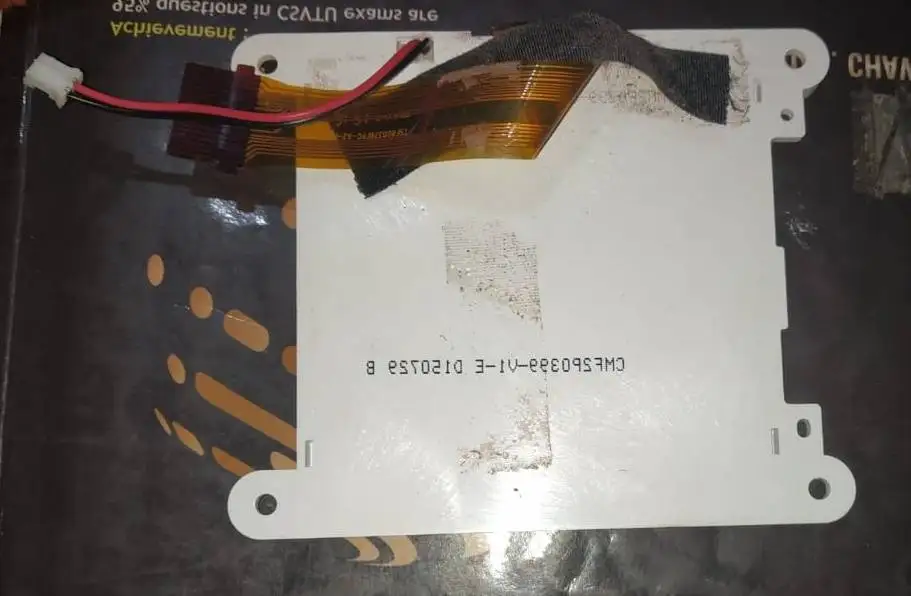

spd lcd panel price

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"TCL"s Panel Manufacturer CSOT Commences Production of High Generation Panel Modules". www.businesswire.com. June 14, 2018. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

Eaton’s SPD series integrated surge protection device offers the most advanced surge protection for integration directly into Eaton electrical assemblies. With an available remote display and the lowest possible let-through voltage, this surge device brings superior protection to Eaton panelboards, switchboards, automatic transfer switches, bus plugs, motor control centers and switchgears.

One of these glass substrates would cover the floor of a nine-square-meter room. Eight 60-inch displays or six 70-inch displays can be produced from a single substrate. By effectively manufacturing large-screen LCDs, we can maximize our advantage in making 60-inch-and-larger LCDs.

To manufacture LCD panels using these massive G10 glass substrates, our LCD panel plant is 360 meters wide across the front and 400 meters deep. The plant can yield 78,000 glass substrates per month, and it has a production capacity equivalent to approximately 470,000 70-inch LCDs per month.

Color filters, a key component of LCD panels, are manufactured in-house in two plants. These plants do more than just provide high-quality, cost-efficient products; they also continue to develop products with new functions and greater performance.

The related plants are linked like arteries, so that materials can be transported between plants using minimal time and energy. The transport paths total approximately 1.9 kilometers (1.2 miles) in length and are much more efficient than trucks at delivering the large, thin G10 glass substrates. Using this transport system contributes to the efficient manufacture of large-screen LCDs.

Serial Peripheral Interface (SPI) is a synchronous serial communication interface best-suited for short distances. It was developed by Motorola for components to share data such as flash memory, sensors, Real-Time Clocks, analog-to-digital converters, and more. Because there is no protocol overhead, the transmission runs at relatively high speeds. SPI runs on one master (the side that generates the clock) with one or more slaves, usually the devices outside the central processor. One drawback of SPI is the number of pins required between devices. Each slave added to the master/slave system needs an additional chip select I/O pin on the master. SPI is a great option for small, low-resolution displays including PMOLEDs and smaller LCDs.

Philips Semiconductors invented I2C (Inter-integrated Circuit) or I-squared-C in 1982. It utilizes a multi-master, multi-slave, single-ended, serial computer bus system. Engineers developed I2C for simple peripherals on PCs, like keyboards and mice to then later apply it to displays. Like SPI, it only works for short distances within a device and uses an asynchronous serial port. What sets I2C apart from SPI is that it can support up to 1008 slaves and only requires two wires, serial clock (SCL), and serial data (SDA). Like SPI, I2C also works well with PMOLEDs and smaller LCDs. Many display systems transfer the touch sensor data through I2C.

Low-Voltage Differential Signaling (LVDS) was developed in 1994 and is a popular choice for large LCDs and peripherals in need of high bandwidth, like high-definition graphics and fast frame rates. It is a great solution because of its high speed of data transmission while using low voltage. Two wires carry the signal, with one wire carrying the exact inverse of its companion. The electric field generated by one wire is neatly concealed by the other, creating much less interference to nearby wireless systems. At the receiver end, a circuit reads the difference (hence the "differential" in the name) in voltage between the wires. As a result, this scheme doesn’t generate noise or gets its signals scrambled by external noise. The interface consists of four, six, or eight pairs of wires, plus a pair carrying the clock and some ground wires. 24-bit color information at the transmitter end is converted to serial information, transmitted quickly over these pairs of cables, then converted back to 24-bit parallel in the receiver, resulting in an interface that is very fast to handle large displays and is very immune to interference.

There’s a variety of display panel out there and even more on the way. But looking at all the different types of panels can be baffling. They come in various acronyms, and many of those acronyms are confusingly similar. How do LCD, LED and OLED compare? What about the different types of LCD panels? And how do these different technologies impact your viewing experience for things like gaming? To help, we’ve created this guide so you can gain a firm understanding of today’s display panel technology and which features really matter.

The first type of panels we’ll cover are LCD (liquid crystal display) panels. The main thing to understand about LCD panels is that they all use a white backlight (or sidelight, etc.). They work by shining a bright white light into your eyes, while the rest of the panel is for changing this backlight into individual pixels.

LED stands for light-emitting diode. You’ll often see LCD panels that are LED, but that doesn’t necessarily mean much when choosing an LCD. LED is just a different type of backlight compared to the old cold cathode backlights. While you could congratulate yourself on not using mercury, which is found in cathodes, at this point all LCDs use LED backlights anyway.

The second thing to understand is that LCDs take advantage of a phenomena known as polarization. Polarization is the direction in which the light wave is oscillating, or swinging back and forth at the same speed. Light comes out of the backlight unpolarized. It then passes through one polarizer, which makes all the light oscillate the same way.

Now you have an on and off (and between) switch for light. To produce color all that’s needed is three color filters, red, green and blue, that block all light other than that color from coming through. The difference between different types of LCD panels is mostly in how this in-between liquid crystal part works.

This design allows for fast response times (the time between the panel getting the frame it’s supposed to display and actually displaying it). It also allows for fast refresh rates. Consequently, TN panels are the only 240 hertz (Hz) gaming monitors available right now.

TN panels are cheap but suffer from poor viewing angles due to the “twist” only being aligned in one direction for viewing the panel straight on. They can also have poor color and contrast due to this twist mechanism not being the most precise or accurate.

VA stands for vertical alignment, again referring to the crystal alignment. These came about in the 1990s. Instead of using liquid crystals to twist a light’s polarization, a VA panel’s liquid crystals are aligned either perpendicular (vertical to) or parallel (horizontal to) the two polarizers. In the off state, the crystals are perpendicular to the two opposing polarizers. In the on state, the crystals begin to align horizontally, changing the polarization to match the second polarizer and allowing the light to go through the crystals.

This structure produces deeper blacks and better colors than TN panels. And multiple crystal alignments (shifted a bit off axis from each other) can allow for better viewing angles compared to TN panels.

However, VA panels come with a tradeoff, as they are often more expensive than TN panels and tend to have lower refresh rates and slower response times than TN panels. Consequently, you won’t see quite as many VA panel gaming monitors.

IPS stands for in-plane switching. These panels debuted after TN panels in the mid-1990s. The crystals are always horizontal to the two polarizers and twist 90° horizontally to go from off to on. Part of this design requires the two electrodes (which apply current to the liquid crystal to change its state) to be on the same glass substrate, instead of aligned with each other on the sandwiching glass substrates above and below the crystal (as in other types of LCDs). This, in turn, blocks a bit more light than both TN and VA panels.

IPS panels have the best viewing angles and colors of any LCD monitor type, thanks to its crystal alignment always lining up with the viewer. And while they don’t offer as fast a response time or refresh rate as TN panels, clever engineering has still gotten them to 144hz, and with nice viewing angles you’re not necessarily going wrong with an IPS gaming panel.

How do LCD panels go about reaching HDR brightness when incorrect polarization and color filters block so much light?The answer is quantum dots. These clever little things are molecules that absorb light and then re-emit that light in the color you engineered them to.

Today’s quantum dot layers usually go between a blue backlight and the polarization step, and are often used to produce red and green that more closely matches the color filters, so more light passes through them. This allows more of the backlight to come through instead of being blocked by the color filters, it can also reduce crosstalk, or colors slipping through the wrong subpixel, ensuring better colors of LCDs.

Other uses of quantum dots are being tried, however. One promising one is using QD molecules to replace the color filters entirely, allowing even more light through. Because LCD backlights produce more light than OLED panels (more on those below), this would allow LCDs to become the brightest displays around.

Motion blur/ghosting can be a result of how long an image takes to switch from one to another and how long an image is displayed on screen (persistence). But both of these phenomena differ greatly between individual LCD panels regardless of underlying LCD tech. And both are often better controlled by higher refresh rates, rather than clever panel engineering, at least for LCD displays.

Choosing an LCD panel based on underlying LCD tech should be more about cost vs desired contrast, viewing angles and color reproduction than expected blur, or other gaming attributes. Maximum refresh rate and response time should be listed in any respectable panel’s specs. Other gaming tech, such as strobe, which flashes the backlight on and off quickly to reduce persistence, may not be listed at all and is not part of the underlying type of LCD used. For that kind of info you’ll have to check the detailed reviews here on our site.

OLED, or organic light emitting diode, panels, are different from LCDs. There are no polarization tricks here. Instead, each pixel (or subpixel of red, green, or blue) lights itself up as a voltage is applied to a giant complex molecule called, yep, an organic light emitting diode. The color emitted is dependent on the molecule in question, and brightness is dependent on the voltage applied. OLEDs can reach HDR brightness because their molecules put out the right colors to begin with without being blocked.

Due to its approach to color and brightness, OLEDs have great contrast ratios. There’s no need to block a backlight, so there’s no worries about light bleeding through. Blacks are very black, and colors look great. OLEDs can also strobe, or flash off and on quickly to lower persistence. They can also use a trick called rolling scan.This turns blocks of the screen on and off one at a time, from top to bottom in a roll. This is all done as the image is sent to the screen, which cuts down on persistence blur a lot. This is why every major VR headset that can afford it uses OLED panels today.

Unfortunately, that’s where the advantages of OLED end. Refresh rates of OLED panels have never surpassed about 90Hz. And they’re quite expensive. A large part of that $1,000 iPhone X price is due to its OLED display. The current molecules used in OLEDs also degrade relatively quickly over time, especially those used for the color blue(opens in new tab), making the screen less and less bright.

OLEDs were also supposed to use less power than LCDs, but newer, giant OLED molecules that take less voltage to turn on have yet to appear. And while molecules covering the colors of the P3 HDR gamut are out today, those covering the larger BT.2020 gamut have yet to be found commercially. So OLEDs, while once promising and seemingly the future, have yet to live up to that promise.

A relevant question: If our fastest gaming displays are 240Hz TN panels now, just how fast do we need to go anyway? Well, a 2015 study places maximum human perception at 500Hz. So from that perspective, we’re halfway there. But that’s halfway there with today’s HDR, and not in lightfield 3D, or other possible advancements. And mobile devices could always use displays that take up less power.

In other words, in order to get fancy 3D effects, or much higher brightness, or any other desirable features, a different, new type of panel may be required. MicroLED tech is one such technology; think of it as OLED without the organic part and with the potential to improve contrast, response times and energy usage over standard LED panels. If you want to know more you can go here, but the real takeaway is that MicroLEDs work almost exactly like OLEDs.

It also boasts a ventilated race-style seat, padded handlebars, and an LCD console that displays metrics such as your speed, number of calories burned, time, and distance. Plus, it comes with a Bluetooth heart rate monitor armband.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey