difference between lcd touch screen digitizer quotation

• Perform highly diversified duties to install and maintain electrical apparatus on production machines and any other facility equipment (Screen Print, Punch Press, Steel Rule Die, Automated Machines, Turret, Laser Cutting Machines, etc.).

LCD (liquid crystal display) is the technology used for displays in notebook and other automated industry computers. It is also used in screens for mobile devices, such as laptops, tablets, and smartphones.

Like light-emitting diode (LED) and gas-plasma technologies, LCDs allow displays to be much thinner than cathode ray tube (CRT) technology. LCDs consume much less power than LED and gas-display displays because they work on the principle of blocking light rather than emitting it.

Each LCD touch screen monitor contains a matrix of pixels that display the image on the screen. Early LCDs screen had passive-matrix screens, which controlled individual pixels by sending a charge to their row and column. Since a limited number of electrical charges could be sent each second, passive-matrix screens were known for appearing blurry when images moved quickly on the screen.

Modern LCDs display typically use active-matrix technology, which contains thin film transistors, or TFTs touch screen. These transistors include capacitors that enable individual pixels to "actively" retain their charge. Therefore, the active-matrix LCDs touch panel are more efficient and appear more responsive than passive-matrix displays.

The backlight in liquid crystal display provides an even light source behind the LCD screen. This light is polarized, meaning only half of the light shines through to the liquid crystal layer.

The touchscreen panel a display device that senses physical touch by a person’s hands or fingers, or by a device such as a stylus, and then performs actions based on the location of the touch as well as the number of touches.

Touch screen glass can be quite useful as an alternative to a mouse or keyboard for navigating a graphical user interface. Touch screens are used on a variety of devices such as computer and laptop displays, smartphones, tablets, cash registers, and information kiosks.

A touch-screen digitizer is one piece in a multilayered "sandwich." In modern devices, the screen that produces the images is found at the bottom layer; the digitizer is a transparent sheet that occupies a middle layer on top of the screen, and a thin sheet of hard, protective glass forms the top layer.

Touching the screen triggers touch sensors immediately under your fingertip; a specialized electronic circuit receives signals from these sensors and converts them into a specific location on the screen as X and Y coordinates. The circuit sends the location to software that interprets the touch and location according to the app you"re using.

For example, when you dial a phone number, your fingers touch the numbers on a virtual keypad on the phone"s screen. The software compares the locations touched against the keypad and generates a phone number one digit at a time.

Touch Screen Glass– The bottom layer is the ITO glass, typically thickness is between 1 and 3 millimetre. If you drop your device, the cracked glass ends up resembling an elaborate spiderweb.

Digitizer – The digitizer is located above the glass screen. It is the electrical force that senses and responds to touch. When you tap your fingertip or swipe it across the screen, the mere touch acts as data input to the device’s center. If your device fails to respond to touch, it’s time for a new digitizer.

The touch screen digitizer is an electrical mechanism that is fused with the glass screen; so if you need to replace the digitizer, you’ll have to replace the glass, too, and vice versa.

Touch Screen Panel- Touchscreen is the thin transparent layer of plastic, which reads the signal from the touch and transports it to the processing unit. It is the part that you can touch without disassembling the device.

LCD – LCD display is an acronym for liquid crystal display. The LCD is the visual component underneath the glass that displays the image on the screen. You can not get to the LCD without taking the device apart first.

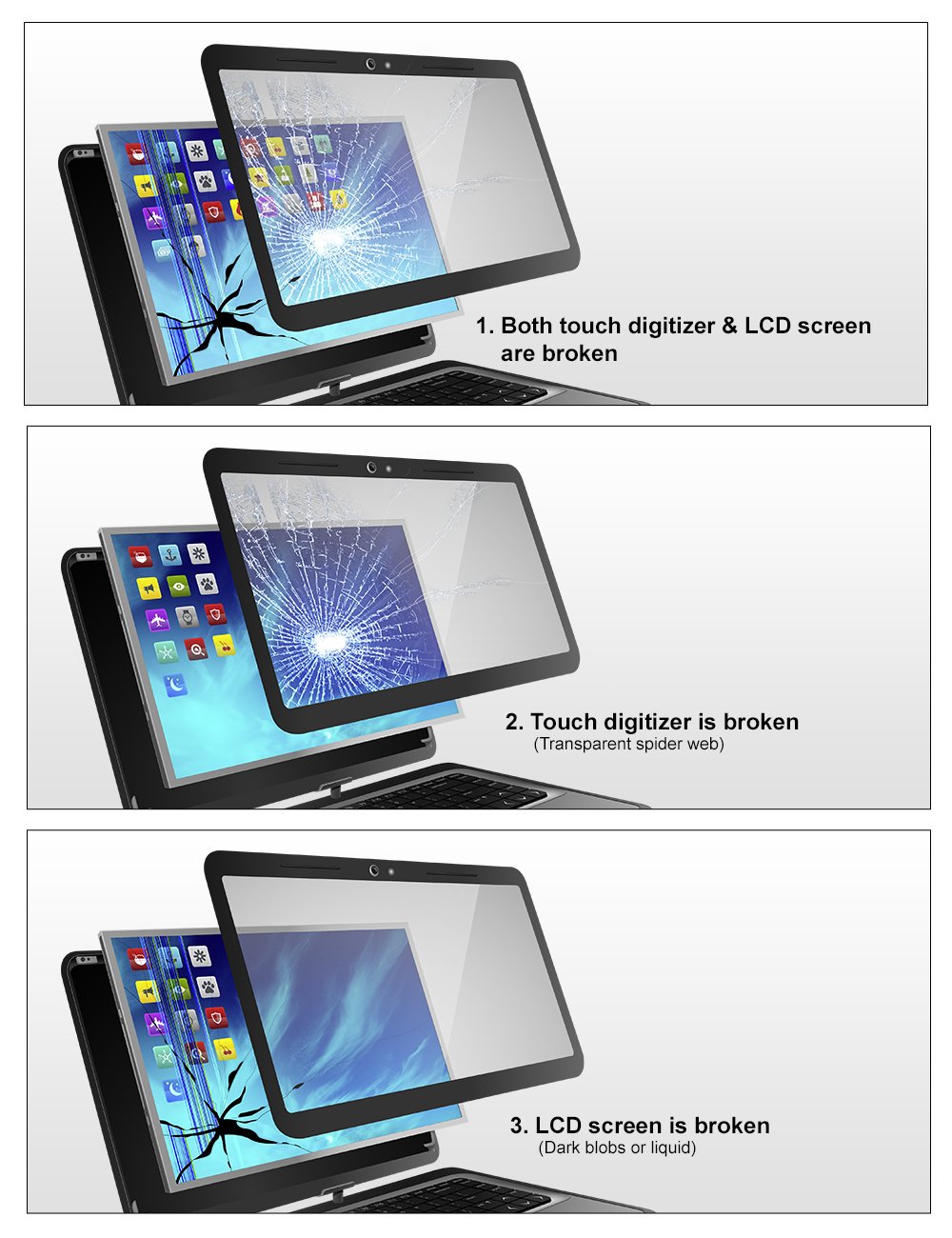

Most of the time people don’t know the difference between a touchscreen and a LCD screen. When there are dark black blobs on your screen, it’s not because the display screen is damaged, it is the caused due to the damage in the LCD of your mobile phone whereas when there are cracks on your screen its mainly due to the damaged caused to your touchscreen and as compared to an LCD screen it is easier to fix as you only need to replace the display screen of you mobile phone.

An LCD is the part of a phone that displays the image we see on screen. It is the layer which produces and displays the image, therefore if the LCD is damaged you can still use the touchscreen although the panel would have either the aforementioned dark black blobs or the spider web type dark cracks on the display or both it would still function normally. To repair the LCD, a technician would have to pull apart the phone part by part to reach the LCD and assess the damage done which is not required for a touch screen. LCD, which is a liquid crystal display, is widely used in mobile phones as it uses low power and produces good quality images.

The images which are displayed in a LCD are produced through small elements which are called pixels. Pixel is a word everybody is familiar with but what exactly is a pixel? Pixel is made up of a layer of molecules lined up between two transparent electrodes and polarizing filters. There are several types of LCDs, reflective, transmissive and transflective, each has a specific function. A transmissive LCD can produce a clear and good quality image in low light while Reflective screen can produce a very good image in bright light. The transflective screen as the name indicates can produce a good quality image in both conditions, hence it is a mixture of both transmissive and reflective LCD.

Touchscreen is now a part of almost every digital gadget in the 21st century. From mobile phones and laptops to TVs and switch boards, it is now used almost everywhere your eyes fall on. But what exactly is a touchscreen? A touchscreen is basically a device which allows us to directly interact by using our fingers or a stylus. The stylus is a special kind of pen whose tip is covered with a unique coating which allows it to directly interact with the computer. We can use one finger or multiple gestures to interact with a touchscreen device. It doesn’t require a mouse or any alternative device such as a keyboard for navigation. A touchscreen can use several methods to sense our finger, it can use a grid which consists of infrared beams or it can use touch sensitive units to sense our gestures.

With touchscreen, there are several gestures that we can make which would be quite tiresome if we use a mouse or a keyboard like when we double tap the screen while using gallery or while reading a pdf file the screen tends to zoom in and when we double tap again it zooms out similarly we can easily drag different icons and swipe to scroll upwards, downwards even sideways. A touch screen is also referred to as an input device as it takes input directly from the user. The computers require a mouse which makes them hard to use but touchscreen is very simple to use as you are directly interacting with the icons, it is also cost efficient to manufacture touchscreen as it does not require buttons for each icon.

In conclusion it can be said that LCD and Touch Screen have very different functions which makes them different from each other. One deals with production of images and the other deals with receiving the input from the user directly. Although they are different, they are equally important for a digital device.

Your iPod, iPhone and tabletare commonly known to have three key components: a glass panel, digitizer (aka touch screen) and LCD. What are the differences? Let’s clearly define these layers:

Digitizer –The digitizer is located just under the glass screen. It is the electrical force that senses and responds to touch. When you tap your fingertip or swipe it across the screen, the mere touch acts as data input to the device’s center. If your device fails to respond to touch, it’s time for a new digitizer. The digitizer is an electrical mechanism that is fused with the glass screen; so if you need to replace the digitizer, you’ll have to replace the glass, too, and vice versa. UEGoffers a Front Glass (Digitizer Touch Screen) Repair Service on tablets.

Touch Screen – The term touch screen is interchangeable with the term digitizer. You’ll often see the combined terms Digitizer Touch Screen offered as a repair service.

LCD – LCD is an acronym for liquid crystal display. The LCD is the visual component underneath the glass that displays the image on the screen. UEGoffers LCD repairs on tablets, iPhonesand iPods.

When you drop your device, you may immediately pick it up and try to turn it on to see what happened. Sometimes, the screen will be completely cracked, but there’s still a display. Other times, the screen is cracked and there is no display. A few different things happen when an iPad or iPhone drops. Understanding what happens to the screen can help you know what type of repair you need.

When you drop your iPad or iPhone and the screen doesn’t come on (there is no display) or the display is distorted, it’s likely the LCD screen is broken. This screen has everything to do with seeing what you love about your device. Videos, games, email, and everything else depends on your LCD screen.

Sometimes, you may be able to see the screen, but when you touch it to do something, it won’t react to your touch. This is usually because the digitizer is damaged. Many times, this happens even when you can’t see a crack on your device. This is why many people don’t think they need a screen replacement, and actually, in some cases they still don’t need it. Other components may be damaged that cause the touch not to work, but when those are all working okay, it’s the screen.

There are some cases in which both the LCD and digitizer need to be replaced. If there’s no display or a distorted one AND there’s no touch response, the LCD and digitizer need to be replaced. This is usually what people need when they turn to us with a shattered iPad or iPhone.

If you still don’t know if you should have a LCD or digitizer repair, contact our certified technicians. They can look at your device for free to provide you a repair quote. You can trust our technicians to give you the truth, so you can save money when you may not need both screens replaced. If you do, you can be sure that you’ll receive a quality repair with quality parts.

On most touchscreens there are usually two layers that make up just the digitizer. The glass on top that you touch and the actual digitizer sheet which consists of the touch matrix circuitry. The digitizer sheet is adhered to the glass so it often appears to be one piece. So you where correct to assume glass cover, digitizer and then lcd. The digitizer sheet and glass have a small gap that has an adhesive in it. On both the glass(bottom) and digitizer(top) is a transparent metallic conductive coating which is usually indium tin oxide. The human touch is conductive which allows for the electical sensors in the digitizer and glass sheets to sense the touch at a specific location.

Some of the newest technology such as Super AMOLED is able to get away from the two conductive sheets and has the touch sensors built into only one sheet, so these touchscreens would be an exception. So most forms of touchscreens consist of three or more layers.

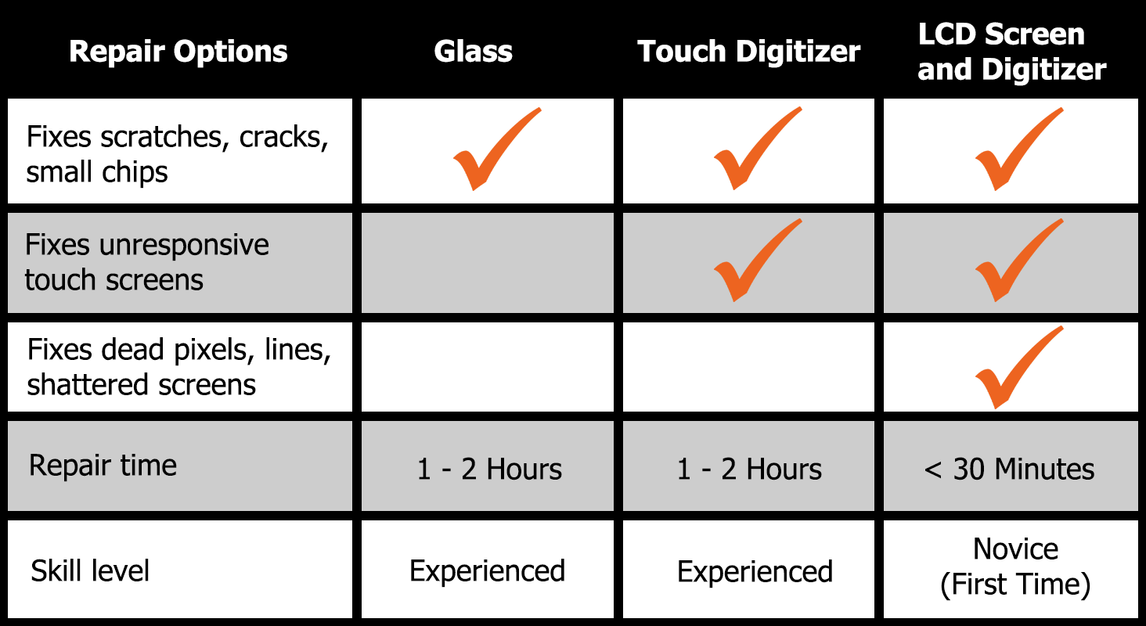

The easiest repair for mobile phones to complete is the LCD assembly replacement. This repair takes less than an hour and requires the least amount of technical ability. For some devices the LCD assembly can be replaced simply by removing a few screws and cables. Also, as the assembly includes the glass, touch screen and the LCD, you can be confident it will fix all common screen issues.

For iPad and other tablets, if the screen parts aren"t fused, then you can do a glass touch digitizer only replacement. Otherwise, the full assembly is the easiest repair. Either way, it usually takes 1-2 hours.

While it can be significantly cheaper repair, If the screen parts are fused, the screens must be heated to loosen the adhesive between the screen and LCD and you need special equipment. This includes all iPhone and most other mobile phones and some iPads or tablets. A heat gun or hair dryer can be used for this. The screen is then gently and very slowly pried apart from LCD. DIYers need to use care to insure the LCD is not damaged in the process.

Tip: Transferring the home button on an iPhone or an iPad can be the most tricky part. It takes a little patience and heat. You can purchase screens that have the home button pre-installed (along with other small parts) and this is the easiest of all repair. This can take 15-30 minutes. However, Touch ID function only works with the original home button so you have to transfer if you want to retain it. Note: some of the iPads don"t have a screen replacement option that includes the home button like the iPad Pro and newer iPad Mini. iPad 1st Gen to 9th Gen screens, have a home button pre-installed option.

Simply put, the digitizer is your iPhone’s touchscreen. In more detail, the digitizer is a glass panel that converts your touch into signals that your iPhone uses to do what you want. The digitizer is not actually the glass that you touch; it is underneath the top (protective) layer of glass. That’s why, generally, when you break the glass on your iPhone, your touchscreen still works. Check out Cell Phone City’s iPhone page for a quote to get your iPhone screen replaced.

On older iPhone models (4S and older) the digitizer was actually attached directly to the top layer of glass. That engineering (glass on glass) resulted in more cases of the touchscreen malfunctioning when the iPhone screen was broken. Newer iPhone models (iPhone 5 and newer) are built with the digitizer attached to the LED screen instead, leaving a few more layers on construction in between the top glass and the digitizer. This new construction offers better touch response, as well as some extra protection to the digitizer.

Most new aftermarket iPhone replacement screens have the old digitizer technology in them to cut down on costs. If you look at your iPhone screen replacement and it seems shinier than the original screen that cracked. Your eyes may not be playing tricks on you. When the digitizer is attached to the top glass it results in much more glare. The new replacement screens are responding well to touch, but do have subtle differences when compared to premium replacement and OEM screens. If you are having problems with the digitizer/touchscreen on your iPhone, contact Cell Phone City for a free inspection. We can let you know which kind of screen you have, and what can be done to improve the performance.

A surface capacitive touchscreen uses a transparent layer of conductive film overlaid onto a glass sublayer. A protective layer is then applied to the conductive film. Voltage is applied to the electrodes on the four corners of the glass sublayer to generate a uniform electric field. When a conductor touches the screen, current flows from the electrodes to the conductor. The location of the conductor is then calculated based on the activity of the currents. Surface capacitive touchscreens are often used for large screen panels.

Projected capacitive touchscreens are extremely precise and quick to respond and are typically found on smaller devices such as iPhones, iPod touches, or iPads. Unlike the surface capacitive touchscreens, which use four electrodes and a transparent conductive film, the projected capacitive touchscreens use a vast amount of transparent electrodes arranged in a specific pattern and on two separate layers. When a conductor moves near the screen, the electrical field between the electrodes changes, and sensors can instantly identify the location on the screen. Projected capacitive touchscreens can accurately register multi-touch events.

You interact with a touch screen monitor constantly throughout your daily life. You will see them in cell phones, ATM’s, kiosks, ticket vending machines, manufacturing plants and more. All of these use touch panels to enable the user to interact with a computer or device without the use of a keyboard or mouse. But did you know there are several uniquely different types of Touch Screens? The five most common types of touch screen are: 5-Wire Resistive, Surface Capacitive touch, Projected Capacitive (P-Cap), SAW (Surface Acoustic Wave), and IR (Infrared).

We are often asked “How does a touch screen monitor work?” A touch screen basically replaces the functionality of a keyboard and mouse. Below is a basic description of 5 types of touch screen monitor technology. The advantages and disadvantages of type of touch screen will help you decide which type touchscreen is most appropriate for your needs:

5-Wire Resistive Touch is the most widely touch technology in use today. A resistive touch screen monitor is composed of a glass panel and a film screen, each covered with a thin metallic layer, separated by a narrow gap. When a user touches the screen, the two metallic layers make contact, resulting in electrical flow. The point of contact is detected by this change in voltage.

Surface Capacitive touch screen is the second most popular type of touch screens on the market. In a surface capacitive touch screen monitor, a transparent electrode layer is placed on top of a glass panel. This is then covered by a protective cover. When an exposed finger touches the monitor screen, it reacts to the static electrical capacity of the human body. Some of the electrical charge transfers from the screen to the user. This decrease in capacitance is detected by sensors located at the four corners of the screen, allowing the controller to determine the touch point. Surface capacitive touch screens can only be activated by the touch of human skin or a stylus holding an electrical charge.

Projected Capacitive (P-Cap) is similar to Surface Capacitive, but it offers two primary advantages. First, in addition to a bare finger, it can also be activated with surgical gloves or thin cotton gloves. Secondly, P-Cap enables multi-touch activation (simultaneous input from two or more fingers). A projected capacitive touch screen is composed of a sheet of glass with embedded transparent electrode films and an IC chip. This creates a three dimensional electrostatic field. When a finger comes into contact with the screen, the ratios of the electrical currents change and the computer is able to detect the touch points. All our P-Cap touch screens feature a Zero-Bezel enclosure.

SAW (Surface Acoustic Wave) touch screen monitors utilize a series of piezoelectric transducers and receivers. These are positioned along the sides of the monitor’s glass plate to create an invisible grid of ultrasonic waves on the surface. When the panel is touched, a portion of the wave is absorbed. This allows the receiving transducer to locate the touch point and send this data to the computer. SAW monitors can be activated by a finger, gloved hand, or soft-tip stylus. SAW monitors offer easy use and high visibility.

IR (Infrared) type touch screen monitors do not overlay the display with an additional screen or screen sandwich. Instead, infrared monitors use IR emitters and receivers to create an invisible grid of light beams across the screen. This ensures the best possible image quality. When an object interrupts the invisible infrared light beam, the sensors are able to locate the touch point. The X and Y coordinates are then sent to the controller.

We hope you found these touch screen basics useful. TRU-Vu provides industrial touch screen monitors in a wide range of sizes and configurations. This includes UL60601-1 Medical touch screens, Sunlight Readable touch screens,Open Frame touch screens, Waterproof touch screens and many custom touch screen designs. You can learn more HERE or call us at 847-259-2344. To address safety and hygiene concerns, see our article on “Touch Screen Cleaning and Disinfecting“.

LCD touch panel, also known as touch panel, is an inductive LCD device that can receive touch and other input signals. When touching the graphic buttons on the screen, the tactile feedback system on the screen can drive various connection devices according to the pre-programmed program, which can replace the mechanical button panel and create a vivid audio and video effect through the LCD screen.

The working part of the LCD touch screen is generally composed of three parts: two transparent resistive conductor layers, an isolation layer between the two conductor layers, and electrodes.

For operational convenience, people use a touch screen instead of a mouse or keyboard. When working, we must first touch the touch screen installed in the front of the display with a finger or other object, and then the system is positioned according to the location of the finger touch icon or menu to select the information input.

LCD touch screen consists of touch detection components and touch screen controller; touch detection components installed in front of the monitor screen, used to detect the user’s touch location, accepted and sent to the touch screen controller.

The main role of the LCD touch screen controller is to receive touch information from the touch point detection device, and convert it into contact coordinates, and then sent to the CPU, it can also receive commands from the CPU and to execute.

Plastic doesn"t shatter or otherwise fall apart, unless you try to cut or burn it on purpose. It can also be made matte, which makes the screen much more readable in presence of reflections and glares. Since plastic doesn"t have to be hard, it can be made thinner than glass, improving touch sensitivity.

Unfortunately, it looks cheap even before it is scratched (and plain terrible after), so you can"t make big money selling phones with plastic screens. Worse, people will carry these cheap-looking phones for ages (because the screen won"t shatter), projecting that cheap-looking and outdated image of your brand everywhere they go. So you either go out of business, or switch to glass like everyone else.

TFT LCD monitors are susceptible to glare and reflection from direct sunlight or high-bright applications. In almost all TFT LCDs there is an air gap between the TFT panel and the cover lens. Having an air gap causes repeat refraction between each component level of the display when in high-brightness installations. Reducing the reflection inside these components with optical bonding gives greater contrast and makes the screen more viewable in outdoor or high bright conditions without the need to increase the brightness of the screen itself.

Optical bonding is a process where a layer of resin is applied between the glass or touchscreen and TFT LCD TFT panel of a monitor, bonding them to make a solid laminate with no gaps or pockets of air. When choosing a screen for any project, you should evaluate the environment and operating conditions the screen will have to endure. Industrial grade screens and panel PCs are made rugged with all types of features available to withstand any type of application. One such feature available to consider is optical bonding.

When LCD displays are manufactured, including touchscreens, the front glass of the screen is layered onto the LCD module. This doesn’t present a problem in standard viewing environments, however in certain conditions, like with outdoor placement, the tiny gap between the 2 layers can impair viewing performance.

The display from an non-optically bonded monitor is created by the light of the LCD reflecting through the gap and then the outer glass of the screen. The light is interrupted and bends when it passes through the gap and glass of the screen and some of the light is actually reflected back to the LCD module, this is called refraction. This refraction through the layers impairs the intensity and clarity of the end image and thus lowers brightness and readability. By bonding the LCD module and glass together you remove the interruptions and chances for the light to be reflected back. More light gets through to the surface of the screen and therefore the image is brighter.

The same principle is applied when an external source of light hits the screen. With an non-bonded screen, the gap between the glass and LCD module creates opportunities for refraction which bounces external light back off the screen to the viewer as glare. When bonded together the light passes through the bonded layers and is absorbed somewhat into the screen. Optical bonding is therefore important in making screens sunlight readable.

The most obvious benefit to adding a resin bonding layer between the glass and LCD module is that it physically prevents dust and liquid ingress from getting between the two. The quality of manufacturing means that dust and water isn’t a big problem for screens in standard environments. What can be a problem however is condensation getting between the glass and LCD panel in environments with wide temperature ranges or fluctuating humidity. Condensation can cause screens to become foggy from moisture that penetrates the air gap. Again, the physical filling of the gap prevents this problem from arising. Optical bonding should therefore be considered for any outdoor application as well as indoor applications where consistent temperatures aren’t maintained.

A touch monitor with optical bonding maintains a more accurate touch response because the pressure is maintained through the substrate, rather than being delayed by a gap.

Assured Systems are partnered with design and manufacturers industrial displays with optically bonded touch screens request, their displays or touchscreen displays can be optically bonded to remove the air gap inside the screen. If you require an optically bonded display or optically bonded panel PC please get in touch with Assured Systems.

In these Conditions of Sale: “The Company” means Require IT Ltd “The Buyer” means the person, firm or Company ordering or buying goods from the Company. “The Goods” mean the Goods the subject matter of the relevant order for sale. “Working Days” means any other day other than a Saturday, Sunday or Bank Holiday. “Calendar Day” means any day of the year. “Conditions” this document and (unless the context other requires) includes any special terms and conditions agreed in writing between the Buyer and Seller. “Date” stipulated in the Buyers order and accepted by the Seller. “Item” means the goods (including any instalment of the goods parts for them) which the Seller is to supply in accordance with these Conditions.

No contract in respect of the Goods between the Company and the Buyer shall exist until the Buyer’s order has been accepted by the Company. In the event that the Buyers order seeks to make the sale subject to terms different from these conditions, acceptance of the Buyers order by the Company (whether or not such acceptance is accepted by formal order acknowledgement) shall be deemed to be a fresh offer by the Company on the basis of these conditions. In which event (unless these conditions are accepted by the Buyer prior to delivery) acceptance of delivery of the Goods by the Buyer shall constitute acceptance of the Company’s offer and the contract of Sale shall be formed at that moment. No conditions or terms stipulated in any other communications or document shall vary or annul any of these conditions except insofar as the same are expressly consented to in writing by the Company. By clicking to buy any of our items on means the Buyer has agreed with our Terms and Conditions.

The Company and the Buyer expressly agree that until the Company has been paid in full for the Goods comprised in this or any other sales contract between them and all outstanding amounts due to the Company from the Buyer or any associated or subsidiary or holding company of the Buyer or from any Director or shareholder of the Buyer or any other such company.

In the event of such disposition the Buyer or its Director(s) (if a Limited Company) has the fiduciary duty to account to the Company for proceeds thereof but may retain therefrom an excess of such proceeds over the amount outstanding to the Company under this or any other sales contract between them and for all outstanding amounts due to the Company from the Buyer or any associated or subsidiary or holding Company of the Buyer or from any Director or shareholder of the Buyer or any other such Company.

The Company takes no responsibility for the fitting of the screen by the Buyer. If the Buyer damages the screen whilst fitting, the responsibility is that of the Buyer.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey