lcd panel disassembly manufacturer

Industrial repair utilizes all facets of AGDisplays’ capabilities. We repair most aspects of LCD technologies so that our customers do not have to replace whole units for minor repairs. AGDisplays are experts in LCD panels and LCD technology. At our 84,000 square foot facility, AGDisplays performs both low-volume and high-volume production levels; we maintain high tech, state of the art equipment to perform precise procedures. With our high level of expertise, our teams provide technical skills and lend our creative problem-solving abilities to give our customers LCD displays that meet the demanding needs of your industries.

With over 40+ years of experience, we train our individuals through a specific curriculum in which we evaluate regularly. Our team is ready to deliver high-performance display repairs to our customers. Trained personnel are evaluated prior to employment and during employment on a regular basis to determine their workmanship quality exceeds the standards set by AGDisplays. We also provide repair warranty services for panels that are no longer under OEM warranty.

AGDisplays is focused on refurbishing and repairing your LCDs; we specialize in providing cost-effective alternatives to LCD replacements. We may use recycled LCD parts, which are always 100% tested. Using refurbished parts gives the customer the ability to keep cost low. Using AGDisplays’ repair/refurbish service guarantees your products are using quality and inspected components.

AGDisplays most often uses brand new, quality LCD components when repairing and refurbishing your display product. Our company values quality components, that’s why strictly maintain our databases, and follow supply chain processes. We have an International Procurement Office in China that are constantly verifying vendors with whom we maintain current business practices.

Our LCD experts prepare custom display layouts including unit dimensions and segment content to redesign your panel for optimal functionality. Inspections on deliverables are evaluated to ensure AGDisplays is only working with quality materials. During manufacturing, various product inspections take place such as performance measures. For quality assurance measures, we perform a full diagnostic analysis for each repaired unit that can include the following:

Our quality resources become available to you at an affordable price. We have a direct relationship with LCD distributors, providing our customers with the same resources.

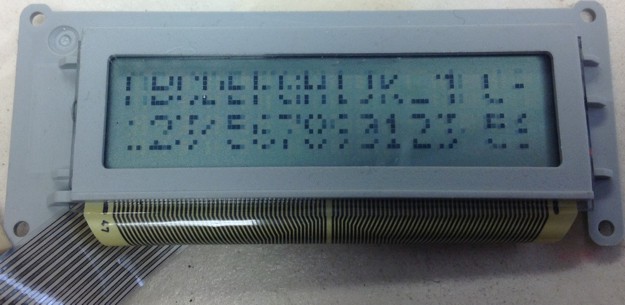

LCD repolarization is the process in which a person or company will remove an existing polarized film from an LCD stack up. Polarizing films are used in an LCD stack up to increase readability and clarity created on the LCD. The films polarize light to create a defined direction. LCDs may use various types and combinations of films; not all of these films are considered polarizing films. In the LCD Industry typical laminations can consist of optical polarizer laminations to the LCD glass surface or perhaps an anti-reflective film laminated to the top polarizer. AGDisplays employs three different types of polarizers: reflective, transflective or transmissive. An LCD stack configuration is determined by the lighting conditions your LCD will operate in.

Reflective polarizers are applied to the bottom layer of the LCD glass and reflect 100% of the ambient light that enters through the top layer of the glass. Transmissive polarizers allow the light from a backlight source to pass through the bottom and top layers, towards the user. In this instance, the backlight must be on for the display to be readable. Benefits of this polarizer are increased display brightness, reduced driving current and extended half-life of the backlight. Transflective polarizers allow display readability with the LCD backlight on or off. This polarizer reflects some ambient light passing through the front glass; at the same time, it uses the backlight source to pass through the glass.

The AGDisplays experts perform LCD repolarization in one of the multiple Class 1000 clean rooms that are located in our facility. Using a clean room is important because it minimizes the risk of contamination find its way into the LCD as an AGDisplays technician is performing a repolarization on an LCD display.

Depending on the type of polarization used in the particular LCD build, the film may also increase display contrast and readability, create sharper and clearer image quality, provide deeper colors, increase viewing angles and more.

LCDs can be repolarized to return your scratched display to original form, and additional lamination services such as anti-reflective and anti-microbial properties, EMI protection, and LCD protection. With our lamination enhancements, you can be assured that your LCD is protected from surface scratches, acid-etching, and other particle contaminants. Replacing a polarized film will not repair damage to a broken LCD. AGDisplays can replace damaged LCD screens that cannot be repaired by repolarization.

Every LCD screen eventually fails, usually due to the backlight behind the screens. That is why we have a backlight solution for every LCD screen on the market. Plazmo currently has the single largest global stock of drop-in CCFL and LED backlight assemblies.

Each of our assemblies comes complete with a pre-wired harness, OEM connector plug, silicone end caps and an optional metal rail. Nearly every LCD screen has a unique model design and we have developed the molds and manufacturing specifically to fit more than 200,000 LCD screen models in use today.

Plazmo also has robust manufacturing capabilities and specializes in perfectly replicating OEM backlight assemblies. Using our LED and CCFL backlight assemblies, we pass on savings to our customers while helping keep their LCD screens running smoothly.

Rochester Industrial Services is perfectly positioned to provide quick, affordable repairs for your industrial electronic display terminals. Even if you have obscure or off-brand video display equipment, chances are we can help no matter what manufacturer or model you have. If you are in need of service, repair, or maintenance on any CRT Monitor, LCD Panel, or Touch Screen Monitor not covered in the categories below, please check our contact info.

4. #Press the LCD glass side of the panel, if the vertical lines disappear or reappear, it can be judged that the cause of poor contact, OM checking should be able to find the poor contact.

4. #The above disassembly judgment can basically solve the problems of point-off in the market. If you can’t tell the truth, you can directly change the lamp tube.

The above is the full text of LCD screen failure repair guide, we hope it is helpful to you. If you need to buy LCD and find a reliable LCD supplier, we suggest you to read our other great blog – How to find a reliable LCD supplier.

Founded in 2014, VISLCD is a professional LCD supplier. We provide LCD modules, touch LCD and customized LCD in various sizes with stable quality and competitive price. Welcome to contact us for any LCD demand, thank you.

We also know that a damaged screen can impact your visitors’ experience or even delay an upcoming event. To help you move forward, we execute LED panel repairs quickly and efficiently. We complete repairs for various industries, such as broadcast, education, stadiums, and corporate organizations.

Affordable service contracts are available, so you can keep up with routine maintenance for your LED panels. We can also step in and perform repairs as needed.

Try using lcd panel repair found on Alibaba.com to make many types of production jobs faster and easier. Each model can be filled with different types of liquid and quickly dispensed into containers. Use lcd panel repair to fill paint cans with speed and precision. Other compatible fluids include resin or glue, making such devices suitable for manufacturing all kinds of helpful products.

All lcd panel repair are built to be easy to operate, reducing labor and training times needed. Some versions can pour food-grade liquids such as beer or milk into bottles for future sealing. Most units work automatically so workers can program them and stay back as they work on their own. When installed on a factory floor, they offer greater efficiency to help save time and costs.

Shop for lcd panel repair at Alibaba.com to find many helpful suppliers with a wide range of options that can be ordered. Choose just the right size to fit the intended workspace. Pick a wattage level that promises good speed and power without using too much electricity and driving up costs. Certain designs can dispense products in the form of powder or granules into nearby containers. Use these to package particular powdered food and pharmaceutical ingredients.

Search for lcd panel repair on Alibaba.com and enjoy lower costs when working with various liquids or powders. Whether for use in food manufacturing or building materials, there are plenty of options to browse. Find a satisfactory brand that will improve efficiency for better overall quality in each final product.

For over 20 years we"ve been helping clients worldwide by designing, developing, & manufacturing custom LCD displays, screens, and panels across all industries.

Newhaven Display has extensive experience manufacturing a wide array of digital display products, including TFT, IPS, character displays, graphic displays, LCD modules, COG displays, and LCD panels. Along with these products, we specialize in creating high-quality and affordable custom LCD solutions. While our focus is on high-quality LCD products, we also have a variety of graphic and character OLED displays we manufacture.

As a longtime leader in LCD manufacturing, producing top-quality LCD modules and panels is our highest priority. At Newhaven Display, we’re also incredibly proud to uphold our reputation as a trusted and friendly custom LCD manufacturing company.

As a custom LCD manufacturing company, we ensure complete control of our custom displays" reliability by providing the industry"s highest quality standards. Our design, development, production, and quality engineers work closely to help our clients bring their products to life with a fully custom display solution.

Customer support requests sent by phone, email, or on our support forum will typically receive a response within 24 hours. For custom LCD project inquiries, our response time can take a few days or weeks, depending on the complexity of your display customization requirements. With different production facilities and a robust supply chain, we are able to deliver thefastest turnaround times for display customizations.

Our excellent in-house support and custom display modifications set Newhaven Display apart from other LCD display manufacturers. From TFTs, IPS, sunlight readable displays, HDMI modules, EVE2 modules, to COG, character, and graphic LCDs, our modifications in the customization process are completed at our Illinois facility, allowing us to provide quality and fast turnaround times.

As a display manufacturer, distributor, and wholesaler, we are able to deliver the best quality displays at the best prices. Design, manufacturing, and product assembly are completed at our headquarters in Elgin, Illinois. Newhaven Display International ensures the best quality LCD products in the industry in this newly expanded facility with a renovated production and manufacturing space.

LCD panel manufacturing is divided into an Array, the Cell, such as the Module is installed in a series of technological process each process will produce some process defects, such as dim bright flash point of these defects such as broken window will cause local show bad, but we can through the laser line cut, welding, darkening method to repair or fade in the actual production in about 5% of the point defects, with a laser repair or fade out after, can promote panel product yield, and reduce the production cost of the panel companies.

Point defect is the most common problem of the LCD panel, the LCD panel manufacturing process, including dust organic metal foreign bodies will be adsorption to the LCD panel when the utensil was to close to the color filter area, corresponding to the color filter pixels emit a much brighter than the rest of the normal pixel light, which is referred to as a pixel point Semishare joint American ESI to become the industry"s first flexscan technology being developed for the pixel window, BM repair and DM repair.

South Korean flat-panel display (FPD) process equipment manufacturers have held a market-leading position for some time and are the driving force behind many of the recent advances seen in the manufacture of organic light emitting diode (OLED) and active-matrix light emitting diode (AMOLED) displays.

As modern FPD manufacturing techniques become more complex and difficult, panel defects are increasingly likely. Robust inspection and repair procedures have been developed to ensure that errors, where they do occur, have minimal effect on display quality. Processes needing repair operations in liquid crystal display (LCD) manufacturing, for instance, include those involving thin film transistor (TFT) substrates, colour filter (CF) substrates and TFT / CF alignment (cell assembly).

Damage to any one of the millions of transistors within the LCD panel may leave a sub-pixel permanently on or off, creating a tiny dark or bright spot on the display. Broken or shorted TFT data lines are often the cause of bright / black line defects. Repair structures integrated into the TFT layer allow white pixel defects to be turned to ‘black" or ‘dull" by irradiation with a laser. The laser is used in ablation / welding and is focused on the defect to either vaporize it or to create new contacts in the case of TFT repair. The spot-size (diameter) of the laser beam needs to be carefully controlled so as to encompass the defect but leave the normal substrate around it undamaged. Precise manipulation of the laser aperture, in the range of 5 – 50 microns (µm) in diameter, is vital to ensure successful panel repair and improved process yield.

In the FPD repair process, the precise position of the laser beam on a panel substrate is controlled by a scanning mirror, or similar, while the substrate sits on an XY air-bearing stage. The aperture stop lies between the laser source and the intended target. Depending on the application, changes may be made to the laser beam shape, spread (divergence) or even intensity in order to meet process requirements. TPC"s variable aperture stop design is novel for FPD repair as objective-lens systems are typical in this application. One advantage of a mechanically adjusted aperture is that laser spot sizes can be precisely controlled to within 1 µm or less, the typical feature size of 10th generation devices, which allows very accurate control of the beam spread.

Mr Hwang continues: “The laser repair tool rapidly tracks back and forth across the panel to the location of every defect, which necessitates a light weight design to maximise throughput. The aperture assembly accommodates four voice coil motors, each with an ATOM encoder, all enclosed within an area of approx. 100 mm square. ATOM"s best-in-class feedback performance provides improvements in aperture control, whilst the low mass (<4 g) of the readhead ensures that overall design weight remains uncompromised.”

ELSIN provides warranty and post-warranty repairs of LCD screens for service organizations, LCD panel makers, manufacturers and distributors of monitors, laptops, TVs and individual customers.

As the only company in the Czech Republic we carry out repairs of LCD panels including replacement of polarization film and repair of defective lines / blocks for sizes of 10 ” – 65 ” with a capacity of over 2000 pieces per month.

If you select the exact model number in the #4 selection box (GA401nnn models) and then click on Display in the Categories section you will find the part numbers for the various LCD screens that may be used in the laptop.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey