tft lcd principle brands

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

The transmittance of a pixel of an LCD panel typically does not change linearly with the applied voltage,sRGB standard for computer monitors requires a specific nonlinear dependence of the amount of emitted light as a function of the RGB value.

Less expensive PVA panels often use dithering and FRC, whereas super-PVA (S-PVA) panels all use at least 8 bits per color component and do not use color simulation methods.BRAVIA LCD TVs offer 10-bit and xvYCC color support, for example, the Bravia X4500 series. S-PVA also offers fast response times using modern RTC technologies.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

STONE Technologies is a proud manufacturer of superior quality TFT LCD modules and LCD screens. The company also provides intelligent HMI solutions that perfectly fit in with its excellent hardware offerings.

STONE TFT LCD modules come with a microcontroller unit that has a 1GHz Cortex-A8 CPU. Such a module can easily be transformed into an HMI screen. Simple hexadecimal instructions can be used to control the module through the UART port. Furthermore, you can seamlessly develop STONE TFT LCD color user interface modules and add touch control, features to them.

Becoming a reputable TFT LCD manufacturer is no piece of cake. It requires a company to pay attention to detail, have excellent manufacturing processes, the right TFT display technology, and have a consumer mindset.

Now, we list down 10 of the best famous LCD manufacturers globally. We’ll also explore why they became among the top 10 LCD display Manufacturers in the world.

LG Display is a leading manufacturer of thin-film transistor liquid crystal displays (TFT-LCD) panels, OLED, and flexible displays.LG Display began developing TFT-LCD in 1987 and currently offers Display panels in a variety of sizes and specifications using different cutting-edge technologies (IPS, OLED, and flexible technology).

Samsung Electronics is South Korea’s largest electronics industry and the largest subsidiary of the Samsung Group. In the late 1990s, Samsung Electronics’ independent technology development and independent product innovation capabilities were further enhanced. Its product development strategy not only emphasizes “leading the technology but also using the most advanced technology to develop new products to meet the high-end market demand at the introduction stage”.In addition to the matching principle, it also emphasizes the principle of “leading technology, developing new products with the most advanced technology, creating new demand and new high-end market”.

With innovative and differentiated technologies, QINNOOptoelectronics provides advanced display integration solutions, including 4K2K ultra-high resolution, 3D naked eye, IGZO, LTPS, AMOLED, OLED, and touch solutions. Qinnooptoelectronics sets specifications and leads the market. A wide range of product line is across all kinds of TFT LCD panel modules, touch modules, for example, TV panel, desktop and laptop computer monitor with panels, small and medium scale “panels, medical, automotive, etc., the supply of cutting-edge information and consumer electronics customers around the world, for the world TFT – LCD (thin-film transistor liquid crystal display) leading manufacturers.

AU Optronics Co., LTD., formerly AU Optronics Corporation, was founded in August 1996. It changed its name to AU Optronics after its merger with UNIOPtronics in 2001. Through two mergers, AU has been able to have a full range of generations of production lines for panels of all sizes.Au Optronics is a TFT-LCD design, manufacturing, and r&d company. Since 2008, au Optronics has entered the green energy industry, providing customers with high-efficiency solar energy solutions.

Sharp has been called the “father of LCD panels”.Since its founding in 1912, Sharp developed the world’s first calculator and LIQUID crystal display, represented by the living pencil, which was invented as the company name. At the same time, Sharp is actively expanding into new areas to improve people’s living standards and social progress. Made a contribution.

BYD IT products and businesses mainly include rechargeable batteries, plastic mechanism parts, metal parts, hardware electronic products, cell phone keys, microelectronics products, LCD modules, optoelectronics products, flexible circuit boards, chargers, connectors, uninterruptible power supplies, DC power supplies, solar products, cell phone decoration, cell phone ODM, cell phone testing, cell phone assembly business, notebook computer ODM, testing and manufacturing and assembly business, etc.

Tianma microelectronics co., LTD., founded in 1983, the company focus on smartphones, tablets, represented by high order laptop display market of consumer goods and automotive, medical, POS, HMI, etc., represented by professional display market, and actively layout smart home, intelligent wear, AR/VR, unmanned aerial vehicles (UAVs) and other emerging markets, to provide customers with the best product experience.IN terms of technology, the company has independently mastered leading technologies such as LTPS-TFT, AMOLED, flexible display, Oxide-TFT, 3D display, transparent display, and in-cell/on-cell integrated touch control. TFT-LCD key Materials and Technologies National Engineering Laboratory, national enterprise Technology Center, post-doctoral mobile workstation, and undertake national Development and Reform Commission, The Ministry of Science and Technology, the Ministry of Industry and Information Technology, and other major national thematic projects. The company’s long-term accumulation and continuous investment in advanced technology lay the foundation for innovation and development in the field of application.

TFT-LCD was invented in 1960 and successfully commercialized as a notebook computer panel in 1991 after continuous improvement, thus entering the TFT-LCD generation.

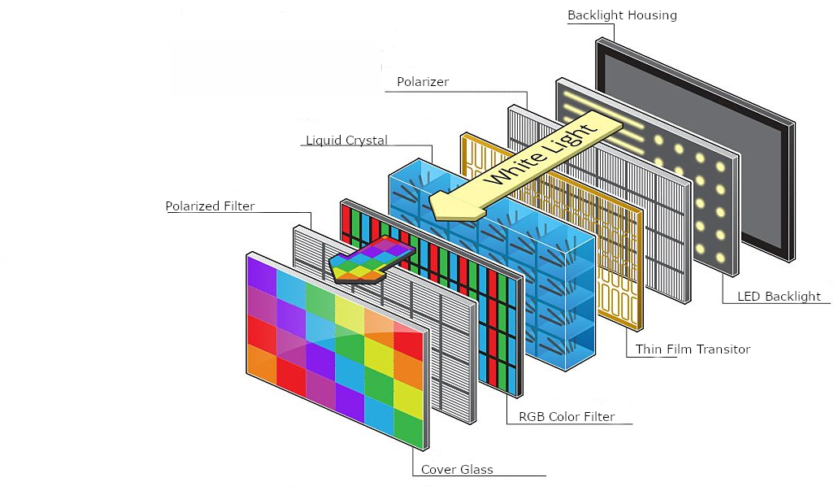

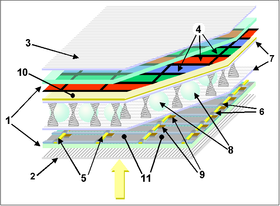

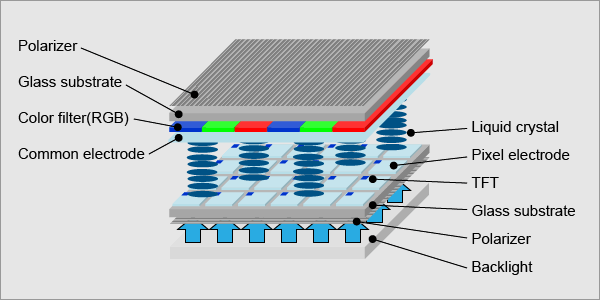

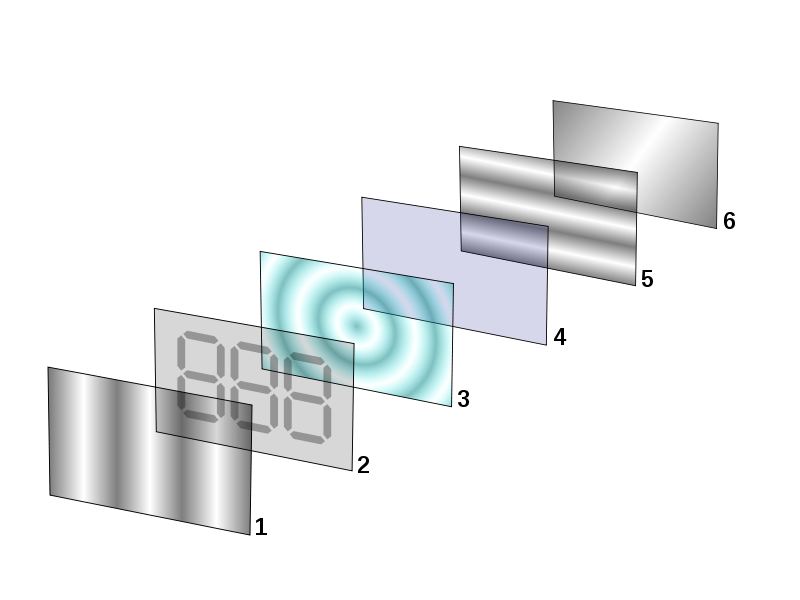

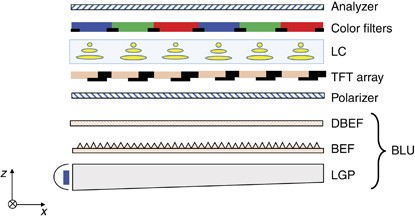

Simply put, the basic structure of the TFT-LCD panel is a layer of liquid crystal sandwiched between two glass substrates. The front TFT display panel is coated with a color filter, and the back TFT display panel is coated with a thin film transistor (TFT). When a voltage is applied to the transistor, the liquid crystal turns and light passes through the liquid crystal to create a pixel on the front panel. The backlight module is responsible for providing the light source after the TFT-Array panel. Color filters give each pigment a specific color. The combination of each different color pixel gives you an image of the front of the panel.

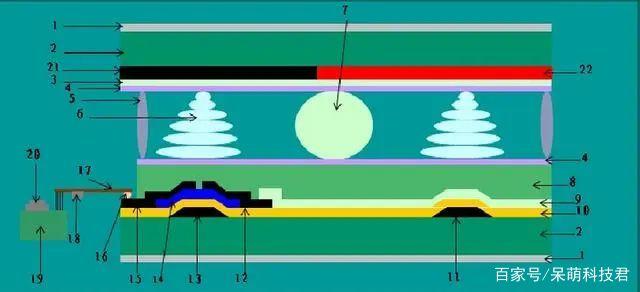

The TFT panel is composed of millions of TFT devices and ITO (In TI Oxide, a transparent conductive metal) regions arranged like a matrix, and the so-called Array refers to the region of millions of TFT devices arranged neatly, which is the panel display area. The figure below shows the structure of a TFT pixel.

No matter how the design of TFT display board changes or how the manufacturing process is simplified, its structure must have a TFT device and control liquid crystal region (if the light source is penetration-type LCD, the control liquid crystal region is ITO; but for reflective LCD, the metal with high reflection rate is used, such as Al).

The TFT device is a switch, whose function is to control the number of electrons flowing into the ITO region. When the number of electrons flowing into the ITO region reaches the desired value, the TFT device is turned off. At this time, the entire electrons are kept in the ITO region.

The figure above shows the time changes specified at each pixel point. G1 is continuously selected to be turned on by the driver IC from T1 to TN so that the source-driven IC charges TFT pixels on G1 in the order of D1, D2, and Dn. When TN +1, gATE-driven IC is selected G2 again, and source-driven IC is selected sequentially from D1.

Many people don’t understand the differences between generations of TFT-LCD plants, but the principle is quite simple. The main difference between generations of plants is in the size of glass substrates, which are products cut from large glass substrates. Newer plants have larger glass substrates that can be cut to increase productivity and reduce costs, or to produce larger panels (such as TFT display LCD TV panels).

The TFT-LCD industry first emerged in Japan in the 1990s, when a process was designed and built in the country. The first-generation glass substrate is about 30 X 40 cm in size, about the size of a full-size magazine, and can be made into a 15-inch panel. By the time Acer Technology (which was later merged with Unioptronics to become AU Optronics) entered the industry in 1996, the technology had advanced to A 3.5 generation plant (G3.5) with glass substrate size of about 60 X 72 cm.Au Optronics has evolved to a sixth-generation factory (G6) process where the G6 glass substrate measures 150 X 185 cm, the size of a double bed. One G6 glass substrate can cut 30 15-inch panels, compared with the G3.5 which can cut 4 panels and G1 which can only cut one 15-inch panel, the production capacity of the sixth generation factory is enlarged, and the relative cost is reduced. In addition, the large size of the G6 glass substrate can be cut into large-sized panels, which can produce eight 32-inch LCD TV panels, increasing the diversity of panel applications. Therefore, the global TFT LCD manufacturers are all invested in the new generation of plant manufacturing technology.

The TRANSISTor-LCD is an acronym for thin-film TFT Display. Simply put, TFT-LCD panels can be seen as two glass substrates sandwiched between a layer of liquid crystal. The upper glass substrate is connected to a Color Filter, while the lower glass has transistors embedded in it. When the electric field changes through the transistor, the liquid crystal molecules deflect, so as to change the polarization of the light, and the polarizing film is used to determine the light and shade state of the Pixel. In addition, the upper glass is fitted to the color filter, so that each Pixel contains three colors of red, blue and green, which make up the image on the panel.

The luminescence principle is tied to the vapor electroplating organic film between the transparent anode and the metal cathode. The electron and electric hole are injected, and the energy is converted into visible light by the composite between the organic film. And can match different organic materials, emit different colors of light, to achieve the requirements of the full-color display.

The organic light display can be divided into Passive Matrix (PMOLED) and Active Matrix (AMOLED) according to the driving mode. The so-called active driven OLED(AMOLED) can be visualized in the Thin Film Transistor (TFT) as a capacitor that stores signals to provide the ability to visualize the light in a grayscale.

Although the production cost and technical barriers of passive OLED are low, it is limited by the driving mode and the resolution cannot be improved. Therefore, the application product size is limited to about 5″, and the product will be limited to the market of low resolution and small size. For high precision and large picture, the active drive is mainly used. The so-called active drive is capacitive to store the signal, so when the scanning line is swept, the pixel can still maintain its original brightness. In the case of passive drive, only the pixels selected by the scan line are lit. Therefore, in an active-drive mode, OLED does not need to be driven to very high brightness, thus achieving better life performance and high resolution.OLED combined with TFT technology can realize active driving OLED, which can meet the current display market for the smoothness of screen playback, as well as higher and higher resolution requirements, fully display the above superior characteristics of OLED.

The technology to grow The TFT on the glass substrate can be amorphous Silicon (A-SI) manufacturing process and Low-Temperature Poly-Silicon (LTPS). The biggest difference between LTPS TFT and A-SI TFT is the difference between its electrical properties and the complicated manufacturing process. LTPS TFT has a higher carrier mobility rate, which means that TFT can provide more current, but its process is complicated.A-si TFT, on the other hand, although a-Si’s carrier movement rate is not as good as LTPS’s, it has a better competitive advantage in cost due to its simple and mature process.Au Optronics is the only company in the world that has successfully combined OLED with LTPS and A-SI TFT at the same time, making it a leader in active OLED technology.

The LTPS membrane is much more complex than a-SI, yet the LTPS TFT is 100 times more mobile than A-SI TFT. And CMOS program can be carried out directly on a glass substrate. Here are some of the features that p-SI has over A-SI:

LCD screens are backlit to project images through color filters before they are reflected in our eye Windows. This mode of carrying backlit LCD screens, known as “penetrating” LCD screens, consumes most of the power through backlit devices. The brighter the backlight, the brighter it will appear in front of the screen, but the more power it will consume.

The high value-added small TFT LCD panel of the "ORTUS" brand realizes high pixel count, high definition and low power consumption while enhancing outdoor visibility by using HAST®(Hyper Amorphous Silicon TFT) as its core technology, and is adopted for various equipment such as industrial equipment.

LCD (Liquid Crystal Display)may be a fresh noun for many users, but the history of this technology may far exceed our imagination. As early as the end of the 19th century, Austrian botanists discovered liquid crystals, that is, a substance has both the fluidity of liquids and certain crystal-like arrangement characteristics.

This phenomenon is called the electro-optic effect. Utilizing the electro-optical effect of liquid crystals, British scientists produced the first liquid crystal display, the LCD display, in the last century.

According to the driving method of the LCD panel, the most common currently is a TFT (Thin Film Transistor) type driver. It achieves independent and precise control of each pixel through the active switch, so it can achieve more fine display effects than the previous passive driver (commonly known as pseudo color). Therefore, most LCD displays,LCD displayTVs and some mobile phones are driven by TFT.

Therefore, as long as we change the voltage value applied to the liquid crystal, we can control the intensity and color of the light that finally appears, so that we can change the color combination with the different hue on theLCD display panel.

Among the world famous brands, the screen of South Korea"s samsung and LG is known to be produced and sold by themselves.Display screens of other niche brands, and those brands capable of self-production and self-marketing, also have an unassailable position in their own segments, facing various brands.For buyers, how to find suitable suppliers from these LCD panel manufacturers?

The world-renowned LCD panel production line is mainly controlled by several enterprises: au optronics in Taiwan;Chi mei electronics in Taiwan, China;Sharp, Japan;South Korea samsung, South Korea LG;Philips;Boe, etc.These companies supply the world"s main demand for liquid crystal displays.

LG Display is currently the world"s first LCD panel manufacturer. It is affiliated to LG group and headquartered in Seoul, South Korea.Its subsidiaries are: LG electronics, LG display, GS caltex, LG chemistry, LG life and health, etc., covering the fields of chemical energy, electronics and appliances, communication and service.LG Display"s customers include Apple, HP, DELL, SONY, Toshiba, PHILIPS, Lenovo, Acer and other world-class consumer electronics manufacturers.LG"s manufacturing base in China is in nanjing, shenyang.

Samsung electronics is South Korea"s largest electronics company and the largest subsidiary of the samsung group.Its product development strategy emphasizes not only the matching principle of "leading technology, using the most advanced technology to develop new products in the leading-in stage to meet the high-end market demand", but also the matching principle of "leading technology, using the most advanced technology to develop new products, creating new demand and new high-end market".Samsung"s customers are mainly targeting samsung itself.Samsung"s manufacturing base in China is in suzhou, nanjing.

Innolux is a tft-lcd panel manufacturing company founded by foxconn technology group in 2003.The factory is located in longhua foxconn technology park in shenzhen.Innolux has a strong display technology research and development team, coupled with foxconn"s strong manufacturing capacity, to effectively play the vertical integration benefits, to improve the level of the world plane display industry will have a pointer contribution.In March 2010, it merged with chi mei electronics and tong bao optoelectronics.

Au optronics, formerly known as acer technology, was founded in August 1996. It was renamed au optronics after the merger of au optronics and united optronics in 2001.Au optronics is the world"s first tft-lcd design, manufacturing and development company to be publicly listed on the New York stock exchange (NYSE).

Boe, founded in April 1993, is the largest display panel manufacturer in China and a provider of Internet of things technology, products and services.At present, boe has reached the world"s first place in the field of notebook LCD, flat LCD and mobile LCD. With its success in joining the apple supply chain, boe will become the world"s top three LCD panel manufacturers in the near future.

Sharp is known as "the father of LCD panel".Since its founding in 1912, sharp corporation has been developing the world"s first calculator and liquid crystal display, represented by the live pencil, which is the name of the company. At the same time, sharp corporation has been actively expanding new fields, contributing to the improvement of human living standards and social progress.Sharp is already owned by foxconn.

The company has set up tft-lcd key materials and technology national engineering laboratory, national enterprise technology center, post-doctoral mobile workstation, and undertakes national development and reform commission, ministry of science and technology, ministry of industry and information technology and other major national special projects.The company"s strong technology and scientific research capabilities become the cornerstone of the company"s sustainable development.

When compared to the ordinary LCD, TFT LCD gives very sharp and crisp text/graphic with shorter response time. TFT LCD displays are used in more and more applications, giving products better visual presentation.

TFT is an abbreviation for "Thin Film Transistor". The color TFT LCD display has transistors made up of thin films of Amorphous silicon deposited on a glass. It serves as a control valve to provide an appropriate voltage onto liquid crystals for individual sub-pixels. That is why TFT LCD display is also called Active Matrix display.

A TFT LCD has a liquid crystal layer between a glass substrate formed with TFTs and transparent pixel electrodes and another glass substrate with a color filter (RGB) and transparent counter electrodes. Each pixel in an active matrix is paired with a transistor that includes capacitor which gives each sub-pixel the ability to retain its charge, instead of requiring an electrical charge sent each time it needed to be changed. This means that TFT LCD displays are more responsive.

To understand how TFT LCD works, we first need to grasp the concept of field-effect transistor (FET). FET is a type of transistor which uses electric field to control the flow of electrical current. It is a component with three terminals: source, gate, and drain. FETs control the flow of current by the application of a voltage to the gate, which in turn alters the conductivity between the drain and source.

Using FET, we can build a circuit as below. Data Bus sends signal to FET Source, when SEL SIGNAL applies voltage to the Gate, driving voltage is then created on TFT LCD panel. A sub-pixel will be lit up. A TFT LCD display contains thousand or million of such driving circuits.

Topway started TFT LCD manufacturing more than15 years ago. We produce color TFT LCD display from 1.8 to 15+ inches with different resolutions and interfaces. Here is some more readings about how to choose the right TFT LCD.

LCD displays. Of course, there is only one color for the backlight and one color for the characters, but as you can see here on the picture above, there could be many colors of backlights. We can have a white backlight, orange, green, blue or any backlight color.

The last part of this article covers graphic displays and character displays, the difference between them and how it influences the cost of an LCD display. The most basic LCD displays are the segmented monochrome LCD displays or icon displays. In this kind of LCD displays we have only some icons and characters, but they are defined when the display is being produced. What we see on the display is defined and we cannot have anything else, the other area is completely off. You can only switch on and off the display segments. This is the cheapest technology to produce, and it is made by mask during the production, so it is usually reserved for high volume applications, that are very well defined during the production phase. For example, this can a be kind of watch, or calculator, or temperature controller. The advantage is the cost, but the disadvantage is that later we cannot change anything, we cannot change the software and add another icon.

Next, we have the fully graphic display. In this kind of LCD display we have a matrix of pixels. It could be 64 by 256, or 64 by 128 pixels, so on this kind of screen we can show almost every image, because we can switch every pixel on and off. We can show letters, characters, images, small, big, anything we want. The disadvantage is the vast number of pixels that we need to connect. The controller and the glass are complicated, because we need to route the wires from every pixel out from the glass and connect it to the controller. So, in the monochrome LCD display family, this kind of display is the most expensive. Other kinds of displays are cheaper, not only because the glass is simple, but because the controllers are simple too.

In this Display 101 article we discuss thedigital parallelRGB LCD display interface and how the row and column driving signals are generated from the digital parallel RGB interface.

An LCD display consists of an array of liquid crystal segments. The crystal itself doesn’t emit light. With no electrical field, crystals organize in a random pattern. When an electric field is applied, the crystals align to the electrical field. Various strength of electric fields works like a “gate” to pass different intensity of backlight through the crystals. If the crystals are aligned perpendicular to the backlight, then the backlight can’t pass through the crystals. [1]

From the electronic structure point of view, an LCD panel consists of a grid of electrical signals. The pixels are addressed by a matrix where every interaction belongs to a pixel. Each pixel is connected perpendicularly to the row and column through a transistor. When the row and column are selected by an IC controller, the responding pixel at the interaction of the row and the column is enabled or disabled.[2]

How to generate a specific color for a pixel? Each pixel is composed of 3 segments that individually pass light through a red, green, and blue filter, to make an RGB display color pixel. For a 320*240 RGB TFT display, there are 960 (320*3) columns and 240 rows.

Most LCD displays have a digital parallel RGB interface. It works between the graphic controller as a signal source and the input of the RGB display module.

The image data is transmitted digitally as “0 ”or “1 “ by TTL voltage levels. For the RGB interface, each of the signals has a corresponding line. Below are the signal connections of the LCD RGB display interface of 24 bits per pixel.

The same principle is applied to the HSYNC syncpulse, marked with HBP and HFP. The HSYNC pulse is responsible for a new row.Between twoHSyncpulses, the grey level RGB color data for one row (line) needs to be transmitted.[4]

In this article, you will learn how to use TFT LCDs by Arduino boards. From basic commands to professional designs and technics are all explained here.

There are several components to achieve this. LEDs, 7-segments, Character and Graphic displays, and full-color TFT LCDs. The right component for your projects depends on the amount of data to be displayed, type of user interaction, and processor capacity.

TFT LCD is a variant of a liquid-crystal display (LCD) that uses thin-film-transistor (TFT) technology to improve image qualities such as addressability and contrast. A TFT LCD is an active matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven LCDs with a few segments.

In Arduino-based projects, the processor frequency is low. So it is not possible to display complex, high definition images and high-speed motions. Therefore, full-color TFT LCDs can only be used to display simple data and commands.

There are several components to achieve this. LEDs, 7-segments, Character and Graphic displays, and full-color TFT LCDs. The right component for your projects depends on the amount of data to be displayed, type of user interaction, and processor capacity.

TFT LCD is a variant of a liquid-crystal display (LCD) that uses thin-film-transistor (TFT) technology to improve image qualities such as addressability and contrast. A TFT LCD is an active matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven LCDs with a few segments.

In Arduino-based projects, the processor frequency is low. So it is not possible to display complex, high definition images and high-speed motions. Therefore, full-color TFT LCDs can only be used to display simple data and commands.

In electronics/computer hardware a display driver is usually a semiconductor integrated circuit (but may alternatively comprise a state machine made of discrete logic and other components) which provides an interface function between a microprocessor, microcontroller, ASIC or general-purpose peripheral interface and a particular type of display device, e.g. LCD, LED, OLED, ePaper, CRT, Vacuum fluorescent or Nixie.

The LCDs manufacturers use different drivers in their products. Some of them are more popular and some of them are very unknown. To run your display easily, you should use Arduino LCDs libraries and add them to your code. Otherwise running the display may be very difficult. There are many free libraries you can find on the internet but the important point about the libraries is their compatibility with the LCD’s driver. The driver of your LCD must be known by your library. In this article, we use the Adafruit GFX library and MCUFRIEND KBV library and example codes. You can download them from the following links.

Upload your image and download the converted file that the UTFT libraries can process. Now copy the hex code to Arduino IDE. x and y are locations of the image. sx and sy are size of the image.

while (a < b) { Serial.println(a); j = 80 * (sin(PI * a / 2000)); i = 80 * (cos(PI * a / 2000)); j2 = 50 * (sin(PI * a / 2000)); i2 = 50 * (cos(PI * a / 2000)); tft.drawLine(i2 + 235, j2 + 169, i + 235, j + 169, tft.color565(0, 255, 255)); tft.fillRect(200, 153, 75, 33, 0x0000); tft.setTextSize(3); tft.setTextColor(0xffff); if ((a/20)>99)

while (b < a) { j = 80 * (sin(PI * a / 2000)); i = 80 * (cos(PI * a / 2000)); j2 = 50 * (sin(PI * a / 2000)); i2 = 50 * (cos(PI * a / 2000)); tft.drawLine(i2 + 235, j2 + 169, i + 235, j + 169, tft.color565(0, 0, 0)); tft.fillRect(200, 153, 75, 33, 0x0000); tft.setTextSize(3); tft.setTextColor(0xffff); if ((a/20)>99)

If you are TFT LCD module users, we will provide you with the most suitable TFT LCD products, including the selection of control board, accessories, testing, maintenance and a series of services.

The TFT LCD monitor is a flat and ultra-thin display device, composed of a certain number of colors or black and white pixels, which are placed in front of the light source or the reflective surface. LCD displays are favored by engineers because of their low power consumption and are suitable for electronic devices that run on batteries. Its main working principle is to stimulate the liquid crystal molecules to generate dots, lines and surfaces with the back light tube to form a picture.

Traditional CRT monitors use picture tube technology for imaging, so they need a built-in vacuum picture tube and an electron gun at the end, so that the length is generally more than 30 cm, and the volume of the entire display is larger. The uart display TFT LCD uses liquid crystal material, and then applies the corresponding imaging technology to display, without installing a picture tube inside the display, so that the volume is small.

The traditional CRT display is limited by display technology, and its size is smaller than the display area of the fluorescent screen. However, due to the different imaging principles of liquid crystal displays, the marked size is the actual display area.

The CRT display adopts cathode picture tube imaging. The electron beam contained in it will generate a lot of static electricity and radiation during operation, and the faster the electron beam runs, the greater the radiation. Long-term use will cause damage to the eyes and skin, such as eye myopia, skin allergies and other problems. However, because the LCD display uses liquid crystal material, it does not need to use electron beams when working, so there are no problems of static electricity and radiation that affect vision. In addition, the formation of a picture of the CRT display is formed by scanning, and only when the scanning frequency reaches a certain value, there is no flicker, while the TFT LCD display display does not need the scanning process, and a picture is formed almost at the same time, even if the refreshed frequency is very low, there is no flicker at all.

In addition to the power consumption of the circuit and the picture tube, the CRT display also has the power consumption of the display screen, while the tft lcd power consumption is mainly on the backlight and the circuit, and the power consumption of the display screen can be ignored. In addition, because the liquid crystal display does not use a picture tube and an electron gun for imaging like a CRT display, it does not need to consider the high radiation effect caused by increasing the electron beam emitted by the electron gun, but only obtains the brightness through the backlight emitted by the fluorescent tube. Therefore, it has a stronger anti-interference ability, and even in an environment with concentrated light, it will present a good display effect.

The traditional CRT monitor mostly adopts the analog display mode, and the displayed signal output adopts the analog output mode, which may cause the loss of the image during the transmission process, resulting in the decline of the picture quality. Outputting digital signals will not cause signal loss, but at present, most LCD monitors still use VGA interfaces for analog monitors, and only a few manufacturers have set up digital video signal interfaces.

Due to the different materials and technologies used in TFT liquid crystal displays, some of its parameters are generally relatively fixed, which requires more intelligent performance adjustment of the display. In this regard, each manufacturer has its own mature technology.

LCD (liquid crystal display) is the most widely used display technology. They are used for automotive, appliance, telecommunication, home appliance, industrial, consumer electronic, military etc. But LCD displays have some drawbacks, such as slow response, narrow viewing angle, lower contrast etc. One annoying phenomenon often complained about by users is image sticking.

If a fixed image remains on a display for a long period of time, the faint outline of that image will persist on the screen for some time before it finally disappears. Normally, it happens to LCD and plasma screens, but for the purpose of our discussion, we will focus on TFT LCD displays. Image sticking is also referred to as “image persistence”, “image retention”, “ghosting” or “burn-in image.”

An LCD screen includes a thin layer of liquid crystal material sandwiched between two electrodes on glass substrates, with two polarizers on each side. A polarizer is an optical filter that lets light waves of a specific polarization pass through while blocking light waves of other polarizations. The electrodes need to be transparent so the most popular material is ITO (indium tin oxide). Since an LCD can’t emit light itself, normally a backlight is placed behind an LCD screen in order to be seen in a dark environment. The light sources used for a backlight can be LED (light emitting diode) or CCFL (cold cathode fluorescent lamps). The LED backlight is the most popular. Of course, if you want a color display, a layer of RGB color filter can be made into an LCD cell. A touch panel can also be added in front of an LCD display.

When an electric field is applied to the liquid crystal molecules, they become untwisted. When the polarized light reaches the layer of liquid crystal molecules, the light passes straight through without being twisted. When it reaches the second polarizer, it will also pass through, meaning the viewer sees the display as bright. Because LCD technology uses electric fields instead of electric current (electron passes through), it has low power consumption.

The cause of LCD image sticking is due to an accumulation of ionic impurities inside the liquid crystal materials. When slight DC voltage occurs, the charged impurities will move the electrodes and build up a reversed voltage field. When the power is removed, the reversed voltage will kick in to make the LCD molecules twisted different from the other part of the LCD, which shows up as the image sticking. The longer the time, the more impurities will migrate, the larger the reversed voltage will be, and the imaging sticking will appear worse.

For LCD manufacturers, try to protect liquid crystal materials exposed to the air by using nitrogen gas or dried air to avoid absorbing moisture that can create a huge amount of impurities in the liquid crystal material, as water is an excellent solvent. Controlling the humidity of the fab is also very important, as is selecting the right liquid crystal materials and their manufacturers. Different liquid crystal materials have different moisture absorbing abilities. Different liquid crystal material factories have different capabilities in terms of controlling impurities. Despite the fact that high purity can mean high in cost, using higher purity liquid crystal materials and designing the circuitry to get rid of DC in LCD display drivers can avoid an image sticking issue.

Unlike the “burn-in” issue common with CRTs, an image sticking issue is not permanent. It will eventually recover after some time. One way to expedite erasing a retained image is to have a screen on in an all-black pattern for 4-6 hours. If you want to make it even faster, the display can be put into an environment with a temperature of around 35 to 50°C for 1-2 hours. As this elevated temperature is within the working temperature range, it will not damage the LCD panels.

Operating principle of LCD screen.The working principle of LCD screen. Lcd display is the mainstream technology in the display field at present, with a wide range of products. The following focuses on the working principle of LCD display.

LCD is the abbreviation of liquid crystal display. At present, TFT-LCD is the mainstream technology. LCD needs a backlight and a polarizer. The most important thing is that in two parallel glass sheets, a TFT thin film transistor (you can understand that there are many circuits), and on the above substrate, a CF filter (red, green, blue and RGB). Since the CF color filter has RGB color blocks, we will first pass through the TFT transistor substrate, then through the liquid crystal molecules, and then to the CF color filter according to the above order in the process of passing through the fluorescent screen. In each color block, because of the difference in transmissivity, there will be red, green, and blue colors.

Since the CF color filter has RGB color blocks, we will first pass through the TFT transistor substrate, then through the liquid crystal molecules, and then to the CF color filter according to the above order in the process of passing through the fluorescent screen. In each color block, because of the difference in transmissivity, there will be red, green, and blue colors. Of course, these color blocks must be much smaller to form a colorful picture, which is called "pixel"!

Let"s take a look at our hero, LCD, which is a special physical form. What we know most is gas, water vapor, liquid, ice, and a kind of plasma that everyone has heard of. This time, we need to get familiar with the shape of liquid crystal, which has the characteristics of both crystal and liquid. Most liquid crystal molecules are "rod molecules". They originally have various directions, but under different voltages, they will show different luminous properties, just like the metal in the magnetic field. When affected by the electric field, they will have specific directivity. Therefore, we can properly control the arrangement of liquid crystal molecules, so that some light can pass through, while others cannot, which will cause the difference in light transmittance.

Operating principle of LCD screen.The above is a purely theoretical explanation. I hope this article can help you understand the working principle of LCD more deeply.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey