lcd panel shortage factory

We wanted to give you a quick update on the global component shortage that is affecting displays and other products in this rapidly changing scenario and the issues we are all facing.

CDS is working very closely with our manufacturing partners and factories, who are putting in a huge amount of effort to try to secure TFT panels, interface boards, touchscreens, panel PC and the driver ICs needed for all those products to keep shipping schedules on time and reduce any delays that may become evident. Now there are constant negotiations and bartering to get the best allocation of product that we possibly can, and our factories are doing their best to secure all the stock they and we require.

Global monitor panel shipments declined in the first quarter of the year, a report showed on Wednesday, mainly due to Samsung Displays exit from the monitor LCD display manufacturing business and a shortage of semiconductors.

The worldwide monitor panel shipments fell 8.6 percent on-quarter to 39.9 million units in the January-March period, according to the latest report from market researcher TrendForce.

"TrendForce indicates that SDC will exit the monitor LCD panel manufacturing business after it reaches its shipment target of 1.2 million panels in 1H21," it said. "This figure represents a staggering 93.8 percent decline compared to the 19.3 million units of LCD panels that SDC shipped throughout last year."

Samsung Display, the world"s top mobile display panel maker, has been focusing on its migration to next-generation quantum-dot (QD) displays, while withdrawing from the LCD business, reports Yonhap news agency.

But for large LCD panels for TVs, the company recently said it is mulling extending its manufacturing for one more year due to soaring demand from TV makers and rising panel prices.

TrendForce said the global monitor panel market also suffered a setback in the first quarter due to a shortage of components, such as integrated circuits and timing controllers.

"In addition, since TV and notebook (laptop) panels have higher profit margins compared to monitor panels, panel suppliers generally allocate less of their production capacities for manufacturing monitor panels relative to other products," it said.

"TrendForce believes that panel suppliers will likely in turn allocate more production capacities to clients in the monitor segment in 4Q21," it said.

"More specifically, the current shortage of components in the upstream supply chain, which has been exerting significant downward pressure on monitor panel shipments, will be gradually alleviated in 2H21."

The lockdowns brought on by this crisis had caused many manufacturers to temporarily shut down. With the increasing amount of products incorporating LCDs and many productions lines down, it has become more difficult to meet

The start of a new year is normally a busy time for computer manufacturers and technology companies, and 2021 has proven no different. What has proven different this year is the availability of some crucial supplies. with the COVID-19 pandemic in full swing, people have made a major shift to working at home. This shift has had a severe impact on computer and component manufacturers worldwide. The workforce has spent much of the past year buying new LCD monitors and laptops while investing in various work-from-home solutions to make it a little easier to keep things running even when they can’t make it to the office.

Outside of business concerns, the demand for leisure devices has also increased. People who cannot go out and socialize are instead purchasing gaming systems, PCs, and TVs, while parents are buying their children tablets and notebooks as entertainment. The pandemic has created an increase in demand and industry-wide shortages of both display panels and power management IC components, including phones. The shortage isn’t just due to the pandemic, of course. Many component manufacturers were already seeing an increase in demand generated by the rollout of 5G technology and the release of two new major game consoles. That the pandemic just happened to hit during a time of significant technological change simply increased existing demand that much more. This sudden demand for all of the components parts in display screens, computers, and TVs brought about a unique situation. Not only is it unnecessary for component manufacturers to market to clients this year, but many are also having to actively turn business away or schedule it for months down the line.

For manufacturers higher up in the supply chain, this is good news. TSMC’s share prices have risen by 50% in 2020 alone; United Microtechnology’s value has more than doubled. While they are working on expanding their capacity, the current demand for new devices and their associated components is likely to continueexceeding supplyfor the rest of the calendar year.However, for people and businesses that need these delayed devices, the shortage is moreserious.

Component and computer shortages affect many more parties than simply the manufacturers. Consumers and businesses at the end of the supply chain see effects as well when it is so difficult to get new machines produced. The problem is that none of these components are used in isolation. The microchips, LCD components, touchscreen elements, and even glass for screens are all utilized in a wide variety of technology, including things that your business may use. Indeed, as demand for phones increases, it becomes harder to source chips for all devices. The result is that it’s simply harder and more expensive to get any type of computing technology. From phones to laptops to desktops, the chip shortage makes it more challenging to find the technology you may need.

IT products like desktop PCs are slightly less impacted by the current shortages than many other products. In general, people who made the switch to working from home have been more likely to purchase a laptop instead of a desktop. Even so, desktop machines are still being affected by shortages and long wait times. In addition, the increased demand for gaming PCs is keeping

When this pressure is combined with the need for functional work laptops, it entails that mobile devices and LCD panels may be facing delivery times as long as three months. It is possible to obtain devices on a shorter timeline, but at present, it appears that end-users like businesses will pay the price. Early estimates suggest that PC prices might rise by as much as 30% in 2021 to account for the shortages. When all these delays and shortages are combined, it spells a clear message: this is not the time to upgrade your hardware. Instead, focus on improving and securing the hardware you already have.

COVID-19 has had a dramatic effect on the electronics industry. The worldwide drive for people to work and educate from home and the increase in demand for medical products have taken the supply of electronics components from overcapacity to shortage and extended lead times. This was multiplied by the shutdown of manufacturing and the attempt to catch up with previous demand. The industrial market has also gotten hit by the loss of small gen fab capacity due to the shutting down of older, less competitive fabs.

Before COVID-19, the display market had been in an oversupply with the slowdown in cell phone demand. With the increased demand for laptops, monitors, and even TVs has backfilled this capacity and driven us into a shortage situation. This shortage of electronic components is not only in the display market but extends to basic components like resistors and capacitors.

The outlook for your ability to get the 2021 model TV you might have your eyes on, and the price you might have to pay for it isn’t good right now, following reports of component shortages limiting production yields this year.

According to reports out of Asia, widespread component supply shortages could impact availability on LCD TV panels from TCL owned panel maker China Star Optoelectronics Technology (CSoT) and Innolux, two of the world’s largest LCD panel suppliers.

The display panel manufacturers were reported by Korean electronics business news site The Elec on Mondayas warning that supplies of panels are expected to be “tight throughout the year.”

TCL chairman Li Dongsheng used a media briefing last week to announce that panel shortages will continue in the first half of 2021, following conditions already hampered last year during the start of the Covid-19 pandemic.

The Elec article also cited Innolux president James Yang warning of a shortage in LCD panels caused by strong demand for LCD coming out of the global Covid-19 crisis, and he also added the conditions are expected to continue through 2021.

Innolux has seen shortages in LCD components including power semiconductors, driver ICs and glass substrates that have kept production below capacity. Shortages of integrated circuits and semiconductors could continue right up to the first half of 2022, Yan cautioned.

Ironically, prior to the run on LCD panel supplies, manufacturers were also faced with the dilemma of overproduction causing a glut in inventory, which was driving prices artificially lower. This was the result of giant new LCD fabs coming online in China and other areas of Asia.

TV manufacturers reportedly have been moving aggressively to replenish inventories of LCD panels to meet strong sales of TVs and other devices to meeting escalating demand, particularly in the United States and Europe.

At the same time, Samsung Display LCD monitor panel supplies for monitors are on course to terminate by the end of the first quarter 2021, and supply of IT panels overall will only continue to tighten up as demand increases for TVs and notebook panels, according to Asian analyst reports.

China-based Sigmaintell last week estimated the average selling price for a 21.5-inch LCD module for monitors would rise $3 to $55 this month, compared to a $2.50 increase for 23.8-inch panels and $2 increase for 27-inch monitor panels.

Strong demand for LCD panels in the wake of the coronavirus pandemic has created shortages that will remain in the entire 2021, according to Innolux president James Yang.

Global production capacity for LCD panels exceeds global demand currently, but actual output is much less than the capacity due to continued shortages of key components including polarizers, power ICs, driver ICs and glass substrates, Yang said at a March 3 investors conference.

Shortage of ICs is the most serious and may remain until first-half 2022, Yang noted. Japan-based Nippon Electric Glass and Asahi Glass, two main suppliers of glass substrates, have seen factory accidents and the glass supply is expected to be tight in first-half 2021, Yang indicated.

In view of potential demand for high value-added automotive displays along with development of smart cockpits and integration of various digital information, Innolux has worked with clients developing high-end free-form miniLED-backlit LCD automotive displays of over 20 inches for use in high-end car models, Yang said, adding Innolux has begun small-volume shipments for such displays, and aims to become the market leader in 2023.

Due to the pandemic and along with increasing deployments of 5G infrastructure, global demand for online education is growing fast, and Innolux"s shipment for notebook-use LCD panels in 2020 hiked 50% on year to become the second-largest supplier worldwide, Yang indicated.

Of global demand for Chromebooks used in online education, 30% was met in 2020 and 70% is not yet satisfied, and Innolux is optimistic about shipments for notebook-use LCD panels in 2021, Yang noted.

In view of fast increasing application of AI, IoT and 5G, Innolux has stepped into business other than LCD panels. Based on TFT-LCD manufacturing technology, Innolux has worked with US-based Kymeta to produce liquid crystal meta-surface antennas and with InnoCare Optoelectronics, its subsidiary, to produce X-ray flat panel detectors for medical diagnosis.

However, you won’t be pleased that the shortage will increase, and it will likely persist until the following year due to some developments that have affected manufacturing.

The actual quantity of the damaged goods and products was not specified, but you’d be impressed to know that AUO’s facility in Taiwan produces millions of panels. It made more than 10 million large modules for TVs and a little less than 9.5 million small to medium screens meant for monitors last month. An hour of stoppage means that several thousand will get delayed, but that doesn’t count the number of broken panels that are already fragile or sensitive, to begin with.

Foundries for other parts such as memory modules or processors aren’t as affected even if they suspended operations as well. TrendForce reported that they were indeed halted by the earthquake, but the damage to their equipment and product was limited since they aren’t as fragile as LCD panels.

It also doesn’t get any better at this point since existing shortages for boards and ICs have already affected supply and pricing. Factor in the effect of the pandemic, and you will get a level of uncertainty for manufacturing and sales in 2021. These two massive disruptions seem like they will make the shortage we are experiencing now worse, so we have no choice but to recommend grabbing what you can as soon as possible.

Half of the ill effects we mentioned are speculation at this point, and even the CEO of AU Optronics has not yet commented regarding the effects on pricing. However, basic economics will dictate that a large-scale shortage like this will lead to price hikes, especially at a time where demand and the growth of the display and monitor market are steadily expanding.

In recent weeks, all leading PC makers have complained about the tight supply of LCD panels due to shortages of components and complicated logistics. As it turns out, the situation might get worse in the coming weeks and months due to an earthquake in Taiwan and a power outage in Japan, eventually resulting in higher prices at retail.

Last week an earthquake struck Taiwan. This isn"t an extraordinary event for the country, but it does have repercussions. AU Optronics (AUO), one of the leading makers of LCD panels, said this week that some of its production lines had been impacted by the quake, and it had taken it "at least a few hours" to clean up and repair them before resuming operations. Some of the output was lost because of the disaster, reports DigiTimes, citing Paul Peng, the chairman of AU Optronics.

Mr. Peng did not quantify the company"s losses, but AUO makes hundreds of thousands of LCD panels every day, so the earthquake will clearly impact the supply of display panels. Back in November, AUO produced 10.81 million large-sized panels for LCD TVs, desktops, and notebooks as well as 9.35 million small-and-medium-sized panels. AUO says it has now resumed normal operations.

On November 10, a power outage in Takatsuki, Japan, disrupted operations at Nippon Electric Glass"s Shiga-Takatsuki plant that manufactures glass substrates for flat-panel displays. The outage lasted for five hours and damaged some of NEG"s production equipment, the company revealed in its statement.

NEG owns about 10% of the world"s glass substrate manufacturing capacity and supplies glass substrates for LCD panels to numerous panel makers, according to the chairman of AUO. Consequently, NEG"s production problems will impact the whole market as customers that buy from NEG will have to source components from other suppliers.

The chairman of AU Optronics did not reveal his expectations concerning prices of LCD panels and displays in the coming months. Still, it is evident that shortages usually lead to price hikes. The only question is how significant the hikes will be.

![]()

What exactly is short in the market? Your iPhone’s screen is one solid unit made up of several elements that are fused together with OCA (optically clear adhesive). The exterior glass, the digitizer panel (touch sensor), the polarizer and LCD panel. The LCD panel is the key component that is in short supply. Originally Apple had 3 manufacturers to produce LCD panels (LG, Sharp and Toshiba). Apple’s authorized manufacturers have the exclusive technology to produce LCD panels. Other Chinese manufacturers can copy the glass, digitizer, polarizers, OCA, flex cables, backlights, frames and everything except for the main component of the LCD assembly.

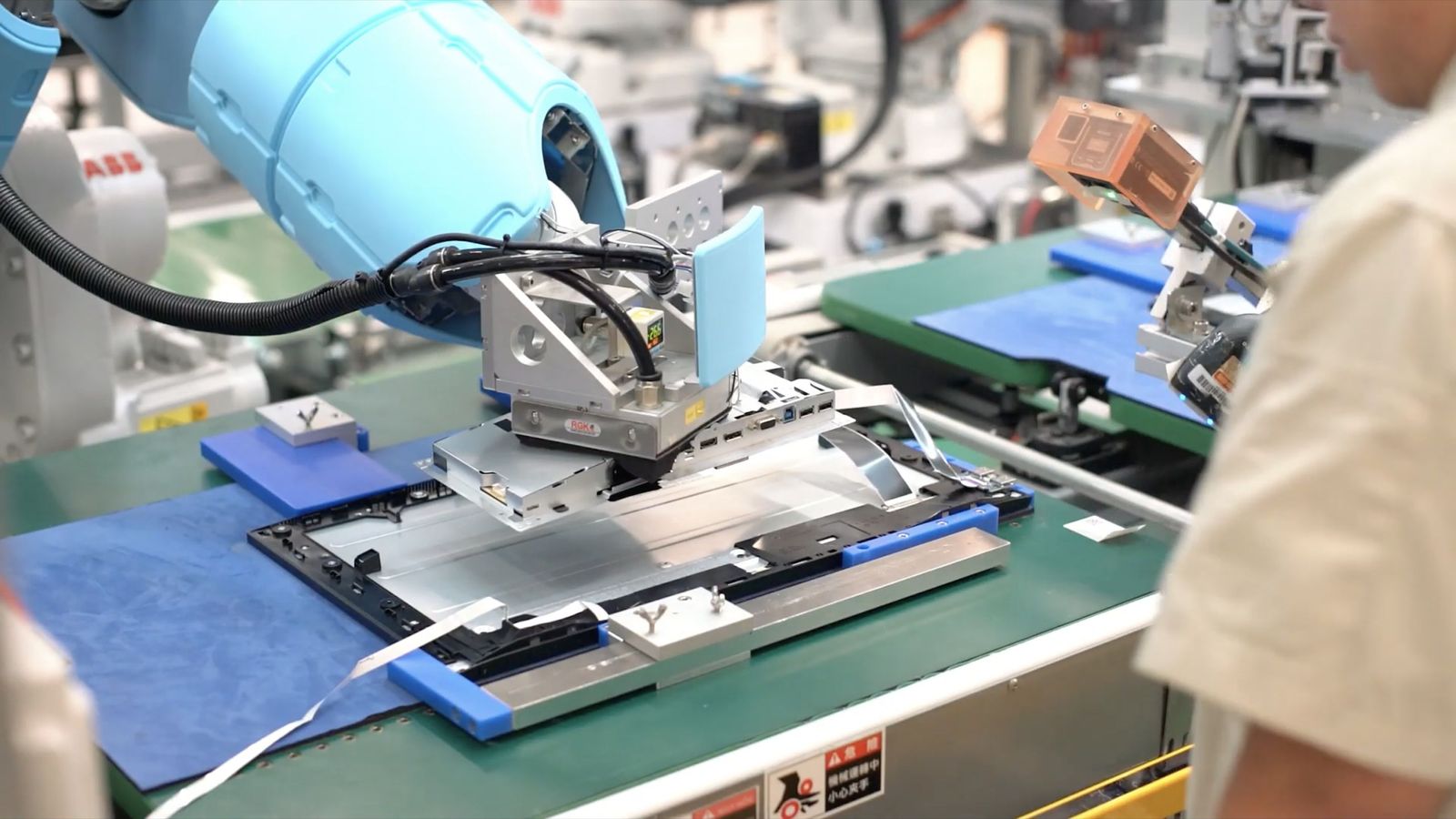

How were we getting these parts before? A big leak in Apple’s supply chain. The iPhone 5, 5S and 5C all share most of the same raw components including the LCD panel, the only difference is the flex cable and plastic frame. Independent factories in China can produce these components and can manufacture any 5 series assembly from an LCD panel. Shown on the left is a pulse pressing machine, used to connect the flex cable to the LCD. We use one of these to repair LCDs with damaged flex cables.

So what’s happening?A few things, first Apple has cut off LG and Toshiba, making Sharp their exclusive supplier for iPhone LCD panels and implemented very tight security. Secondly, they have had Foxconn destroy stockpiles of series 5 LCD panels to reduce the parts and material leakage to factories that re-engineer them for the independent repair industry. Along with this strategy, Apple has instructed Foxconn to reduce series 6 materials leakage from their manufacturing centers. Lastly, Apple is working aggressively with US Customs to seize inbound parts.

How long is this shortage going to last? In short,we have no idea. At the time of this writing, LCD prices have been steadily rising for 6 months and replacement iPhone 6S LCDs cost twice what Apple charges for their repair service. Apple does not intend to compete with independent repair shops, instead they are squeezing the profit out of the industry. LCD refurbishing may help shops cut cost but without new LCD panels entering the system it won’t last long.

What does this mean for the independent repair community?Apple is the only repair operation that is immune. Even the Chinese LCD refurbishing plants used by the large chain repair companies are running out of LCDs. Continually rising costs may push out the big chains but with lower overhead and clever problem-solving, the owner-operated shops stand a fighting chance.

![]()

The escalating coronavirus crisis is impacting production at display panel factories located in the semi-quarantined city of Wuhan, China, spurring a significant near-term reduction in the global supply of panels used in liquid crystal display televisions (LCDs) and other products.

The five factories in the city producing liquid crystal displays (LCDs) and organic light-emitting diode (OLED) panels will experience near-term slowdowns in production compared to expected levels, according to IHS Markit technology research, now a part of Informa Tech.

With the situation evolving quickly, IHS Markit technology research is still assessing the magnitude of the supply shortfall on multiple display types and markets. However, leading Chinese panel makers stated they believe that total capacity utilization for all LCD fabs in the country could fall by at least 10 percent and perhaps by more than 20 percent during the month of February.

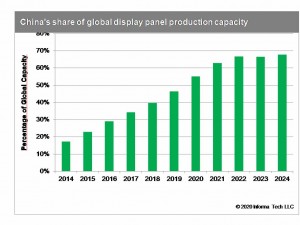

With China expected to own 55 percent of global display manufacturing capacity in 2020, the immediate impact of the production reduction has been a worldwide decrease in availability and an increase in pricing for LCD-TV panels. This has resulted in turmoil throughout the display supply chain as suppliers and purchasers alike scramble to adjust to swiftly changing market conditions.

“Display facilities in Wuhan currently are dealing with the very real impacts of the coronavirus outbreak,” said David Hsieh, senior director, displays, at IHS Markit technology research. “These factories are facing shortages of both labor and key components as a result of mandates designed to limit the contagion’s spread. In the face of these challenges, top display suppliers in China have informed our experts that a near-term production decline is unavoidable.”

The leading Chinese suppliers of LCD panels for TVs, notebook PCs and PC monitors now are planning to raise panel prices more aggressively. For example, the price for an open-cell LCD-TV panel was originally expected to rise by $1 or $2 per month in February. However, the actual increase may be $3 to $5 for the month.

Beyond the immediate production impact at these facilities, the coronavirus is also likely to trigger delays in the ramp-up of manufacturing at new display fabs during the first half of 2020. This will reduce overall panel availability during the next few months. It also could result in further panel supply tightness as TV display buyers hasten the pace of their panel purchases to build stockpiles for future shortfalls.

While major panel makers are rightly concerned about the coronavirus’s impact on consumer sales, demand for their products from TV makers has actually increased. TV makers are pulling in their panel demand and sometimes double-booking orders to shore up their inventories. The panel maker indicated that the demand surge for orders delivered in February is as large as 10 percent above the previous demand forecast.

The labor shortage encountered by fabs in Wuhan is partly the result of the Chinese government’s move to extend the Lunar New Year holiday by three days, with the last day now scheduled for Sunday, February 2. The extension is designed to reduce travel and cut down on public gatherings to contain the spread of the disease.

LCD panel makers outsource much of the production of such modules. However, production at several key third-party module suppliers has now ceased, impacting panel production severely throughout the country. Key module supplier SkyTech is sharply reducing production until mid-February.

Panel makers maintain their own captive LCD module factories. However, these operations are also facing production bottlenecks amid the coronavirus crisis.

The module shortage potentially could expand the impact of the contagion beyond China—with a knock-on effect on production at display manufacturers worldwide.

A boy looks at a prototype model of the world"s largest 108-inch sized LCD TV, produced by Japan"s electronics giant Sharp in 2007. Electronics makers worldwide face a shortage of liquid crystal displays used for large-screen televisions due to soaring demand, particularly in emerging markets such as China, Sharp said Monday.

Electronics makers worldwide face a shortage of liquid crystal displays used for large-screen televisions due to soaring demand, particularly in emerging markets such as China, Sharp said Monday.

Rising demand for three-dimensional televisions and light-emitting diode (LED) televisions is adding pressure on an already strained supply chain as makers look towards using higher-performance panels, the company said.

Last week the maker said it expects to sell 15 million LCD televisions worldwide for the current fiscal year, up from 10 million units the previous year.

The company, which pioneered the technology behind LCDs, will double its production capacity faster than expected at its newest Japanese factory in Sakai city, considered the world"s most advanced display plant.

Demand for light emitting diodes, which are used as backlights in recently launched LCD models, is also increasing at a faster-than-expected pace, the company said.

/cloudfront-us-east-2.images.arcpublishing.com/reuters/6FON3LY6UBPBBESSEW7UWBAITI.jpg)

Prior to the Covid-19 pandemic outbreak in early 2020, the flat-panel display (FPD) market was gloomy. Oversupply, falling prices and losses were the common themes in the market.

It’s been a different story during the outbreak. In 2020, the FPD market rebounded. In the stay-at-home economy, consumers went on a buying spree for monitors, PCs, tablets and TVs. As a result, demand for displays exploded. And shortages soon surfaced for display driver ICs and other components.

Cars, industrial equipment, PCs, smartphones and other products all incorporate flat-panel displays in one form or another. The majority of TV screens are based on liquid-crystal displays (LCDs). TVs use other display types, such as organic light-emitting diodes (OLEDs) and quantum dots.

Smartphone displays are based on LCDs and OLEDs. Other display technologies, such as microLEDs and miniLEDs, are in the works. Flat-panel displays are made in giant fabs. Suppliers from China, Korea and Taiwan dominate the display market.

It’s been a roller coaster ride in the arena. “Before Covid, the FPD market in the second half of 2019 was not very pretty,” said Ross Young, CEO of Display Supply Chain Consultants (DSCC), in a presentation at Display Week 2021. “We had declining revenues, declining prices, declining margins, companies announcing their exit in the LCD market, CapEx was falling, and there was little interest from investors.”

Demand for PCs, TVs and other products fueled renewed growth for displays. In total, the flat-panel display market reached $118 billion in 2020, up 6% over 2019, according to DSCC. That’s above the previous 2% growth forecast.

The numbers include LCDs, OLEDs and other displays. Of those figures, the LCD market reached $84 billion, while OLEDs were $33 billion in 2020, according to DSCC.

Then, the market is projected to hit a record $152 billion in 2021, up 29% over 2020, according to the firm. Of those figures, the LCD market is expected to reach $113 billion, while OLEDs are $39 billion, they said.

Average selling prices are up, but the market is still beset with component shortages. “Panel prices have risen significantly, particularly since August of last year. They’ve more than doubled in some cases,” Young said. “Adding to the pricing pressure have been components shortages in driver ICs, touch controllers, glass substrates compensation film, polarizers and other materials. We do expect prices to peak in Q3 (of 2021) as a result of shortages easing and the impact of double booking, leaving some potential air pockets in demand. We expect panel pricing to fall in the fourth quarter, but we’re not expecting sharp downturns, as in the past, due to slower supply growth.”

Going forward, the market may come back down to earth. “After 29% growth in 2021, the FPD market is expected to fall by 5% in 2022, as shortage concerns ease, supply growth outpaces demand growth, and prices fall. We expect the IT markets to decline. TV revenues will fall significantly on lower prices, but still slower price declines than in previous downturns,” he said.

Why it matters: The global semiconductor industry was worth $439 billion in 2020, and is on track to grow even bigger this year. However, that growth potential is being eroded by a shortage of $1 chips that are essential for every display panel that needs to be manufactured.

A global shortage of chips has wreaked havoc on the supply chains of the tech and auto industries. This has caused many companies to scale back production at a time when demand is soaring for their products. This is the result of a combination of factors, and the current situation will probably not change until the end of next year.

According to a Bloomberg report, there is now a serious shortage of display driver chips that is creating headaches for manufacturers of LCD and OLED panels. This in turn will affect all manner of consumer devices, from the lowly smartwatch to smartphones, tablets, laptops, computer monitors, TVs, smart appliances, and infotainment systems. Every new car or plane comes with one or more display panels, which only adds to the demand.

Nevertheless, the shortage of these driver chips will likely cause further delays and price hikes for products that are currently in high demand, and the manufacturers of these chips don"t see a solution in sight.

The shortfall is already visible in the doubling of prices for large LCD panels over the last year. Himax Technologies CEO Jordan WU told Bloomberg "I have never seen anything like this in the past 20 years since our company"s founding."

A promotional image of a quantum-dot LED TV (Samsung Electronics)Samsung Display, the display making arm of Samsung Electronics, is poised to fully shut down its unprofitable liquid crystal display panel business for televisions in June, after over 30 years of operation.

“(Samsung Display) will terminate its supply of LCD panels in June,” an industry source said Monday. The company has been manufacturing its lower-end panels in Asan, South Chungcheong Province.

The long-awaited move came as LCD TV panel prices have been on a constant decline. This led to greater losses for Samsung Display, while Chinese competitors have been ramping up their dominance in the global industry supported by state subsidies and tax breaks.

LCD TVs are considered lower-end when compared to those using cutting-edge TV components such as organic light-emitting diode panels and quantum dot display panels.

According to market intelligence firm Omdia‘s estimate compiled by Daishin Securities, 43-inch LCD panel prices fell 46 percent from September 2021 to May this year, while that of 55-inch panels and 65-inch panels both declined 34 percent over the cited period.

This marks the end of Samsung’s three-decade LCD TV panel business. Once the largest LCD TV panel supplier in the world, Samsung Display‘s market share has gradually shrunk from 22 percent in 2014 to around 2 percent this year.

Samsung Display had sought to exit the business from before 2021, but has been hanging on in part due to Samsung Electronics’ LCD panel supply shortage.

Choi Kwon-young, executive vice president of Samsung Display, confirmed the company’s full exit from the LCD TV panel business within this year in a first-quarter conference call in April.

Given that Samsung’s LCD TV panel exit has long been anticipated and carried out gradually, Samsung Electronics will “unlikely be affected by Samsung Display‘s LCD panel exit” in terms of its continuity in the LCD TV set business, noted Kim Hyun-soo, an analyst at Hana Financial Investment on Monday.

Samsung looks to pivot to quantum dot display technologies for its TV panel business, using quantum dot light-emitting diodes or quantum dot organic light-emitting diodes.

As for the anticipated collaboration between TV maker Samsung Electronics and the world‘s sole white-OLED TV panel supplier LG Display, Kim of Hana said the launch of Samsung’s OLED TV is unlikely within this year due to prolonged negotiations.

We have been reporting on how COVID-19 is having a devastating impact on the LCD supply chain increased demand in for devices such as laptops, laptops and gaming devices. It is now widely reported across the world"s media that there simply aren’t enough chips to go around and global component shortages are set to be with us until 2023.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey