active-matrix LCDs, it is a kind of LCD technologies.

Actually, IPS technology is a kind of TFT display with thin film transistors for individual pixels. But IPS displays have superior high contrast, wide viewing angle, color reproduction, image quality etc. IPS screens have been found in high-end applications, like Apple iPhones, iPads, Samsung mobile phones, more expensive LCD monitors etc.

Both TFT LCD displays and IPS LCD displays are active matrix displays, neither of them can produce color, there is a layer of RGB (red, green, blue) color filter in each LCD pixels to make LCD showing colors. If you use a magnifier to see your monitor, you will see RGB color. With switch on/off and different level of brightness RGB, we can get many colors.

Neither of them can’t release color themselves, they have relied on extra light source in order to display. LED backlights are usually be together with them in the display modules as the light sources. Besides, both TFT screens and IPS screens are transmissive, it will need more power or more expensive than passive matrix LCD screens to be seen under sunlight. IPS screens transmittance is lower than TFT screens, more power is needed for IPS LCD display.

OLED vs. IPS LCD is a topic that comes up whenever consumers upgrade to a newer TV or a smartphone. Should you buy a TV that uses an IPS LCD display or should you pick up a TV with an OLED screen? Well, the answer isn’t so straightforward because they both have their advantages and disadvantages. In this article, we will explain how these screen technologies work and which one you should opt for while buying a TV.

IPS LCD (In-Plane Switching Liquid Crystal Display) and OLED (Organic Light-Emitting Diode) are the two most commonly used screen technologies. Older technologies, such as TN (Twisted Nematic) and PLS (Plane-to-Line Switching) displays, have almost disappeared (except in the world of PC monitors and budget laptops) because IPS LCD and OLED are clearly better in almost all aspects. Other technologies such as Mini-LED, MicroLED, and QNED technologies are extremely new and they won’t become mainstream for a few years.

So, when you are finally deciding which TV to buy, the real battle is between OLED and IPS LCD. So where do these stand? Which is better for you? Which one should you pick for your new home theatre? Read on for more information on the OLED vs IPS LCD battle.

IPS LCD displays are perhaps the most common display type days, especially in TVs and laptops. Laptops, entry-level and mid-range smartphones, and most TVs use LCD displays. So, how do IPS displays work? IPS displays use an array of LCD pixels that shift colour as required. However, they don’t emit light on their own. That’s the reason they need a backlight made up of LEDs (Light-Emitting Diodes). The backlight can be arranged in various layouts: towards the edges, spread across the whole display, or separated into different sections.

IPS screens display the black colour by changing the alignment of LCDs so that pixels block the transmission of light, but some light still gets through. That’s the reason IPS LCD displays can’t display true deep black colour. Instead, they display dark grey and there is some ‘backlight bleed’.

OLED displays have traditionally been restricted to high-end devices. Even today, only high-end TVs and laptops feature OLED displays. In the world of smartphones, though, OLED technology has been democratised and even mid-range smartphones these days use OLED displays with high brightness and high refresh rates.

In a nutshell, OLED displays don’t use separate backlight sources. Instead, every pixel can reproduce its own light (also known as self-emissive displays). So, there’s no need for an additional backlight and each pixel can be turned on or off as needed. Since there is no need for a separate backlight plane, OLED displays are much thinner than LCD displays. They also offer a much better contrast ratio and viewing angles. However, the organic material used in OLED pixels tends to “burn” over the years that results in ghosting. Moreover, they can’t be as bright as LCD, Mini-LED, or Micro-LED displays.

We have given you a brief overview of IPS and OLED technologies. But which one is better? And which of these will be right for you? Here’s a list of pros and cons to help you in your purchase decision, where it is for smartphones or TVs.

OLEDs have a quicker response time: OLEDs individually-lit pixels can switch on/off or change colour faster. This makes for lower ghosting during fast-and-frenetic action scenes or while playing games. Ghosting refers to when the image on the screen seems to be following itself around or is blurry at the edges.

OLED TVs are slimmer and flexible: As we mentioned earlier, OLED displays don’t need a bulky backlight plane, so OLED TVs are really slim. The next wave of display technologies – foldable and rollable displays – will also be powered by OLED.

IPS LCD TVs offer higher brightness: IPS LCD TVs use a powerful backlight which also lets them get much brighter than their OLED counterparts. This can make for better HDR and even offer a better viewing experience if your TV room gets a lot of sunlight.

IPS TVs suffer from backlight bleed and blooming: This is less of an issue with high-end IPS TVs, but some cheaper models may suffer from glow (bright, greyish areas near the corners of the screen) or backlight bleed (patches or leaks of light, usually around the edges).

OLED TVs can suffer burn-in: OLED displays are at risk of burn-in, a condition in which a static image left on for too long can get permanently ‘burned’ onto the display and may appear like a ghostly dark patch.

OLEDs may get dimmer with age: OLEDs use organic substances which tend to decay over time. So, OLED displays lose brightness with age. It is quite slow and modern OLED TVs are not as affected by this as older OLED TVs, and this really shouldn’t be an issue, but you need to be aware of this.

IPS TVs are much cheaper: OLED is a relatively newer technology and is more expensive to manufacture. Currently, very few companies make OLED display panels. LG Display makes most of the OLED panels found on OLED TVs, while Samsung Display, CSOT, LG Display, and BOE make OLED screens for smartphones and smaller products. Most manufacturers also tend to restrict OLED tech to their largest, most feature-packed range, fueling the perception of OLED being expensive.

In both LCD and OLED displays, producing these cells – which are highly complex – is by far the most difficult element of the production process. Indeed, the complexity of these cells, combined with the levels of investment needed to achieve expertise in their production, explains why there are less than 30 companies in the whole world that can produce them. China, for instance, has invested more than 300 billion yuan (approximately $45 billion USD) in just one of these companies – BOE – over the past 14 years.

Panox Display has been involved in the display industry for many years and has built strong and long-term partner relationships with many of the biggest OLED and LCD panel manufacturers. As a result, we are able to offer our clients guaranteed access to display products from the biggest manufacturers.

Founded in 2001, AUO – or AU Optronics – is the world’s leading TFT-LCD panel manufacturer (with a 16% market share) that designs, develops, and manufactures the world’s top three liquid crystal displays. With panels ranging from as small as 1.5 inches to 46 inches, it boasts one of the world"s few large-, medium -and small-sized product lines.

AUO offers advanced display integration solutions with innovative technologies, including 4K2K ultra-high resolution, 3D, ultra-thin, narrow bezel, transparent display, LTPS, OLED, and touch solutions. AOU has the most complete generation production line, ranging from 3.5G to 8.5G, offering panel products for a variety of LCD applications in a range of sizes, from as small as 1.2 inches to 71 inches.

Now Sharp is still top 10 TV brands all over the world. Just like BOE, Sharp produce LCDs in all kinds of size. Including small LCD (3.5 inch~9.1 inch), medium LCD (10.1 ~27 inch), large LCD (31.5~110 inch). Sharp LCD has been used on Iphone series for a long time.

Beside those current LCDs, the industrial LCD of Sharp is also excellent and widely used in public facilities, factories, and vehicles. The Sharp industrial LCD, just means solid, high brightness, super long working time, highest stability.

Truly’s factory in Shanwei City is enormous, covering an area of 1 million square meters, with a net housing area of more than 100,000 square meters. It includes five LCD production lines, one OLED production line, three touch screen production lines, and several COG, LCM, MDS, CCM, TAB, and SMT production lines.

Its world-class production lines produce LCD displays, liquid crystal display modules (LCMs), OLED displays, resistive and capacitive touch screens (touch panels), micro camera modules (CCMs), and GPS receiving modules, with such products widely used in the smartphone, automobile, and medical industries. The LCD products it offers include TFT, TN, Color TN with Black Mark (TN type LCD display for onboard machines), STN, FSTN, 65K color, and 262K color or above CSTN, COG, COF, and TAB modules.

In its early days, Innolux attached great importance to researching and developing new products. Mobile phones, portable and mounted DVD players, digital cameras, games consoles, PDA LCDs, and other star products were put into mass production and quickly captured the market, winning the company considerable market share.

Looking forward to the future, the group of photoelectric will continue to deep LCD display field, is committed to the development of plane display core technology, make good use of global operations mechanism and depth of division of labor, promise customers high-quality products and services, become the world"s top display system suppliers, in 2006 in the global mobile phone color display market leader, become "Foxconn technology" future sustained rapid growth of the engine.

The company has three LCD factories and one LCM factory. It has acquired state-of-the-art TFT-LCD manufacturing technology, which enables it to achieve the highest efficiency in the mass production of thin-film transistor liquid crystal display production technology. Its customers include many of the biggest and most well-known electronics companies and computer manufacturers in Taiwan and overseas.

TCL CSOT actively produces Mini LED, Micro LED, flexible OLED, printing OLED, and other new display technologies. Its product range is vast – including large, medium, and small panels and touch modules, electronic whiteboards, splicing walls, automotive displays, gaming monitors, and other high-end display application fields – which has enabled it to become a leading player in the global panel industry.

In the first quarter of 2022, TCL CSOT’s TV panels ranked second in the market, 55 inches, 65 " and 75 inches second, 8K, 120Hz first, the first, interactive whiteboard and digital sign plate; LTPS flat panel, the second, LTPS and flexible OLED fourth.

EDO (also known as EverDisplay Optonics) was founded in October 2012 and focuses on the production of small- and medium-sized high-resolution AMOLED semiconductor display panels.

The company opened its first production line – a 4.5-generation low-temperature polysilicon (LTPS) AMOLED mass production line – in 2014, which started mass producing AMOLED displays in November 2014.

In order to ramp up production output, the company began construction of a 6th-generation AMOLED production line in December 2016, with a total investment of 27.3 billion yuan (almost $4 billion USD). The line, which has a production capacity of 30,000 glass substrates per month, produces flexible and rigid high-end AMOLED displays for use in smartphones, tablet pens, vehicle displays, and wearable devices.

Tianma Microelectronics was founded in 1983 and listed on the Shenzhen Stock Exchange in 1995. It is a high-tech enterprise specializing in the production of liquid crystal displays (LCD) and liquid crystal display modules (LCM).

After more than 30 years of development, it has grown into a large publicly listed company integrating LCD research and development, design, production, sales, and servicing. Over the years, it has expanded by investing in the construction of STN-LCD, CSTN-LCD, TFT-LCD and CF production lines and module factories across China (with locations in Shenzhen, Shanghai, Chengdu, Wuhan and Xiamen), as well R&D centers and offices in Europe, Japan, South Korea and the United States.

JDI (Japan Display Inc.) was established on November 15, 2011, as a joint venture between the Industrial Innovation Corporation, Sony, Hitachi, and Toshiba. It is dedicated to the production and development of small-sized displays. It mainly produces small- and medium-sized LCD display panels for use in the automotive, medical, and industrial fields, as well as personal devices including smartphones, tablets, and wearables.

Although Sony’s TVs use display panels from TCL CSOT (VA panel), Samsung. Sony still produces the world’s best micro-OLED display panels. Sony has many micro OLED model such as 0.23 inch, 0.39 inch, 0.5 inch, 0.64 inch, 0.68 inch, 0.71 inch. Panox Display used to test and sell many of them, compare to other micro OLED manufacuturers, Sony`s micro OLEDs are with the best image quality and highest brightness (3000 nits max).

In the ruthlessly competitive smartphone market, the choice of display technology is one of the more important decisions that a manufacturer will make. Advances in touchscreen features and capabilities have in the past contributed to clear shifts in market share from one device to another. Handset manufacturers create marketing campaigns aimed at bringing consumers’ attention to the key visual and design differences central to their new model’s display and the displays of competing products.

There is always a question about how much consumers are willing to pay for incremental improvements in the viewing experience, or for a fractionally thinner form factor enabled by a new display, but edge-to-edge or infinity displays look poised to gain traction. The best evidence of this today is coming from the market for high-end smartphones, where OLED (organic light-emitting diode) display technology, pioneered by Samsung Display, is offering an alternative to proven, high-yield LCD (Liquid Crystal Display) technology.

While gadget enthusiasts readily recognize that a new OLED display offers, in some respects, a superior viewing experience to that of an LCD screen, the reality is that both OLED and LCD technologies in handheld form factors have reached an extraordinarily high level of quality. In terms of resolution, color gamut, contrast and brightness, today’s mobile phone displays – whether OLED or LCD – provide a stunning viewing experience.

Since OLED is the “new and improved” technology, it might be tempting to assume that it is on course to usurp LCD in almost all smartphones with the passage of time. But, in fact, each technology offers a mix of advantages and disadvantages, and more likely outcome is the continued use of both technologies for many years to come.

As the leading provider of touch controllers, display driver integrated circuits (DDICs), and touch and display driver integration (TDDI), Synaptics’ industry experience positions the company well to assess the upcoming market and technology trends for smartphone displays and display drivers.

The mix of benefits and drawbacks for OLED encompasses both the user’s viewing experience and the handset manufacturer’s operations, particularly involving system design and production.

From a purely visual perspective, OLED displays offer distinct benefits. The Organic LEDs offer a larger color gamut and a faster refresh rate, resulting in reduced motion artifacts and displays that “pop”. OLED displays are emissive, meaning they don’t require a backlight. Individual pixels can be turned on and off, resulting in high contrast with deeper, darker blacks and fully saturated color. By comparison, in an LCD panel the pixels are like windows. A backlight behind the window lights up the pixels. When a pixel is required to be dark, its “shutter” closes to block the backlight, but some light can still leak through.

Flexibility in industrial design is another important advantage of OLED technology. Removing the separate backlight and applying TFE (Thin Film Encapsulation) technology allows companies to produce curved displays, such as those found on some models of the Galaxy smartphone. The new and distinctive appearance of these phones is made even more appealing because the OLED panel is thinner and lighter than an LCD panel of the same surface area.

OLED displays are not without their drawbacks, however, as manufacturing cost and power consumption when the screen is brightly lit are still issues. Furthermore, the longevity of the panels is still a concern. An OLED display’s blue pixels degrade faster when the display is bright than the red and green pixels, which means that the viewing experience can worsen over the lifetime of the panel. Also, their organic materials are sensitive to moisture and oxygen, and require complex technology to ensure trouble-free operation over the lifetime of the phone. OLED displays at higher resolutions are still more expensive than LCDs due in part to the relatively low yields during manufacturing and assembly. Yields are improving, especially for flexible displays, but today they remain a premium priced product.

Advances in LCD technology have led to substantial improvements in viewing angle, resolution, and contrast, enabling LCDs to remain the display of choice for a majority of high-end smartphones. Price is always a factor when making design choices that must balance market appeal with integrated features and profitability, and the performance of well-priced high-quality LCDs has made it an optimum choice for mainstream phones as well.

Another factor where LCD has the advantage is the need for smartphone manufacturers to manage their supply chains very carefully to maintain volume production runs of many millions of units per month. The LCD panel market is proven, enjoys stable high yields at the highest resolutions, and is supported by a well-populated ecosystem of display manufacturers and component suppliers, including the requisite display driver integrated circuits (DDICs). By contrast, today Samsung Display is the only high volume supplier of mobile OLED panels, and most of its output goes to its sister company that manufactures smartphones.

Over time, the smartphone market will mature and bring up additional high-volume OLED panel manufacturers. Competition always drives innovation and cost, and various manufacturers of LCD panels already have plans to install manufacturing capacity for OLED panels in order to diversify their offering. Before the end of this decade, the OLED supply chain is expected to have scaled up sufficiently to meet the volume demands for all leading smartphone brands. At the same time, larger size and flexible-foldable designs will create new markets, as yield and supply improve.

Today, owing to this limited supply chain and associated cost premium, OLED displays have been introduced at the top end of the model range, especially in flagship smartphones, such as the Samsung Galaxy S. Most other smartphone manufacturers are expected to offer an OLED-based model beginning in 2017. Wider adoption of OLED technology in mid-range smartphones is unlikely to take place before 2019. So despite the increased investments in OLED manufacturing, LCD panels are likely to maintain their strong market position well into the next decade (see Figure 1).

Every display panel requires a DDIC or TDDI, which is a device that converts the data signals from the phone’s processor into the outputs needed to control each of the panel’s millions of pixels. For this reason, a DDIC or TDDI must be specifically designed and configured for each different model and type of display panel, whether LCD or OLED.

Because every manufacturers’ display requirements are different, it is essential for their engineering teams to work closely with the IC vendor engineering teams to achieve a successful integration for optimal industrial design and best performance. This requires close cooperation all along the supply chain—from the display, backlight, and IC vendors through the device manufacturers.

In addition to integrating the display with the display driver, it is also beneficial to integrate the display’s other major functions: touch navigation and user interface. Incorporating the touchscreen controller into the DDIC is known by the acronym TDDI (Touch and Display Driver Integration).

TDDI offers important benefits to both the manufacturers and users of smartphones. By replacing two chips – a touchscreen controller IC and a DDIC – with a single chip integrating both functions, manufacturers are able to reduce the size, complexity, and cost of the display assembly, and to simplify their supply chains and production processes. TDDI even enables manufacturers to design a better and brighter display, including those with narrower borders because there is no need for external routing on the sides or top of the display panel. These narrower borders allow the bezel-less designs that are needed to produce full-size, edge-to-edge “infinity” displays.

As flagship designs push towards ever larger, brighter, better displays against the constraints of comfortable industrial design the edges of the phone must give. This leaves little room for extra buttons, sensors, and integration becomes critical. The move away from rigid display materials will be first, towards flexible display packaging and plastic backplanes, which even LCD manufacturers are working on. The question is only how quickly the industry ramps manufacturing capabilities. Ultimately, your mobile device may be truly foldable, but manufacturers will want to bring these features to mid-range devices as well.

Smartphone manufacturers are enjoying the cost-saving, additional features, and performance benefits of TDDI today for phones that use an LCD panel. The same benefits can be expected for phones with flexible OLED panels, but this will take time because both OLED display manufacturers and TDDI vendors will first need to learn from the implementation of discrete DDICs and touchscreen controllers in OLED displays. Then, the current manufacturing and integration challenges facing mobile OLED displays will be overcome, making this innovative technology available for the broadest selection of models from a growing range of phone manufacturers.

LCD is currently the mainstream technology for smartphone displays, with a broad, mature supply chain and with panels that are used in low-end smartphones all the way up to flagship products. Companies like Synaptics are providing display manufacturers with the latest display and touch capabilities via high-performance DDIC and, increasingly, TDDI solutions. OLED provides benefits over LCD due to the fact that OLED panels do not require a backlight and can be flexible. While OLED displays are now common in flagship models from Samsung and others, the OLED supply chain will need to grow and mature further for OLED to gain traction in mainstream phones. Whether display panels are LCD or OLED, Synaptics - as the industry leader in touch controllers, DDICs, and TDDI - is well positioned to bring continued innovation and display driver products to the global smartphone market.

When the touch technology is deposited on the cover glass using the sensor on lens approach, you end up with a separate touch module that can be sold to the LCD display assemblers. This would mean more revenues for the touch technology manufacturers who would supply these modules.

On the other hand, the on-cell alternative means that the LCD panel manufacturers can add these touch layers onto their own panels. The display assemblers would then just have to purchase a simple cover glass to complete the display. The touch module makers would be cut out of the process.

For now, it appears that the sensor on lens approach has an advantage over on-cell solutions. The on-cell approach means that LCD makers would have to make two separate models of each panel: one with touch and one without. This could add cost to an industry that is already running on razor-thin margins. Also, on-cell touch is limited to the size of the LCD panel; sensor on glass modules can be larger than the LCD panel, providing room for the dedicated touch points that are part of many smartphone designs.

In case you"ve been wondering where OLED displays fit into all this: An OLED display stack is somewhat different from an LCD stack. It only requires one substrate (glass) layer as opposed to LCD"s two, and the OLED material layer is much thinner than the LCD layer. As a result, the finished display can be half as thick as an LCD panel, saving weight and thickness -- which is important in a smartphone design.

(A number of smartphones today use a form of active-matrix OLED display called Super AMOLED; these include several Samsung devices such as the and the Motorola Droid Razr M).

As a practical matter, glass is still used as the encapsulating layer, so OLEDs generally have two layers of glass. In addition, not all OLEDs are RGB -- some use white emitters instead to try to reduce the differential aging problem, and add a color filter layer to the stack.

In spite of all this, as far as touch screen technologies are concerned, OLEDs are more like LCDs than they are different: Both have active matrix TFT backplanes, and both tend to have a cover glass layer for protection. So essentially the same stack configurations are available to OLED panels.

No matter which solution wins out, it is clear that pro-cap technology is the best method for touch screens on mobile devices -- at least for the foreseeable future. Still, there are some changes already showing up in touch screen technology.

For example, some panel makers are creating "in-cell" touch panels, where one of the conductive layers actually shares the same layer as the thin film transistors (TFTs) used to switch the display"s sub-pixels on and off. (These transistors are fabricated directly on the semiconductor backplane of the display.) This approach not only reduces the electromagnetic noise in the system, but also uses a single integrated controller for both the display and the touch system. This reduces part counts and can make the display component thinner, lighter, more energy efficient and more reliable.

This approach only makes sense for very high volume products, such as a smartphone from a major vendor that is expected to sell millions of units, because the panel will have to be made specifically for that unique model. The first products using "in-cell" touch technology have already appeared on the market, such as the new , but it looks as though it will take years before this approach will become a widespread solution.Additional resources

Some device manufacturers are also adding stylus support to their products. The new higher-resolution displays make it useful for some users to have access to a pointing or writing device that has a finer tip than a finger. Some devices rely on an "active" stylus that can be sensed by the pro-cap system, such as the Samsung Galaxy Note. Others, such as the , are choosing single-point infrared optical sensing that can detect the position of any pointed object on the screen.

Meanwhile, system designers are developing new ways to interact with mobile devices via touch, such as and . Even as other modes of interaction -- such as speech recognition for voice input -- become more sophisticated, touch is likely to remain the primary way we control our devices.

What is Micro OLED? Why Micro OLED is good choice for AR/VR devices. Apple"s first VR/MR headset will be launched next year. This headset will be equipped with three screens, two of them are micro OLED displays.

FFALCON innovation released the new generation of consumer XR glasses FFALCON Air 1S. uses BirdBath+MicroOLED technology to create a 130-inch high-definition screen experience for users.

The OnePlus Nord Watch features a 1.78 inch AMOLED rectangular screen with a 368x448 resolution and a 60Hz refresh rate. The watch has no built-in GPS, so it can only receive its location from a smartphone via Bluetooth 5.2.

Now LCD is the most common VR device screen on the market, and a few VR products use OLED screens and Mirco-OLED screens. Micro OLED is unfamiliar for VR players. Arpara 5K PC VR, the world"s first VR device, is using the micro-OLED display.

This enhanced IPS LCD Screen is 2.9 inch 480*720, Panox Display`s convertor board on FPC make higher resolution compatible with GBA circuit board. This makes 3*3 pixels display one pixel as the original display.

Leica has released a new thermal camera for modern hunting, it has extreme precision and maximum repeatability, superior image quality, and an extra-large field of view. Which use using a 0.39 inch 1024x768 pixels Micro OLED with a 50 Hz refresh rate.

HUD stands for Head Up Display, it help driver focus on driving, and read driving information at a glance with the digital umbers. These HUD are using a round shape 1.39 inch AMOLED.

Smart homes are becoming increasingly common because the things they offer – including increased security, intelligence, comfort and performance – appeal to our basic human instincts. Smart homes are, of course, full of terminal products and, unsurprisingly, LCD displays are a fundamental element of such devices. In this article, we will examine some of the common features of smart home LCD touch screens.

OLED Display modules are self- emitting without backlight so it makes OLED modules slimmer and lower power consumption. With advantages in wider viewing angle up to 175 degree, higher contrast, faster response, OLED display modules are the most advanced technology and optimal option among the monochrome displays products.

Raystar’s OLED teams are with rich experience in management, design, manufacturing, research in developing the new and high quality OLED character and graphic modules. It is ideal display for consumer and industrial applications such as Audio, Automotive control panels, Medical devices, White goods or Home automation products and more. OLED display panel modules will be the next and the best displays to apply for your design.

OLED displays have higher contrast ratios (1 million : 1 static compared with 1,000 : 1 for LCD screens), deeper blacks and lower power consumption compared with LCD displays. They also have greater color accuracy. However, they are more expensive, and blue OLEDs have a shorter lifetime.

OLED displays offer a much better viewing angle. In contrast, viewing angle is limited with LCD displays. And even inside the supported viewing angle, the quality of the picture on an LCD screen is not consistent; it varies in brightness, contrast, saturation and hue by variations in posture of the viewer.

There are no geographical constraints with OLED screens. LCD screens, on the other hand, lose contrast in high temperature environments, and lose brightness and speed in low temperature environments.

Blue OLEDs degrade more rapidly than the materials that produce other colors. Because of this, the manufacturers of these displays often compensate by calibrating the colors in a way that oversaturates the them and adds a bluish tint to the screen.

With current technology, OLED displays use more energy than backlit LCDs when displaying light colors. While OLED displays have deeper blacks compared with backlit LCD displays, they have dimmer whites.

LCDs use liquid crystals that twist and untwist in response to an electric charge and are lit by a backlight. When a current runs through them, they untwist to let through a specific amount of light. They are then paired with color filters to create the display.

AMOLED (Active-Matrix Organic Light-Emitting Diode) is a different form of OLED used in some mobile phones, media players and digital cameras. It offers higher refresh rates with OLEDs and consume a lot less power, making them good for portable electronics. However, they are difficult to view in direct sunlight. Products with AMOLED screens include Galaxy Nexus, Galaxy S II, HTC Legend and PlayStation Vita.

OLED displays are commonplace on all high-end phones, tablets, smartwatches, televisions, and even many of the many budget phones. However, there isn"t one type of OLED technology. Depending on your device, you may have an OLED, AMOLED, or POLED display.

OLED promises inky blacks, high contrast, low response times, and incredible brightness. There are a few downsides (primarily the burn-in phenomenon), but overall it"s the best screen technology you"ll find. We explain the background behind the acronyms, the difference between POLED and AMOLED, and which is better, helping you choose the right phone.

Before we get into the differences between the types of OLED screens, let"s look at the similarities. Regardless of your OLED device, whether a laptop or a smartphone, there are some standard fundamentals.

Every OLED screen comprises millions of diodes, hence the name organic light-emitting diode. Viewed under a microscope, each screen consists of a series of red, green, and blue diodes that can be individually turned on and off. Behind this, the light-emitting pixels of an OLED display emit blue and yellow light. The yellow and blue light combine to form white light, passing through the red, green, and blue subpixels to produce a single pixel. Because each pixel handles its light and color, OLED displays do not need a separate backlight.

As an OLED screen doesn"t need a backlight, black is produced by turning off the pixels, resulting in deep, consistent blacks. This allows manufacturers to implement things like an always-on display without quickly burning through battery life.

Another critical advantage of OLED tech is high contrast ratios. Technically, OLED displays offer "infinite contrast," or 1,000,000:1 contrast ratios. This is because OLED displays reproduce black by turning off pixels entirely, and contrast is measured by comparing the brightest part of the screen to the darkest part. Improved contrast makes on-screen content more vivid and makes bright highlights look more impressive. This also means that OLED screens can reach higher brightness than the best IPS LCD screens.

OLED displays can display more colors with greater color accuracy than their LCD peers. This is great for photographers and videographers using their phones to preview, edit, and create content.

OLED displays have near-instantaneous pixel response times. Older LCD screens often have lower response times because to change from one color to another, they must physically change the orientation of a liquid crystal, which takes time. An OLED display turns a subpixel on or off with an electrical charge, giving them a faster pixel response time.

The omission of a separate backlight and the use of fewer components means OLED displays can be thinner than LCDs, making them more versatile in their applications. This means they are more fragile and prone to damage in high-impact or high-stress situations. Engineers combat this by using technologies like Gorilla Glass and robust metal frames. Mitigation strategies like these raise the cost of OLED screens.

OLED displays can also be transparent, depending on the materials used. Transparent displays are helpful for in-display fingerprint readers and under-display cameras, which allow manufacturers to design smartphones with fewer and smaller bezels, notches, and display cutouts. When notches and cutouts are necessary, OLED displays have more even brightness around those cutouts and notches compared with LCDs, where the backlight has to make it around the cutout, and things get a little messy.

Of particular import to smartphones, OLED displays often consume less power, especially when

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey