3 5 tft lcd shield arduino library factory

Spice up your Arduino project with a beautiful large touchscreen display shield with built in microSD card connection. This TFT display is big (5" diagonal) bright (12 white-LED backlight) and colorfu 480x272 pixels with individual pixel control. As a bonus, this display has a optional resistive touch panel attached on screen by default.

The shield is fully assembled, tested and ready to go. No wiring, no soldering! Simply plug it in and load up our library - you"ll have it running in under 10 minutes! Works best with any classic Arduino (UNO/Due/Mega 2560).

This display shield has a controller built into it with RAM buffering, so that almost no work is done by the microcontroller. You can connect more sensors, buttons and LEDs.

Of course, we wouldn"t just leave you with a datasheet and a "good luck!" - we"ve written a full open source graphics library at the bottom of this page that can draw pixels, lines, rectangles, circles and text. We also have a touch screen library that detects x,y and z (pressure) and example code to demonstrate all of it. The code is written for Arduino but can be easily ported to your favorite microcontroller!

For 5 inch screen,the high current is needed.But the current of arduino uno or arduino mega board is low, an external 5V power supply is needed. Refer to the image shows the external power supply position on shield ER-AS-RA8875.

If you"ve had a lot of Arduino DUEs go through your hands (or if you are just unlucky), chances are you’ve come across at least one that does not start-up properly.The symptom is simple: you power up the Arduino but it doesn’t appear to “boot”. Your code simply doesn"t start running.You might have noticed that resetting the board (by pressing the reset button) causes the board to start-up normally.The fix is simple,here is the solution.

Spice up your Arduino project with a beautiful large touchscreen display shield with built in microSD card connection. This TFT display is big (3.5" diagonal) bright (6 white-LED backlight) and colorful (18-bit 262,000 different shades)! 320x480 pixels with individual pixel control. As a bonus, this display has a optional resistive touch panel with controller XPT2046 attached by default and a optional capacitive touch panel with controller FT6236 attached by default, so you can detect finger presses anywhere on the screen and doesn"t require pressing down on the screen with a stylus and has nice glossy glass cover.

The pin32 (SDO) of 3.5 display module is also used by touch panel or SD card SPI interface, so we must cut off this pin to avoid conflict with the touch panel or SD card.

The shield is fully assembled, tested and ready to go. No wiring, no soldering! Simply plug it in and load up our library - you"ll have it running in under 10 minutes! Works best with any classic Arduino (Due/Mega 2560).

This display shield has a controller built into it with RAM buffering, so that almost no work is done by the microcontroller. You can connect more sensors, buttons and LEDs.

Of course, we wouldn"t just leave you with a datasheet and a "good luck!" - we"ve written a full open source graphics library at the bottom of this page that can draw pixels, lines, rectangles, circles and text. We also have a touch screen library that detects x,y and z (pressure) and example code to demonstrate all of it. The code is written for Arduino but can be easily ported to your favorite microcontroller!

If you"ve had a lot of Arduino DUEs go through your hands (or if you are just unlucky), chances are you’ve come across at least one that does not start-up properly.The symptom is simple: you power up the Arduino but it doesn’t appear to “boot”. Your code simply doesn"t start running.You might have noticed that resetting the board (by pressing the reset button) causes the board to start-up normally.The fix is simple,here is the solution.

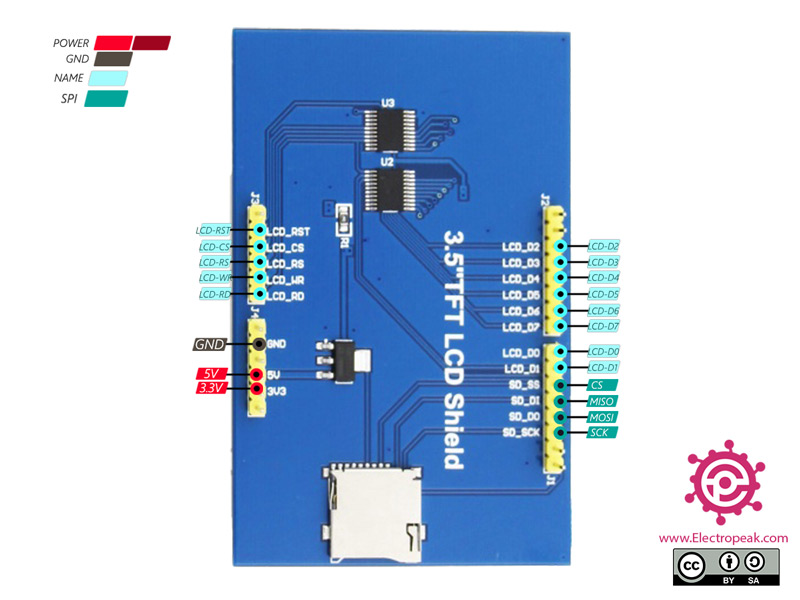

This module is a 3.5-inch TFT LCD module with “320X480” resolution and 65K color display. It is suitable for Arduino Uno and Mega2560 development boards, and also supports SD card expansion function. It uses 8-bit parallel port communication, and the driver IC is ILI9486.

The 3.5-inch display is a ready-made shield for Arduino Uno, which can also be placed on the Arduino Mega. The pins of this shield are designed to be easily installed on the Arduino. The bad point about these modules is that they use all Arduino Uno pins.

my_lcd.Fill_Triangle(x_spec+i*side_len-1,y_spec+(i+1)*h_len-1,x_spec+side_len/2+i*side_len-1,y_spec+i*h_len-1,x_spec+(i+1)*side_len-1,y_spec+(i+1)*h_len-1);

my_lcd.Fill_Triangle(x_spec+i*side_len-1,y_spec+(5-i)*h_len-1,x_spec+side_len/2+i*side_len-1,y_spec+(4-i)*h_len-1,x_spec+(i+1)*side_len-1,y_spec+(5-i)*h_len-1);

my_lcd.Draw_Line(2+random(my_lcd.Get_Display_Width()-4),17+random(my_lcd.Get_Display_Height()-34),2+random(my_lcd.Get_Display_Width()-4),17+random(my_lcd.Get_Display_Height()-34));

my_lcd.Draw_Rectangle(2+random(my_lcd.Get_Display_Width()-4),17+random(my_lcd.Get_Display_Height()-34),2+random(my_lcd.Get_Display_Width()-4),17+random(my_lcd.Get_Display_Height()-34));

my_lcd.Draw_Round_Rectangle(2+random(my_lcd.Get_Display_Width()-4),17+random(my_lcd.Get_Display_Height()-34),2+random(my_lcd.Get_Display_Width()-4),17+random(my_lcd.Get_Display_Height()-34),5);

my_lcd.Draw_Triangle(2+random(my_lcd.Get_Display_Width()-4),17+random(my_lcd.Get_Display_Height()-34),2+random(my_lcd.Get_Display_Width()-4),17+random(my_lcd.Get_Display_Height()-34),2+random(my_lcd.Get_Display_Width()-4),17+random(my_lcd.Get_Display_Height()-34));

my_lcd.Fill_Round_Rectangle(my_lcd.Get_Display_Width()/2-1-120+1, my_lcd.Get_Display_Height()/2-1-60+1, my_lcd.Get_Display_Width()/2-1+120-1, my_lcd.Get_Display_Height()/2-1+60-1,5);

The liquid crystal display module based on SPI communication interface, provide 3.5 "TFT LCD, resistive touch screen, built-in Flash flash and SD card external expansion storage. This TFT panel connects directly on top of an Arduino pin compatible device.

2.Extract the content to your Arduino library folder. In Windows this is usually located in Arduino IDE folder\libraries. Check Arduino"s official guide if you want more information on how to install the Arduino Library The official guide of Arduino

3.Start Arduino IDE, you can find ready to run Examples in the menu. File--> Examples-> DmTftLibraries. select the right board and COM port: DM-TFT35-107

TFT LCDs are the most popular color displays – the displays in smartphones, tablets, and laptops are actually the TFT LCDs only. There are TFT LCD shields available for Arduino in a variety of sizes like 1.44″, 1.8″, 2.0″, 2.4″, and 2.8″. Arduino is quite a humble machine whenever it comes to process or control graphics. After all, it is a microcontroller platform, and graphical applications usually require much greater processing resources. Still, Arduino is capable enough to control small display units. TFT LCDs are colorful display screens that can host beautiful user interfaces.

Most of the smaller TFT LCD shields can be controlled using the Adafruit TFT LCD library. There is also a larger TFT LCD shield of 3.5 inches, with an ILI9486 8-bit driver.

The Adafruit library does not support the ILI9486 driver. Actually, the Adafruit library is written to control only TFT displays smaller than 3.5 inches. To control the 3.5 inch TFT LCD touch screen, we need another library. This is MCUFRIEND_kbv. The MCUFRIEND_kbv library is, in fact, even easier to use in comparison to the Adafruit TFT LCD library. This library only requires instantiating a TFT object and even does not require specifying pin connections.

TFT LCDs for ArduinoUser interfaces are an essential part of any embedded application. The user interface enables any interaction with the end-user and makes possible the ultimate use of the device. The user interfaces are hosted using a number of devices like seven-segments, character LCDs, graphical LCDs, and full-color TFT LCDs. Out of all these devices, only full-color TFT displays are capable of hosting sophisticated interfaces. A sophisticated user interface may have many data fields to display or may need to host menus and sub-menus or host interactive graphics. A TFT LCD is an active matrix LCD capable of hosting high-quality images.

Arduino operates at low frequency. That is why it is not possible to render high-definition images or videos with Arduino. However, Arduino can control a small TFT display screen rendering graphically enriched data and commands. By interfacing a TFT LCD touch screen with Arduino, it is possible to render interactive graphics, menus, charts, graphs, and user panels.

Some of the popular full-color TFT LCDs available for Arduino include 3.5″ 480×320 display, 2.8″ 400×200 display, 2.4″ 320×240 display and 1.8″ 220×176 display. A TFT screen of appropriate size and resolution can be selected as per a given application.

If the user interface has only graphical data and commands, Atmega328 Arduino boards can control the display. If the user interface is a large program hosting several menus and/or submenus, Arduino Mega2560 should be preferred to control the TFT display. If the user interface needs to host high-resolution images and motions, ARM core Arduino boards like the DUE should be used to control the TFT display.

MCUFRIEND_kbv libraryAdafruit TFT LCD library supports only small TFT displays. For large TFT display shields like 3.5-inch, 3.6-inch, 3.95-inch, including 2.4-inch and 2.8-inch TFT LCDs, MCUFRIEND_kbv library is useful. This library has been designed to control 28-pin TFT LCD shields for Arduino UNO. It also works with Arduino Mega2560. Apart from UNO and Mega2560, the library also supports LEONARDO, DUE, ZERO, and M0-PRO. It also runs on NUCLEO-F103 and TEENSY3.2 with Sparkfun Adapter. The Mcufriend-style shields tend to have a resistive TouchScreen on A1, 7, A2, 6 but are not always in the same direction rotation. The MCUFRIEND_kbv library can be included in an Arduino sketch from the library manager.

The 3.5-inch TFT LCD shield needs to be plugged atop the Arduino board. The Mcufriend-style shields are designed to fit into all the above-mentioned Arduino boards. The shields have a TFT touch screen that can display colorful images and interfaces and a micro SD card reader to save images and other data. A 3.5-inch TFT LCD touch screen has the following pin diagram.

The drawFastVLine function draws a vertical line that starts in x, y location, and its length is h pixel and its color is t. The drawFastHLine function draws a horizontal line that starts in x and y location, and the length is w pixel, and the color is t. The drawLine function draws a line that starts in xi and yi locationends is in xj and yj, and the color is t. These methods draw lines with 5-pixel thickness.

Voltage type: 5v or 3v voltage input voltage,input is selectable. Because TFT can only work under 3.3 V voltage, so when the input voltage VIN is 5V, need through the 3.3 V voltage regulator IC step down to 3.3V , when the input voltage of 3.3 V, you need to use the zero resistance make J2 short , is equivalent to not through the voltage regulator IC for module and power supply directly.

Some people say that this shield requires 3.3 [Volts] to work, but the Vcc pin connected goes to 5V and it contains a Voltage regulator. I suppose it drops the voltage from 5[V] to 3.3[V] in the middle of the back side of the screen shield (see the upper photo - U1).

After using the geometry test included in the library folder UTF Geometry mentioned on #5, and using all the drivers found in the documentation included by Henning Karlsen in a .pdf doc, I couldn"t get this shield to work.

After two theory-loaded blog posts about handling data array-like in strings (Strings, arrays, and the less known sp(lit)str(ing) function and Strings & arrays - continued) which you are highly recommended to read before continuing here, if you haven"t already, it"s big time to see how things work in practice! We"ll use a string variable as a lookup lookup table containing data of one single wave period and add this repeatedly to a waveform component until it"s full.A few weeks ago, I wrote this article about using a text variable as an array, either an array of strings or an array of numbers, using the covx conversion function in addition for the latter, to extract single elements with the help of the spstr function. It"s a convenient and almost a "one fits all" solution for most use cases and many of the demo projects or the sample code attached to the Nextion Sunday Blog articles made use of it, sometimes even without mentioning it explicitly since it"s almost self-explaining. Then, I got a message from a reader, writing: "... Why then didn"t you use it for the combined sine / cosine lookup table in the flicker free turbo gauge project?"105 editions of the Nextion Sunday blog in a little over two years - time to look back and forth at the same time. Was all the stuff I wrote about interesting for my readers? Is it possible at all to satisfy everybody - hobbyists, makers, and professionals - at the same time? Are people (re-)using the many many HMI demo projects and code snippets? Is anybody interested in the explanation of all the underlying basics like the algorithms for calculating square roots and trigonometric functions with Nextion"s purely integer based language? Are optimized code snippets which allow to save a few milliseconds here and there helpful to other developers?Looking through the different Nextion user groups on social networks, the Nextion user forum and a few not so official but Nextion related forums can be surprising. Sometimes, Nextion newbies ask questions or have issues although the required function is well (in a condensed manner for the experienced developer, I admit) documented on the Nextion Instruction Set page, accessible through the menu of this website. On top of that, there is for sure one of my more than 100 Sunday blog articles which deals not only with that function, but goes often even beyond the usual usage of it. Apparently, I should sometimes move away from always trying to push the limits and listen to the "back to the roots!" calls by my potential readers...Do you remember the (almost) full screen sized flicker free and ultra rapid gauge we designed in June? And this without using the built-in Gauge component? If not, it"s time to read this article first, to understand today"s improvements. The June 2022 version does its job perfectly, the needle movement is quick and smooth, and other components can be added close to the outer circle without flickering since there is no background which needs constantly to be redrawn. But there was a minor and only esthetic weak point: The needle was a 1px thin line, sometimes difficult to see. Thus, already a short time after publishing, some readers contacted me and asked if there were a way to make the needle thicker, at least 2 pixels.Recently, when playing with a ESP32 based NodeMCU 32S and especially with its WiFi configuration, I did as (I guess) everybody does: I loaded an example sketch to learn more about the Wifi library. When you set up the ESP32 as an access point, creating its own wireless network, everything is pretty straightforward. You can easily hard code the Wifi name (SSID) and the password. But what about the client mode ? Perhaps one needs to use it in different environments. And then, a hard coded network name and password are definitively not the best solution. Thus, I thought, why not use a Nextion HMI for a dynamic WiFi setup functionality?

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey