arduino mega tft lcd example factory

Spice up your Arduino project with a beautiful large touchscreen display shield with built in microSD card connection. This TFT display is big (3.5" diagonal) bright (6 white-LED backlight) and colorful (18-bit 262,000 different shades)! 320x480 pixels with individual pixel control. As a bonus, this display has a optional resistive touch panel with controller XPT2046 attached by default and a optional capacitive touch panel with controller FT6236 attached by default, so you can detect finger presses anywhere on the screen and doesn"t require pressing down on the screen with a stylus and has nice glossy glass cover.

The shield is fully assembled, tested and ready to go. No wiring, no soldering! Simply plug it in and load up our library - you"ll have it running in under 10 minutes! Works best with any classic Arduino (Due/Mega 2560).

Of course, we wouldn"t just leave you with a datasheet and a "good luck!" - we"ve written a full open source graphics library at the bottom of this page that can draw pixels, lines, rectangles, circles and text. We also have a touch screen library that detects x,y and z (pressure) and example code to demonstrate all of it. The code is written for Arduino but can be easily ported to your favorite microcontroller!

If you"ve had a lot of Arduino DUEs go through your hands (or if you are just unlucky), chances are you’ve come across at least one that does not start-up properly.The symptom is simple: you power up the Arduino but it doesn’t appear to “boot”. Your code simply doesn"t start running.You might have noticed that resetting the board (by pressing the reset button) causes the board to start-up normally.The fix is simple,here is the solution.

Voltage type: 5v or 3v voltage input voltage,input is selectable. Because TFT can only work under 3.3 V voltage, so when the input voltage VIN is 5V, need through the 3.3 V voltage regulator IC step down to 3.3V , when the input voltage of 3.3 V, you need to use the zero resistance make J2 short , is equivalent to not through the voltage regulator IC for module and power supply directly.

Alibaba.com offers 406 arduino tft screen products. About 58% % of these are lcd modules, 21%% are lcd touch screen, and 4%% are integrated circuits (old).

The liquid crystal display module based on SPI communication interface, provide 2.8 "TFT LCD, resistive touch screen, built-in Flash flash and SD card external expansion storage. This TFT panel connects directly on top of an Arduino pin compatible device.

2.Extract the content to your Arduino library folder. In Windows this is usually located in Arduino IDE folder\libraries. Check Arduino"s official guide if you want more information on how to install the Arduino Library. The official guide of Arduino

We covered the basics of accelerometer previously inUsing Arduino with Parts and Sensors – Accelerometer Part 1andUsing Arduino with Parts and Sensors – Accelerometer Part 2. Today we’ll be testing KX022-1020 accelerometer using TFT liquid crystal panel. We’ll discuss how to control the TFT LCD in more detail in the next article. In addition, we’ll further exploreArduino Create. For more information about Arduino Create, please refer back tothisarticle.

Let’s briefly review what accelerometer is. An accelerometer is a sensor that can detect the state of motion, such as “tilt,” “shock,” “vibration” and so forth. Accelerometers are classified into one axis, two axes, and three axes. For example, one axis detects one direction (vertical only); two axes detects two directions (vertical and horizontal); and three axes three directions (vertical, horizontal and height).

We’ll continue using Arduino Create Web Editor as we did in our lasttutorial. To add the library, you can upload the zip file by selecting it from “Libraries” on the left menu and clicking on “ADD ZIP LIBRARY.”

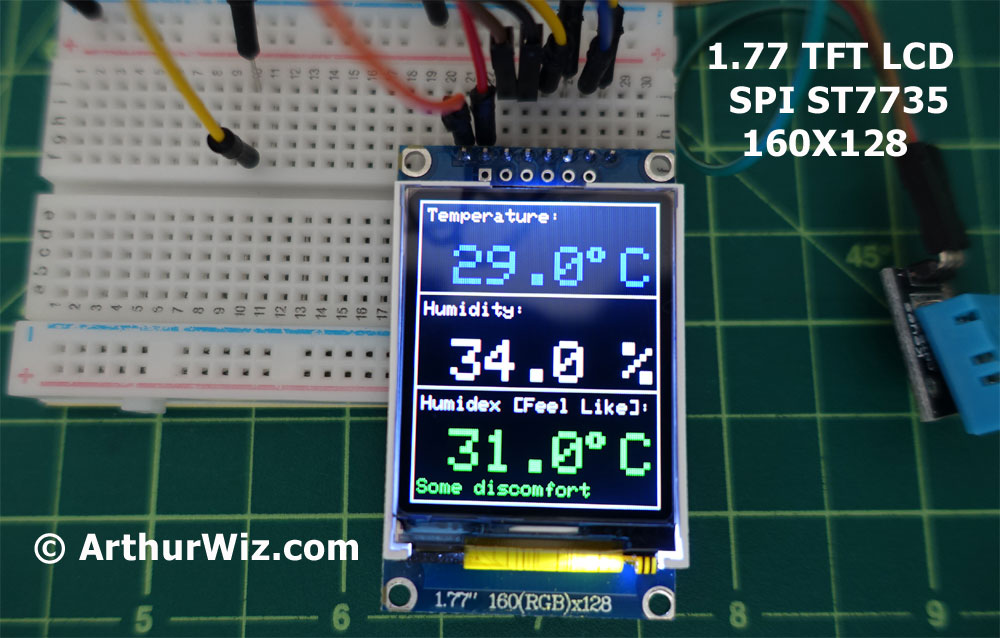

Now the sample program is working fine, let’s try to display the values on a 1.8 inch TFT LCD monitor. Although this TFT liquid crystal monitor has a resolution slightly smaller than 126 x 160 px, it’ll be quite useful when displaying numbers or letters with Arduino etc.

When using the TFT monitor, the connection method and the library used in the program may be different depending on the specification of each TFT monitor. The TFT monitor used in this tutorial is a monitorSainSmart ST7735R. In addition to Arduino, the monitor is also compatible with Raspberry.

In order to use the monitor to run the program in Arduino, we’ll have to modify the downloaded library a little bit.We’ll go over how to control the TFT LCD in more detail in the next article. Once everything is set, you will be able to output numerical values in the monitor as shown in the video below:

In the next part, we’ll create a simple device using the same accelerometer and TFT monitor. We’ll show how to create graphs and display the values obtained from the accelerometer on the TFT monitor.

In two of my previous articles I showed you how to reverse engineer the Nokia 2730 LCD for connecting to a device with 3.3V I/O’s and then I showed you how to build a 16-channel level converter for connecting devices together that have differing I/O level requirements.

This article brings together the knowledge we have gained in the previous two articles and puts it to use by creating a project that will allow a Nokia QVGA 24-bit colour TFT LCD to be indirectly connected to an Arduino Mega via a level converter, all on one small 50mm PCB.

All quite straightforward so far. The real innovation will be in the graphics library that I present in part two of this article set. The graphics library will use the external memory interface built in to the Arduino Mega to transfer data to the LCD in a single assembly instruction.

There is no faster way to transfer data out of the Arduino Mega to a peripheral. Doing it like this opens up the possibility of full colour bitmap graphics at a respectable refresh speed.

Perhaps the first surprise of this article is my choice of LCD. Given that the previous article showed how to reverse engineer the Nokia 2730 LCD you could have been forgiven for assuming that this was the one I’d use.

Here’s a photograph of the LCD side of the connector. If you look closely you can see where the ground pins connect directly into the ‘ground pour’ inside the ribbon cable. This helps to identify where pin 1 is located because the big “1” silkscreen’d on to the FPC is in the wrong place.

We need both 5V and 3.3V inputs for this design. 5V will be used to power the backlight driver as well as set the reference level for the Arduino side of the level converter. 3.3V will be used to set the reference for the LCD side of the regulator.

The backlight draws the most power from this design so I will optionally allow 5V to be supplied externally from a supply that shares a common ground with the Arduino itself.

TFTs like these draw a very small amount of current, typically less than 10mA so I will supply it indirectly from a GPIO pin through the level converter. This allows me to control the order in which power is applied. Many TFTs prefer their I/O supply to come up before the panel supply and for safety I’m going to assume that this is the case with this device. Had the device required significant amounts of current I would have had to use a couple of transistors to switch the current on and off.

The Nokia 6300, like the Nokia 2730, uses an 8-bit 8080 protocol to communicate with the LCD. The 8080 protocol consists of a chip select signal, 8 bits of data, read and write lines and another line that is used to indicate whether you want to transfer data or set a command register value.

The above image summarises the state of the 8080 bus during a write cycle. The key point to note is that data is transferred to the controller on the rising edge of the WR line. Can we get this line from the Arduino Mega’s external memory interface? Well yes, we can. The following diagram from the datasheet shows the timing of the external memory bus.

Selecting a low address line (A8) means that we can free up address lines 10 to 15 for GPIO, saving 6 pins. It doesn’t matter that our selected address locations 0x8000 and 0x8100 are high up in the address range who’s address lines are free’d for GPIO. The ATMega will still correctly control A8. Not only is this design fast, it’s frugal with pins too. Here is the mapping of Arduino pins to their LCD function.

Now that we have a design we can create the schematic in the Eagle designer. All the 5V signals from the Arduino that are destined for the LCD are routed through the level converter and will come out the other side at 3.3V.

After creating the schematic the next stage is to switch to the CAD designer and lay out the board. I placed the components and routed the traces manually. The connector is placed so that the FPC will wrap around the board edge and allow me to mount the LCD on the other side using double-sided sticky tabs.

With the LCD facing up, the interface pins face down and press directly into the sockets on the Arduino. The pin header is placed as close to the edge of the board as possible so that adjacent Arduino pins are not obscured.

After staring at the layout until I’m square-eyed (sound familiar to anyone?) I’m feeling confident that the header pins are all where they should be, the connector positioning will result in the LCD ending up in the right place and the silk-screening will end up on the correct side of the board.

I construct the boards by tinning the pads and then reflowing the larger components such as the level converter, LCD connector socket and the NCP5007 using a hot-plate. I then reflow the smaller discrete components using my Aoyue hot-air gun.

After the completed PCB is cleaned and dried the design is completed by pressing the LCD connector into its socket and mounting the panel on double-sided sticky pads. That it fits comfortably on to the pads was a bit of a relief because the metal back of the panel must stand clear of the traces and particularly the vias on that side of the board.

The open holes in between the groups of header pins allow the unused Arduino pins to be accessed for general purpose use. The designers of the Arduino clearly knew what they were doing when they grouped together the external memory pins in the same place.

It is required to connect the 3.3V and GND pins to the Arduino. With the blue jumper connected 5V will be taken directly from the Arduino board and used to power the backlight. With the jumper disconnected I must supply a regulated 5V myself to the 5V (in) pin.

Now that the build is complete we need a software graphics library to exploit the capabilities of our new hardware. Continue reading part two of this two part series of articles where I present an advanced, high performance graphics library with lots of examples to try out and videos to watch.

Type ‘B’ boards support the faster 64K driver. Type ‘A’ boards do not. The raw fill rate for the 64K colour mode is 1.32 megapixels/second. It is 1.06 megapixels/second for the 262K and 16M modes on both boards.

To interface TFT LCD Display with Arduino, for designing custom HMI TFT LCD Display provide rich colours, detailed images, and bright graphics with their full-colour RGB mode it comes in different pixels 128 x 160 pixels, 320×240 pixels and many more.

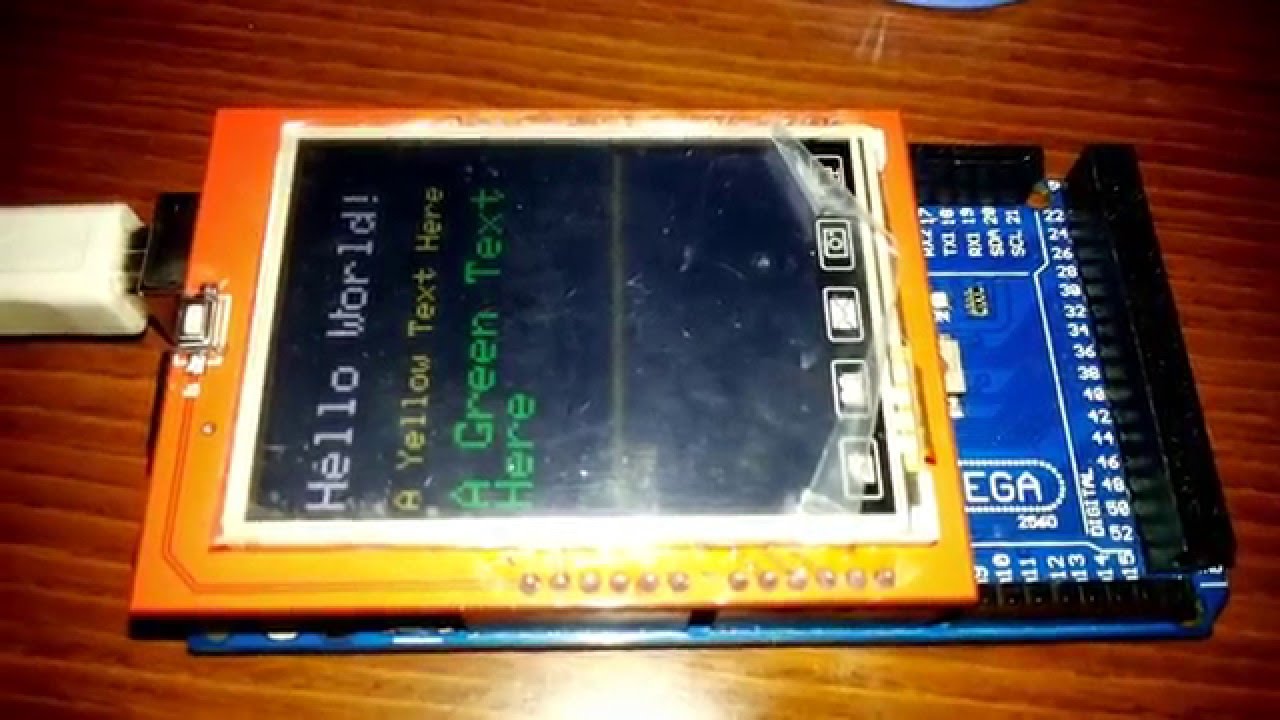

In this tutorial, we’ll interface the 1.8 TFT LCD display with Arduino Uno. You’ll learn how to interface the TFT LCD with Arduino to write text on this LCD. This tutorial presents the coding, wiring diagram and components list required for the LCD display.

Creating an interface between the user and the system is very important. This interface can be created by displaying useful data, and menus. There are several components to achieving this. LEDs, 7-segments, OLEDs, and full-color TFT LCDs. The right component for your projects depends on the amount of data to be displayed, and the type of user interaction.

TFT LCD is a variant of a liquid-crystal display (LCD) that uses thin-film-transistor (TFT) technology to improve image qualities such as addressability and contrast. In the case of Arduino, the processor frequency is low. So it is not possible to display complex and high-speed motions. Therefore, full-colour TFT LCDs can only be used to display simple data and commands. This TFT has 128 x 160 pixels. 1.8 TFT display can load images from an SD card. It has an SD card slot at the back. You can see the front and back views of the TFT LCD in the figures below.

TFT is an abbreviation of “Thin Film Transistor”. It has transistors made up of thin films of Amorphous silicon. It serves as a control valve to provide an appropriate voltage onto liquid crystals for individual sub-pixels. The working principle is very simple the TFT LCD composes of many pixels that can emit light of any colour. The desired image achieves by controlling each pixel to display the corresponding colour. In TFT LCD, the backlight technology is generally used. In order to accurately control the colour and brightness of each pixel, it is necessary to install a shutter-like switch after each pixel. When the “blinds” are opened, light can pass through them. When the shutters are closed, light cannot pass through them.

Connect your PC to Arduino and open Arduino IDE. For the very first steps, you can refer to Connecting Windows PC with Arduino tutorial. You can get the .ino code and libraries from my download area with the following link:

This is the section before setup which uses for globe variables defining and libraries additions. TFT.h is the library for TFT LCD Display and uses for writing and drawing on the display. The TFT display communicates with the Arduino via SPI communication, so you need to include the SPI library.

This is the setup section in which Serial.begin(9600) initialize. TFTscreen.begin() is use to initialize the library. TFTscreen.background(0, 0, 0) is use to customize the screen background color here TFTscreen.background(0, 0, 0) means the background colour is black. TFTscreen.setTextSize(2) is use to set the font size.

In the loop section first, we will print the “Hi_peppe8o!” in the centre of the LCD and this will be in three different colours (Red, Green, Blue) you can choose any colour using the different colour codes. After 300 milliseconds a straight line will be displayed, after 300 milliseconds a square will be displayed, after 300 milliseconds a circle will be displayed, and after 300 milliseconds screen will be black/ erase and these all shapes and the text will be repeated in the void loop.

The LCD displays the text of “Hi_peppe80” and after that displays the line, square, and circle and then erases everything after completing this sequence. The command used for clearing all the data is TFTscreen.background(0,0,0):

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey