lifetime of lcd displays factory

Responsible for performing installations and repairs (motors, starters, fuses, electrical power to machine etc.) for industrial equipment and machines in order to support the achievement of Nelson-Miller’s business goals and objectives:

• Provide electrical emergency/unscheduled diagnostics, repairs of production equipment during production and performs scheduled electrical maintenance repairs of production equipment during machine service.

Perhaps you’ve wondered how long a digital display lasts. It’s a great question. One quick search on Google will tell you that an LCD panel has a lifespan of about 60,000 hours, which is equivalent to almost seven years.

Of course, LCDs aren’t the only kind of displays. You also have LED, OLED, QLED, ELD, PDP, and MicroLED, plus many other variations. Obviously, that 7-year estimation will not apply across the board. For the sake of ease, let’s just focus on some of the common types of displays that most of us are familiar with.

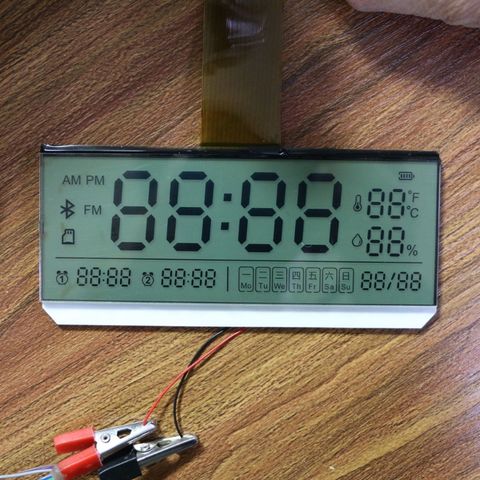

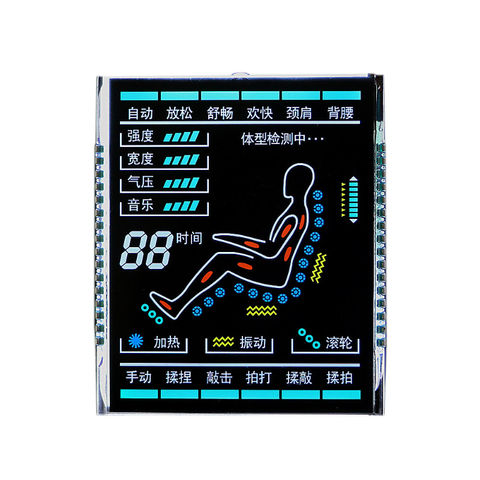

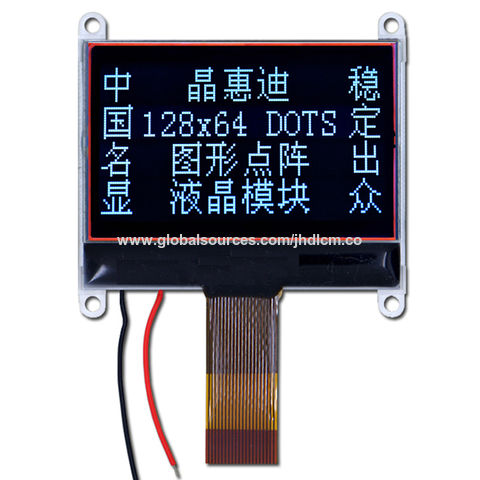

Here’s some LCD alphabet soup: There are LED LCD displays, CFFL LCD displays, LED displays, and more. With all these acronyms, it can get a bit confusing. What"s important to note is whether or not the display uses an LCD panel, and how the LCD panel is illuminated. You can read more about thedifferences between types of LCD and LED signage, but these are the most common types:

LCD displaysgenerate images and colors via a Liquid Crystal Display (LCD) panel, which is not self-emitting and requires an external light source to illuminate the image, typically an LED backlight. Their full name "LED-backlit LCD display" is commonly shortened to "LED displays", which is why they"re often confused with the true LED displays we"ve identified above.

Unfortunately, LED backlights used in LCD displays burn out over time. If used at high or maximum brightness, which is necessary for outdoor applications,an LED backlight will last between 40,000 to 60,000 hours. Or, about 4.5 to 7 years.

OLED stands for Organic Light Emitting Diode. OLED displays differ from common LCD displays in that their pixels are self-illuminating. In other words, there is no LED backlight required to illuminate the the display image; everything occurs within the OLED pixels themselves. According to onearticle from the US Department of Energy,OLED screens have a life expectancy of about 40,000 hours at 25% brightness, and 10,000 hours at full brightness. That equates to about 1 to 4.5 years, which is a much shorter (albeit, brilliant) lifetime than an LCD display.

Perhaps you noticed that the acronym QLED closely resembles the acronym OLED. This is not accidental. QLED is basically Samsung’s original design built to compete with OLED technology. However, the two are not the same. QLED stands for Quantum Light Emitting Diode. While QLED is similar to a regular LED design, it in fact differs by using nanoparticles called “Quantum dots” to achieve its unique brightness and color. Samsung approximates that the lifespan ofQLED panels are likely to last 7-10 years. After that, a user is likely to notice traces of degradation.

MicroLED is an emerging display technology, consisting of small LEDs in tiny arrays within each pixel. This technology goes beyond the offerings of the formerly frontrunning OLEDs, with much darker blacks and more radiant contrast levels. And, unlike OLEDs, MicroLEDs are not organic. They are not as subject to burn-in, and thus, have a longer lifespan than OLEDs. However, they are significantly more expensive - so much, in fact, that they aren’t considered a viable option for the majority of consumers.According to Samsung, the lifespan of its MicroLED panels should last about 100,000 hours, or, roughly 11 years.

PDP stands for Plasma Display Panel, and it refers to displays that use small cells full of plasma. The atoms within the plasma emit light upon being charged by electricity. While PDP is generally considered to offer better colors than LCDs, they consume a lot more power and usually cannot be battery-operated.The average lifespan of the newest generation of PDPs is approximated to be 100,000 hours, or 11 years of continual use.

In some ways,reflective LCD panelsoperate similarly to other LCDs, only they have one key difference - they do not require a backlight. Instead, they rely on ambient light (or sunlight) in order to produce images. This opens the door to some groundbreaking possibilities. The first (and most appreciable) is low power consumption. Reflective displays use up to 95% less energy. Not bad - especially in a world that is continually looking for new ways to go green. Take into consideration the financial implications of this. Lower power means less money spent on operating costs.

Being that reflective displays do not require a backlight (a component that is particularly subject to degradation), and since they do not generate as much heat, it is safe to say that the lifespan of these displays should far exceed that of backlit LCD panels (which was 7 years at the high end). However, being that thisinnovative technologyis relatively new, its actual lifespan is therefore more difficult to estimate -- simply because it has yet to be reached.

There are also a few challenges that can affect reflective displays. For one, they rely on ambient light. On a nice sunny day, these displays perform beautifully and can be easily seen in even the brightest of conditions. This performance wanes as the available ambient light decreases. And, since they do not generate light of their own, they are not designed to be viewed under nighttime or extremely low light conditions (without additional lighting features). In short, their images are visible to the degree that ambient light is present. However, in light of this, side light (and front light) options are being explored.

One company at the front lines of this research isAzumo. Azumo has created a light guide that laminates to the front of a display. It requires 90% less energy than the backlight of a traditional LCD display. This greatly improves the problem of low light visibility otherwise encountered, and keeps reflective displays in the same low energy consumption ballpark. One issue, however, is that Azumo currently only offers its light guides for smaller-sized units. If you happen to want this feature applied to a display that is over 10” diagonally, then you’re still on the search for a solution.

Other “pioneer companies” are at the frontier of this research as well, and many are already innovating new solutions to increase the viability of reflective technology - both in their low light visibility and in the screen sizes they are available in. Due to the huge potential offered by reflective technology, it is fair to assume that we will see even greater enhancements to it in the very near future.

One other factor to consider regarding reflective technology is its cost. That reflective layer is more costly to manufacture than many of the backlights it replaces, creating a seemingly greater upfront cost for those who are interested in investing in energy-efficient signage. However, these initial price points are quickly justified as buyers will recognize the significantly lower operating costs and increased longevity (not even including replacement costs of other “expired” displays) that comes with their purchase of reflective display signage. If a backlit LCD panel only lasts 7 years, for example, you’ll have paid for that LCD twice in the period of ten years. A very valid question arises… is that “cheaper” backlight really cheaper? Probably not. It only feels that way at first.

Sun Vision Displayis working hard to create reflective display solutions for the digital signage world. We are currently offering them in 32" and 43" diagonal sizes, with a 55” size in development. These displays are built formany environments. We are thrilled to be bringing such innovative solutions to the market.

If you have any questions, or if you would like to talk to a representative about how our solutions might work for you, please don’t hesitate to contact us. Simply scroll down to the bottom of the page to our form, and we’ll get back to you in a timely manner. We look forward to the possibility ofworking with you!

How long will your LED display last? In nearly every industry, from retail businesses to concert halls to corporate centers, decision makers need to evaluate the return on investment (ROI) of their LED signage. In most cases, potential buyers go straight to the obvious place: the LED manufacturer’s spec sheet. The industry standard for LED lifespan is 100,000 hours, or about 10 years, and most people assume that’s how long their display will last. But it’s not quite that simple.

“The reality is, your screen can often last significantly longer than 100,000 hours,” says Kevin Izatt, a senior product manager in Samsung’s Display division. “We’ve had displays that have been up for 15-plus years with more than adequate brightness. Because the diode is actually only one factor in the lifespan of your LED display.”

The biggest contributor to diode degradation is heat. As you increase a diode’s brightness, it produces more heat. Your display’s physical environment also contributes to the temperature of the diodes, especially for outdoor displays.

The quality of your display’s power supply — and how hard it drives the diodes — can have a significant impact on your screen’s lifespan. The other components being powered, such as fans and electrical components, have their own lifespans as well, which are also impacted by the power supply.

“Fans are mechanical; they break down,” explains Izatt. “And similar to your computer, the electrical components don’t last forever. Together, these factors all contribute to the lifespan of an LED display. Looking at just the diode lifespan doesn’t give you the complete story — almost always, another part will go out first.”

“Something like airflow is very important,” says Izatt. “You need a screen that has good cooling, and a design that allows heat to flow out of the back through vents.”

It’s easy to see why: The circuit boards powering the display release heat, and that heat needs to go somewhere. Without a strong design, thermal stress will degrade the life of the display, except for the highest-quality parts — optimal conditions notwithstanding.

“Lots of variations on the color and brightness you use will impact the life of the diode,” explains Izatt. “For instance, black doesn’t use any of the diodes at all. And if your content is using lots of gray, that’s a much lower power output than white.”

To help businesses transition from LCD to longer-lasting LED signage, Samsung has launched a trade-in program. Samsung will come on site to remove your existing display and provide a discount on a new LED bundle kit.

Traded-in LCD displays that are still operating will be refurbished and resold, and your business will receive a cash rebate. Nonworking displays will be recycled and their parts reused.

You can’t rely on the number on the diode spec sheet; the lifespan of your LED display depends on many more factors. “Overall quality has a tremendous impact on the life of the display that diode specs just don’t take into account,” says Izatt. Your best bet is to look at the purchase holistically and invest in a top-tier product.

As you plan your LED signage rollout — or an upgrade — learn how to configure and tailor your screens’ real-time messaging with an integrated CMS in thisfree guide. And if you haven’t decided what kind of display is best suited to your current project, compare all ofSamsung’s LED displays.

One of the most difficult things about digital signage is evaluating the cost of a deployment and the true return on any investment, especially for advertisers. Unlike other advertising, where accurate audience figures, demographics and other feedback can be delivered to advertisers, digital signage success can be vague at the very best.

And when it comes to the cost of deployment, not are only are there the initial costs of the digital signage screen, networking, installation, software management and developing content, but there can be a lot of hidden costs too: Repair, maintenance and replacing screens are often areas not thought about during initial proposals for projects, but these costs can soon mount up.

All screens, whether commercial grade or consumer grade will have a limited lifespan. While the old CRT TVs could often to run for decades (well my trusty portable did, anyway) before expiring, the same cannot be said for modern LCDs and plasmas.

The lifespan of a modern flatscreen is measured by a half-life, when the screen’s dims to half its original brightness. With LCDs, while the actually display itself could perhaps run for decades, the TV’s half-life is governed by the backlight. And depending on what system provides the backlight (LEDs seem to have the longest life), a typical LCD display will last between 30,000-80,000 hours before the screen reaches its half-life, with commercial grade screens at the higher end.

Plasmas have less longevity with the plasma/gases powering the image decaying over time, providing a half-life perhaps half of that of LCDs, which is one of the reasons that plasmas are utilized less than LCDs for digital signage.

Unlike consumer TVs, which operate for a limited period each day, depending on how much programming we watch, digital signage screens are typically left on 24 hours a day. And unlike consumer TVs, which operate in the warmth and comfort of our homes, the locations where digital signage has to operate can affect life-span too.

All screens are designed to operate under set parameters. Variable temperatures, pollution, bright light, exposure to the elements and the shock of impacts, all have a dramatic effect on a screen’s life, severely shortening the intended life-span; however, by minimizing these variables and keeping the screen as near to the manufacturers optimum conditions as possible will ensure you get the most out of your screen; saving money in the regularity a screen has to be replaced.

LCD enclosures are commonly used for outdoor digital signage and information screens in drafty concourses and manufacturing facilities as they weatherproofing and a ruggedness essential in these conditions; however, LCD enclosures also contain environmental systems such as air-filters, cooling fans, heaters (in cold areas), anti-glare screens—all ensuring the internal conditions of the LCD enclosure are the optimum for a screen to operate in, helping to the maximum the life-span of the screen, and ultimately saving money.

You may still remember the first TV that came into your home, probably fitted with a cathode ray tube. At the time, the idea of flat screens was almost a science fiction thing, and probably none of the people in the house thought that the appliance had an expiry date. Today, however, we know from experience that this is not the case, and that any gadget is designed to last, at most, as long as the technology on which it is based. So that you don’t have to replace your monitor prematurely, we would like to offer these tips to increase your LED display’s lifespan.

These recommendations are especially useful for professionals and organizations that decide to include outdoor advertising in their business strategy, either by using giant LED screens, digital sign boards, LED Smart City panels or other similar products. By following some small guidelines, not only will the initial investment be more profitable, but this also helps to improve the technical quality of the campaign and, ultimately, the company’s corporate image.

However, before getting into the subject, it is important to point out that we are dealing with a technology that is too recent to talk about complete life cycles. Even so, it is estimated that the average lifespan of an LED display is between 60,000 and 100,000 hours, depending on the use of the screen. Thus, in the best-case scenario, this would be equivalent to using an LED screen for six hours a day for 45 years.

Another aspect that must be made clear is that, when referring to lifespan, we always think of the main component of the screen: the panel, despite the fact that there are other elements that can negatively affect the operation of an LED display. Without going any further, it is much more likely that a circuit will be damaged before the panel is (ignoring, of course, the logical loss of brightness due to the passage of time and the appearance of dead pixels).

Likewise, the replacement of an LED display does not have to occur because it no longer works: its performance may no longer be optimal, which can compromise the achievement of the goals set in any given marketing campaign.

We know that the ideal location for an outdoor LED display, at least from an advertisement point of view, will not always coincide with the place that has the best climatic and atmospheric conditions for the conservation of your display. In any case, and although our outdoor LED displays are equipped with rain protection, a rather dry climate with a moderate number of hours of sunshine is more conducive to the conservation of any LED display than one that is rainier and sunnier. As for indoor LED displays, avoid placing them in rooms with humidity or where they tend to accumulate dust. In this way, you can better protect it from environmental conditions.

If you are installing indoor LED displays in your store window, make sure that the sunlight does not hit the display directly, as this would force you to adjust the contrast and brightness to very high levels. While Visual LED displays always ensure perfect visibility regardless of environmental brightness, forcing these settings would increase power consumption and therefore could shorten the life of the monitor. Keep this in mind when dealing with window display dressing in your business.

This recommendation is another of the most important tips to extend the life of your screen. If the screen is not going to be hung on the wall, itshould be placed on a surface that is resistant and not tilted. To select the ideal distance for users, multiply the size of the TV by four and place it at the user’s eye level, as it can make them lose interest if they have to force their neck to view the screen properly. Otherwise, it could cause discomfort.

Although there are many users who mistake them, the truth is that these are two different elements. Surge suppressors are devices designed to counteract short voltage surges, equivalent to a network cycle. These elements can be accompanied by other protections, such as filters against electromagnetic interference and electrical noise. When the duration of the surge is prolonged, or frequently repeated, the suppressor may be damaged and stop working, so this is not a suitable solution for regulating the voltage.

Voltage regulators, in turn, counteract voltage variations with a duration of more than one network cycle, i.e. over 16.6 milliseconds. In this way, a voltage with great stability and without fluctuations is achieved, even if there are increases and decreases in the voltage on the grid. Thus, in short, the voltage regulator provides a constant level of voltage, essential for the proper functioning of any electrical device.

Therefore, both the surge suppressor and the voltage regulator are complementary and equally necessary, so it is not recommended to use both of them. Currently, there are companies that sell them both integrated in a single regulator technology (or electronic regulator).

To extend your LED display’s lifespan, it is essential to always use products with a suitable formulation for the external components of the display. In saying this, we are not just referring to chemical products, but also to other products commonly used at home to polish televisions, such as vinegar. When you buy your screen, Visual Led will tell you which products are best suited to remove dirt from your LED display.

It may seem obvious, but this is one of the most common mistakes made by both individuals and companies. In case you need to change the location of your LED displays for shops and shop windows, always hold them at the ends. Obviously, you also have to be careful not to accidentally bang them.

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

Sony produces and sells commercial MicroLED displays called CLEDIS (Crystal-LED Integrated Displays, also called Canvas-LED) in small quantities.video walls.

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"TCL"s Panel Manufacturer CSOT Commences Production of High Generation Panel Modules". www.businesswire.com. June 14, 2018. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

Shilov, Anton. "JOLED Starts Construction of New Printed OLED Facility". www.anandtech.com. Archived from the original on 2019-06-30. Retrieved 2019-06-30.

The estimated backlight lifetime is about 30,000 hours or eight years of use at ten hours per day. (However, lifetime is not guaranteed for eight years.) The lifetime means the time from the initial brightness level to deteriorate 50% in normal operation. EIZO offers a Backlight Saver function so you can use the product for a long period of time.

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

Recently, ‘Liquid crystal display (LCD) vs. organic light-emitting diode (OLED) display: who wins?’ has become a topic of heated debate. In this review, we perform a systematic and comparative study of these two flat panel display technologies. First, we review recent advances in LCDs and OLEDs, including material development, device configuration and system integration. Next we analyze and compare their performances by six key display metrics: response time, contrast ratio, color gamut, lifetime, power efficiency, and panel flexibility. In this section, we focus on two key parameters: motion picture response time (MPRT) and ambient contrast ratio (ACR), which dramatically affect image quality in practical application scenarios. MPRT determines the image blur of a moving picture, and ACR governs the perceived image contrast under ambient lighting conditions. It is intriguing that LCD can achieve comparable or even slightly better MPRT and ACR than OLED, although its response time and contrast ratio are generally perceived to be much inferior to those of OLED. Finally, three future trends are highlighted, including high dynamic range, virtual reality/augmented reality and smart displays with versatile functions.

Display technology has gradually but profoundly shaped the lifestyle of human beings, which is widely recognized as an indispensable part of the modern world

In this review paper, we present recent progress on LCDs and OLEDs regarding materials, device structures to final panel performances. First, in Section II, we briefly describe the device configurations and operation principles of these two technologies. Then, in Section III, we choose six key metrics: response time, contrast ratio, color gamut, lifetime, power efficiency, and panel flexibility, to evaluate LCDs and OLEDs. Their future perspectives are discussed in Section IV, including high dynamic range (HDR), virtual reality/augmented reality (VR/AR) and smart displays with versatile functions.

Liquid crystal (LC) materials do not emit light; therefore, a backlight unit is usually needed (except in reflective displays) to illuminate the display panel. Figure 1 depicts an edge-lit TFT-LCD. The incident LED passes through the light-guide plate and multiple films and is then modulated by the LC layer sandwiched between two crossed polarizers

Schematic diagram of the (a) TN mode, (b) VA mode, (c) IPS mode and (d) FFS mode. The LC director orientations are shown in the voltage-off (left) and voltage-on (right) states.

IPS mode was first proposed in 1973 by SorefFigure 2c). As the voltage increases, the strong in-plane fringing electric fields between the interdigital electrodes reorient the LC directors. Such a unique mechanism makes IPS a favorable candidate for touch panels because no ripple effect occurs upon touching the panel. However, the peak transmittance of IPS is relatively low (~75%) because the LC molecules above the electrodes cannot be effectively reoriented. This low transmittance region is called a dead zone

FFS mode was proposed in 1998 by three Korean scientists: SH Lee, SL Lee, and HY KimFigure 2d). As a result, the electrode width and gap are able to be much smaller than those of IPS, leading to much stronger fringe fields covering both the electrode and gap regions. Thus the dead zone areas are reduced. In general, both positive (p-FFS) and negative (n-FFS) Δε LCs can be used in the FFS mode

As summarized in Table 1, these four LCD modes have their own unique features and are used for different applications. For example, TN has the advantages of low cost and high optical efficiency; thus, it is mostly used in wristwatches, signage and laptop computers, for which a wide view is not absolutely necessary. MVA mode is particularly attractive for large TVs because a fast response time, high CR and wide viewing angle are required to display motion pictures. On the other hand, IPS and FFS modes are used in mobile displays, where low power consumption for a long battery life and pressure resistance for touch screens are critical.

Abbreviations: FFS, fringe-field switching; IPS, in-plane switching; LCD, liquid crystal display; MVA, multi-domain vertical alignment; TN, twisted nematic; TV, television.

The basic structure of an OLED display, proposed by Tang and VanSlykeFigure 3a. Electrons and holes are injected from electrodes to organic layers for recombination and light emission; hence, an OLED display is an emissive display, unlike an LCD. Currently, multi-layer structures in OLEDs with different functional materials are commonly used, as shown in Figure 3b. The emitting layer (EML), which is used for light emission, consists of dopant and host materials with high quantum efficiency and high carrier mobility. Hole-transporting layer (HTL) and electron-transporting layer (ETL) between the EML and electrodes bring carriers into the EML for recombination. Hole- and electron-injection layers (HIL and EIL) are inserted between the electrodes and the HTL and ETL interface to facilitate carrier injection from the conductors to the organic layers. When applying voltage to the OLED, electrons and holes supplied from the cathode and anode, respectively, transport to the EML for recombination to give light.

Schematic diagram of an OLED. (a) Basic structure proposed by Tang and VanSlyke in 1987. (b) Multi-layer structure employed in current OLED products. EIL, electron-injection layer; ETL, electron-transporting layer; EML, emitting layer; HTL, hole-transporting layer; HIL, hole-injection layer.

Generally, each layer in an OLED is quite thin, and the total thickness of the whole device is <1 μm (substrates are not included). Thus the OLED is a perfect candidate for flexible displays. For an intrinsic organic material, its carrier mobility (<0.1 cm2 Vs−1) and free carrier concentration (1010 cm−3) are fairly low, limiting the device efficiency. Thus doping technology is commonly used

The EML is the core of an OLED. Based on the emitters inside, OLED devices can be categorized into four types: fluorescence, triplet-triplet fluorescence (TTF), phosphorescence, and thermally activated delayed fluorescence (TADF)

First, upon electrical excitation, 25% singlets and 75% triplets are formed with higher and lower energy, respectively. In a fluorescent OLED, only singlets decay radiatively through fluorescence with an ~ns exciton lifetime, which sets the theoretical limit of the internal quantum efficiency (IQE) to 25%, as shown in Figure 4a.

Illustration of the emission mechanisms of OLEDs: (a) fluorescence, (b) TTF, (c) phosphorescence, and (d) TADF. ISC, intersystem crossing; RISC, reverse intersystem crossing; TF, triplet fusion.

Two triplet excitons may fuse to form one singlet exciton through the so-called triplet fusion process, as shown in Figure 4b, and relaxes to the energy from the singlet state, called TTF, which improves the theoretical limit of the IQE to 62.5%.

With the introduction of heavy metal atoms (such as Ir and Pt) into the emitters, strong spin-orbital coupling greatly reduces the triplet lifetime to ~μs, which results in efficient phosphorescent emission. The singlet exciton experiences intersystem crossing to the triplet state for light emission, achieving a 100% IQE, as shown in Figure 4c. Owing to the long radiative lifetime (~μs) in a phosphorescent OLED, the triplet may interact with another triplet and polaron (triplet-triplet annihilation and triplet-polaron annihilation, respectively), which results in efficiency roll-off under high current driving

In practical applications, red and green phosphorescent emitters are the mainstream for active matrix (AM) OLEDs due to their high IQE. While, for blue emitters, TTF is mostly used because of its longer operation lifetime

To evaluate the performance of display devices, several metrics are commonly used, such as response time, CR, color gamut, panel flexibility, viewing angle, resolution density, peak brightness, lifetime, among others. Here we compare LCD and OLED devices based on these metrics one by one.

A fast response time helps to mitigate motion image blur and boost the optical efficiency, but this statement is only qualitatively correct. When quantifying the visual performance of a moving object, motion picture response time (MPRT) is more representative, and the following equation should be used

From Figure 5, we can gain several important physical insights: (1) Increasing the frame rate is a simple approach to suppress image motion blur, but its improvement gradually saturates. For example, if the LC response time is 10 ms, then increasing the frame rate from 30 to 60 fps would significantly reduce the MPRT. However, as the TFT frame rate continues to increase to 120 and 240 fps, then the improvement gradually saturates. (2) At a given frame rate, say 120 fps, as the LC response time decreases, the MPRT decreases almost linearly and then saturates. This means that the MPRT is mainly determined by the TFT frame rate once the LC response time is fast enough, i.e., τ≪Tf. Under such conditions, Equation (1) is reduced to MPRT≈0.8Tf. (3) When the LC response is <2 ms, its MPRT is comparable to that of an OLED at the same frame rate, e.g., 120 fps. Here we assume the OLED’s response time is 0.

The last finding is somehow counter to the intuition that a LCD should have a more severe motion picture image blur, as its response time is approximately 1000 × slower than that of an OLED (ms vs. μs). To validate this prediction, Chen et al.

If we want to further suppress image blur to an unnoticeable level (MPRT<2 ms), decreasing the duty ratio (for LCDs, this is the on-time ratio of the backlight, called scanning backlight or blinking backlight) is mostly adopted

As Figure 6 depicts, there are two types of surface reflections. The first one is from a direct light source, i.e., the sun or a light bulb, denoted as A1. Its reflection is fairly specular, and in practice, we can avoid this reflection (i.e., strong glare from direct sun) by simply adjusting the display position or viewing direction. However, the second reflection, denoted as A2, is quite difficult to avoid. It comes from an extended background light source, such as a clear sky or scattered ceiling light. In our analysis, we mainly focus on the second reflection (A2).

To investigate the ACR, we have to clarify the reflectance first. A large TV is often operated by remote control, so touchscreen functionality is not required. As a result, an anti-reflection coating is commonly adopted. Let us assume that the reflectance is 1.2% for both LCD and OLED TVs. For the peak brightness and CR, different TV makers have their own specifications. Here, without losing generality, let us use the following brands as examples for comparison: LCD peak brightness=1200 nits, LCD CR=5000:1 (Sony 75″ X940E LCD TV); OLED peak brightness=600 nits, and OLED CR=infinity (Sony 77″ A1E OLED TV). The obtained ACR for both LCD and OLED TVs is plotted in Figure 7a. As expected, OLEDs have a much higher ACR in the low illuminance region (dark room) but drop sharply as ambient light gets brighter. At 63 lux, OLEDs have the same ACR as LCDs. Beyond 63 lux, LCDs take over. In many countries, 60 lux is the typical lighting condition in a family living room. This implies that LCDs have a higher ACR when the ambient light is brighter than 60 lux, such as in office lighting (320–500 lux) and a living room with the window shades or curtain open. Please note that, in our simulation, we used the real peak brightness of LCDs (1200 nits) and OLEDs (600 nits). In most cases, the displayed contents could vary from black to white. If we consider a typical 50% average picture level (i.e., 600 nits for LCDs vs. 300 nits for OLEDs), then the crossover point drops to 31 lux (not shown here), and LCDs are even more favorable. This is because the on-state brightness plays an important role to the ACR, as Equation (2) shows.

Calculated ACR as a function of different ambient light conditions for LCD and OLED TVs. Here we assume that the LCD peak brightness is 1200 nits and OLED peak brightness is 600 nits, with a surface reflectance of 1.2% for both the LCD and OLED. (a) LCD CR: 5000:1, OLED CR: infinity; (b) LCD CR: 20 000:1, OLED CR: infinity.

Recently, an LCD panel with an in-cell polarizer was proposed to decouple the depolarization effect of the LC layer and color filtersFigure 7b. Now, the crossover point takes place at 16 lux, which continues to favor LCDs.

For mobile displays, such as smartphones, touch functionality is required. Thus the outer surface is often subject to fingerprints, grease and other contaminants. Therefore, only a simple grade AR coating is used, and the total surface reflectance amounts to ~4.4%. Let us use the FFS LCD as an example for comparison with an OLED. The following parameters are used in our simulations: the LCD peak brightness is 600 nits and CR is 2000:1, while the OLED peak brightness is 500 nits and CR is infinity. Figure 8a depicts the calculated results, where the intersection occurs at 107 lux, which corresponds to a very dark overcast day. If the newly proposed structure with an in-cell polarizer is used, the FFS LCD could attain a 3000:1 CRFigure 8b), corresponding to an office building hallway or restroom lighting. For reference, a typical office light is in the range of 320–500 luxFigure 8 depicts, OLEDs have a superior ACR under dark ambient conditions, but this advantage gradually diminishes as the ambient light increases. This was indeed experimentally confirmed by LG Display

Calculated ACR as a function of different ambient light conditions for LCD and OLED smartphones. Reflectance is assumed to be 4.4% for both LCD and OLED. (a) LCD CR: 2000:1, OLED CR: infinity; (b) LCD CR: 3000:1, OLED CR: infinity. (LCD peak brightness: 600 nits; OLED peak brightness: 500 nits).

For conventional LCDs employing a WLED backlight, the yellow spectrum generated by YAG (yttrium aluminum garnet) phosphor is too broad to become highly saturated RGB primary colors, as shown in Figure 9aTable 2. The first choice is the RG-phosphor-converted WLEDFigure 9b, the red and green emission spectra are well separated; still, the green spectrum (generated by β-sialon:Eu2+ phosphor) is fairly broad and red spectrum (generated by K2SiF6:Mn4+ (potassium silicofluoride, KSF) phosphor) is not deep enough, leading to 70%–80% Rec. 2020, depending on the color filters used.

Transmission spectra of color filters and emission spectra of (a) YAG WLED, (b) KSF WLED, (c) QDEF and (d) Vivid Color LED. KSF, potassium silicofluoride; QDEF, quantum dot enhancement film; WLED, white light-emitting diode; YAG, yttrium aluminum garnet.

Abbreviations: FWHM, full width at half maximum; KSF, potassium silicofluoride; LED, light-emitting diode; QDEF, quantum dot enhancement film; RoHS, restriction of hazardous substances; WLED, white light-emitting diode; YAG, yttrium aluminum garnet.

aHere we only consider Cd-based quantum-dots (QDs). For heavy-metal-free QDs, e.g., InP QD, the FWHM is broader (40–50 nm) and color gamut is 70–80%. Their optical efficiency is slightly lower than that of Cd-based QDs.

A QD-enhanced backlight (e.g., quantum dot enhancement film, QDEF) offers another option for a wide color gamutFigure 9c), so that high purity RGB colors can be realized and a color gamut of ~90% Rec. 2020 can be achieved. One safety concern is that some high-performance QDs contain the heavy metal Cd. To be compatible with the restriction of hazardous substances, the maximum cadmium content should be under 100 ppm in any consumer electronic product

Recently, a new LED technology, called the Vivid Color LED, was demonstratedFigure 9d), which leads to an unprecedented color gamut (~98% Rec. 2020) together with specially designed color filters. Such a color gamut is comparable to that of laser-lit displays but without laser speckles. Moreover, the Vivid Color LED is heavy-metal free and shows good thermal stability. If the efficiency and cost can be further improved, it would be a perfect candidate for an LCD backlight.

A color filter array is another effective approach to enhance the color gamut of an OLED. For example, in 2017, AUO demonstrated a 5-inch top-emission OLED panel with 95% Rec. 2020. In this design, so-called symmetric panel stacking with a color filter is employed to generate purer RGB primary colors

As mentioned earlier, TFT LCDs are a fairly mature technology. They can be operated for >10 years without noticeable performance degradation. However, OLEDs are more sensitive to moisture and oxygen than LCDs. Thus their lifetime, especially for blue OLEDs, is still an issue. For mobile displays, this is not a critical issue because the expected usage of a smartphone is approximately 2–3 years. However, for large TVs, a lifetime of >30 000 h (>10 years) has become the normal expectation for consumers.

Here we focus on two types of lifetime: storage and operational. To enable a 10-year storage lifetime, according to the analysis−6 g (m2-day)−1 and 1 × 10−5 cm3 (m2-day)−1, respectively. To achieve these values, organic and/or inorganic thin films have been developed to effectively protect the OLED and lengthen its storage lifetime. Meanwhile, it is compatible to flexible substrates and favors a thinner display profile

The next type of lifetime is operational lifetime. Owing to material degradation, OLED luminance will decrease and voltage will increase after long-term drivingT50) can be as long as >80 000 h with a 1000 cd m−2 luminanceT50, half lifetime) with an initial luminance of 1000 nits. However, this is still ~20 × shorter than that of red and green phosphorescent OLEDs

To further enhance the lifetime of the blue OLED, the NTU group has developed new ETL and TTF-EML materials together with an optimized layer structure and double EML structureFigure 10a shows the luminance decay curves of such a blue OLED under different initial luminance values (5000, 10 000, and 15 000 nits). From Figure 10b, the estimated T50 at 1000 nits of this blue OLED is ~56 000 h (~6–7 years)

Power consumption is equally important as other metrics. For LCDs, power consumption consists of two parts: the backlight and driving electronics. The ratio between these two depends on the display size and resolution density. For a 55″ 4K LCD TV, the backlight occupies approximately 90% of the total power consumption. To make full use of the backlight, a dual brightness enhancement film is commonly embedded to recycle mismatched polarized light

The power efficiency of an OLED is generally limited by the extraction efficiency (ηext~20%). To improve the power efficiency, multiple approaches can be used, such as a microlens array, a corrugated structure with a high refractive index substrateFigure 11 shows the power efficiencies of white, green, red and blue phosphorescent as well as blue fluorescent/TTF OLEDs over time. For OLEDs with fluorescent emitters in the 1980s and 1990s, the power efficiency was limited by the IQE, typically <10 lm W−1(Refs. 41, 114, 115, 116, 117, 118). With the incorporation of phosphorescent emitters in the ~2000 s, the power efficiency was significantly improved owing to the materials and device engineering−1 was demonstrated in 2011 (Ref. 127), which showed a >100 × improvement compared with that of the basic two-layer device proposed in 1987 (1.5 lm W−1 in Ref. 41). A white OLED with a power efficiency >100 lm W−1 was also demonstrated, which was comparable to the power efficiency of a LCD backlight. For red and blue OLEDs, their power efficiencies are generally lower than that of the green OLED due to their lower photopic sensitivity function, and there is a tradeoff between color saturation and power efficiency. Note, we separated the performances of blue phosphorescent and fluorescent/TTF OLEDs. For the blue phosphorescent OLEDs, although the power efficiency can be as high as ~80 lm W−1, the operation lifetime is short and color is sky-blue. For display applications, the blue TTF OLED is the favored choice, with an acceptable lifetime and color but a much lower power efficiency (16 lm W−1) than its phosphorescent counterpartFigure 11 shows.

Power efficiency of white, red, green and phosphorescent blue and fluorescent/TTF blue OLEDs over time. Data are compiled from Refs. 41, 45, 114, 115, 116, 117, 118, 119, 120, 121, 122, 123, 124, 125, 126, 127, 128, 129, 130, 131, 132, 133.

To compare the power consumption of LCDs and OLEDs with the same resolution density, the displayed contents should be considered as well. In general, OLEDs are more efficient than LCDs for displaying dark images because black pixels consume little power for an emissive display, while LCDs are more efficient than OLEDs at displaying bright images. Currently, a ~65% average picture level is the intersection point between RGB OLEDs and LCDs

Flexible displays have a long history and have been attempted by many companies, but this technology has only recently begun to see commercial implementations for consumer electronics

In addition to the aforementioned six display metrics, other parameters are equally important. For example, high-resolution density has become a standard for all high-end display devices. Currently, LCD is taking the lead in consumer electronic products. Eight-hundred ppi or even >1000 ppi LCDs have already been demonstrated and commercialized, such as in the Sony 5.5″ 4k Smartphone Xperia Z5 Premium. The resolution of RGB OLEDs is limited by the physical dimension of the fine-pitch shadow mask. To compete with LCDs, most OLED displays use the PenTile RGB subpixel matrix scheme

The viewing angle is another important property that defines the viewing experience at large oblique angles, which is quite critical for multi-viewer applications. OLEDs are self-emissive and have an angular distribution that is much broader than that of LCDs. For instance, at a 30° viewing angle, the OLED brightness only decreases by 30%, whereas the LCD brightness decrease exceeds 50%. To widen an LCD’s viewing angle, three options can be used. (1) Remove the brightness-enhancement film in the backlight system. The tradeoff is decreased on-axis brightness

In addition to brightness, color, grayscale and the CR also vary with the viewing angle, known as color shift and gamma shift. In these aspects, LCDs and OLEDs have different mechanisms. For LCDs, they are induced by the anisotropic property of the LC material, which could be compensated for with uniaxial or biaxial films

Cost is another key factor for consumers. LCDs have been the topic of extensive investigation and investment, whereas OLED technology is emerging and its fabrication yield and capability are still far behind LCDs. As a result, the price of OLEDs is about twice as high as that of LCDs, especially for large displays. As more investment is made in OLEDs and more advanced fabrication technology is developed, such as ink-jet printing

Currently, both LCDs and OLEDs are commercialized and compete with each other in almost every display segment. They are basically two different technologies (non-emissive vs. emissive), but as a display, they share quite similar perspectives in the near future. Here we will focus on three aspects: HDR, VR/AR and smart displays with versatile functions.

Both LCD and OLED are HDR-compatible. Currently, the best HDR LCDs can produce brighter highlights than OLEDs, but OLEDs have better overall CRs thanks to their superior black level. To enhance an LCD’s CR, a local dimming backlight is commonly used, but its dimming accuracy is limited by the number of LED segmentations

Also worth mentioning here is ultra-high brightness. Mostly, people pay more attention to the required high CR (CR>100 000:1) of HDR but fail to notice that CR is jointly determined by the dark state and peak brightness. For example, a 12-bit Perceptual Quantizer curve is generated for a range up to 10 000 nits, which is far beyond what current displays can provide

The peak brightness of LCDs could be boosted to 2000 nits or even higher by simply using a high-power backlight. OLEDs are self-emissive, so their peak brightness would trade with lifetime. As a result, more advanced OLED materials and novel structural designs are highly desirable in the future. Another reason to boost peak brightness is to increase sunlight readability. Especially for some outdoor applications, such as public displays, peak brightness is critical to ensure good readability under strong ambient light. As discussed in the section of ‘CR and ACR’, high brightness leads to a high ACR, except that the power consumption will increase.

Immersive VR/AR are two emerging wearable display technologies with great potential in entertainment, education, training, design, advertisement and medical diagnostics. However, new opportunities arise along with new challenges. VR head-mounted displays require a resolution density as high as >2000 ppi to eliminate the so-called screen door effect and generate more realistic immersive experiences.

An LCD’s resolution density is determined by the TFTs and color filter arrays. In SID 2017, Samsung demonstrated an LCD panel with a resolution of 2250 ppi for VR applications. The pitches of the sub-pixel and pixel are 3.76 and 11.28 μm, respectively. Meanwhile, field sequential color provides another promising option to triple the LCD resolution density

Currently, displays are no longer limited to traditional usages, such as TVs, pads or smartphones. Instead, they have become more diversified and are used in smart windows, smart mirrors, smart fridges, smart vending machines and so on. They have entered all aspects of our daily lives.

As these new applications are emerging, LCDs and OLEDs have new opportunities as well as new challenges. Let us take a vehicle display as an example: high brightness, good sunlight readability, and a wide working temperature range are required

We have briefly reviewed the recent progress of LCD and OLED technologies. Each technology has its own pros and cons. For example, LCDs are leading in lifetime, cost, resolution density and peak brightness; are comparable to OLEDs in ACR, viewing angle, power consumption and color gamut (with QD-based backlights); and are inferior to OLED in black state, panel flexibility and response time. Two concepts are elucidated in detail: the motion picture response time and ACR. It has been demonstrated that LCDs can achieve comparable image motion blur to OLEDs, although their response time is 1000 × slower than that of OLEDs (ms vs. μs). In terms of the ACR, our study shows that LCDs have a comparable or even better ACR than OLEDs if the ambient illuminance is >50 lux, even if its static CR is only 5000:1. The main reason is the higher brightness of LCDs. New trends for LCDs and OLEDs are also highlighted, including ultra-high peak brightness for HDR, ultra-high-resolution density for VR, ultra-low power consumption for AR and ultra-versatile functionality for vehicle display, transparent display and mirror display applications. The competition between LCDs and OLEDs is still ongoing. We believe these two TFT-based display technologies will coexist for a long time.

Chen J, Hardev V, Hartlove J, Hofler J, Lee E. A high-efficiency wide-color-gamut solid-state backlight system for LCDs using quantum dot enhancement film. SID Symp Dig Tech Pap

Lee SH, Lee SL, Kim HY. Electro-optic characteristics and switching principle of a nematic liquid crystal cell controlled by fringe-field switching. Appl Phys Lett

Mori H, Itoh Y, Nishiura Y, Nakamura T, Shinagawa Y. Performance of a novel optical compensation film based on negative birefringence of discotic compound for wide-viewing-angle twisted-nematic liquid-crystal displays. Jpn J Appl Phys

Ito Y, Watanabe J, Saitoh Y, Takada K, Morishima SI et al. Innovation of optical films using polymerized discotic materials: past, present and future. SID Symp Dig Tech Pap

Takeda A, Kataoka S, Sasaki T, Chida H, Tsuda H et al. A super-high image quality multi-domain vertical alignment LCD by new rubbing-less technology. SID Symp Dig Tech Pap

Kim KH, Lee K, Park SB, Song JK, Kim SN et al. Domain Divided Vertical Alignment Mode with Optimized Fringe Field Effect. Proceedings of the 18th IDRC, Asia Display

Kim SS, You BH, Cho JH, Kim DG, Berkeley BH et al. An 82-in. ultra-definition 120-Hz LCD TV using new driving scheme and advanced Super PVA technology. J Soc Inf Display

Hsiao K, Tang GF, Yu G, Zhang ZW, Xu XJ et al. Development and analysis of technical challenges in the world"s largest (110-in.) curved LCD. SID Symp Dig Tech Pap

Yu IH, Song IS, Lee JY, Lee SH. Intensifying the density of a horizontal electric field to improve light efficiency in a fringe-field switching liquid crystal display. J Phys D Appl Phys

Song DD, Zhao SL, Luo YC, Aziz H. Causes of efficiency roll-off in phosphorescent organic light emitting devices: triplet-triplet annihilation versus triplet-polaron quenching. Appl Phys Lett

Giebink N, D’Andrade BW, Weaver MS, Brown JJ, Forrest SR. Direct evidence for degradation of polaron excited states in organic light emitting diodes. J Appl Phys

Féry C, Racine B, Vaufrey D, Doyeux H, Cinà S. Physical mechanism responsible for the stretched exponential decay behavior of aging organic light-emitting diodes. Appl Phys Lett

Mills PR, Tomkins SC, Schlangen LJ. The effect of high correlated colour temperature office lighting on employee wellbeing and work performance. J Circadian Rhythms

Xie RJ, Hirosaki N, Takeda T. Wide color gamut backlight for liquid crystal displays using three-band phosphor-converted white light-emitting diodes. Appl Phys Express

Wang L, Wang XJ, Kohsei T, Yoshimura KI, Izumi M et al. Highly efficient narrow-band green and red phosphors enabling wider color-gamut LED backlight for more brilliant displays. Opt Express

The European Parliament, The Council of the European Union Directive 2002/95/EC on the restriction of the use of certain hazardous substances in electrical and electronic equipment. The European Parliament, The Council of the European Union, 2003; pp19–23.

Li WJ, Yao L, Liu HC, Wang ZM, Zhang ST et al. Highly efficient deep-blue OLED with an extraordinarily narrow FHWM of 35 nm and a y coordinate<0.05 based on a fully twisting donor-acceptor molecule. J Mater Chem C

Kondakov DY, Sandifer JR, Tang CW, Young RH. Nonradiative recombination centers and electrical aging of organic light-emitting diodes: direct connection between accumulation of trapped charge and luminance loss. J Appl Phys

Hashimoto N, Ogita K, Nowatari H, Takita Y, Kido H et al. Investigation of effect of triplet-triplet annihilation and molecular orientation on external quantum efficiency of ultrahigh-efficiency blue fluorescent device. SID Symp Dig Tech Pap

Lin BY, Lee MZ, Tseng PC, Lee JH, Chiu TL et al. 16.1-times elongation of operation lifetime in a blue TTA-OLED by using new ETL and EML materials. SID Symp Dig Tech Pap

Lee C, Kim JJ. Enhanced light out-coupling of OLEDs with low haze by inserting randomly dispersed nanopillar arrays formed by lateral phase separation of polymer blends. Small

Lin HY, Chen KY, Ho YH, Fang JH, Hsu SC et al. Luminance and image quality analysis of an organic electroluminescent panel with a patterned microlens array attachment. J Optics

Meerheim R, Scholz S, Olthof S, Schwartz G, Reineke S et al. Influence of charge balance and exciton distribution on efficiency and lifetime of phosphorescent organic light-emitting devices. J Appl Phys

Wang ZB, Helander MG, Qiu J, Puzzo DP, Greiner MT et al. Unlocking the full potential of organic light-emitting diodes on flexible plastic. Nat Photonics

Yamada Y, Inoue H, Mitsumori S, Watabe T, Ishisone T et al. Achievement of blue phosphorescent organic light-emitting diode with high efficiency, low driving voltage, and long lifetime by exciplex-triplet energy transfer technology. SID Symp Dig Tech Pap

Greinert N, Schoenefeld C, Suess P, Klasen-Memmer M, Bremer M et al. Opening the door to new LCD applications via polymer walls. SID Symp Dig Tech Pap

Lee S, Moon J, Yang S, Rhim J, Kim B et al. Development of zero-bezel display utilizing a waveguide image transformation element. SID Symp Dig Tech Pap

Yamazaki A, Wu CL, Cheng WC, Badano A. Spatial resolution characteristics of organic light-emitting diode displays: a comparative analysis of MTF for handheld and workstation formats. SID Symp Dig Tech Pap

Käläntär K. A directional backlight with narrow angular luminance distribution for widening the viewing angle for an LCD with a front-surface light-scattering film. J Soc Inf Display

Kim HJ, Shin MH, Lee JY, Kim JH, Kim YJ. Realization of 95% of the Rec. 2020 color gamut in a highly efficient LCD using a patterned quantum dot film. Opt Express

Chen PY, Chen CL, Chen CC, Tsai L, Ting HC et al. 65-inch inkjet printed organic light-emitting display panel with high degree of pixel uniformity. SID Symp Dig Tech Pap

Chen HF, Sung J, Ha T, Park Y, Hong CW. Backlight Local Dimming Algorithm for High Contrast LCD-TV. New Delhi, India: Proceedings of ASID; 2006, pp168–pp171.

Yoo O, Nam S, Choi J, Yoo S, Kim KJ et al. Contrast enhancement based on advanced local dimming system for high dynamic range LCDs. SID Symp Dig Tech Pap

Daly S, Kunkel T, Sun X, Farrell S, Crum P. Viewer preferences for shadow, diffuse, specular, and emissive luminance limits of high dynamic range displays. SID Symp Dig Tech Pap

Chen CH, Lin FC, Hsu YT, Huang YP, Shieh HP. A field sequential color LCD based on color fields arrangement for color breakup and flicker reduction. J Display Technol

Lin FC, Huang YP, Wei CM, Shieh HPD. Color-breakup suppression and low-power consumption by using the Stencil-FSC method in field-sequential LCDs. J Soc Inf Display

Tan GJ, Lee YH, Gou FW, Hu MG, Lan YF et al. Macroscopic model for analyzing the electro-optics of uniform lying helix cholesteric liquid crystals. J Appl Phys

Kimura K, Onoyama Y, Tanaka T, Toyomura N, Kitagawa H. New pixel driving circuit using self-discharging compensation method for high- resolution OLED micro displays on a silicon backplane. J Soc Inf Display

Reinert-Weiss CJ, Baur H, Al Nusayer SA, Duhme D, Frühauf N. Development of active matrix LCD for use in high-resolution adaptive headlights. J Soc Inf Display

Okuyama K, Nakahara T, Numata Y, Nakamura T, Mizuno M et al. Highly transparent LCD using new scattering-type liquid crystal with field sequential color edge light. SID Symp Dig Tech Pap

Görrn P, Sander M, Meyer J, Kröger M, Becker E et al. Towards see-through displays: fully transparent thin-film transistors driving transparent organic light-emitting diodes. Adv Mater

The LCD is currently the display of choice in small devices and is also popular in large-screen TVs. Regular LEDs often form the digits on digital clocks and other electronic devices. OLEDs offer many advantages over both LCDs and LEDs:

Because the light-emitting layers of an OLED are lighter, the substrate of an OLED can be flexible instead of rigid. OLED substrates can be plastic rather than the glass used for LEDs and LCDs.

OLEDs are brighter than LEDs. Because the organic layers of an OLED are much thinner than the corresponding inorganic crystal layers of an LED, the conductive and emissive layers of an OLED can be multi-layered. Also, LEDs and LCDs require glass for support, and glass absorbs some light. OLEDs do not require glass.

OLEDs do not require backlighting like LCDs (see How LCDs Work). LCDs work by selectively blocking areas of the backlight to make the images that you see, while OLEDs generate light themselves. Because OLEDs do not require backlighting, they consume much less power than LCDs (most of the LCD power goes to the backlighting). This is especially important for battery-operated devices such as cell phones.

OLEDs have large fields of view, about 170 degrees. Because LCDs work by blocking light, they have an inherent viewing obstacle from certain angles. OLEDs produce their own light, so they have a much wider viewing range.

Lifetime - While red and green OLED films have longer lifetimes (46,000 to 230,000 hours), blue organics currently have much shorter lifetimes (up to around 14,000 hours[source: OLED-Info.com]).

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey