hkc lcd panel manufacturer

LCD TV Sets, and expanded full set of tooling design, plastic injection and LCD backlight, etc.In 2006, total sales amount of HKC grew to USD500,000,000, exports cover about 40%.

(Yicai Global) June 7 -- HKC Optoelectronics Technology has completed its pre-listing tutoring and is ready for an initial public offering, sources at China"s third-largest maker of liquid crystal display panels told Yicai Global.

HKC has LCD panel production bases in Chongqing and Mianyang in southwest China and Chuzhou in the east, and has formed a vertical industrial chain including LCD panels, light-emitting diode backlights, LCD modules and whole machine production.

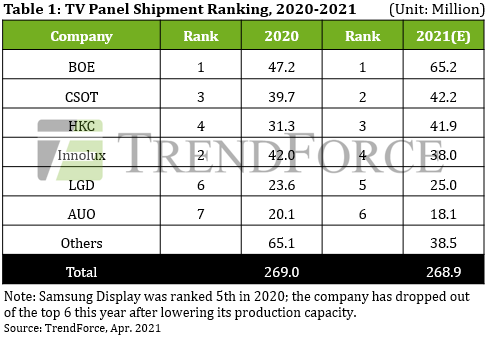

The Shenzhen-based firm ranked third among Chinese companies for global display panel shipments last year, after BOE Technology Group and TCL China Star Optoelectronics Technology, according to data from Sigmaintell Consulting. HKC also accounted for 10.1 percent of the global television screen market, and 6.5 percent of the global display panel market.

As a relative latecomer to the industry, HKC initially offered low-priced products. As its position in the market stabilized in recent years, it has gradually raised prices and prepared to go public.

But global LCD panel prices have been falling, posing a challenge for HKC"s short-term business outlook. According to research firm Omdia, since last September the average price of 43-inch LCD panels has dropped 46 percent, and for 55- and 65-inch panels prices are down 34 percent.

“Current prices pose a big challenge for all panel makers,” Zhang Hong, director of TV research at Sigmaintell, told Yicai Global, adding that losses are growing at some manufacturers of LCD TV panels.

Cinno Research’s Chief Analyst Zhou Hua told Yicai Global that HKC"s LCD panel production line has had a lot of support from the local government, but in the current economic environment it is harder to secure such high subsidies.

HKC is more vulnerable to market cycles than BOE or TCL CSOT and is has less business flexibility than smaller producers, Zhou said, which is why the firm needs new sources of financing by going public.

China-based LCD panel maker HKC is applying for listing on ChiNext market under the Shenzhen Stock Exchange to raise CNY9.5 billion (US$1.42 billion), according to industry sources.

HKC invested CNY24 billion to set up its first 8.6G LCD line in Chongqing, China in 2015, and has since built another three 8.6G lines, with the one in Changsha coming into operation in April 2022.

The funds to be raised via IPO will be used to enhance R&D of medium- to large-size OLED panels and expand production capacity for miniLED fine-pitch displays and miniLED-backlit LCD panels for smartphones, notebooks and TVs at the Changsha plant, integrate R&D with production for oxide TFT technology at its Mianyang plant, and develop IoT-based smart display solutions.

China-based panel maker BOE Technology in June 2021 acquired a 2% stake in HKC for strategic partnership in assembly of LCD displays and TVs. BOE has three flexible OLED panel production lines and has fully utilized production capacities at two of them and is undertaking trial production at the third.

BOE shipped about 60 million flexible OLED panels in 2021, hiking nearly 60% on year. According to forecast by Omdia, BOE will ship 100 million flexible OLED panels in 2022. Besides, BOE has begun production of miniLED-backlit panels for AOC, Skyworth and Konka.

China-based panel maker CSOT has fully utilized first-phase production capacity for flexible OLED panels at a factory in central China and is expanding the capacity in the second phase with operation to begin by the end of 2022.

Display panel maker HKC has recently completed pre-listing counseling, Yicai reported on Tuesday. LCD panel prices have fallen to record lows, posing a profit challenge for the firm, which is the third-largest display panel maker in China.

Previously, the China Securities Regulatory Commission disclosed a CICC report on the IPO and listing guidance for HKC. CICC believes that HKC is qualified with the corporate governance structure and internal control system as a listed company.

Founded in December 2001, HKC builds up LCD panel production bases in Chongqing, Chuzhou and Mianyang. It has formed a vertical industrial chain spanning from LCD panels, LED backlights, LCD modules to whole machine production.

In terms of various panel applications, HKC’s LCD products have a relatively high share of area shipped in TVs and monitors, accounting for 10.1% of the global TV panel market and 6.5% of the global display panel market in 2021.

As a latecomer in the industry, HKC was initially known for lower prices in its initial competition with the industry leaders. Gradually, HKC is adding value to its panels as its industry position of third place in terms of area shipped in the Chinese panel industry stabilizes, and with the demand of going public.

However, in May this year, the price of LCD panels fell drastically. Research firm Omdia estimates that from September 2021 to May 2022, the price of 43-inch LCD panels fell 46 percent, and the price of 55- and 65-inch panels both fell 34 percent.

HKC is preparing to increase its whole machine project and expand overseas with its LCD panels. According to the Bozhou government website on May 27, HKC intends to invest in Bole City, Xinjiang Uygur Autonomous Region, to build a complete LCD project, which will have an annual output of 5 million sets of complete machines. This will include conference machines, monitors, science and education, televisions, car screens, notebooks, cell phones, splicing screens, and more.

A wide variety of hkc options are available to you, such as others, call center and on-line technical support and return and replacement.You can also choose from led, lcd and widescreen hkc,As well as from new, {2}, and {3}. and whether hkc is curved, not curved, or dual screens.

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"TCL"s Panel Manufacturer CSOT Commences Production of High Generation Panel Modules". www.businesswire.com. June 14, 2018. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

In the first half with Korea samsung factory display (SDC) out of the supply and acquisition of boe display cec panda, display pattern of supply will be also changed accordingly, overall performance for the group of the market share declined slightly, samsung display and cec panda share contract, the other panel factory present different amplitude share is growing, the following detailed analysis of each panel makers.

● BOE shipped 24.52 million units in the first half, up 24 percent from a year earlier. As the leading panel supplier, in addition to aggressive product specification upgrades, the display also allocated more capacity in the second quarter, and supply increases will continue in the third quarter. After the acquisition of Panda, its market share in the first half of the year increased by 5% to 31%. The internal supply is led by 23.8 inches and 27 inches, ranking first in the market shipment of its corresponding size. The shipment in the first half of the year was in line with its annual plan, and the size of 27 inches and above increased significantly.

● Huike (HKC) shipped 4.38m units, a significant increase from last year when the initial supply of display panels was added. The production capacity of 8.6 generation line was planned to expand steadily throughout the year. Thanks to the active production expansion, the market share reached 5% in the first half of the year. The current size layout is relatively single, the second half of the esports and widescreen have incremental planning, with the gradual implementation of the planning, in the market segment will also occupy a place.

● Samsung Display (SDC) shipped 1.2 million units in the first half of the year, and supplies are running out. Other panel manufacturers have stepped in to fill the gap.

In the second half of the year, due to the weakening demand for TV, the production capacity strategy of panel manufacturers is inclined to IT products. For example, BOE, TCL CSOT and CCE-Panda have planned to increase the production capacity allocation of display. The backward panel factory HKC will continue to expand its production in the second half of the year. Factory production capacity is also a small increase in stability, superposition of supply material relief, each panel factory be able to release the backlog of semi-finished products inventory, expect the second half of the display panel shipment will expand scale growth, the shipment is expected in the third quarter of 43.43 million, in the fourth quarter shipment can reach more than 45 million pieces, in the second half of the shipment year-on-year growth of 1.9%, rose 12.1%.

Chinese display panel makers are expected to shift some of their liquid crystal display (LCD) TV lines for those of monitors, according to market research firm TrendForce.

This was due to their 10.5-generation TV LCD lines increasing in operations __ the previous 8.5 and 8.6-generation TV LCD lines will be shifted to monitor LCD lines.

TV panel supply was insufficient during the second half of 2020 due to the COVID-19 pandemic and Samsung Display halting LCD panel production but Chinese companies will maintain their plan to shift some of their TV panel lines for those for IT, the research firm said.

CSOT and HKC will secure market shares previously controlled by Samsung Display, TrendForce said. BOE was the leader in IT panels with CSOT and HKC following it.

CSOT will increase its monitor panel production capacity with the acquisition of Samsung Display’s 8.5-generation factory in Suzhou. CSOT has competence in VA panels but was weak in IPS, TrendForce noted.

HKC has three 8.6-generation fabs in Chongqing, Chuzhou, and Mianyang. The company has both IPS and VA technologies but lacks experience in producing curved VA panels, the research firm said.

COST is aiming to expand in the premium and mid-tier LTPS notebook panel market. It will need to compete with Samsung Display’s OLED panels in this segment. CSOT is expanding notebook panel shipment to offset the fall in orders for smartphone panels from Huawei due to US sanctions.

HKC will focus on mid- to low-tier notebook market. TrendForce believes it will take time for the company to gain a meaningful market share in the market.

There are various panel technologies. Each has its own specific features - viewing angles, color reproduction, response time, brightness/contrast, production cost, etc. The image quality depends directly on the type of the display panel used.VA

The most widely used panels are those with 6, 8, and 10 bits for each of the RGB components of the pixel. They provide 18-, 24-, and 30-bit color, respectively.8 bits (6 bits + FRC)

Frame Rate Control (FRC) is a method, which allows the pixels to show more color tones. With quick cyclic switching between different color tones, an illusion for a new intermediate color tone is created. For example, by using FRC, a 6-bit display panel is able to show 16.7 millioin colors, which are typical for 8-bit display panels, and not the standard 262200 colors, instead. There are different FRC algorithms.Yes

The maximum number of colors, which the display is able to reproduce, depends on the type of the panel in use and color enhancing technologies like FRC.16777216 colors

The backlight is the source of light of the LCD display panels. The type of backlight determines the image quality and the color space of the display. There are various backlights such as CCFL, LED, WLED, RGB-LED, and etc.W-LED

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey