ito lcd panel manufacturer

The globaltop ITO companiesare conducting research and development (R&D) activities to minimize the production costs of ITO to create numerous growth opportunities in the market. The rising adoption of solar panels and thin-film photovoltaic (PV) cells is further driving the market growth. ITO forms an indispensable component in producing these cells and panels as its usage offers a higher light absorption rate and improves cost efficiency. Looking forward, the market is expected to grow at a CAGR of around 6% during 2021-2026.

Samsung Corning Precision (SCP) Material Co. Ltd. is the world leader in specialty glass and ceramics. It creates and makes keystone components that enable high-technology systems for consumer electronics, mobile emissions control, telecommunications and life sciences. The company includes products such as glass substrates for LCD televisions, computer monitors and laptops; ceramic substrates and filters for mobile emission control systems; optical fiber, cable, hardware & equipment for telecommunications networks; optical biosensors for drug discovery; and other advanced optics and specialty glass solutions for several industries including semiconductor, aerospace,

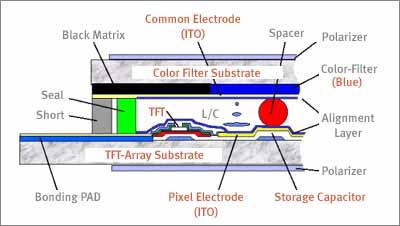

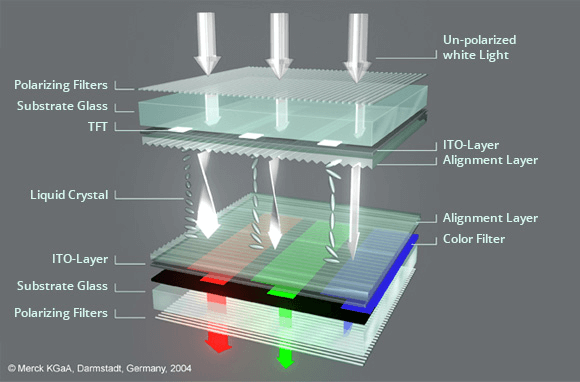

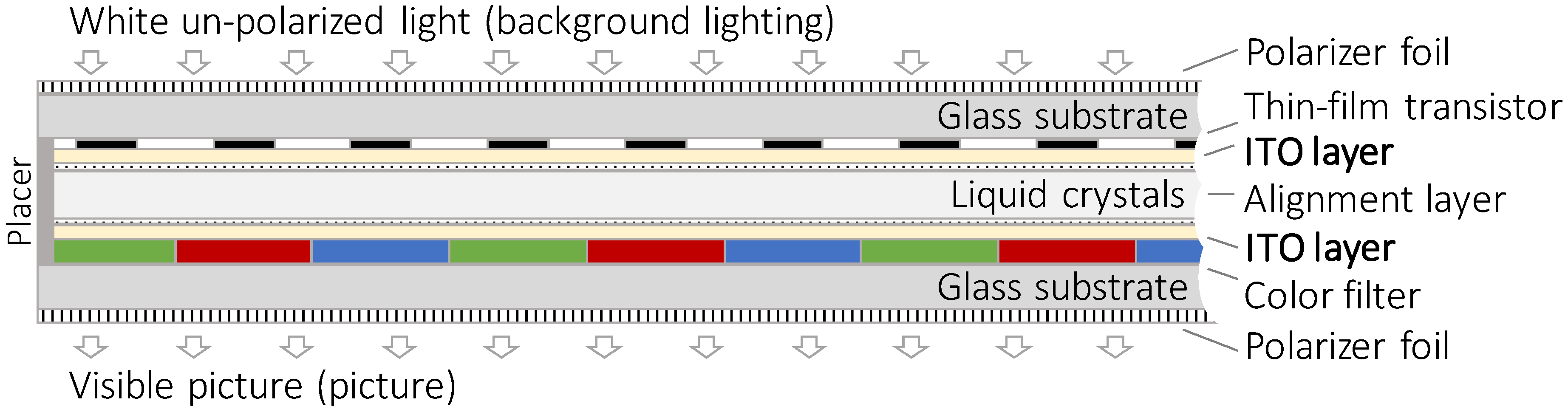

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"TCL"s Panel Manufacturer CSOT Commences Production of High Generation Panel Modules". www.businesswire.com. June 14, 2018. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

Many LCD technologies, such as monochrome character, dot matrix and segment displays, make use of ITO glass. Even though ITO glass has been in existence for some time, it is still an important aspect in LCD designs and will be covered in the article below.

The article about ITO glass was written by Barbara Dutra, an exchange engineering student from Brazil, who is currently an intern at Focus Display Solutions. Her current job responsibilities include ISO certification, Test and quality insurance of inbound LCD displays and writing technical articles.

The Indium tin oxide is a material used in modern devices that manipulates ambient light. ITO is a good material, because it has a good response time to conduct electricity and an appropriate transparency for the emission of light.

It is also used in flat panel TVs where each pixel is turned ON or OFF by a pair of transparent electrodes ITO. Touch screen displays are the latest innovations using that material.

The first touchscreen devices were sold with a pen and were manufactured with two layers of ITO glass separated by a small gap. When the resistive screens were touched with a pen, the two layers came into contact, creating a short circuit and allowing a current to pass and be detected by the device.

New devices, implementing newer technology, use the finger to allow the short circuit that identifies the position without the need of a pen. The touch in the screen changes its capacitance at that location and this change is perceived by a single layer of ITO.

The ITO glass is a thin transparent film similar to common glass, but unlike glass, it is a conductor of electricity because it is a kind of transparent conductive oxide (TCO). So it has the property of reflecting electromagnetic radiation in the infrared region (spectrum) and having a low electrical resistivity.

The ITO is the best TCO because it is a good combination of transparency and conductivity. Because of its transparency, ITO glass does not absorb light photons. Absorption occurs when the photon energy corresponds to what is necessary to let the electron in an excited state.

To produce the thin films of ITO glass, it is common to use sputtering techniques with radio frequency assisted by constant magnetic field (RF magnetron sputtering). The sputtering technique involves the transport of molecules or atoms ejected from a source (also called the target) to a substrate.

The ITO glass is an expensive material because of the indium mineral, but this is not the biggest problem. The biggest challenge is the shortage expected to take place in a few years because indium is a rare mineral.

This is bad news because the market of touch screen devices is in an expansion mode and every day the demand increases since bigger and bigger screens are created using a larger amount of ITO.

Some hypotheses are the cadmium oxide, silver nanowires and graphene (carbon nanomaterial). The first is almost as transparent as ITO glass and has a greater capacity of conduct electricity, but it is very unstable and deteriorates quickly (half-life).

One solution to this problem is to apply 20% of ITO in the cadmium oxide just to create a film of protection on the material. Another problem, an environmental one, is that this oxide is more toxic and demands care in the manipulation and disposal of waste. This could be a future environmental problem.

Silver is very similar to high quality ITO, but it is quite flexible. Unfortunately silver nanowires are ten times more expensive to produce than the already expensive ITO and cheaper metals seem to not work.

The graphene can be used for touch screen displays because of the characteristics but is an expensive technology today. In the future the price between ITO glass and carbon nanotubes will be equivalent because of the lack of indium and carbon segment growth cheapening their cost. So, the graphene looks a promising option.

But that does not rule out this option because the processing power is in expansion. Anyway these free indium techniques do not solve a fundamental problem: with or without touch, the electrodes that provide power to the pixels on the LCD screen depend on the ITO glass. This will be solved only with the development of new materials that emulate the highly desirable ability of the ITO glass to combine transparency and conductivity.

It is safe to say that the cost of LCD displays does not look to be decreasing any time soon, if at all. Part of the reason for higher cost displays is not only the potential cost increase due to an ITO shortage. But a labor shortage that is taking place in many LCD manufacturing locations.

![]()

Phil Zarrow: Jim, let’s talk about the wonderful world of indium-tin oxide (ITO). Obviously, as the name implies, it’s indium, tin, and oxygen in oxide form, but how is it used? What are some of the applications?

Jim Hisert: Well, indium-tin oxide is used as a clear conductive layer on almost all electronics devices that have a display. It’s used in flat panel televisions, it’s also used for touchscreen devices - a touchscreen, flat panel device could have up to 4 layers of ITO.

Jim Hisert:Well, we’ve been working with customers on developing ITO and increasing the density of targets, which is one of the main drivers in the technology. In doing that we have found different powder distributions and morphologies that work the best. We’ve developed with the market, and the market has developed with our products.

Jim Hisert:Well, for applications [of ITO], I really like the video you did with Dr. Ron Lasky. In addition to that, I have a blog, and I talk about indium-tin oxide and other indium-related subjects. We also have a specific ITO blog where we talk about target technology. And, you can always contact me at jhisert@indium.com if you have any questions.

With the development of science and technology, LCD screens have become a go-to product for many because they emit no radiation, have large display information, and offer long service life.

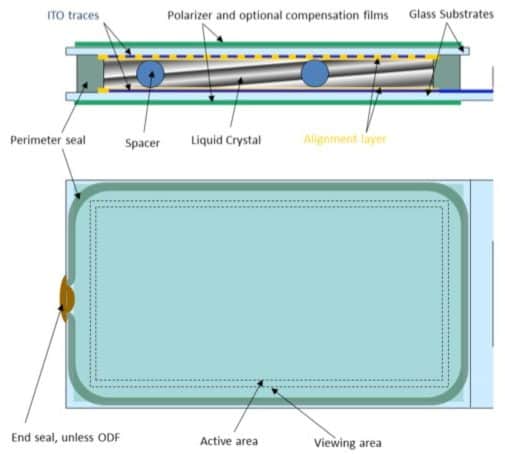

ITO glass input: The appropriate ITO glass is selected for the basket, which is dependent on the requirements of the product in question. It is vital that the specification and model of the ITO glass meet the requirements of the product. The ITO layer must be inserted into the basket facing upwards.

Glass cleaning and drying: ITO glass will be washed with cleaning agents and deionized water (DI water). Any impurities and oil stains on the ITO surface will be washed by physical or chemical methods, with the water then removed and the product dried in preparation for the next stage of the process.

Photoresist coating: An even layer of photoresist will be applied to the conductive layer of ITO glass, and the photoresist-coated glass will be pretreated at a certain temperature.

Etching: The ITO film without photoresist is etched away with an acid etching solution, so as to obtain the ITO electrode pattern required. Note: ITO glass is conductive glass (In203 and Sn02), which easily reacts with acid. This is used to etch away excess ITO, so as to obtain the corresponding pull electrode.

Film removal: A high concentration of lye (Naoh solution) is used as a film removal solution to peel off the remaining photoresist on the glass, so as to form ITO graphics that exactly match the photoresist mask on ITO glass.

There are 2 automatic production lines in Panox Display factory, has a capacity of 300K pcs every months. Main OEM products include 1.7icnh, 2.4 inch,2.8 inch, 3.2inch,4.3 inch,4.7inch, 5.0 inch,5.5 inch ,6.0 inch LCD and other sizes, most of them applied in Mobile displays, such as Moto G5,LG ..

Many products demand a custom LCD to meet application specific display requirements, electrical specifications, or mechanical dimensions. For over 10 years Panox Display has specialized in designing and producing custom LCDs and can quickly help you to create the ideal display for your product. Please click here to send your request designing a custom LCD panel.

We have thousands of standard products that are in stock and available from our Seattle, WA and Hong Kong warehouses to support fast product development and preproduction without MOQ. The stock covers TN, STN LCD display panels, COB, COG character LCD display, graphic LCD display, PMOLED, AMOLED display, TFT display, IPS display, high brightness and transflective, blanview sunlight readable display, super high contrast ratio display, lightning fast response displays, efficient low power consumption display, extreme temperature range display, HMI display, HDMI display, Raspberry Pi Display, Arduino display, embedded display, capacitive touch screen, LED backlight etc. Customers can easily purchase samples directly from our website to avoid time delays with setting up accounts and credit terms and shipping within 24 hours.

Many of our customers require customized OEM display solutions. With over two decades of experience, we apply our understanding of available display solutions to meet our customer’s requirements and assist from project concept to mass production. Using your ideas and requirements as a foundation, we work side by side with you to develop ideas/concepts into drawings, build prototypes and to final production seamlessly. In order to meet the fast changing world, we can provide the fastest turnaround in the industry, it takes only 3-4 weeks to produce LCD panels samples and 4-6 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen samples. The production time is only 4-5 weeks for LCD panels and 5-8 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen.

New Vision Display is a custom LCD display manufacturer serving OEMs across diverse markets. One of the things that sets us apart from other LCD screen manufacturers is the diversity of products and customizations we offer. Our LCD portfolio ranges from low-cost monochrome LCDs to high-resolution, high-brightness color TFT LCDs – and pretty much everything in between. We also have extensive experience integrating LCD screen displays into complete assemblies with touch and cover lens.

Sunlight readable, ultra-low power, bistable (“paper-like”) LCDs. Automotive grade, wide operating/storage temperatures, and wide viewing angles. Low tooling costs.

Among the many advantages of working with NVD as your LCD screen manufacturer is the extensive technical expertise of our engineering team. From concept to product, our sales and technical staff provide expert recommendations and attentive support to ensure the right solution for your project.

As a leading LCD panel manufacturer, NVD manufactures custom LCD display solutions for a variety of end-user applications: Medical devices, industrial equipment, household appliances, consumer electronics, and many others. Our state-of-the-art LCD factories are equipped to build custom LCDs for optimal performance in even the most challenging environments. Whether your product will be used in the great outdoors or a hospital operating room, we can build the right custom LCD solution for your needs. Learn more about the markets we serve below.

Ton-Whay Electronic Co., Ltd. was built in 1983 specializing in LCD Panels. In the beginning, Ton-Whay made OEM orders for Japanese customers. In the 1992, we used auto production equipment to enhance work process. Hence the products we make are more reliable, longer loading life, and less tolerance. By 1997, ISO 9002 was inducted because our construction got larger and larger. In 2000, we decided to add two kinds of electrical capacitors into our facilities, including film and ceramic capacitors. In the meantime, part of manufactures was moved to China for higher quality and low production cost. We further cooperate with Japanese capacitors to develop high rank production process. Look forward to your coming. We hope that we can set up a good business relationship with you.

Established in June 1992, Woei Cherng strives to improve people’s life quality to be more healthy, peaceful and happy. We stand on the principles of “Professionalism, Integrity, Sincerity, Enthusiasm, Promptness, Constant Advancement” to serve our local & foreign customers for almost 20 years and have earned high satisfaction and trust from customers worldwide. Our business items contain: industrial fire equipment, security surveillance system design, LCD Panels, main control panel, LED light system, water treatment products, etc. The products are spread to Government Ministries, banks, education institutes, and enterprise in Taiwan as well as America, Japan, Singapore, Malaysia, Vietnam Latvia, Norway, Spain, etc. Woei Cherng has always been putting in maximum efforts to improve us constantly....

(1) computer parts & peripherals- cables, computer cards & electrical connectors, OEM & ODM internet phones. (2) components parts & electronic components- LCD Panels, industrial speakers, power supply ( supplies), coaxial cable TV system, wiring accessories, TV games, speakers, remote control devices, electric meters.

Sunlike Display Tech. Corporation is a specialized exporter and manufacturer of LCD Panels since 1996. Guarantee, warranty, price and service are our company competitive advantages. Our products exported to Europe, U.S.A. , Asia, Australasia. The customers" designs and OEM/ODM orders are welcome. We greatly appreciate the prospect of introducing ourselves and our products to your company. If you have any questions please call or send your e-mail. We are looking forward to your response and developing a continued business relationship.

Jing Zhuan Co., Ltd. is a trading company that offers a wide variety of electronic components as required in the related telecommunication field. Our product includes: standard & custom-design LCD Panels; LCD Panels; standard & custom-design LCD modules such as: COB, COG, TAB, TFT; backlighting CCFL, LEDs; connectors such as: heatseals, rubber connectors, FMC (flexible metal circuit). Products can be applied to consumer electronics like calculators, watches; equipment meters used for industrials, sports and medical equipments; communication & computer; other applications used in automobiles, audios & videos. Our goal is to assists all of our clients to the best of our abilities. We are established not only to do business, but also to seek and form friendly, durable relationships with customers....

electronic components & parts- flexible printed circuit, flexible printing circuits ( FPC), electroluminescent display, heat seal connectors, electrical connectors, LCD Panels, SMD PCB membrane switches & nameplates, flat panel LCD displays, LCD flat panel monitors, electroluminescent displays, EL lamps, LCD modules & heat seal module,LCM, printed circuit board ( PCB) assembly ( assemblies), touch Panels, inverter modules.

Prochase Enterprise Co.,Ltd. has been not only compounding many multi functional engineering plastics and elastomers base on the customers requirements but also playing an international trading service role to seek for and offer the materials what customers request. In order to match the request of customers cost down in many industries such as electronic, electric, lighting, communication, playing station, camera, autos, OA equipments, so on. We are a leading and good reputable exporter, importer and compounder since 1992 in following plastics and business lines: LCD Panels, engineering plastics, release film, fluoro silicone release film, protective film, anti-scratch protective film, etc. Be trust us! We are the best option of yours!

manufacturer & exporter of personal & home media devices- dvd recorder, portable dvd player, HDMI DVD players, dual-drive dvd recorder, dvd hdd recorder, dvd+ tuner, dvd player, portable vcd player, flash portable media players, PMP, portable multimedia player, portable video players, dvd player & vdr combo, portable MPEG4/ DivX DVD players, touch panel media player, micro digital players, LCD TV, color TFT Panels, dvd home theater system, 5.1 channels home theater systems, sound bar, MP3/MP4 players, GPS navigators.

PC & computer peripherals- liquid crystal displays, TFT LCD monitors, car VGA, audio and video ( AV) products, handheld ( hand held ) and tablet PCs, custom LCD, in dash car televisions and monitors, integrated TV & computer monitors, stand alone ( standalone) car monitors and TVs, digital TV tuners, GPS, built in DVD players and car PC, IR remote control and touch screen Panels, interactive and touch screen terminals, mobile DVD changers.

electronic components, computer products & PC peripheral, computer parts & accessory ( accessories)- (1) module-TFT LCD, mono STN LCD and TFT modules, LCD module solutions, TFT LCD module & touch panel solution, open frame LCD & solutions, TFT LCD module & driving board & BL inverter solutions, character LCD modules, graphic LCD modules, TN STN FSTN LCD modules, open frame touch Panels, open frame LCD monitor module. (2) hand held ( handheld) PC ( computer), mini PC.

others- big size hot and cold mirrors, LCD protect Panels, monitor anti radiation glass filters, enhance AL and block blue mirrors, fog lamp coating, any shape glass cutting and grinding.

A leading private enterprise of integration of developing, manufacturing, and marketing LCD Panels. We promise to provide "feature designs(measure body creation)"solution policy to meet the different requirements from different customers. Under the great efforts of excellent Taiwan designers and all other colleagues in mainland, we have already finished researching "Drive of Electric Circuit" against 15", 17", 19", FTF LCD monitor and 30" LCD TV. It has been launched in the oversea market. What we are aiming for is to produce best products and get customers" 100% trust and 100% satisfaction. "All employees involved, high quality, customers" satisfaction" are our quality policy to be carried out. And we are looking forward to cooperating with all interested customers in home and abroad.

computer peripherals & PC components- LCD monitors, LCD Panels, custom LCD, LCD TV, TFT LCD monitors, TFT LCD, TFT LCD Panels, TFT LCD TV, LCD monitor manufacturers, LCD flat Panels monitors, liquid crystal displays.

Exceed Perseverance Electronic, founded in 1999, has thrived to the leading LED manufacturer and exporter. We mainly provide LED lamp, LCD Panels, display, dot matrix, smd, super flux, power so on to some leading electronic companies in the world. All the advanced equipments are from Taiwan area and Japan, which assures to provide qualified products to our clients. This R&D team can develop a new model within two weeks, and at least 6 new ripe products each year. Additionally, we have an in-house QC department, including experienced engineers and specially-trained staff. Each process strictly follows ISO9001 standard. We would like to cooperate with any clients, together create the bright future!

Ampire is a Taiwan-based TFT LCD Panel manufacturer with over 15 years experience in the filed. To satisfy the various needs, we provide diversified and high quality products with different technology and custom design ability. We are an excellent enterprise with ISO9001-2000, QS9000, ISO14001 and TS16949 certifications. We are happy to establish business relationship with customers all over the world. If you are interested in our products, or you are looking for cooperation partners in Taiwan for TFT LCD Panels, welcome to contact us for further information.

Powercom was founded in 1987, a leading provider & manufacturer of LCD Panels, off-line & on-line UPS, inverter, AVR, surge protection, UPSMON software, and etc. As an international manufacturer with ISO: 9001 certificate, we are keenly expanding to provide worldwide customers with better solutions. Our market competitiveness is not only derived from hardware design, but also from unique software research and development. Powercom is confident about our products and believes our products will satisfy your markets! OEM and ODM orders are welcome. Contact us now! Thank you for your visiting and wish you find helpful information here. We hope to establish long-time cooperation with you.

Shenzhen Niceview Technology Co., Ltd. is one of leading manufacturers and exporter of TFT LCD Panel. Our products are exported to many countries and regions in the world, such as Mid-East, South and East Asia, Europe and the United States. We have earned the excellent reputation for the qualities of qualities of TFT LCD Panels and fine service from customers all over the world. We also accept OEM orders. If you are interested in any of our products, please feel free to contact us directly for more details. We welcome both domestic and overseas customers to establish a long term business relationship with us. We are looking forward to receiving your inquiries. We may suggest you to visit our product page of TFT LCD Panels to get more our product information.

Top LCD Monitor manufacturer from China- KTC Computer LCD Monitor Manufacturers Technology Co., Ltd., founded in 1993, is a professional manufacturer for LCD screens, CRT Monitors, SKD LCD monitors, FPD Monitor, LCD desktop monitors, LCD computer ( PC) monitors, LCD display Panels, LCD Panels, TFT LCD & CRT color monitors products. We are an enterprise with SGS ISO 14001:2004 environmental management system and Swiss SGS ISO 9001:2000 quality control system. All of our products are approved with CCC, CE, CB, TCO03, FCC, UL and CQC. With the increasingly fierce industry competition, according to the concept of professional service and perfect satisfaction, we will continue to increase research and innovation efforts and provide the most competitive and valuable products and services.

electronic display devices- (1) LCD controller IC, STN LCD modules, TFT LCD module, LCD module, LCD modules, LCD display modules, backlight LCD module, backlight LCD modules, TFT LCD modules, LCD Panels, PC TV, LCD controllers, LCD displays, LCD drivers, LCD displays, LCD monitor drivers, LCD driver IC, TFT LCD driver IC, TFT LCD Panels, LCD TFT display modules. (2) video products & equipments- LCD TV ( television).

We are specializing in the manufacture of Saw blade products, and power tool - consumer electrical ( electronic, electric) finished products supply ( supplies)- solar Panels, solar panel, PVC ( plastic) floor tiles, web cameras ( cams), personal digital assistants ( PDA), computer peripherals, optical products, MP3 & MP4 players, security ( safety, safe, surveillance) systems, household ( home, house) sewing machines ( machinery, machineries), umbrellas, DVD & VCD players, TFT LCD monitors.

In recent time, China domestic companies like BOE have overtaken LCD manufacturers from Korea and Japan. For the first three quarters of 2020, China LCD companies shipped 97.01 million square meters TFT LCD. And China"s LCD display manufacturers expect to grab 70% global LCD panel shipments very soon.

BOE started LCD manufacturing in 1994, and has grown into the largest LCD manufacturers in the world. Who has the 1st generation 10.5 TFT LCD production line. BOE"s LCD products are widely used in areas like TV, monitor, mobile phone, laptop computer etc.

TianMa Microelectronics is a professional LCD and LCM manufacturer. The company owns generation 4.5 TFT LCD production lines, mainly focuses on making medium to small size LCD product. TianMa works on consult, design and manufacturing of LCD display. Its LCDs are used in medical, instrument, telecommunication and auto industries.

TCL CSOT (TCL China Star Optoelectronics Technology Co., Ltd), established in November, 2009. TCL has six LCD panel production lines commissioned, providing panels and modules for TV and mobile products. The products range from large, small & medium display panel and touch modules.

Established in 1996, Topway is a high-tech enterprise specializing in the design and manufacturing of industrial LCD module. Topway"s TFT LCD displays are known worldwide for their flexible use, reliable quality and reliable support. More than 20 years expertise coupled with longevity of LCD modules make Topway a trustworthy partner for decades. CMRC (market research institution belonged to Statistics China before) named Topway one of the top 10 LCD manufactures in China.

The Company engages in the R&D, manufacturing, and sale of LCD panels. It offers LCD panels for notebook computers, desktop computer monitors, LCD TV sets, vehicle-mounted IPC, consumer electronics products, mobile devices, tablet PCs, desktop PCs, and industrial displays.

Beijing time on October 26th news, China touch screen network news, touch screen technology was born in the 1970s US military. In recent years, iPod music players and later iPhones have become the driving force behind the development of touch screens. With the popularity of these two new applications, the development of touch screens has been greatly promoted. iSuppli has predicted that the global shipment of major touch screen technology will increase from $2.4 billion in 2006 to $4.4 billion in 2012. Faced with such rapid growth, touch screen technology and industry are also rapidly changing and developing. Due to the expansion of production by major manufacturers, the number of ITO film suppliers used in the two main types of touch screen technologies, namely resistive and capacitive touch screens, has been limited, resulting in the shortage of ITO (Indium Tin Oxide) film supply in the touch screen market in the past two years. .

Jiangnan Securities analysis believes that the demand for touch screens increased significantly in 2007, while the growth rate of upstream ITO conductive film production lags behind, resulting in tight supply, and the relevant manufacturers have obtained higher interest rates. Jiangnan Securities analysts believe that after the PDA market bubble in 2002, touch screen material suppliers have not expanded their products for a long time.

According to Displaybank, the global total production of ITO conductive film in 2007 increased by only 13.4% year-on-year. In 2007, touch screen manufacturers were constrained by the upstream ITO conductive film supply restrictions, and capacity expansion was blocked. In 2008, the total output of ITO conductive film increased by 71.2%, especially the leading manufacturer, Nitto Denko, which began to expand production capacity in April 2008.

In 2008, the supply of ITO conductive film shifted from the supply shortage in 2007 to the balance between supply and demand. Hong Jinwei, president of Suzhou Haorui Microelectronics Co., Ltd., said in an interview with China Electronics News that the current supply of ITO film tends to be normal. Now the high-end membrane production technology is mainly in the hands of Japanese manufacturers, such as Nitto Denko, Oike Industrial, etc., other materials such as conductive polymers, carbon nanotubes, ATO (AntimonyTinOxide) and other materials manufacturers in the future. If you can solve the problem of transparency and square resistance well, you have a chance. Similarly, domestic ITO manufacturers have the opportunity to participate in market competition if they can solve these technical problems.

After more than 20 years of development, China"s ITO industry has entered a mature stage, but due to the rapid development of its downstream display industry, the ITO industry continues to have new opportunities and new developments. The ITO film has two trends in the future. One is that the LCD panel manufacturer has completed it by itself, and no need to supply the coating product in the external factory. The other one is the accessory factory. The currently seen application is the touch screen, and the touch screen changes from resistance to capacitance. Coating products offer new development opportunities.

Due to the abundant production capacity of low-end and mid-end ITO products, high-end products such as ITO conductive glass for touch screens are becoming a new hot spot for domestic ITO manufacturers. Domestic manufacturers are striving to improve R&D level and product quality to cope with new business opportunities. The relevant person in charge of Leybold said in an interview with the reporter of China Electronics News that at present, there are many domestic ITO manufacturers. In order to avoid price wars, differentiated competition is the way for enterprises to go. The touch screen is a new application area that Leybold is very concerned about.

The relevant person in charge of CSG said in an interview with the reporter of China Electronics News that CSG is currently a relatively large glass production group in China. In the ITO conductive glass business, CSG is mainly positioned at the high end, mainly STN and touch screen related products. . "At present, the overall application market growth of ITO glass is not obvious. Now it is necessary to find new applications. The touch screen is a new direction." The person in charge said.

They can be divided into two categories, one requires ITO, such as the first three touch screens; the other type does not require ITO, such as the latter screens. Currently, resistive touch screens and capacitive touch screens using ITO materials are the most widely used on the market.

In 2007, Nitto Denko, a high-end film manufacturer of touch screens, invested 1.8 billion yen to increase the production of electrode films for touch screens. It is understood that the company"s electrode film consists of two layers of polyethylene terephthalate (PET) and a transparent electrode ITO layer (indium tin oxide). By turning PET into two layers, durability and input are improved, and input can be achieved with a tap. In April 2008, the company increased its production capacity by three times.

From the current point of view, China"s ITO manufacturers still have a long way to go if they really want to enter the touch screen field. From the history of touch screen development, the touch screen exhibits periodic development characteristics. Objectively speaking, the growth of the current touch screen market has brought a rare opportunity for domestic manufacturers to develop and transform. In the STN/CSTN era, domestically-developed manufacturers, which have been greatly developed in the STN/CSTN era, have been suppressed by TFTs and their business growth has been hindered. Driven by the development of the current touch screen market, many of the original coating technologies have achieved a gorgeous turn, ushered in a new high-speed business growth.

There has been a significant shift in the global display industry lately. Apart from new display technologies, the display world is now dominated by players in Asian countries such as China, Korea, and Japan. And rightly so, the world’s best famous LCD module manufacturers come from all these countries.

STONE Technologies is a proud manufacturer of superior quality TFT LCD modules and LCD screens. The company also provides intelligent HMI solutions that perfectly fit in with its excellent hardware offerings.

STONE TFT LCD modules come with a microcontroller unit that has a Cortex A8 1GHz Standard 256MB. Such a module can easily be transformed into an HMI screen. Simple hexadecimal instructions can be used to control the module through the UART port. Furthermore, you can seamlessly develop STONE TFT LCD color user interface modules and add touch control, features to them.

In this post, we list down 10 of the best famous LCD manufacturers globally. We’ll also explore why they became among the reputable LCD module manufacturers in the world.

Samsung is the world’s largest semiconductor and consumer electronics manufacturer by revenue. The electronics giant is well-known for its smartphones and home appliances, but the company also manufactures LCD, LED, and OLED panels.

Probably the most in-demand and popular display panel product for Samsung is their OLED technology. Most of its current smartphones use their trademark Super AMOLED displays. The technology allowed Samsung’s smartphones to be ultra-thin, with better image brightness, and less energy consumption.

Samsung now produces panels for smart TVs. With their ever-evolving technological expertise and high-quality products, the company shows no signs of slowing down as one of the world’s best famous LCD module manufacturers.

Stone provides a professional product line that includes intelligent TFT-LCD modules for civil, advanced, and industrial use. Furthermore, Stone also creates embedded-type industrial PCs. The company’s products are all highly-reliable and stable even when used with humidity, vibration, and high temperatures.

Stone Technologies caters to a wide range of clients and industries, being among the world’s best famous LCD module manufacturers. The company’s products are used in the following industries:

Originally, LG Display was a joint venture of mother company LG Electronics and the Dutch company Phillips. They dedicated the company to creating active-matrix LCD panels. Another joint venture called LG. Phillips Displays was created to manufacture deflection yokes and cathode ray tubes.

LG Display has risen above the rest because of its world-class module products. Because of this, the company caters to a massive range of famous clients including Hewlett Packard, Apple, Sony, Dell, Acer, and Lenovo. LG Display also creates LCD modules and similar display panels for the company’s television product range.

Innolux Corporation is another famous LCD module manufacturer. This company was established in 2003 and is currently based in Zhunan, Miaoli County, Taiwan.

The company is a well-known manufacturer of display panels in Taiwan. Innolux supplies TFT-LCD and LED panels, open cells, and touch modules for the following products:

What makes Innolux stand out from other LCD module manufacturers is the company’s commitment to its humanistic qualities. Innolux believes that they are in the business to contribute to the well-being and prosperity of their customers. This is then achieved by creating world-class products that satisfy its clients.

Sharp is a Japanese company founded in 1912. It is now based in Sakai, Osaka Prefecture. The company produces various kinds of electronic products including mobile phones, LCD panels, calculators, PV solar cells, and consumer electronics. Sharp has produced TFT-LCD products as early as the 1980s.

For the regular public consumers, Sharp produces a variety of smart TVs and LCD TVs marketed under the Aquos brand. The company’s television line-up boasts of impressively high-quality technology. The TVs are equipped with technologies that support 4K and 8K UHD display, allowing for a great high-resolution viewing experience.

BOE Display is among the leading display manufacturers in the world. The company started in 1993 and is currently based in Beijing, China. Apart from display panels, BOE also manufactures smart systems using IoT technology.

The company manufactures display products for smartphones, computers, televisions, monitors, tablets, vehicles, wearable devices, and medical equipment. Specifically, here are some of the display products that BOE creates:

The company proudly utilizes high-end technologies to create world-class display solutions. For instance, AU’s production lines can manufacture a variety of display applications in a full panel size range. The manufacturing lines also support:

Sustainability is among the ultimate goals of AU Optronics. The company takes steps to integrate green solutions into their products for more sustainable development. This commitment to sustainability, among other strong qualities, makes AU Optronics one of the best LCD manufacturers in the world.

Most of these products use TFT-LCD panels alongside other technologies to create ultra-high-definition images. Also, modern Toshiba display products incorporate IoT and artificial intelligence for a smarter product experience.

Kyocera is a Japanese LCD manufacturer. The company started in 1959 as a fine technical ceramics manufacturer but gradually added consumer electronics products to its offerings.

The Japanese company acquired Optrex Corporation in 2012. The acquisition paved the way for creating an R&D center and more production, sales, and marketing bases. Hence, Kyocera’s global LCD business boomed even more.

The company also operates factories, R&D centers, and marketing facilities in Asia, the Middle East, Europe, Africa, North and South America, and Oceania continents. Kyocera has a vast worldwide reach that makes it one of the world’s best famous LCD module manufacturers.

To wrap all this up, we listed 10 of the world’s best famous LCD module manufacturers. These are all highly-respected companies that built their reputations and climbed up the ladder of LCD module manufacturing. Their quality products, dedication to their craft, and excellent customer service truly make them among the world’s best display solutions providers.

Asia has long dominated the display module TFT LCD manufacturers’ scene. After all, most major display module manufacturers can be found in countries like China, South Korea, Japan, and India.

In this post, we’ll list down 7 best display module TFT LCD manufacturers in the USA. We’ll see why these companies deserve recognition as top players in the American display module industry.

STONE Technologies is a leading display module TFT LCD manufacturer in the world. The company is based in Beijing, China, and has been in operations since 2010. STONE quickly grew to become one of the most trusted display module manufacturers in 14 years.

Now, let’s move on to the list of the best display module manufacturers in the USA. These companies are your best picks if you need to find a display module TFT LCD manufacturer based in the United States:

Planar Systems is a digital display company headquartered in Hillsboro, Oregon. It specializes in providing digital display solutions such as LCD video walls and large format LCD displays.

Microtips Technology is a global electronics manufacturer based in Orlando, Florida. The company was established in 1990 and has grown into a strong fixture in the LCD industry.

What makes Microtips a great display module TFT LCD manufacturer in the USA lies in its close ties with all its customers. It does so by establishing a good rapport with its clients starting from the initial product discussions. Microtips manages to keep this exceptional rapport throughout the entire client relationship by:

Displaytech is an American display module TFT LCD manufacturer headquartered in Carlsbad, California. It was founded in 1989 and is part of several companies under the Seacomp group. The company specializes in manufacturing small to medium-sized LCD modules for various devices across all possible industries.

The company also manufactures embedded TFT devices, interface boards, and LCD development boards. Also, Displaytech offers design services for embedded products, display-based PCB assemblies, and turnkey products.

Displaytech makes it easy for clients to create their own customized LCD modules. There is a feature called Design Your Custom LCD Panel found on their site. Clients simply need to input their specifications such as their desired dimensions, LCD configuration, attributes, connector type, operating and storage temperature, and other pertinent information. Clients can then submit this form to Displaytech to get feedback, suggestions, and quotes.

A vast product range, good customization options, and responsive customer service – all these factors make Displaytech among the leading LCD manufacturers in the USA.

Products that Phoenix Display offers include standard, semi-custom, and fully-customized LCD modules. Specifically, these products comprise Phoenix Display’s offerings:

Clients flock to Phoenix Display because of their decades-long experience in the display manufacturing field. The company also combines its technical expertise with its competitive manufacturing capabilities to produce the best possible LCD products for its clients.

True Vision Displays is an American display module TFT LCD manufacturing company located at Cerritos, California. It specializes in LCD display solutions for special applications in modern industries. Most of their clients come from highly-demanding fields such as aerospace, defense, medical, and financial industries.

The company produces several types of TFT LCD products. Most of them are industrial-grade and comes in various resolution types such as VGA, QVGA, XGA, and SXGA. Clients may also select product enclosures for these modules.

All products feature high-bright LCD systems that come from the company’s proprietary low-power LED backlight technology. The modules and screens also come in ruggedized forms perfect for highly-demanding outdoor industrial use.

LXD Incorporated is among the earliest LCD manufacturers in the world. The company was founded in 1968 by James Fergason under the name International Liquid Xtal Company (ILIXCO). Its first headquarters was in Kent, Ohio. At present, LXD is based in Raleigh, North Carolina.

We’ve listed the top 7 display module TFT LCD manufacturers in the USA. All these companies may not be as well-known as other Asian manufacturers are, but they are equally competent and can deliver high-quality display products according to the client’s specifications. Contact any of them if you need a US-based manufacturer to service your display solutions needs.

We also briefly touched on STONE Technologies, another excellent LCD module manufacturer based in China. Consider partnering with STONE if you want top-of-the-line smart LCD products and you’re not necessarily looking for a US-based manufacturer. STONE will surely provide the right display solution for your needs anywhere you are on the globe.

Fluorinated greenhouse gases (F-GHGs) are among the most potent and persistent greenhouse gases (GHGs) contributing to global climate change. These gases play a vital role in the manufacture of flat panel displays--most commonly liquid crystal display (LCD) panels--that go into televisions, computer monitors, and many other display products. The overall climate impact of the millions of display products used can be greatly reduced if suppliers of these components take steps to mitigate release of these F-GHGs to the atmosphere. While progress is underway, your awareness and support as a brand, retailer, or institutional buyer can expedite this effort. This webinar explained the manufacturing processes which release F-GHGs into the environment, how LCD suppliers are working to reduce their emissions, and the steps participants can take to support further improvements.

Sputtering target has a wide range of applications. The industries with many sputtering targets are mainly concentrated in the integrated circuit, flat-panel display, solar cell, magnetic recording media, and optical devices.

Among them, sputtering target material for flat-panel display is mainly used for ITO glass and touch screen electrode plate. Sputtering target coating is primarily used in the production of the display panel and touch screen panel. It is mainly used to make ITO glass and touch screen electrodes.

Indium tin oxide (ITO) is the most widely used among the sputtering targets, followed by molybdenum, aluminum, silicon, and other metal targets. AEM Deposition provides sputtering targets suitable for flat-panel displays, as shown in the following table:

1) In the production process of the flat-panel display panel, ITO glass is formed by sputtering and coating on a glass substrate many times. Then it is coated, processed, and assembled to produce an LCD panel, PDP panel, and OLED panel.

2) For the production of a touch screen, ITO glass needs to be processed, coated to form electrodes, and then assembled with a protective screen and other components.

Among them, the silicon dioxide film formed by the sputtering of silicon target mainly plays the role of increasing the adhesion and flatness of glass and ITO film, surface passivation and protection, and the etching of moalmo (molybdenum aluminum molybdenum) target after coating mainly plays the role of metal lead bridging.

Also, in order to realize the anti-reflection and anti shadow functions of flat-panel display products, the corresponding coating can be added to the coating process. AEM Deposition, as a professional sputtering target manufacturer, provides not only sputtering targets for flat-panel display but also provides sputtering targets for other application fields. Please refer to the following table for details:

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey