model un60j6200afxza-mh01 lcd panel factory

Here are the diagrams and repair parts for Samsung UN60J6200AFXZA-MH01 lcd television, as well as links to manuals and error code tables, if available.Continue reading

@thumper36945 it"s not just Samsung it"s every LCD that is broken. Once you get to a certain size it becomes impractical due to the high cost of the LCD panel to replace it. The only way you can do it, is by trying to find a TV like yours that has a failure anywhere else but the panel. Then you can harvest the panel from that. Try to take a look at the back of the panel and do a search by the actual manufacturers label instead of the TV type. You may get a bit better of a deal than at Samsung but it will most likely still be way more than a new TV.

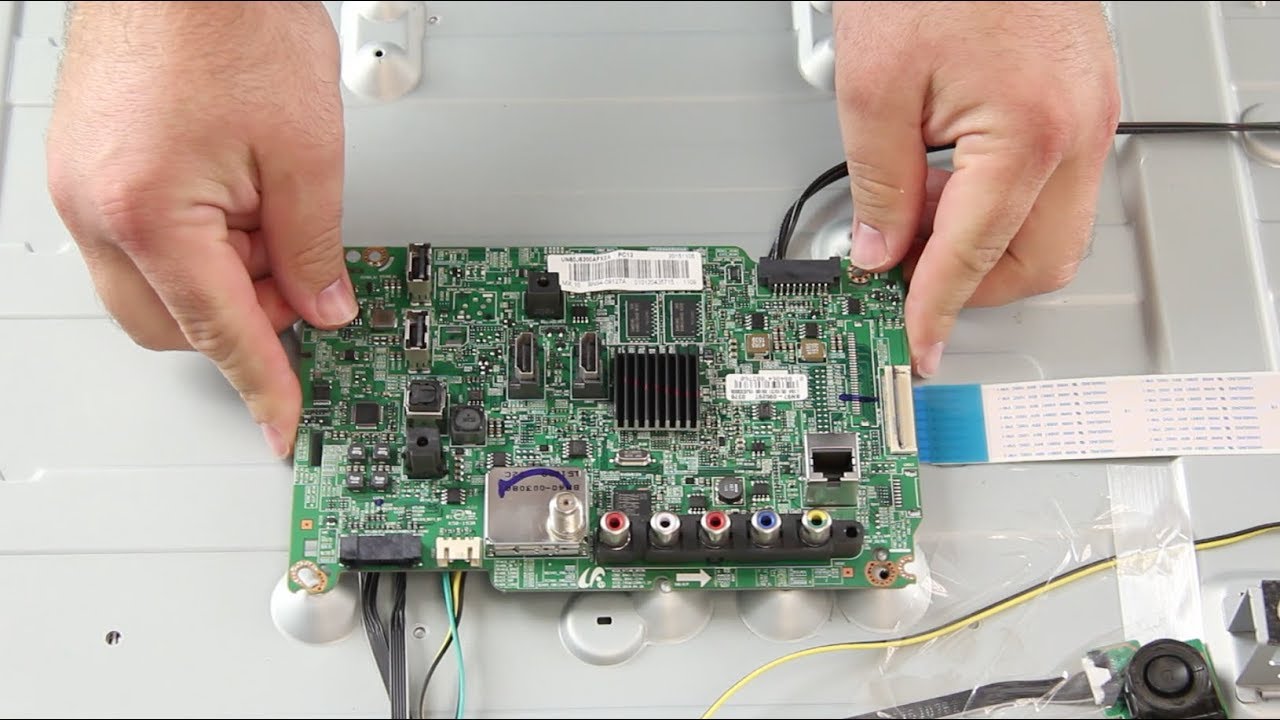

Shop for Repair, Replacement Parts and Accessories for your Samsung Model Number UN60J6200AFXZA, Samsung UN60J6200A, Samsung UN60J6200 including the main board, motherboard, power supply board, remote control, stand base, stand guide, stand screws, lcd/led display panel (screen replacement) and more.

Compared to Samsung, LG"s LCD factory at Paju felt like a ghost town — despite housing thousands of people on-site. Of course, the sub-zero temperatures at the time probably accounted for that. It was also doubly eerie because the LCD plant is the tallest building visible from North Korea — as it"s so close to the border — and the army base built next door to protect it probably makes it even more of a target!

While televisions of one type or other have been in Australia for over 50 years, they have gone through several changes, with flat panels the latest iteration. LCD TVs have been mainstream products for about four years, but what makes them tick? This year we were fortunate enough to have visited both the Samsung and LG plants in South Korea to get a better understanding of how an LCD TV is made, and what the future holds for the technology.

Samsung is one of the world"s largest manufacturers of LCD panels, and it claims to produce one out of every four in the world. One of Samsung"s largest facilities is in Tangjeong, 80km south of Seoul. Samsung has four different plants on this site, and this is where the joint Sony/Samsung S-LCD plant was first built — and still produces Sony panels to this day. CNET Australia visited Tangjeong recently and while we not only got a squiz at the production lines, we also met with the engineers and designers who helped make them possible.

The Tangjeong factory is a large facility south of Seoul, and produces panels for the five-year-old S-LCD collaboration between Sony and Samsung. As a result of this union, Sony owns part of the production lines on the Tangjeong site — this equates to 50 per cent of the L7-1 line, plus half of the combined L8 (1 and 2) lines. The L8-2 factory has only come online in the last month.

Samsung has begun planning its ninth plant, which will produce its Generation 11 panels (L9), and this will fit in behind the two existing factories. It will be capable of producing much larger panels than the L8 plant with 40, 62 and 72 inches possible.

We got to see one of the L7 (no relation to the LA-based band) lines in operation, after donning the fetching blue shoe covers. Unfortunately, we were unable to take photos inside the LCD factory, as apparently corporate espionage is a big problem. However, we"ll do our best to explain the long corridor with its helpful blue signs and series of LCD panels in various states of undress explaining each part of the process.

There were several different "lines" in each factory — each doing a different sized panel. Apparently it takes three days to convert one line to produce another size, so there is some redundancy built into the system to cover for any downtime.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey