uv lcd displays quotation

TRU-Vu High Bright Sunlight Readable Monitors enable users to see clear, sharp video images even in direct sunlight with a bright screen. Our high brightness screens produce at least 1,000 nits brightness. Some go up to 2,500 nits of brightness. This makes them far brighter than standard LCD monitors. Specifically, consumer or commercial-grade monitors typically offer only 150 to 300 nits brightness. High brightness displays and sunlight readable touch screens will ensure crystal-clear video images even in bright sunlight. The result is better performance and bold colors in other high ambient light conditions as well. They are also available with optical bonding as monitors or touch screen displays.

In outdoor or bright conditions, it is imperative to increase the brightness of a display to ensure crisp images. The number of nits an LCD display emits is the main factor in determining the monitor’s perceived brightness. A monitor luminance of around 200-350 nits will work well indoors. Most LCD displays and monitors fall in this range. However, 400-700 nits would be required for use in daylight conditions. Most importantly, a Sunlight readable display requires at least 1,000 nits or more for viewing in direct, bright sunlight . These high brightness displays are available with 16:9 aspect ratio or 4:3 aspect ratio screens. All TRU-Vu Sunlight Readable monitors and high-brightness touch screens are TAA Compliant.

Some monitors feature a sheet of glass over the LCD panel to protect it from accidental or intentional damage. However, the glass also produces unwanted glare and reflections. Internal reflections in the air gap between the glass and the LCD panel diminish image quality even further. In order to combat this, monitors are optically bonded.

Optical bondingis the process of laminating protective glass or a touch screen panel to the LCD panel with an optical-grade resin. This completely fills the air gap between the glass and LCD panel. It not only eliminates the internal reflections, but also increases the contrast ratio. This makes the screen appear much brighter and more viewable in bright light conditions. Optical bonding also eliminates internal moisture and condensation. Moreover, it will make the monitor more rugged and durable. Lastly, an Anti-Reflective coating is applied to the outside of the glass. Consequently, this will drastically reduce glare and surface reflections.

For installations in indirect sunlight, or reflected bright light, our Daylight Viewable displays will most likely suffice. These are also more cost-effective than Sunlight Readable monitors with 1,000 nits brightness. Daylight viewable monitors feature LCD screens with 400 nits to 700 nits brightness. The LCD panels also include optical bonding.

Our outdoor high brightness Sunlight Readable LCD monitors feature waterproof stainless steel enclosures. These are ideal for factory wash-down environments. Additionally, they are perfect for outside use in challenging weather. Our panel mount enclosures are made from steel, stainless steel, or aluminum. This enables them to be flush-mounted. Outdoor LCD monitors with high brightness work in a wider range of temperatures. Consequently, this broadens the environments in which they may be used. Additionally, temperature ranges are very important to consider when using outdoors. When we combine extreme operating temperatures with outdoor waterproof enclosures, we ensure your high brightness monitors will be able to function in even the harshest wet and hot environments. We will also modify or customize any model to meet your exact requirements.

In conclusion, we deploy TRU-Vu outdoor waterproof sunlight readable monitors and high brightness touch screens in a wide range of industries. For example, military, law enforcement, manufacturing plants benefit from high bright LCD displays. Amusement parks, sports stadiums, mass transit, and construction & heavy equipment also rely on high bright sunlight readable displays. In addition, outdoor high brightness LCD monitors are demanded in pipeline inspection, kiosks, marine, oil & gas, drones, security applications. When it counts, you can rely on TRU-Vu Monitors to deliver the optimal weather resistant high bright LCD monitor solution for your specific needs.

Country of Installation * Afghanistan Åland Islands Albania Algeria American Samoa Andorra Angola Anguilla Antarctica Antigua & Barbuda Argentina Armenia Aruba Australia Austria Azerbaijan Bahamas Bahrain Bangladesh Barbados Belarus Belgium Belize Benin Bermuda Bhutan Bolivia Bosnia & Herzegovina Botswana Bouvet Island Brazil British Indian Ocean Territory British Virgin Islands Brunei Bulgaria Burkina Faso Burundi Cambodia Cameroon Canada Cape Verde Cayman Islands Central African Republic Chad Chile China Christmas Island Cocos (Keeling) Islands Colombia Comoros Congo - Brazzaville Congo - Kinshasa Cook Islands Costa Rica Côte d’Ivoire Croatia Cuba Cyprus Czechia Denmark Djibouti Dominica Dominican Republic Ecuador Egypt El Salvador Equatorial Guinea Eritrea Estonia Eswatini Ethiopia Falkland Islands Faroe Islands Fiji Finland France French Guiana French Polynesia French Southern Territories Gabon Gambia Georgia Germany Ghana Gibraltar Greece Greenland Grenada Guadeloupe Guam Guatemala Guernsey Guinea Guinea-Bissau Guyana Haiti Heard & McDonald Islands Honduras Hong Kong SAR China Hungary Iceland India Indonesia Iran Iraq Ireland Isle of Man Israel Italy Jamaica Japan Jersey Jordan Kazakhstan Kenya Kiribati Kuwait Kyrgyzstan Laos Latvia Lebanon Lesotho Liberia Libya Liechtenstein Lithuania Luxembourg Macao SAR China Madagascar Malawi Malaysia Maldives Mali Malta Marshall Islands Martinique Mauritania Mauritius Mayotte Mexico Micronesia Moldova Monaco Mongolia Montenegro Montserrat Morocco Mozambique Myanmar (Burma) Namibia Nauru Nepal Netherlands New Caledonia New Zealand Nicaragua Niger Nigeria Niue Norfolk Island Northern Mariana Islands North Korea North Macedonia Norway Oman Pakistan Palau Palestinian Territories Panama Papua New Guinea Paraguay Peru Philippines Pitcairn Islands Poland Portugal Qatar Réunion Romania Russia Rwanda Samoa San Marino São Tomé & Príncipe Saudi Arabia Senegal Serbia Seychelles Sierra Leone Singapore Slovakia Slovenia Solomon Islands Somalia South Africa South Georgia & South Sandwich Islands South Korea Spain Sri Lanka St. Barthélemy St. Helena St. Kitts & Nevis St. Lucia St. Martin St. Pierre & Miquelon St. Vincent & Grenadines Sudan Suriname Svalbard & Jan Mayen Sweden Switzerland Syria Taiwan, Province of China Tajikistan Tanzania Thailand Timor-Leste Togo Tokelau Tonga Trinidad & Tobago Tunisia Turkey Turkmenistan Turks & Caicos Islands Tuvalu Uganda Ukraine United Arab Emirates United Kingdom United States Uruguay U.S. Outlying Islands U.S. Virgin Islands Uzbekistan Vanuatu Vatican City Venezuela Vietnam Wallis & Futuna Western Sahara Yemen Zambia Zimbabwe

Liquid Crystal Display (LCD) technology and display quality continues to evolve, while prices for LCDs have declined dramatically in the last few years. These two factors have helped to increase demand for LCDs in a variety of new and challenging applications, such as outdoor displays, where environmental conditions such as high ambient light and heat build-up can affect display quality. This has created a need for unique solutions to help extend the lifetime and display quality of LCDs in these conditions. One such solution is the use of UV blocking glass.

LCDs utilize organic components that are susceptible to ultraviolet degradation, which can manifest as a shift in color or a washed out look. Displays used in outdoor environments or in close proximity to Fluorescent black lights and other long wave UV emitters are at considerable risk of Ultraviolet degradation. Outdoor LCD devices are at high risk, but with more indoor UV emitter applications being developed it has become apparent that sunlight based ultraviolet radiation is not the only concern. Indoor UV emitter applications are being developed or are currently in use by medical and forensics groups for example.

The atmosphere itself blocks a significant portion of sunlight Ultraviolet radiation up to 280 nm, which is the top end of the UV C range. Oxygen is the primary element responsible for the atmospheres filtering effect on UV C. Indoor UV C emitters are in relative close proximity to the LCDs they would potentially affect and thus are not likely to benefit as much from the filtering effects of the atmosphere. UV C is also damaging to people and so high intensity emitters use protective barriers to contain the UV C radiation. For this reason, LCDs within the application would need a protective UV Blocking Glass.

UV B is less blocked by the atmosphere, but is still significantly blocked by ordinary glass (although this is not generally true for Silica or quartz glass). In situations where an application uses UV B radiation, it is recommended that the application be sealed to prevent excessive human exposure. Any application that needs an LCD to be exposed to UV B radiation regularly should utilize a UV Blocking Glass coating to ensure that the LCD does not degrade.

While ordinary glass blocks a significant portion of UV B this still leaves a significant portion of the UV A range that permeates the front of an LCD. It is this UV A range that has often eluded efforts to prevent ultraviolet degradation. Its effects are often not as obvious, but can be seen in many everyday situations where carpet, drapes or other natural and synthetic polymer objects are left in a window for long periods of time. They fade, crack or disintegrate due to the unblocked UV A radiation that passes through ordinary glass.

ZC&R’s UV Blocking Glass solutions act as a mirror to ultraviolet radiation. In combination with a hot mirror (IR Reflector), this coating helps preserve the performance of an LCD exposed to unfiltered broadband lighting while retaining the visibility and clarity of the display.

LCDs used in outdoor situations have many concerns to deal with in addition to any that they might normally encounter during indoor use. Initially some concerns are weather related such as moisture in the air or extreme temperatures. Another concern that is often not understood or just not known about at all is sunlight damage.

Liquid crystal displays use organic components that are susceptible to UV (<400 nm) and IR (>750 nm). These bandwidths of radiation have an observable impact on the organic components in LCDs. Extended exposure has been known to cause a color shift and a washed out look to images displayed with the LCD.

Over time the UV and IR radiation degrade the organic components causing them to fail to function properly. The amount of time it takes can vary depending on brand and model as well as specific weather conditions the display has been exposed to. For instance some atmospheric disturbances can reduce the amount of Ultraviolet that is transmitted to the display.

In any case it is important to protect your display from the elements, especially if it is going to be exposed to harsh environments not intended by the manufacturer. One way to do this would be to utilize a Hot Mirror with a UV blocker. This will significantly reduce the amount of IR radiation between 750 nm and 1200 nm, as well as the UV radiation below 400 nm. If the LCD is going to be used outdoors for extended periods then an extended hot mirror may be necessary, which extends the bandwidth protection out to 1600 nm and will help reduce some of the longer wavelength IR damage.

Another concern with liquid crystal displays are their susceptibility to overheating due to excess IR radiation. The LCD is intended to operate within a certain range of temperatures according to the manufacturer’s instructions and outdoor use can lead to higher than normal temperatures. The display being exposed to excessive heat can cause the crystal to become isotropic and fail to perform properly. A hot mirror can help alleviate these concerns as well by reducing the amount of infrared radiation that heats the display.

Liquid crystal display (LCD) is a flat panel display that uses the light modulating properties of liquid crystals. Liquid crystals do not produce light directly, instead using a backlight or reflector to produce images in colour or monochrome.

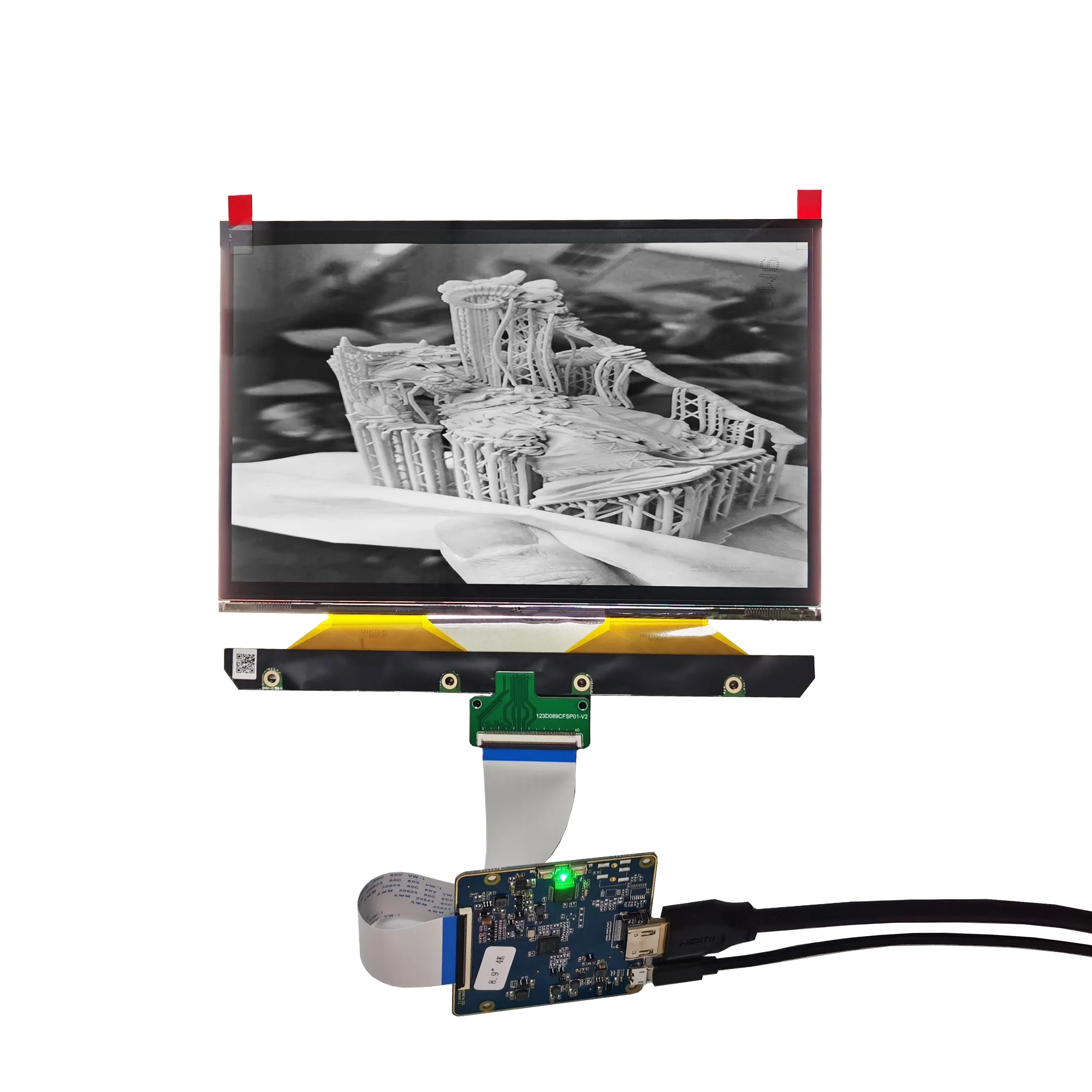

I"m surprised your research hasn"t answered your question, as the concept is relatively simple. You have most of the answer in the question. The missing item is a light source. Usually the source is an array of ultraviolet LED modules. There are resin printers that would not be called LCD printers, as they use computer display projectors to generate both the image and the UV to cure the resin.

The light source that answers your question is visible in the third picture. As noted, the LCD panel blocks the light based on the image to be cured. I think the "uses its own light" is somewhat misleading, unless the builder has found a high-UV output LED LCD panel or is using daylight resins and has configured for long burn-in times.

Marlin Technologies manufactures a wide variety of displays and instrument panels that include numerous features that typical off-the-shelf modules do not. All of our displays and panels are customizable to your specifications for functionality and features.

Like all of our products, our cab displays are specially designed for severe duty, harsh environment mobile applications. They are IP67-rated for outdoor environments, sunlight readable, resistant to moisture, vibration, extreme temperatures, UV, and other environmental factors.

Marlin has extensive experiencing creating custom CAN Bus LCD displays for outdoor, severe duty applications. These displays can combine an LCD along with LED indicators and inputs/outputs to provide complete functional control and operator interface all in one economical package. Marlin can design a solution for your application that will provide the features you need at a price you can afford.

Our displays are used both inside cabs as well as outdoors where environmental extremes are too harsh for other manufacturers’ displays. We engineer the displays with high brightness and contrast for easy viewing in direct sunlight, and incorporate UV-tolerant LCDs and scratch resistant lenses to ensure clear visibility of the LCD throughout time.

Marlin Technologies’ indicator/warning displays are designed to mount into cab dashboards and consoles, or on the outside of your equipment. Indicator/warning displays are customizable for your mobile application.

The Loctite 1406024 is a 7020 UV spot radiometer self-contained, electro-optic instrument designed to measure and display the UV power density (irradiance) emitted by a UV spot curing system. This system is designed to provide the operator with instant feedback on the performance of the spot curing system based upon changes in the irradiance. Loctite 1406024 Features: Measures light guide degradation

Before answering the questions below, it would be helpful to provide a simple overview of how a TFT LCD works. Every monitor or touchscreen computer includes an LCD panel. The LCD panel is the component that you are viewing at this very moment. This panel includes a thin layer of TFT LCD pixels, where each pixel includes a red, blue, and green rectangle. You can actually see the individual pixels on a display if you place a drop of water on it. The drop will magnify the pixel area and reveal a pixel with a red, blue, and green rectangle. Each red, blue, and green rectangle is a small lens that can be adjusted to allow varying amounts of light to pass through. The colors you see on your screen are determined by how much light is passing through each adjustable red, green, and blue element of each pixel.

The light that you see does not come from the pixels themselves, but from the backlight behind the pixels, which is a series of carefully placed LEDs that emit white light that projects through the LCD pixels. You cannot see the individual backlight LEDs when you look at your monitor, because there is layer of light diffusing material between the LED backlight and the LCD pixel layer. The light diffusing material scatters the light from each individual backlight LED, so they do not show up as bright spots on your monitor.

To summarize, the three layers of an LCD panel are the TFT LCD pixel layer, the diffuser layer, and the LED backlight layer. Note that some LCDs have edge-lit backlighting, but there is no need to go into detail about this, as the same principles apply. That completes LCD panel course 101. Now, what makes a display sunlight readable?

There are two general ways to make an LCD brighter and therefore readable in sunlight. The first and simplest way is to increase the brightness of the backlight. LCD brightness is measured in Nits. Typical LCD panels have a screen brightness between 250 Nits to 450 Nits. LCD brightness of 800 Nits or higher is generally considered sunlight readable, but most sunlight readable displays are 1000 nits. Increasing the brightness of the LCD panel backlight is the most common method of making an LCD panel sunlight readable. Most of Teguar’s industrial panel PCs and touchscreen monitors are available with this type of high brightness LCD.

Another way to make an LCD sunlight readable is to change the diffuser material between the LED backlight and the LCD pixels to a “transflective” material. The transflective material is similar to reflective sunglasses or a one way window, where the shiny side is facing the LCD surface. When transflective material is used, the sunlight entering the LCD panel travels through the pixels, bounces off the transflective material, and is reflected back through the pixels to your eyes. In this case, the sunlight has much less of an impact on viewability than a traditional LCD panel, as the sunlight is reflecting back through the LCD pixels and contributing to the LCD brightness. One drawback of transflective diffuser LCDs is that they don’t allow for as much of the backlight to pass through the diffuser material, so in low light conditions the LCD does not appear as bright. Transflective diffuser LCDs are not as common as high brightness backlight LCDs.

Optical bonding improves viewability of touchscreen PCs in sunlight or other high-bright environments. In a touchscreen computer, the touchscreen sensor and the LCD panel are separate components. The touchscreen is mounted in front of the LCD surface and there is a small air gap between these two components. When sunlight passes through the touchscreen layer, some amount of the light is reflected between the LCD surface and the touchscreen; this reflection reduces LCD viewability.

Optical bonding is a process where a clear adhesive gel is placed between the LCD to the touchscreen. The gel hardens and bonds the touchscreen to the LCD to eliminate the air gap, improving contrast and clarity. Optical bonding is available on many of Teguar’s touchscreen computers and industrial monitors.

The brightness of a sunlight readable display may be overwhelming at night, when there is little or no ambient light. Most industrial computers with sunlight readable LCDs are available with an optional auto-dimming feature. With this feature, an ambient light sensor on the front bezel measures incoming light and adjusts the backlight brightness to match the current light conditions. This is typically a requirement for industrial touchscreen computers that are used in both sunlight and moonlight.

Sunlight also comes with a high amount of UV radiation that can damage the components used in touch screens. PCAP touch screens resist UV damage better than Resistive, but even a PCAP screen must be protected from too much UV exposure. Teguar computers are best suited for environments that provide some level of shade, such as a roof or overhang above the computer, or a structure that blocks the screen from direct exposure to the sun. Most outdoor computer manufactures, Teguar included, will offer a specialized shroud/hood that mounts directly to the unit to provide some level of shade.

Touchscreen computers in vehicles commonly require high brightness LCDs, because of the ambient sunlight coming through the windows. Sunlight readable LCDs are also used in many indoor applications surrounded by windows, such as air traffic control centers, railroad cars, marine vessels, agriculture machinery, and public kiosks.

SLA and DLP are traditional resin 3D printing technologies. An SLA printer works at constant precision but the more of its workspace is used, the more it slows down. In DLP machines, the speed is constant but precision decreases when workspace usage grows. Zortrax UV LCD maintains both high speed and precision at all times.

An advanced optical system guarantees almost perfectly even distribution of UV light across the build platform. That"s why the Inkspire is one of the fastest resin 3D printers on the market without compromising any of the print"s quality.

*The approximate lifespan of the LCD screen is around 200 working hours, but it highly depends on the kind of resin you use, and the models you print.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey