cost for an lcd panel supplier

There are wholesale lcd panel available in a variety of sizes (16x2, 16x4, 20x2, 20x4, 24x2, 40x2, and more) as well as many resolutions. Some of the modules allow for clear and colorful displays. You can find some modules that have integrated controllers, coloured and monochrome, and flat-screen and modules with SPI. For greater visibility outdoors, there are also super-bright modules with high luminance ranges.

Explore the extensive selection of wholesale lcd panel LCD displays, TFT, and HMI that can be used across a range of industries, including domestic, medical, industrial, automotive, and many others. You can choose from a number of standard industry sizes and find the wholesale lc panel that are applicable to your required use. If you would like options that allow a smaller environmental footprint due to low power consumption, you can browse the Chip-on-Glass (COG) LCDs. COGs are designed without PCBs so have a slimmer profile.

Alibaba.com features a broad collection of smart and advanced wholesale lcd panel equipped with bright, capacitive screens for the most affordable prices. These wholesale lcd panel are made implying the latest technologies for a better, enhanced, and smart viewing experience. These products are of optimal quality and are sustainable so that they can last for a long time. Buy these wholesale lcd panel from the leading wholesalers and suppliers at discounted prices and fabulous deals. The smart and capacitive wholesale lcd panel offered on the site are applicable for all types of ads displaying, mobile screens, LCD monitors, and many more. You can use them both for commercial as well as residential purposes. These marvellous wholesale lcd panel are provided with bright and strong backlights available in distinct colors for a wonderful screen viewing experience. These wholesale lcd panel are not just used for LCD screens but also are used for TFT, LED, and other.

lcd panel (Liquid crystal display) are made of liquid crystals that form digital images made visible through ambient light or through LED backlight. LCDs are used in the place of other displays that are less efficient such as cathode ray tubes (CRTs) and have become the most popular display type on the market.

Lcd panel enable metal and position detection without having to physically contact the metal object. They offer a wide range of applications in robotics, rail, material handling, aerospace, military, as well as heavy machinery. Choose from different lcd panel types, from the shielded versions that have electromagnetic fields concatenated in the front and unshielded versions which allow wider sensing distances. Whether you want to use your sensors for industrial purposes or source for your brand, there is a wide selection of wholesale lcd panels to choose from. will allow you to customize the applications of your parts in the market. Unlike other packaging materials, plastic bottles are durable, cost-effective, and easy to use, enhancing the efficiency of your business. If you are a retailer, you can also order bulk plastic bottles at Alibaba.com and keep your business running smoothly.

Alibaba.com features a broad collection of smart and advanced lcd panel equipped with bright, capacitive screens for the most affordable prices. These lcd panel are made implying the latest technologies for a better, enhanced, and smart viewing experience. These products are of optimal quality and are sustainable so that they can last for a long time. Buy these lcd panel from the leading wholesalers and suppliers at discounted prices and fabulous deals. The smart and capacitive lcd panel offered on the site are applicable for all types of ads displaying, mobile screens, LCD monitors, and many more. You can use them both for commercial as well as residential purposes. These marvellous lcd panel are provided with bright and strong backlights available in distinct colors for a wonderful screen viewing experience. These lcd panel are not just used for LCD screens but also are used for TFT, LED, and other screen variations.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

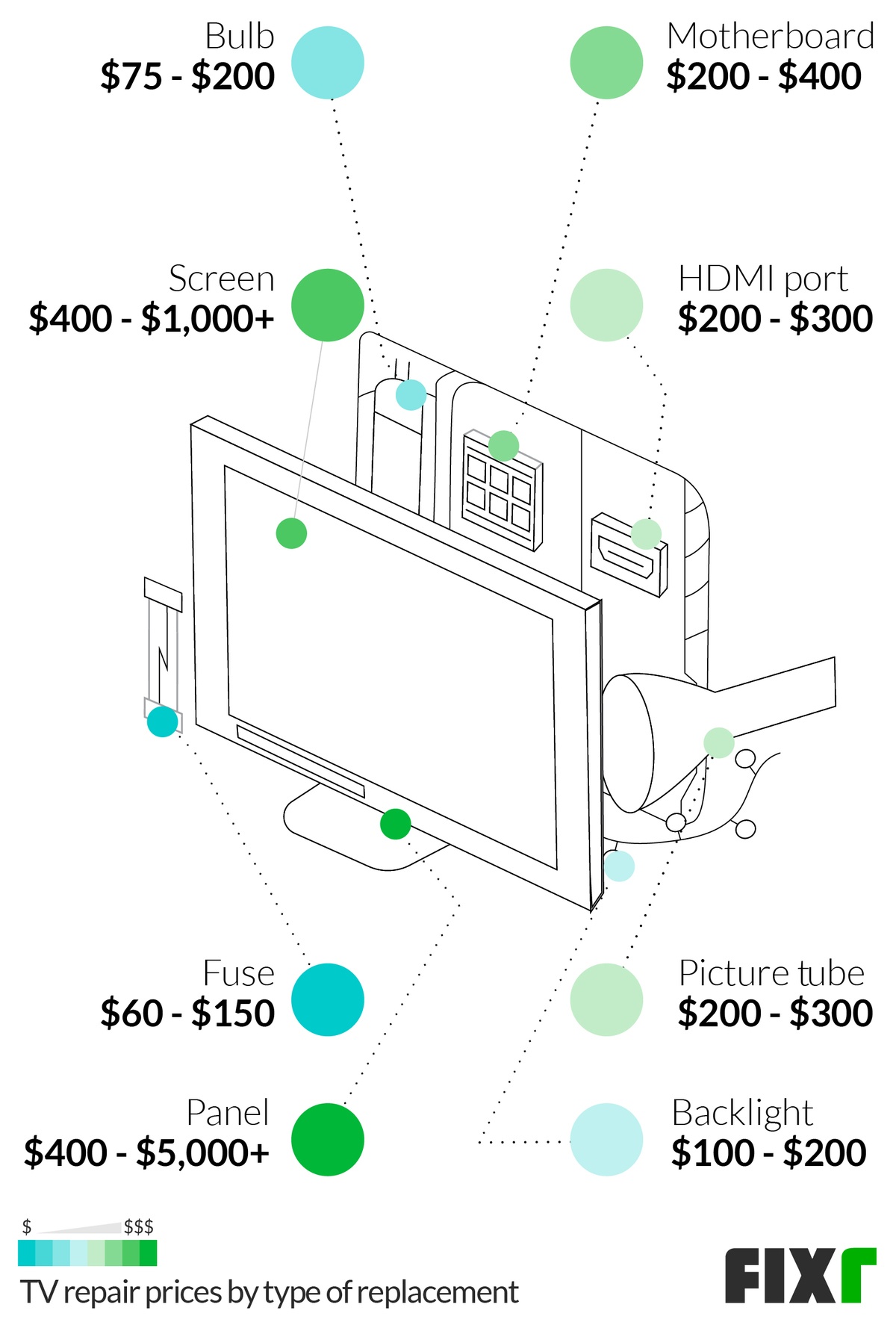

Once it’s recognized that a custom display will be a better design and lead to a lower overall system-level cost it’s time to dive into the actual tooling costs.

There are many factors that go into determining the upfront tooling. There’s also due diligence to be performed prior to making this commitment to ensure that this new custom display supplier will effectively support you over the long term.

Customization can either be semi-custom or fully custom. Semi-custom is where some attributes of a standard product are modified to fit the application. In contrast, fully custom is where the design is started from scratch and each component is designed from the ground up.

Semi-custom is typically the preferred option to start with. And in the case of color TFT, it’s typically the only option, as the TFT panel comes with a significant tooling and minimum order quantity (MOQ) such that the customization costs outweigh the drawbacks of using the closest standard TFT glass platform available.

b) Custom color TFT displays— the bulk of this cost comes from the TFT glass cell at $70K–$200K depending on the type of TFT cell used (standard TN or IPS). The balance of the module is an additional $5,000 – $15,000.

f) Touch panels— resistive touch panels cost approximately $2,500, while capacitive touch panels can range between $4,000 and $10,000. If a standard capacitive touch sensor can be used, and only a custom top surface is customized, the tooling can be reduced to only $1,500.

g) Backlights— monochrome display backlights are less complex and cheaper to tool at $2,000 – $4,000. The color counterpart, due to its high brightness requirement, will run between $4,000 and $10,000.

i) Overlays— this can vary significantly depending on the complexity of the screen printing, as well as any additional features, such as button or LED indicators. The overlay will typically range from $1,500 - $4,500.

Now that we’ve reviewed some of the costs associated with custom displays, here are some tips you can use to make sure that you move forward with the right partner that will then support this custom display for the long term.

Many LCD display manufacturers try to accommodate all order volumes they receive. While this allows them to serve a wider range of customers, it makes them less specialized for serving certain types of customers. As a result, your specific production volumes may be prohibitively expensive.

Seek out a display manufacturer who is optimized to handle your specific production needs for LCD displays. This is necessary to get the display for the right cost and the appropriate level of support.

Always start with a semi-custom approach. Use the available standard products to base the new design on, and then keep modifying as needed. This results in the lowest tooling costs and an easier design process. And in the case of color TFT, unless you are developing the next iPhone, design your display based on one of the standard glass platforms readily available. Then from there, redesign the backlight and the mechanical and electrical interface for your specific application.

Behind every great company are happy customers. Find out whether your supplier has them. Make sure that when this experience is handed off from your supplier’s sales and design team, the production team is just as good and accommodating. This can be accomplished through references and audits.

Initiating a successful relationship for a new custom display is all about having an open and transparent relationship with the right partner. And by designing the ideal custom or semi-custom display with this partner, you can ensure you’re getting the best possible solution for your company.

New Vision Display is a custom LCD display manufacturer serving OEMs across diverse markets. One of the things that sets us apart from other LCD screen manufacturers is the diversity of products and customizations we offer. Our LCD portfolio ranges from low-cost monochrome LCDs to high-resolution, high-brightness color TFT LCDs – and pretty much everything in between. We also have extensive experience integrating LCD screen displays into complete assemblies with touch and cover lens.

Sunlight readable, ultra-low power, bistable (“paper-like”) LCDs. Automotive grade, wide operating/storage temperatures, and wide viewing angles. Low tooling costs.

Among the many advantages of working with NVD as your LCD screen manufacturer is the extensive technical expertise of our engineering team. From concept to product, our sales and technical staff provide expert recommendations and attentive support to ensure the right solution for your project.

In addition, our extensive technology portfolio and manufacturing capabilities enable us to deliver high-quality products that meet the unique specifications of any application. To learn more about what makes us the display manufacturer for your needs, get in touch with us today.

As a leading LCD panel manufacturer, NVD manufactures custom LCD display solutions for a variety of end-user applications: Medical devices, industrial equipment, household appliances, consumer electronics, and many others. Our state-of-the-art LCD factories are equipped to build custom LCDs for optimal performance in even the most challenging environments. Whether your product will be used in the great outdoors or a hospital operating room, we can build the right custom LCD solution for your needs. Learn more about the markets we serve below.

Ready to get started or learn more about how we can help your business? Call us at +1-855-848-1332 or fill out the form below and a company representative will be in touch within 1 business day.

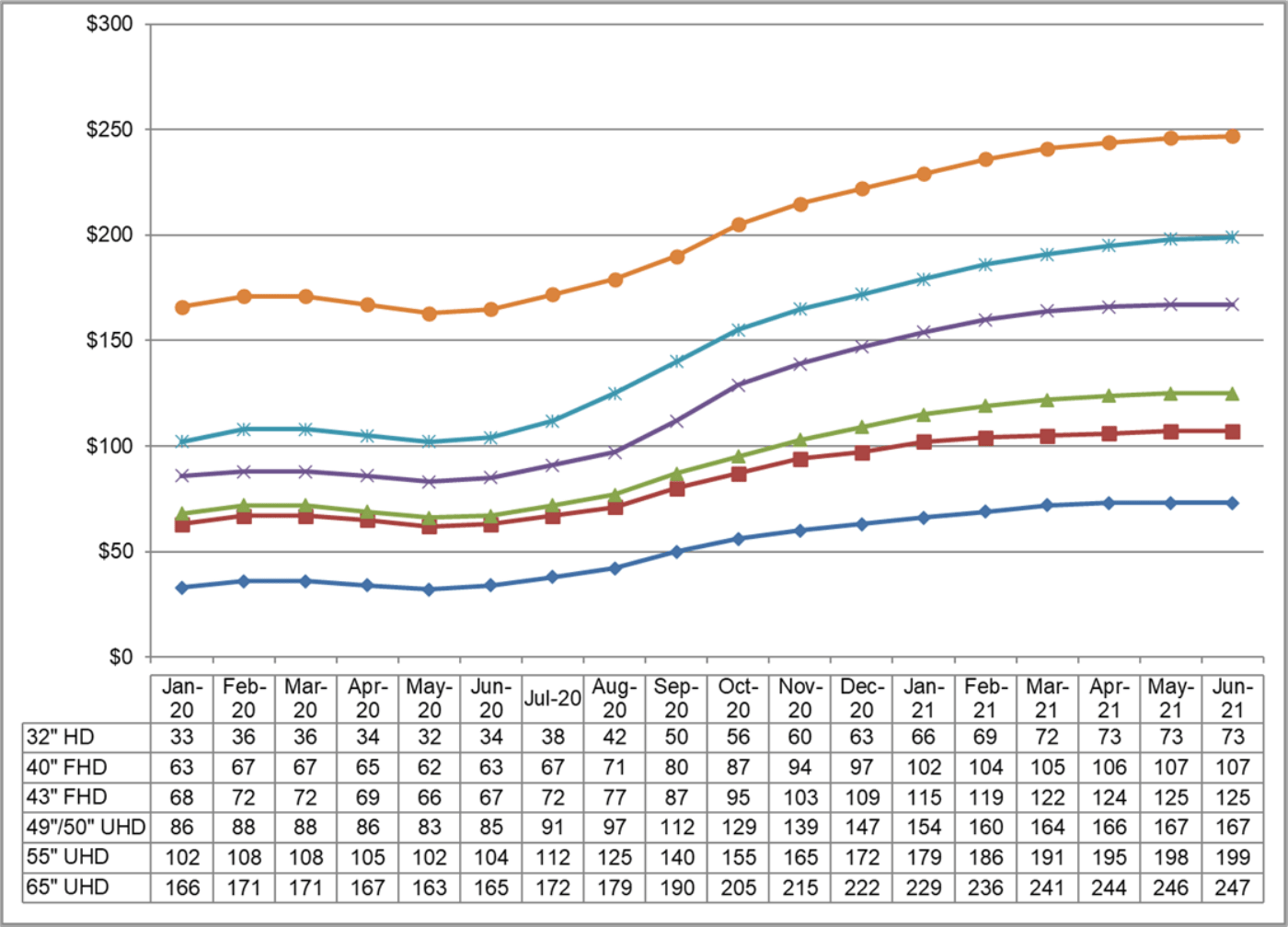

Prices for all TV panel sizes fluctuated and are forecast to fluctuate between 2020 and 2022. The period from March 2020 to July 2021 saw the biggest price increases, when a 65" UHD panel cost between 171 and 288 U.S. dollars. In the fourth quarter of 2021, such prices fell and are expected to drop to an even lower amount by March 2022.Read moreLCD TV panel prices worldwide from January 2020 to March 2022, by size(in U.S. dollars)Characteristic32" HD43" FHD49"/50" UHD55" UHD65" UHD------

DSCC. (January 10, 2022). LCD TV panel prices worldwide from January 2020 to March 2022, by size (in U.S. dollars) [Graph]. In Statista. Retrieved October 20, 2022, from https://www.statista.com/statistics/1288400/lcd-tv-panel-price-by-size/

DSCC. "LCD TV panel prices worldwide from January 2020 to March 2022, by size (in U.S. dollars)." Chart. January 10, 2022. Statista. Accessed October 20, 2022. https://www.statista.com/statistics/1288400/lcd-tv-panel-price-by-size/

DSCC. (2022). LCD TV panel prices worldwide from January 2020 to March 2022, by size (in U.S. dollars). Statista. Statista Inc.. Accessed: October 20, 2022. https://www.statista.com/statistics/1288400/lcd-tv-panel-price-by-size/

DSCC. "Lcd Tv Panel Prices Worldwide from January 2020 to March 2022, by Size (in U.S. Dollars)." Statista, Statista Inc., 10 Jan 2022, https://www.statista.com/statistics/1288400/lcd-tv-panel-price-by-size/

DSCC, LCD TV panel prices worldwide from January 2020 to March 2022, by size (in U.S. dollars) Statista, https://www.statista.com/statistics/1288400/lcd-tv-panel-price-by-size/ (last visited October 20, 2022)

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

Sony produces and sells commercial MicroLED displays called CLEDIS (Crystal-LED Integrated Displays, also called Canvas-LED) in small quantities.video walls.

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

2015, sold to giantplus and tce photomasks, gen 3 still operated by giantplus, gen 4 line sold to giantplus, equipment sold and line demolished, remainder operated by tce

Cantwell, John; Hayashi, Takabumi (January 4, 2019). Paradigm Shift in Technologies and Innovation Systems. Springer Nature. ISBN 9789813293502 – via Google Books.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"TCL"s Panel Manufacturer CSOT Commences Production of High Generation Panel Modules". www.businesswire.com. June 14, 2018. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Business Place Information – Global Operation | SAMSUNG DISPLAY". www.samsungdisplay.com. Archived from the original on 2018-03-26. Retrieved 2018-04-01.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

Byeonghwa, Yeon. "Business Place Information – Global Operation – SAMSUNG DISPLAY". Samsungdisplay.com. Archived from the original on 2018-03-26. Retrieved 2018-04-01.

www.etnews.com (30 June 2017). "Samsung Display to Construct World"s Biggest OLED Plant". Archived from the original on 2019-06-09. Retrieved 2019-06-09.

Colantonio, Andrea; Burdett, Richard; Rode, Philipp (2013-08-15). Transforming Urban Economies: Policy Lessons from European and Asian Cities. Routledge. ISBN 9781134622160. Archived from the original on 2019-01-01. Retrieved 2019-06-09.

Shilov, Anton. "LG"s New 55+ inch OLED Plant in China Opens: Over 1m+ per Year". www.anandtech.com. Archived from the original on 2019-09-14. Retrieved 2019-12-18.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

Shilov, Anton. "JOLED Starts Construction of New Printed OLED Facility". www.anandtech.com. Archived from the original on 2019-06-30. Retrieved 2019-06-30.

Pooler, Michael (29 September 2015). "Subscribe to read". Financial Times. Archived from the original on 2019-10-25. Retrieved 2019-10-25. Cite uses generic title (help)

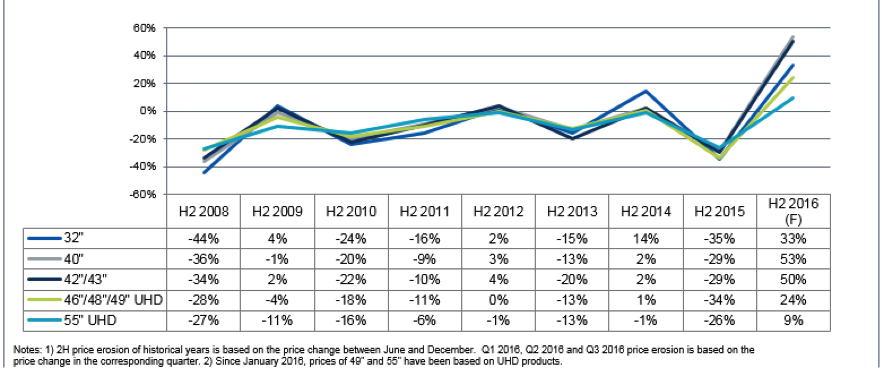

After a full year of rising LCD TV panel prices, the natural effect of rising prices on both supply and demand has kicked in, and prices are starting to fall, based on our latest update and forecast of LCD TV prices. The demand surge, which resulted from the COVID-19 pandemic, has eased and industry supply has caught up to demand. Prices in August and September are falling faster than expected and we now forecast that year-end prices will be lower than they were in December 2020, but still substantially higher than their all-time lows.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

In another ominous sign for global TV industry supply, both demand and prices for TV-sized LCD panels continue to fall at the same time, recent reports from two display market analysts revealed.

Display industry market analysts TrendForce and Omdia each issued potentially troubling LCD TV display panel business updates this week as the global economic outlook continues to impact discretionary spending for non-essential items like TV sets.

The compounding effects of inflation, mounting signs of recessionary conditions ahead and on-going issues with shipping and logistics paint a gloomy picture for those looking to buy or sell a television set in the peak second half of 2022.

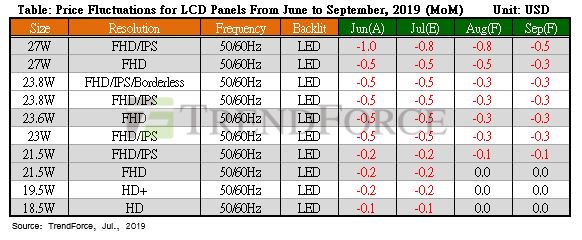

According to TrendForce, the outlook for purchases by TV makers of LCD TV display panels — the major component part for LCD-based TVs that represent the vast majority of the TV sets — continues to decline even as prices for most panel sizes have fallen to record lows.

Recently, it was announced that the 32-inch and 43-inch panels fell by approximately $5-$6 in early June, 55-inch panels fell approximately $7, and prices for 65-inch and 75-inch panels, which face mounting overcapacity pressure, were down $12 to $14, TrendForce said.

“In order to alleviate pressure caused by price decline and inventory, panel makers are successively planning to initiate more significant production control in [the third quarter of 2022],” TrendForce said. “..Overall LCD TV panel production capacity in [the third quarter] will be reduced by 12% compared with original planning.”

According Omdia prices for TV-sized LCD display panels have been falling for the first year since Covid-19 appeared, while the increase in display demand area is expected to be up just 3%, half of the previous year.

Similarly, Omdia’s forecast released Thursday showed global display sales this year would decrease by 15% from last year to $133.18 billion. That compares to the global display sales increases of 14% in 2020 and 26% in 2021 due to the surge in demand for LCD panels and TVs generated by lockdowns forced by the pandemic.

LCD TV panel sales this year are expected to drop by 32% from last year ($38.3 billion) to $25.8 billion, according to Omdia’s predictions. The LCD TV panel demand area is expected to increase by 2% this year from last year, but the panel price decline is large.

“When there is an imbalance in supply and demand, a focus on strategic direction is prioritized,” TrendForce said. “TV panel production capacity of the three aforementioned companies in [Q3 2022] is expected to decrease by 15.8% compared with their original planning, and 2% compared with [the second quarter.]

TrendForce said Taiwanese manufacturers account for nearly 20% of TV panel shipments, and allocation of production capacity among those factories is now subject to “dynamic adjustment.”

The firm said TV sizes 55 inches and below have “fallen below their cash cost in May (which is seen as the last line of defense for panel makers) and is even flirting with the cost of materials, coupled with production capacity reduction from panel makers, the price of TV panels has a chance to bottom out at the end of June and be flat in July.”

As for TV sizes 65 inches and larger, which come largely from the Korean brands, TrendForce said declining demand has forced TV brands to revise downward their shipment targets for this year, with purchase volume for the third quarter of 2022 significantly reduced.

However, the firm said, optimistically, “this price decline may begin to dissipate month by month starting in June but supply has yet to reach equilibrium, so the price of large sizes [65 inches and above] will continue to decline in [the third quarter].”

TrendForce said that as panel makers continue to significant reduce production, the price of TV panels 55 inches and under is expected to remain flat in through the third quarter.

“Panel manufacturers cutting production in the traditional peak season also means that a disappointing [second half 2022] peak season is a foregone conclusion and it will not be easy for panel prices to reverse,” according to TrendForce.

It is possible that if the supply/pricing pressures continue, the number, scale and duration of manufacturers cutting panel production output will grow in an effort to generate momentum for a rebound in TV panel quotations, TrendForce said.

As reported by S. Korean technology trade news site The Elec, Omdia said the LCD TV panel shipment targets for BOE were lowered to 60 million units this year from the original 65.5 million units. HKC decreased its targets from 49.5 million to 42 million, CSOT from 45 to 44.8 million, and LG Display from 23.5 million to 18 million. Innolux’s shipment target increased slightly from 34.5 million units to 34.6 million units.

On the other hand, organic light emitting diode (OLED) TV panel sales this year are expected to reach $5.4 billion, up 12% from last year ($4.8 billion), according to Omdia.

OLED TV panels are being mass-produced by LG Display and Samsung Display, as both manufacturers reduce their exposure in LCDs. Samsung Display will end LCD TV panel production entirly this summer. However, LG Display’s OLED panel production forecast is 10 times that of Samsung Display.

Meanwhile, Samsung Display hiked yield rates for its new large-size QD-OLED panels from 30% of capacity initially, 50% in 2021, 75% in April-May 2022 to 80% now, according to South Korea-based publication The Bell.

Some subscribers prefer to save their log-in information so they do not have to enter their User ID and Password each time they visit the site. To activate this function, check the "Save my User ID and Password" box in the log-in section. This will save the password on the computer you"re using to access the site.

Note: If you choose to use the log-out feature, you will lose your saved information. This means you will be required to log-in the next time you visit our site.

AfghanistanAlbaniaAlgeriaAmerican SamoaAndorraAngolaAnguillaAntigua and BarbudaArgentinaArmeniaArubaAscensionAustraliaAustriaAzerbaijanBahamasBahrainBangladeshBarbadosBelarusBelgiumBelizeBeninBermudaBhutanBoliviaBosnia-HercegovinaBotswanaBrazilBritish Indian Ocean TerritoryBruneiBulgariaBurkina FasoBurundiCambodiaCameroonCanadaCape VerdeCayman IslandsCentral African RepublicChadChileChinaChristmas IslandCocos (Keeling) IslandsColombiaComorosCongoCongo, Dem Rep ofCook IslandsCosta RicaCroatiaCubaCyprusCzech RepublicDenmarkDjiboutiDominicaDominican RepublicEast TimorEcuadorEgyptEl SalvadorEquatorial GuineaEritreaEstoniaEthiopiaFalkland IslandsFaroe IslandsFijiFinlandFranceFrench GuianaFrench PolynesiaFrench Southern TerritoriesGabonGambiaGeorgiaGermanyGhanaGibraltarGreeceGreenlandGrenadaGuadeloupeGuamGuatemalaGuineaGuinea-BissauGuyanaHaitiHeard Island and McDonald IsHondurasHungaryIcelandIndiaIndonesiaIranIraqIrelandIsraelItalyIvory CoastJamaicaJapan 曰本JordanKazakhstanKenyaKirgizstanKiribatiKosovoKuwaitLaosLatviaLebanonLeeward IslesLesothoLiberiaLibyaLiechtensteinLithuaniaLuxembourgMacauMacedonia, FYRMadagascarMalawiMalaysiaMaldivesMaliMaltaMarshall IslandsMartiniqueMauritaniaMauritiusMayotteMexicoMicronesia, Fed States ofMoldovaMonacoMongoliaMontenegroMontserratMoroccoMozambiqueMyanmarNamibiaNauruNepalNetherlandsNetherlands AntillesNew CaledoniaNew ZealandNicaraguaNigerNigeriaNorfolk IslandNorth KoreaNorthern Mariana IslandsNorwayOmanPakistanPalauPalestinePanamaPapua New GuineaParaguayPeruPhilippinesPitcairn IslandPolandPortugalPuerto RicoQatarReunionRomaniaRussiaRwandaST MartinSaint HelenaSaint Kitts and NevisSaint LuciaSaint Vincent and GrenadinesSamoaSao Tome and PrincipeSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSlovakiaSloveniaSolomon IslandsSomaliaSouth AfricaSouth GeorgiaSpainSri LankaSudanSurinameSwazilandSwedenSwitzerlandSyriaTaiwanTajikistanTanzaniaThailandTogoTokelauTongaTrinidad and TobagoTunisiaTurkeyTurkmenistanTurks and Caicos IslandsTuvaluUS Minor Outlying IsUgandaUkraineUnited Arab EmiratesUnited KingdomUruguayUzbekistanVanuatuVenezuelaVietnamVirgin Islands, BritishVirgin Islands, USWallis and FutunaYemenZambiaZimbabwe

The first half of 2022 has passed quietly. Under the impact of multiple factors such as geopolitical conflicts, global hyperinflation, and demand overdraft, the global TV panel market has ushered in the darkest moment.

The end demand in the global TV market continues to be sluggish, brands are deeply controlling their inventory, the prices of LCD TV panels have fallen below the cash cost, and panel makers have also started the largest production cut in history. In 22H2, there are still relatively large uncertainties in the end market. The key to stabilize supply and demand in the global LCD TV panel market in 22H2 is whether the adjustment of panel maker capacity can catch up with the decline of the demand for brand panel purchasing.

The seasonal index showed an "L" shape, and demand will remain weak in 22H2.The annual seasonal index of the global LCD TV panel market usually presents a "V"-shaped characteristic, but the seasonal index of panel shipments in 2022 appears to be an "L"-shaped. The peak season in 22H2 is not prosperous, and demand will still be weak.

• Q1: Affected by factors such as high inflation, high shipping costs, and demand overdraft in the end market, the retail performance was not as good as expected, and the demand for large-size panels of top brands was sluggish; Second-tier makers started the first round of bargain hunting and stocking, which drove the number of panel shipments in Q1 to a record high in Q1 and became the peak of the year.

• Q2: The Russian-Ukrainian war broke out, and the demand in the European market uncontrollably declined. Brand purchasing demand shrank to a new low in the past ten years than expected. Large-size demand continued to deteriorate, and small-size demand also declined. Panel shipments decreased rapidly in Q2.

• Q3: Samsung suspended panel purchases and is expected to continue its inventory control strategy in Q3. At the same time, pessimism spreads and affects the purchasing confidence of other brands, and panel shipments in Q3 may not be prosperous in the peak season.

• Q4: As shipping costs continue to fall, panel prices decline to a low level, and brand inventory tends to be healthy, it is expected that the stocking demand for top brand panels, especially large-size demand, is expected to resume growth in Q4, but there is no strong recovery in end consumption. It is difficult to expect a strong recovery in shipments.

According to Sigmaintell"s data, the global LCD TV panel shipment is expected to be 260 million in 2022, of which 68 million were shipped in Q1, accounting for 26.5% of the annual shipment; From Q2 to Q4, it is expected that the quarterly shipment level will fluctuate around 62 million pieces, and the seasonal index is difficult to exceed 25%, and the seasonal index has an obvious "L" shape.

The large-scale size was hindered, and the average size and area decreased YOY.The upgrade and iteration of the generation line drive the process of large-size, which is the main trend of the development of the global TV panel market. However, the average size of the global LCD TV panel market will decline for the first time in 2022. The main reasons are as follows:

First, due to factors such as high inflation, high shipping costs, and demand overdrafts, the demand for large-size TVs in the North American market has been significantly suppressed;

Third, panel prices drive makers to be more aggressive in stocking small sizes. The 32-inch panel with high price elasticity is the most typical, and the second-tier market demand, such as OEM/ODMs and distributors, occupies half of its shipments. When the price of the panel fell to a relatively low level, the enthusiasm of the second-tier makers was ignited, and the stocking behavior of the second-tier makers pushed up the 32-inch shipment level of the panel maker.

According to Sigmaintell"s data, the overall average size in 2022 is 47.7 inches, a decrease of 0.8 inches YOY. In the first three quarters, due to the sluggish demand for large sizes and the high level of 32-inch shipments, the average size is lower than that in 2021. It is expected that with the advent of the "11.11" promotion season in China, the inventory of brands and channels in the North American market tends to be healthy, and the logistics and panel costs will further decline. It is expected to drive the recovery of large-size demand, thereby promoting the global average size of LCD TV panels to increase to 49.3 inches in Q4, a significant increase of 2 inches from the previous quarter.

The OLED panel market is also difficult to survive alone, falling into the dual dilemma of loss expectations and shrinking volumes.In the background of high global inflation, especially the decline in demand in Europe and North America, the demand for OLED TV panels has been hit hard. First, high inflation has had a severe impact on the demand for entry-level OLED TVs. Secondly, the impact of the price difference of LCD panels has intensified, the price of OLED TV panels has remained high for a long time, and the profits of TV brands have been squeezed, which has led to more conservative strategies and further suppressed demand. Finally, Samsung Electronics suspended the launch of WOLED products in 2022, which has caused a heavy blow to LGD"s annual OLED TV panel shipments. Affected by the above factors, the shipment of WOLED panels in 2022 will be much lower than expected, with high inventories starting from the first quarter and gradually reducing the UT of the G8.5 OLED panel production line in South Korea from the second quarter. The reduction in the UT is accompanied by an increase in costs, and the WOLED panel business may fall into the dual dilemma of loss expectations and shrinking volumes. Overall, according to Sigmaintell’s data, with the support of SDC QD Display panels, the global OLED TV panel shipments in 2022 will be 8.88 million units, an increase of 15.0% YoY, which is lower than expected.

As LCD TV panel prices have fallen below cash costs; panel makers are under enormous pressure to lose money. It is difficult to expect the recovery of end demand in the short term, and panel makers have started the production cut, but each maker has different strategies.

BOE passively reduced production, mainly reducing the capacity of G10.5 and G8.6.Thanks to the advantages of balanced development of multiple categories, the profit of IT panels can still provide a certain guarantee for a high UT and stable operation to BOE. However, after global brands such as Samsung Electronics and LG Electronics made clear their strategy of continuing to control inventory in Q3, the demand situation was not optimistic, and passive production cuts were initiated. Among them, the UT of G8.6 and G10.5 lines has been lowered to a certain extent.

CSOT, the pace of production cut is steadily progressing, mainly reducing the supply of 65-inch and 75-inch panels.CSOT is very dependent on two major customers: Samsung and TCL. Samsung"s procurement strategy adjustment has put enormous pressure on CSOT, and it has reduced production since June. CSOT "s capacity adjustment is mainly focused on the supply of 65-inch and 75-inch panels.

HKC"s ramp-up slowed down, and production expansion was delayed.Affected by the decline in demand, HKC faces greater shipping resistance and inventory pressure. HKC has also gradually started capacity control since June, which is mainly reflected in the slowdown of the new H4 and H5 lines. It is expected that the UT will remain at a low level in Q3.

Taiwan"s panel makers have differentiated strategies and are oriented to operating profit.For Taiwan panel makers, once the price of LCD TV panels hits the red line of cost and drags down profit performance, they will accelerate the contraction of the TV business. AUO has adjusted its capacity since the beginning of Q2. As the demand for various applications continues to decline, the adjustment range of UT gradually spreads from G6 to G8.5. Innolux"s UT adjustment is relatively conservative, mainly reflected in the further control of the 50-inch supply and the transfer of TV capacity to IT, and the supply of TV panels continues to decline.

South Korean panel makers have withdrawn some capacity, and the competitiveness of LCD TV panels has weakened.The cost competitiveness of LCD TV panels of Korean makers is low. As panel prices fall uncontrollably, they will more resolutely implement production control. SDC has closed all of its LCD TV panel production lines and started to maintain inventory shipments in June; The LGD G7.5 line has been gradually reduced since May, and the capacity of Guangzhou"s G8.5 line has also been controlled.

Overall, as panel makers have started to cut production, it has had a certain adjustment effect on the global supply of LCD TV panels. According to Sigmaintell’s data, in Q2, the global LCD TV panel supply area decreased by 1.4% YoY and 2.9% MoM. It is expected that the global LCD TV panel supply area will further decline by 7.3% YoY in Q3. However, in Q3, panel demand fell into a deep destocking cycle, and the decline in panel procurement demand was still higher than the reduction in panel maker production. The global LCD TV panel supply and demand situation are still not optimistic.

In Q3, the two major South Korean brands still strictly controlled their inventory, so the purchasing strategies of Chinese brands also fell into conservative expectations. According to Sigmaintell’s data, the global top 9 TV panel brand purchase demand is expected to be less than 35 million units in Q3, the lowest level in the past five years. On the supply side, although top panel makers have initiated passive production cuts, the reduction in capacity still cannot keep up with the decline in demand. According to Sigmaintell"s data, the global LCD TV panel market S/D ratio will reach 8.6% in Q3, and the supply and demand will continue to be in excess. It is expected that panel prices will maintain a downward trend at a low level.

The price of LCD TV panels continues to decline, while the prices of other types of panels also show an accelerated downward trend. So the pressure on panel makers to lose money increased sharply. However, the global economic and political environment is still unstable, and high inflation may not be effectively alleviated in the short term. Therefore, it is difficult to expect a strong recovery in the global TV market demand. At this dark moment, how can TV panel makers get out of the dilemma? When will supply and demand return to balance? When will panel prices stop declining? Sigmaintell believes that in the short term, it is necessary to increase the scale of production cut. At the same time, since cost is the core competitiveness, cost reduction and efficiency improvement should be actively promoted.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey