arduino oscilloscope tft lcd factory

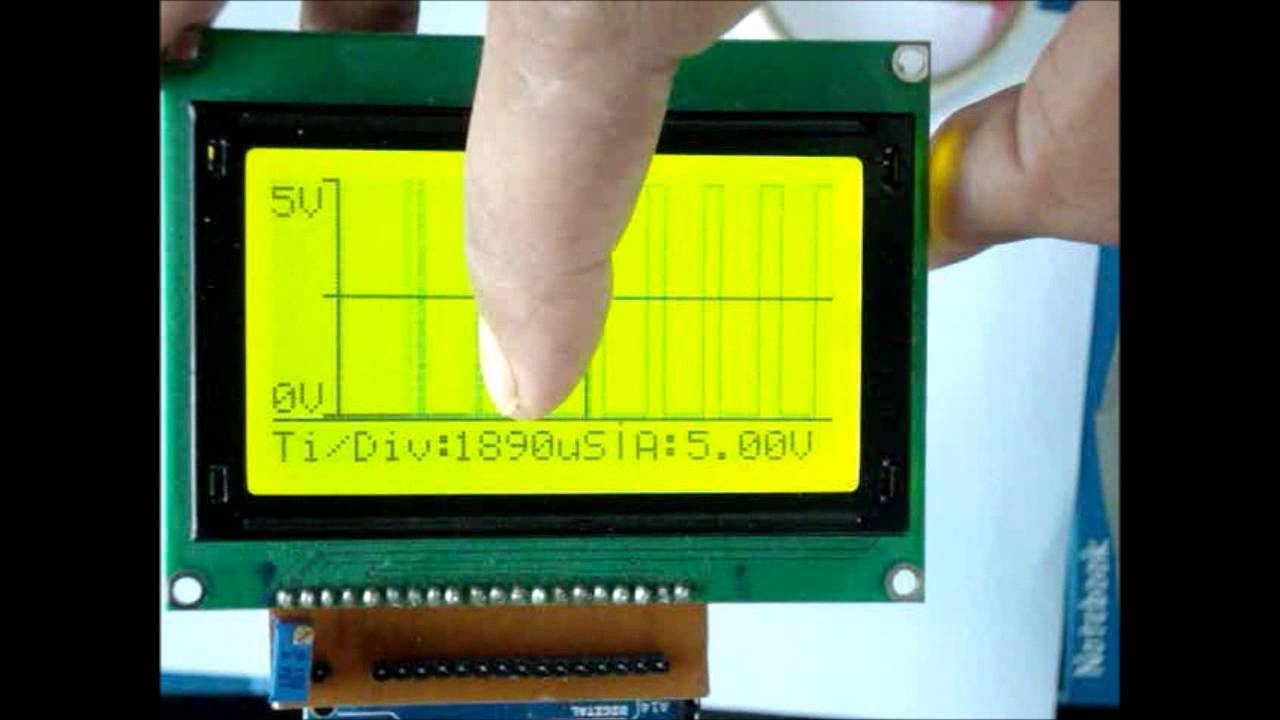

The Oscilloscope is a must-have test instrument for any electronics engineer. It is used to visualize and observe various signals, usually as a two-dimensional plot with one or more signals plotted against time. They are used in the design and debugging of electronic devices to view and compare waveforms, and determine voltage levels, frequency, noise, and other parameters of signals applied at its input as it changes with time. This makes Oscilloscopes a very important tool on the desk of an electronics engineer or maker. Oscilloscopes, however, are quite pricey; entry-level models can cost anywhere from $500 to $2,000. And the advanced oscilloscopes cost few thousands of dollars, which puts them beyond the reach of basic users. But what if we could create one which is cheaper, compact, and easy to make? That is the question that led to today’s tutorial.

For display, we are using a 1.69” TFT display module. It has a resolution of 240x280 pixels. The display controller is ST7789S and to drive this, we will be using the SPI communication.

You can either build this project in a perfboard or you can make a PCB with the files from the link at the bottom of the page. Both PDF files for the toner transfer method and the Gerber file for the manufacturing are included. Here is the PCB layout for the Oscilloscope.

Download the entire code from the Circuit Digest GitHub repo link given at the bottom of this article. In the GitHub repo, you can also find an archive named TFT_eSPI. This modified library is necessary to drive the display. Extract it to the Arduino library folder. If you have already installed TFT_eSPI library, make sure to remove it before extracting the modified one. Once it’s done, select esp32 in the board manager. Then compile the code and upload it. That’s it our DIY Oscilloscope is ready to use. You can power the Oscilloscope using the Micro USB port at the bottom. This port is only for power.

Graphical display terminals using large screen cathode ray tubes (CRT) soon evolved. These displays were essentially “up-sized oscilloscopes” whose X-Y beam deflection was driven by a computer.

The answer proved to be YES! What resulted, I call the Arduino Graphics Interface, or AGI for short. With AGI, you can transform a leftover analog oscilloscope into a high resolution computer graphics display and gain valuable insights into computer graphics, digital-to-analog conversion (ADC), and advanced Direct Memory Access (DMA) hardware and software techniques. It’s easy to add a real time clock (RTC) module and interactive controls to turn the AGI platform into a “CRT CLOCK” (Figure 2) or other high resolution computer graphics display device.

In this article, we’ll focus on the overall concepts, circuit design, and hardware fabrication. In Part 2, we’ll integrate the hardware to XYscope: the software control and plotting library that enables an Arduino Due CPU + analog oscilloscope to become a high resolution XY graphics display. Let’s get started!

You can see that a pair of digital-to-analog converters (DACs) inside of the ATMEL SAM 32-bit CPU (the heart of an Arduino Due) is used to drive the X and Y axes of an analog oscilloscope. Rather than use the normal oscilloscope Amplitude vs. Time display mode, we run the scope in X-Y mode. That is, the internal oscilloscope time base that usually drives the X axis is not used, but rather all XY information for deflecting the CRT beam comes directly from the Arduino through the AGI circuits.

To create graphical images with AGI, the programmer need only build a list of 12-bit X-Y integers that make up the individual points we want to show. One after the other, the DACs of the Due receive and convert each XY integer coordinate pair into small X-Y voltages that drive the CRT beam about the oscilloscope screen. The block diagram shows that we also provide a blanking pulse (a.k.a., Z axis blanking) as a third signal to the scope.

The AGI uses an analog oscilloscope for its graphics output display. You’ll have to dust off your old analog oscilloscope or perhaps buy a vintage unit off eBay. The Oscilloscope Requirements sidebar details the features you need to look for when evaluating possible scope candidates for use with this project. Since we use an oscilloscope as the display screen, the size and display color is fixed by the cathode ray tube inside the scope.

At first, I labored over the multitude of CPU boards available, but it soon became apparent only one board would “Due.” (I know, it’s a terrible pun.) Even though the Beagle Bone and Raspberry Pi families have faster CPUs and more memory, only the Arduino Due CPU includes a pair of DMA-driven on-chip DACs.

While programmed I/O using an Arduino analogWrite() command is a common way to output data to the DACs, the AGI uses DMA techniques. We’ll discuss this further in Part 2, but for now, suffice it to say that we connect the DMA hardware inside the Due to a COUNTER-TIMER which automatically sends the X-Y data array out through the DACs to the oscilloscope screen at very high speeds.

For the AGI project, the Due provides two DAC outputs; each of which translates a 12-bit unsigned integer into one of 4,096 different analog voltage levels. As measured at the processor DAC pins, the CPU outputs a voltage of 0.5V when converting the integer value 0, and outputs 2.75V when converting the integer value 4095. Dividing this 2.25 volt peak-to-peak voltage range by 4096 means that each step or bit change at the DAC input results in a 550 μV change at the DAC output. These signals are buffered by the AGI circuits before they are sent on to the oscilloscope for display.

Using an oscilloscope to monitor the DAC outputs, Figure 4 shows that a full-scale change in output of the DAC from 0 to 4095 in one step takes slightly over 300 ns. Similarly, the step going from 4095 back to 0 is seen to be about 300 ns as well.

Next, note that the X and Y conversions follow each other in time, with the DAC0 signal (the X axis value) changing first, followed one DMA_CLK cycle later by the DAC1 signal (Y axis). Analog sample and hold circuits are used to time-synchronize the X and Y signals to one another before they are sent out to the oscilloscope as the X-Drive (TP8) and Y-Drive (TP9) signals for display.

Given the DAC rise and fall times, it’s possible to determine the highest DMA_CLK frequency we can use. My tests show reliable high quality graphics plotting can be achieved at DMA_CLK frequencies up to 800 kHz. Above 800 kHz, the DAC rise and fall time delays begin to distort the graphics display, appearing as incorrectly plotted points on the oscilloscope screen whenever adjacent members in the XY list are far away from one another.

With the DMA_CLK frequency set to 800 kHz, it’s possible to send about 10,000 points to the screen within the 20 ms target refresh interval. When more than 10K points are present in the display list, the software driver will automatically extend the refresh interval as needed so all points can be displayed. Depending on the phosphor decay characteristics of your oscilloscope screen and your personal POV sensitivity, you will probably notice the onset of image flicker when plotting more than about 12,000 points.

POWER SUPPLY — Any wall wart that can supply 12-15 VDC at .5 amps can be used to power the AGI circuitry. As shown in Figure 5, onboard linear regulators provide clean low-noise regulated +9.75V and +5.0V outputs to power both the AGI analog circuits (9.75V) as well as the logic and Arduino Due CPU (5.0V).

X-Y BUFFER AMPS — In Figure 6, you can see that the DAC0 (X axis) and DAC1 (Y axis) signals from the Due are received and buffered by high frequency op-amp U4. Potentiometers are provided at this stage so that signal gain (amplitude) and offset (screen position) for X and Y can be independently set. The gain pot on each output will vary the amplitude within a 1.0V to 4.0V P-P range. The centering pot varies the signal offset so that it can reside anywhere within a .2V to 4.75V window. Final display adjustment will be a combination of these AGI pots, as well as the oscilloscope gain and centering controls; my scope works well with AGI outputs adjusted to 1.5V P-P centered about +2.5 VDC.

SAMPLE AND HOLD CIRCUITS — As seen in Figure 4, the DAC0 and DAC1 outputs are not simultaneously output by the Due CPU; the X value is converted first, followed by the Y value one DMA_CLK cycle later. Analog switch U5a-b, hold capacitors C9 and C13, and buffer amps U3a-b make up the pair of Sample and Hold (S/H) circuits that align and synchronize the X-Y point pair voltages, so they change together when they’re sent to the oscilloscope for display. The X and Y buffer amps are followed by transmission gates U5a-b and output op-amps U7a-b which work together to form two independent S/H circuits.

DATA CLOCK TIMING — COUNTER_TIMER_0 of the Due is programmed to be the DMA_CLK. This signal drives the internal DMA operations, but as shown in Figure 7, also comes to the outside world through CPU pin D2. This signal is fed to U6a and U8b to create all the needed AGI timing signals. Flip-flop U6a divides the DMA_CLK by 2 to create a signal that represents a point pair transfer completed signal or POINT_CLK. The POINT_CLK_NOT signal is then combined to generate the S/H_PULSE and the SHOW_POINT signals. As depicted in the timing traces of Figure 4, the S/H_PULSE signal is used to “grab and hold” the X-Y voltage pair. Then, the SHOW_POINT pulse is sent to the Z axis of the oscilloscope (a.k.a., “Z-Drive”) to unblank each point after it has settled down and is ready to be illuminated.

You can’t go wrong purchasing an authentic Arduino Due board for this project from www.arduino.cc (about $50 each). However, since the Due design is open source, Due-compatible boards are also available from several other places. Once you have the Due in hand, the AGI interface circuit must be built. I prototyped the AGI circuit using a solderless breadboard (Figure 8) and later built a more robust point-to-point soldered-wire version.

Since I wanted to keep things simple and easy to build, I opted to use only through-hole components for this project. I made the AGI PCB a little larger than a standard Arduino board so that the Due could be easily mounted on top of the AGI circuit board using 4-40 spacers.

Just like any other Arduino project, the AGI system can be programmed using the Arduino Integrated Development Environment (IDE). In Part 2, we’ll focus on the software by looking at CRT_SCOPE: a test and checkout program that you can use to get your build up and running. We’ll also use this program as a vehicle to demonstrate how easy it is to use XYscope: the Arduino AGI software support library.

You can get ready for Part 2 by downloading and installing the Arduino IDE, Due board definition files, Due timer library, and the AGI library. If this is your first Arduino Due project, I suggest you start out with some basic “hello world” and “blinking LED” test programs to get the IDE set up, compiling, and properly connected to your Due. Check out the References for links to the IDE and a few others that you might find interesting.

Overall plot quality is influenced by the quality and performance of the oscilloscope and CRT used. This project works well only with analog oscilloscopes; digital scopes will only produce poor looking output.

Checking a TFT lcd driver is very messy thing especially if its a Chinese manufactured TFT. TFT’s that are supplied by Chinese manufactures are cheap and every body loves to purchase them since they are cheap,but people are unaware of the problems that comes in future when finding the datasheet or specs of the particular TFT they purchased. Chinese manufactures did not supply datasheet of TFT or its driver. The only thing they do is writes about the TFT driver their lcd’s are using on their websites. I also get in trouble when i started with TFT’s because i also purchased a cheap one from aliexpress.com. After so many trials i succeeded in identifying the driver and initializing it. Now i though to write a routine that can identify the driver.

I wrote a simple Arduino Sketch that can easily and correctly identify the TFT Lcd driver. I checked it on 2.4, 3.2 and 3.8 inch 8-bit TFT lcd and it is identifying the drivers correctly. The drivers which i successfully recognized are ILI9325, ILI9328, ILI9341, ILI9335, ST7783, ST7781 and ST7787. It can also recognize other drivers such as ML9863A, ML9480 and ML9445 but i don’t have tft’s that are using this drivers.

The basic idea behind reading the driver is reading the device ID. Since all the drivers have their ID’s present in their register no 0x00, so what i do is read this register and identify which driver tft is using. Reading the register is also a complex task, but i have gone through it many times and i am well aware of how to read register. A simple timing diagram from ST7781 driver explains all. I am using tft in 8-bit interface so i uploaded timing diagram of 8-bit parallel interface. The diagram below is taken from datasheet of ST7781 tft lcd driver.

The most complex tft i came across is from a Chinese manufacturer “mcufriend”. mcufriend website says that they use ILI9341 and ILI9325 drivers for their tft’s. But what i found is strange their tft’s are using ST7781 driver(Device ID=7783). This is really a mesh. I have their 2.4 inch tft which according to their website is using ILI9341 driver but i found ST7783 driver(Device ID=7783). The tft i have is shown below.

I am using Arduino uno to read driver. I inserted my lcd on arduino uno and read the driver. After reading driver i am printing its number on Serial Monitor.

Note:On serial monitor driver number will be displayed like if your lcd is using ST7783 controller than on serial monitor 7783 will be displayed or if tft is using ILI9341 than on 9341 will be displayed.

The code works on Arduino uno perfectly but if you are using any other board, than just change the pin numbers according to the board that you are using also check out for the Ports D and B. TFT Data Pin D0 is connected to Port-B Pin#0 and D1 is connected to Port-B Pin#1. TFT Data Pins D2 to D7 are connected to Port-D Pins 2,3,4,5,6,7. So if you are using Arduino mega than check for the Ports D and B and Make connections according to them. Arduino mega is working on ATmega2560 or ATmega1280 Microcontroller and Arduino uno is working on ATmega328p Microcontroller so both platforms have ports on different locations on arduino board so first check them and then make connections. The same process applies to all Arduino boards.

Asia has long dominated the display module TFT LCD manufacturers’ scene. After all, most major display module manufacturers can be found in countries like China, South Korea, Japan, and India.

In this post, we’ll list down 7 best display module TFT LCD manufacturers in the USA. We’ll see why these companies deserve recognition as top players in the American display module industry.

STONE Technologies is a leading display module TFT LCD manufacturer in the world. The company is based in Beijing, China, and has been in operations since 2010. STONE quickly grew to become one of the most trusted display module manufacturers in 14 years.

Now, let’s move on to the list of the best display module manufacturers in the USA. These companies are your best picks if you need to find a display module TFT LCD manufacturer based in the United States:

Planar Systems is a digital display company headquartered in Hillsboro, Oregon. It specializes in providing digital display solutions such as LCD video walls and large format LCD displays.

The company started in 1983 as a corporate spin-off from the American oscilloscope company Tektronix. In 2015, Planar Systems became a subsidiary of the Chinese manufacturer Leyard Optoelectronics.

Microtips Technology is a global electronics manufacturer based in Orlando, Florida. The company was established in 1990 and has grown into a strong fixture in the LCD industry.

What makes Microtips a great display module TFT LCD manufacturer in the USA lies in its close ties with all its customers. It does so by establishing a good rapport with its clients starting from the initial product discussions. Microtips manages to keep this exceptional rapport throughout the entire client relationship by:

Displaytech is an American display module TFT LCD manufacturer headquartered in Carlsbad, California. It was founded in 1989 and is part of several companies under the Seacomp group. The company specializes in manufacturing small to medium-sized LCD modules for various devices across all possible industries.

The company also manufactures embedded TFT devices, interface boards, and LCD development boards. Also, Displaytech offers design services for embedded products, display-based PCB assemblies, and turnkey products.

Displaytech makes it easy for clients to create their own customized LCD modules. There is a feature called Design Your Custom LCD Panel found on their site. Clients simply need to input their specifications such as their desired dimensions, LCD configuration, attributes, connector type, operating and storage temperature, and other pertinent information. Clients can then submit this form to Displaytech to get feedback, suggestions, and quotes.

A vast product range, good customization options, and responsive customer service – all these factors make Displaytech among the leading LCD manufacturers in the USA.

Products that Phoenix Display offers include standard, semi-custom, and fully-customized LCD modules. Specifically, these products comprise Phoenix Display’s offerings:

Clients flock to Phoenix Display because of their decades-long experience in the display manufacturing field. The company also combines its technical expertise with its competitive manufacturing capabilities to produce the best possible LCD products for its clients.

True Vision Displays is an American display module TFT LCD manufacturing company located at Cerritos, California. It specializes in LCD display solutions for special applications in modern industries. Most of their clients come from highly-demanding fields such as aerospace, defense, medical, and financial industries.

The company produces several types of TFT LCD products. Most of them are industrial-grade and comes in various resolution types such as VGA, QVGA, XGA, and SXGA. Clients may also select product enclosures for these modules.

All products feature high-bright LCD systems that come from the company’s proprietary low-power LED backlight technology. The modules and screens also come in ruggedized forms perfect for highly-demanding outdoor industrial use.

LXD Incorporated is among the earliest LCD manufacturers in the world. The company was founded in 1968 by James Fergason under the name International Liquid Xtal Company (ILIXCO). Its first headquarters was in Kent, Ohio. At present, LXD is based in Raleigh, North Carolina.

We’ve listed the top 7 display module TFT LCD manufacturers in the USA. All these companies may not be as well-known as other Asian manufacturers are, but they are equally competent and can deliver high-quality display products according to the client’s specifications. Contact any of them if you need a US-based manufacturer to service your display solutions needs.

We also briefly touched on STONE Technologies, another excellent LCD module manufacturer based in China. Consider partnering with STONE if you want top-of-the-line smart LCD products and you’re not necessarily looking for a US-based manufacturer. STONE will surely provide the right display solution for your needs anywhere you are on the globe.

You need to connect those 8 pins to 8 pins on the Arduino, along with the RS (Register Select) and CS (Chip Select) pins. The RD pin can be connected to 3.3V and the WR pin to GND, since you only really want to write to the screen (if you do want to read from the screen then you will want to connect RD and WR to two IO pins as well). Reset can be connected to a GPIO or to 3.3V, depending on if you want to do a hard reset at any point or not.

Then it"s just a matter of finding a library that works with the ILI9341 in 8-bit parallel mode (u8glib maybe? I don"t know, I never use Arduino to drive a TFT).

Are you looking for an oscilloscope for your electronics workbench? In this article, we’ll show you how to select the best oscilloscope to suit your requirements, whether you’re a beginner, electronics hobbyist, or maker.

An oscilloscope is a tool that allows you to see how voltage changes over time. It is handy to check electronics circuit operation, analog signals, PWM signals, debugging circuits, etc. To select an oscilloscope, you need to know what kind of signals you’ll need to measure. That will determine the specifications you’ll look for in an oscilloscope.

Bandwidth: this determines the frequency range in which the oscilloscope measures accurately in the display. As a rule of thumb, you should select a bandwidth 5 times higher than the maximum frequency of the signals you’ll measure for more accurate results. For example, a 100MHz bandwidth is more than enough for most hobbyist circuits.

Sample rate: this refers to how many samples per second the oscilloscope takes. The higher the sampling rate, the more accurate the results for faster signals. A higher sampling rate ensures you’re able to detect intermittent events.

Number of channels: for entry-level oscilloscopes, it’s common to see 2 and 4-channel scopes. Adding more channels adds to the price. For a hobbyist, a 2-channel scope is usually enough.

Price: the price is a critical aspect, as it will determine how much you can spend on a scope. There are great entry-level oscilloscopes around $250. However, if you don’t have such an amount of money to spend on this tool, you can always get a toy oscilloscope or a DIY kit to analyze basic circuits. There are also great alternatives for USB oscilloscopes or portable oscilloscopes like the Hantek 3 in 1: Oscilloscope, Multimeter, and Signal Generator (2D72).

In my opinion, the Hantek DSO5102P is one of the best entry-level oscilloscopes you can get for such a price. It has a 100MHz bandwidth, a sample rate of 1G samples per second, a record length up to 40K, and a dual channel. Additionally, the USB port allows you to connect a USB drive to save pictures of the signals. You can also connect it to your computer and use the software provided to analyze your measurements in more detail.

The scope is straightforward to set up, and the menus are intuitive to use, which is perfect for beginners. For a more in-depth look at this oscilloscope, you can watch the video review below or read here: Hantek DSO5102P Digital Storage Oscilloscope (DSO) review.

Rigol is a great brand of oscilloscopes and other measurement tools. So, when you pick a Rigol oscilloscope, you know you’ll get a piece of high-quality equipment. This specific model is one of the most best-selling oscilloscopes in the world.

It comes with 4 channels and offers 50 MHz bandwidth. It also comes with a USB connector, LAN(LXI) (you can connect an Ethernet cable), and AUX Output. This is a great oscilloscope when you take a look at price/performance.

If you can’t afford a “real” oscilloscope, there are DIY kits and toy oscilloscopes that may help you with your circuits. Obviously, these tools are not as accurate as a real oscilloscope and don’t have all the fancy mathematical functions, but still, they can do a great job.

One of the best options is the DSO150 digital oscilloscope. This is an elementary scope with a single channel, 200kHz bandwidth, and 12-bit resolution, and it only costs about $25. This tool doesn’t replace a real oscilloscope, but it is good enough for hobbyists looking to debug circuits where accuracy is not mandatory. Also, this can be a great tool for learning purposes. Watch our video review (or read our review).

Portable oscilloscopes look like multimeters but come with all the controls needed to visualize, analyze and record signals. One great option is the Hantek 3 in 1: Oscilloscope, Multimeter, and Signal Generator (2D72). As the name suggests, it is a multimeter, signal generator, and oscilloscope in a single tool. The controls and menus are not as intuitive as a regular oscilloscope, but it does a great job and occupies much less space. You can watch the following video review about this tool.

The USB oscilloscopes don’t have a display and usually don’t have controls—you connect them to your computer and control everything from software provided by the manufacturer. At the moment, we don’t have any in-depth reviews about USB oscilloscopes, but the Hantek 6022BE seems a good option.

In this article we’ve shown you some of the best oscilloscopes for electronics hobbyists and makers. Our number one pick for beginners and hobbyists is the Hantek DSO5102P Digital Storage Oscilloscope.

However, all models presented are great oscilloscopes, and you won’t be disappointed whichever you chose. Remember that you should take into account your specific needs and select a scope with the right specifications.

Register in our brand new ESP32 course with Arduino IDE. This is our complete guide to program the ESP32 with Arduino IDE, including projects, tips, and tricks! The registrations are open, so

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey