thermal management of lcd displays manufacturer

LCD panels uses LED backlights to operate. Luminance output of LED lights depends heavily on LCD operating temperature. Lower the temperature higher the brightness performance output.

Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

Current Assignee (The listed assignees may be inaccurate. Google has not performed a legal analysis and makes no representation or warranty as to the accuracy of the list.)

Priority date (The priority date is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the date listed.)

G02F—OPTICAL DEVICES OR ARRANGEMENTS FOR THE CONTROL OF LIGHT BY MODIFICATION OF THE OPTICAL PROPERTIES OF THE MEDIA OF THE ELEMENTS INVOLVED THEREIN; NON-LINEAR OPTICS; FREQUENCY-CHANGING OF LIGHT; OPTICAL LOGIC ELEMENTS; OPTICAL ANALOGUE/DIGITAL CONVERTERS

G02F1/00—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics

G02F1/01—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics for the control of the intensity, phase, polarisation or colour

G02F1/13—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics for the control of the intensity, phase, polarisation or colour based on liquid crystals, e.g. single liquid crystal display cells

G02F1/133382—Heating or cooling of liquid crystal cells other than for activation, e.g. circuits or arrangements for temperature control, stabilisation or uniform distribution over the cell

G02F1/133385—Heating or cooling of liquid crystal cells other than for activation, e.g. circuits or arrangements for temperature control, stabilisation or uniform distribution over the cell with cooling means, e.g. fans

G02F—OPTICAL DEVICES OR ARRANGEMENTS FOR THE CONTROL OF LIGHT BY MODIFICATION OF THE OPTICAL PROPERTIES OF THE MEDIA OF THE ELEMENTS INVOLVED THEREIN; NON-LINEAR OPTICS; FREQUENCY-CHANGING OF LIGHT; OPTICAL LOGIC ELEMENTS; OPTICAL ANALOGUE/DIGITAL CONVERTERS

G02F1/00—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics

G02F1/01—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics for the control of the intensity, phase, polarisation or colour

G02F1/13—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics for the control of the intensity, phase, polarisation or colour based on liquid crystals, e.g. single liquid crystal display cells

G02F—OPTICAL DEVICES OR ARRANGEMENTS FOR THE CONTROL OF LIGHT BY MODIFICATION OF THE OPTICAL PROPERTIES OF THE MEDIA OF THE ELEMENTS INVOLVED THEREIN; NON-LINEAR OPTICS; FREQUENCY-CHANGING OF LIGHT; OPTICAL LOGIC ELEMENTS; OPTICAL ANALOGUE/DIGITAL CONVERTERS

G02F1/00—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics

G02F1/01—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics for the control of the intensity, phase, polarisation or colour

G02F1/13—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics for the control of the intensity, phase, polarisation or colour based on liquid crystals, e.g. single liquid crystal display cells

G02F—OPTICAL DEVICES OR ARRANGEMENTS FOR THE CONTROL OF LIGHT BY MODIFICATION OF THE OPTICAL PROPERTIES OF THE MEDIA OF THE ELEMENTS INVOLVED THEREIN; NON-LINEAR OPTICS; FREQUENCY-CHANGING OF LIGHT; OPTICAL LOGIC ELEMENTS; OPTICAL ANALOGUE/DIGITAL CONVERTERS

As an LCD display used in outdoor advertising, it has much higher requirements for the use environment than a general display. During the use of outdoor LCD displays, due to different environments, they are often affected by severe weather such as high temperature, typhoons, rainstorms, and thunder and lightning. To keep the display safe and sound in severe weather, what preventive measures should we take?

First, anti-high temperature: Outdoor LCD displays usually have a large area, which consumes a lot of power during the application process, and the corresponding heat dissipation is also large. In addition, the external temperature is relatively high. If the heat dissipation problem cannot be solved in time, it is likely to be Causes problems such as short circuit heating of the circuit board. In production, ensure that the display circuit board is in good condition, and try to choose a hollow design in the housing design to help heat dissipation. During the installation, according to the device situation, insist that the display screen is in a good ventilation condition, and add heat dissipation equipment to the display screen when necessary, like installing an air conditioner or a fan inside to help the display screen dissipate heat.

Second, anti-typhoon: The outdoor LCD display has different installation positions and different installation methods, such as a wall-mounted, inlaid, pillar, and suspended. So in the typhoon season, in order to prevent the screen of the outdoor LCD display from falling, there are strict requirements on the load-bearing steel frame structure of the display. The engineering unit must design and install strictly in accordance with the standards of typhoon resistance, and at the same time have a certain degree of earthquake resistance to ensure that the outdoor LCD display will not fall and cause casualties and other hazards.

Third, anti-torrential rain: There is much rainy weather in the south, so the LCD display itself must have a high level of waterproof protection to avoid rain erosion. In the outdoor environment, the outdoor LCD display must reach the IP65 protection level, the module must be potted and packaged, the waterproof box is selected, and the module and the box are connected with a waterproof rubber ring.

1. Direct lightning protection: If the outdoor large LCD screen is not within the direct lightning protection range of nearby tall buildings, lightning rods must be installed LCD on the top or near the steel structure of the display;

2. Inductive lightning protection: The outdoor LCD display power system is equipped with 1-2 levels of power lightning protection, and the signal line is equipped with signal lightning protection. At the same time, the computer room power system is equipped with 3 levels of lightning protection, and the signal exit/entry equipment in the computer room is added. Install signal lightning protection device;

4. The front end of the outdoor LCD display and the grounding system of the computer room should meet the system requirements. Generally, the front-end grounding resistance should be less than or equal to 4 ohms, and the grounding resistance of the computer room should be less than or equal to 1 ohm.

Liquid crystal displays (LCD) have become an essential component to the industry of display technology. Involved in a variety of contexts beyond the indoors like LCD TVs and home/office automation devices, the LCD has expanded its usage to many environments, such as cars and digital signage, and, thus, many temperature variations as well.

As with any substance that requires a specific molecular characteristic or behavior, LCDs have an operating temperature range in which the device, if within, can continue to function properly and well. In addition to that, there is also an ideal storage temperature range to preserve the device until used.

This operating temperature range affects the electronic portion within the device, seen as falling outside the range can cause LCD technology to overheat in hot temperatures or slow down in the cold. As for the liquid crystal layer, it can deteriorate if put in high heat, rendering it and the display itself defective.

In order for the LCD panel to avoid defects, a standard commercial LCD’s operation range and storage range should be kept in mind. Without adaptive features, a typical LCD TV has an operating range from its cold limit of 0°C (32°F) to its heat limit of 50°C (122°F) (other LCD devices’ ranges may vary a bit from these numbers).

The storage range is a bit wider, from -20°C (-4°F) to 60°C (140°F). Though these ranges are quite reasonable for many indoor and even outdoor areas, there are also quite a few regions where temperatures can drop below 0°C or rise above 32°C, and in these conditions, LCDs must be adapted to ensure functionality.

Heat, can greatly affect the electronics and liquid crystals under an LCD screen. In consideration of heat, both external heat and internally generated heat must be taken into consideration.

Seen as the liquid crystals are manipulated in a device by altering their orientations and alignments, heat can disrupt this by randomizing what is meant to be controlled. If this happens, the LCD electronics cannot command a certain formation of the liquid crystal layer under a pixel, and the LED backlighting will not pass through as expected, which can often lead to dark spots, if not an entirely dark image. This inevitably disrupts the display’s readability.

Depending on the upper limit of the operation temperature range, LCD device can be permanently damaged by extreme heat. With long exposure to extreme heat, besides the destruction of the liquid crystals, battery life can shorten, hardware can crack or even melt, response time may slow to prevent even more heat generation from the device.

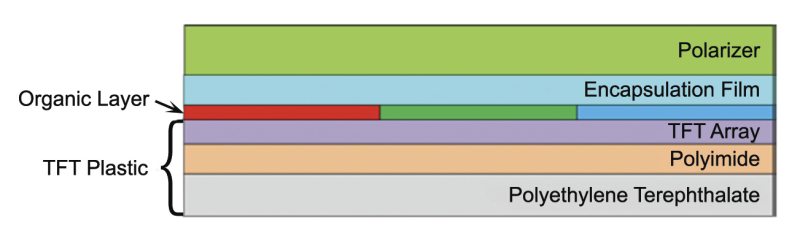

The LED backlight and the internal circuitry, typically TFT-based in the common TFT LCDs, are components that can generate heat that damages the device and its display. To address this concern with overheating, many devices use cooling fans paired with vents.

But this leads to another problem: how can moisture be prevented from entering through the vent? If moisture enters the device and high heat is present, condensation can occur, fogging the display from inside, and in some cases, short-circuiting may cause the device to turn off. In order to circumvent this issue, the shapes of the air vents are specific in a way that allows only for air movement, not forms of moisture.

In the opposite direction is extreme cold. What typically occurs in the cold is “ghosting” (the burning of an image in the screen through discoloration) and the gradual slowing and lagging of response times. Like heat-affected LCD modules, the extreme temperature can affect the liquid crystals. This layer is a medium between the liquid and solid state, so it is still susceptible to freezing.

An LCD device can be left in freezing temperatures because it will likely not be permanently damaged like in the heat, but it is important to understand the device’s limits and how to take precautions when storing the device. The standard and most common lower-bound storage range limit is -20°C, below freezing, but if possible, it would be best to keep it above that limit, or else there is still a risk of permanent damage.

Display types have a lot of variation. Choices like alphanumeric or graphic LCD, human-machine interactive LCD modules and touchscreen panels capabilities, the width of the viewing angle, level of contrast ratios, types of backlighting, and liquid crystal alignment methods are often considered. For example, the twisted nematic LCD provides for the fastest response time at the lowest cost, but cannot offer the highest contrast ratio or widest viewing angle.

Environment-based factors must consider things besides the obvious temperature like UV exposure and humidity/moisture, as they all are necessary in finding the perfect fit extreme temperature LCD module.

Besides the LCD modules, recent new products have opened doors in wide temperature range displays, such as OLED displays. OLED displays offer better displays in regard to contrast, brightness, response times, viewing angles, and even power consumption in comparison to traditional LCD displays.

These benefits, in addition to its ability to achieve a wide temperature range, provide more options for consumers in search of high quality displays for extreme climates.

Here is a picture inside the TV without the rear cover. The power supply includes the inverter stage for the backlight panel using only two HV transformers. Such design idea sounds very good because all EEFL tubes are connected in parallel avoiding the use of small transformers/inverters stages for each lamp minimizing in this way electronic issues on the backlight stage.

Compared to former CCLF, the new EEFL shows superior performance and applications. This incredible technology combines low power consumption and enhanced luminescence as compared to similar lighting sources. The most attractive feature of EEFL (External Electrode Fluorescent Lamp) is the absence of electrodes in the discharge tube, which is the main factor limiting lamp life. Electrode burn-out is the main cause of fault in CCFL. Because each CCFL lamp need its own ballast the new EEFL technology is simpler in electronics circuitry reducing in this way the rate of failures. EEFL lamps consist of a completely enclosed glass tube with external metal electrodes at both ends. This design minimizes electrode burn-out and results in a longer lamp life. Because the electrodes in former CCFL technology are in direct contact with the rare gasses, CCFL run warmer than the EEFL which are completely cool. On average, EEFL lamps have a lamp life of over 50,000 hours.

I figured out that three main areas on the circuit layout requires additional cooling. The hottest part was the digital class D audio amplifier (STA381BW) because overheats to much (manufacturer datasheet claims approx 3 watts of heat dissipation !!!) so I put a passive aluminum cooler to cool it down. Because the rear plastic cover touched the cooler I cut one of the corners. Using a smaller one was to weak to cool down the device at safe temperatures.

The digital scaler image MT5366 processor and glue logic ICs are located below a metallic RFI shield acting at the same time as a heatsink. Unfortunately the metal shield in use affects the efficiency on thermal conductivity of heat because is to thin leading to hot spots on the components. To correct such design issue the most convenient is to install a passive cooler. To cool down the MT5366 system on chip platform processor an older 486 mother board heatsink (the black one after changes third picture below) do the job well. The use of a thicker heatsink improves the thermal conductivity (spread of heat) avoiding hot spots on the devices.

The last part that requires additional cooling was the HDMI switch inputs selector (SiI9185 device schematic picture above) soldered on the right corner next to the HDMI inputs. Its based on the HDMI 1.3, DDC, HDCP specifications including a CEC (consumer electronics control) single wire bus interface to transmit I/O remote commands through a home network and EDID display identification (plug & play feature stored on serials EEPROMs). Researching datasheets from other versions I figured out that the device in operation consumes approximately 1.5 watts average but such information is not released by manufacturer. The device reach a working temperature of approximately 100 grads Celsius when HDMI inputs are enabled receiving stream data. Watching TV channels (digital DVB or analog cable) the HDMI switch remains cool because is in power down/suspend mode. At glance the HDMI switch overheats only when the inputs are enabled. Without an appropriate heatsink the life endurance of the device is affected because such operating condition can lead to a short circuit on terminals due silicon breakdown !!! . The HDMI switch integrates electrostatic discharge protections on its inputs up to 2kV discarding any possibilities of damages due weak ESD spikes but strong lightning electromagnetic discharges are a big problem without ESD protectors.

In the case of factory cooling all mentioned devices use the "ePad" enhancement, a small metal surface below the IC core case to transfer the silicon heat to PCB board. Despite the idea to reduce manufacturing costs avoiding in this way the use of external heatsinks such cheap PCB cooling solution is not appropriate at all. We verified on all the mentioned devices an excessive heat that unfortunately can lead to operational malfunctions/issues leading to a short durability.

After changes the overall heat is reduced due the improvements on heat conductivity and air convection cooling reducing the average working temperature on overall components avoiding at the same time hot spots on digital ICs (core of the silicon device).

To improve more the cooling on the T-Con LCD panel board we put a SinoGuide TCP400 series thermal pad on the main IC to increase the heat transfer on the metallic shield (this is more thick in diameter and seems to be OK for cooling purposes).

At low temperatures, the liquid crystal fluid maintains its viscosity, allowing the IC to refresh the data logic without any latency in the response time. At the high extreme of the operating temperature spectrum, the polarizer and adhesive materials are able to withstand the heat without warping the film and damaging the optical performance of the LCD module.

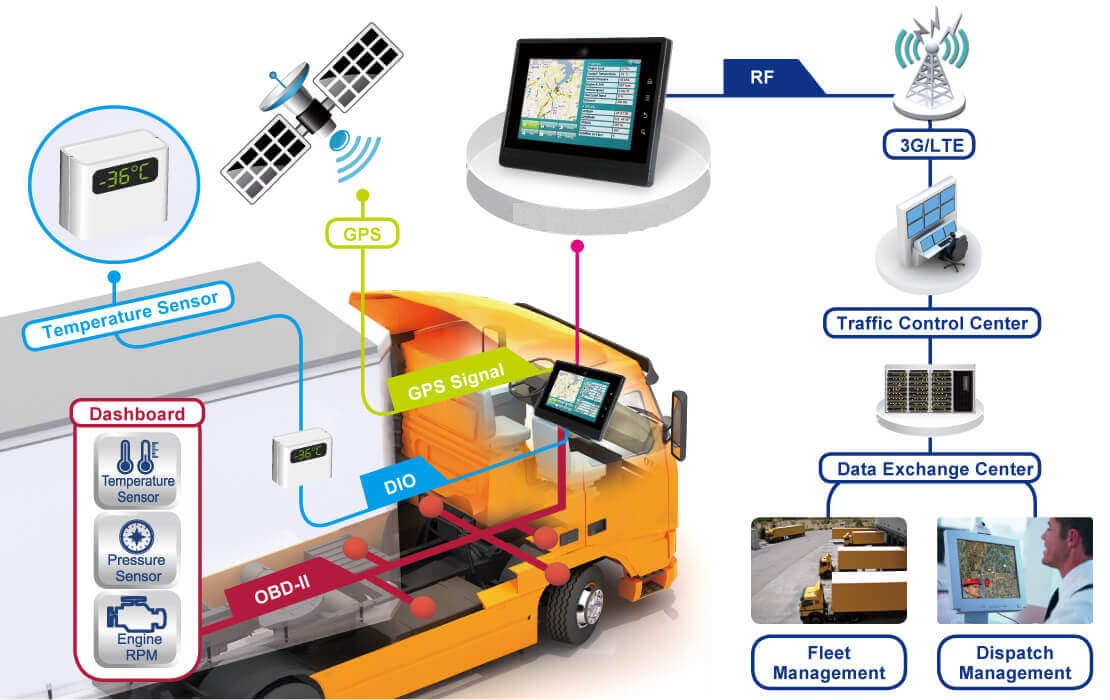

In addition to meeting the stringent quality requirements to withstand high temperature and humidity exposure, our displays also support “smart management” features, in form of a visual interface designed to help control the overall PV or EV application.

Outdoor digital displays are increasingly being used for information dissemination, interactive content location, and advertising in urban locations. While the existing thermal management approaches for indoor digital displays are well understood and generally sufficient due to their lower power dissipation, outdoor liquid crystal displays (LCDs) are subject to many additional constraints, such as harsher and changing ambient environment, solar insolation, and larger internal heat generation in the current state-of-the-art light emitting diodes (LEDs) and other associated electronics. Demands for larger and brighter displays continue to provide significant additional challenges to their thermal design. Here we review the current and emerging thermal management challenges, and current solutions for outdoor digital displays. We review the state-of-the-art of the multi-scale nature of the packaging of the digital displays, from the light sources to the display cabinet. The unique thermal management challenges for outdoor displays are next outlined. We review current thermal management methods for outdoor displays. We conclude by describing emerging applications of outdoor digital displays, and identify associated thermal challenges.

The pace of development in the electronics and telecommunication fields has been accelerating in all aspects of the business. For example, electronics/telecommunications equipment has traditionally been housed in large buildings, smaller buildings (sheds) and outdoor cabinets. The introduction of electronics to the outdoor environment has imposed serious constraints on enclosure design since temperature and humidity are the two major causes of electronics failure. Since most electronic systems do not include environmentally hardened designs, the enclosure must provide an environment in which they can survive. Among the equipment/systems involved are displays such as LCD, LED and other monitors.

The use of LEDs (Light Emitting Diodes) has been increasing exponentially in the last few years. In the beginning, heat dissipation was not a worrisome problem because of the low power the LED’s used. However, their power consumption and their useful life and reliability are dependent on how their temperature can be controlled, especially in view of high-power LEDs used for illumination and outdoor signage applications. The most important goal in LED cooling is to maintain junction temperature (Tj, the temperature at the p-n junction) from rising above prescribed levels since the junction temperature is a good predictor of the useful life of the LED component. In addition, the junction temperature in many cases must be kept relatively constant since fluctuations and shifts affect the intensity and the color of the LED light output. From a thermal standpoint, junction temperature, as with many other electronic components and systems, is influenced by power levels, heat sinking (high conductivity materials, convection cooling, extended surfaces, heat spreading, heat pipes, etc), ambient temperature, interface materials, applied pressures (clamping to reduce thermal contact resistance).

Thermal management of LEDs can range from the use of natural convection to the use of liquid cooling loops that allow for far higher heat removal rates than employing gases as the cooling medium. Air natural and forced convection, up to very recently, have been the cooling methodology of choice when cooling with a fluid. At the system level, and especially for outdoor applications, liquid cooling is normally not suitable; therefore, only cooling solutions that use natural or forced air convection are employed such as fans, blowers, air-to-air heat exchangers, air-conditioners and other passive cooling techniques.

What is more, display devices such as monitors have incorporated LED technology and must also be thermally managed outdoors since they require hardened enclosures to carry out their tasks.

The objective here is to cover the thermal management of LEDs at the system level, both discrete LED modules or outdoor enclosures (LED walls or LED monitors). This assumes that LED and board level thermal management has been dealt with separately. Nowadays, enclosures that contain LEDs are being installed in various environmental conditions. Most will be fitted with either air conditioning/thermoelectric cooling or air-to-air heat exchangers as needed because of relatively high heat dissipation requirements; for lower heat generation levels, flow-through fan cooling is sufficient. For example, there has been an unprecedented growth of the application of LEDs for outdoor (and indoor) signage or video systems such as sports displays, advertising billboards, and gas station pump customer information displays. These all are enclosures with one wall comprised of LEDs. In addition, recently LED display monitors have been installed in outdoor enclosures and therefore require thermal management. Figure 1 shows an illustration of these two types of enclosures.

The goal is to maintain peak temperatures in the enclosures below a certain level that is normally prescribed (the lowest junction temperature of the LED components) by the manufacturers. Humidity levels are of concern, but since most enclosures are either sealed or its temperatures are much higher than the air’s dew points, humidity is generally not a problem (after the transient effect of opening/closing the enclosure is eliminated.)

The designer should be aware that the air temperatures within the enclosures will be a function of: the amount of heat generated by all the electronic equipment in the enclosure; the amount of heat generated by auxiliary and cooling equipment (fans, etc.); ambient conditions (outdoor air), particularly temperature, solar radiation, wind speeds, etc.; objects surrounding the enclosure (shading, ground reflections, buildings, trees, etc.); enclosure design (surface area, shape, paint’s radiation characteristics, etc.) and air exchange with the outside air, either passive by infiltration, or active by fans or blowers.

Let us consider an enclosure that has installed LED equipment that dissipates a certain amount of heat. The first step is always to realize that the design temperature is that temperature that the enclosure air will attain when there is heat balance, or in equation form:

where, Qequipment comprises the LEDs and its electronics heat dissipation, Qsolar load is the solar heat load and Qcooling-system is the amount of heat removed by the cooling system. The solar load is a complicated term because it includes contributions from all modes or heat transfer. For example:

Normally, the value of Qradiated will always be positive (towards enclosure) but the other two can be either positive or negative, depending on the enclosure’s temperature. Thus, if Qbalance is not zero, this means that the temperature inside the enclosure is either higher/lower than the set temperature and the enclosure is losing/gaining heat by convection and conduction.

Furthermore, since incident solar radiation varies during the daylight hours, the designer must decide whether to conduct a steady state or transient analysis. Moreover, since Qradiation is a very complex term that includes, among other effects, solar declination, latitude, time of year, solar azimuth, atmospheric absorption, atmospheric clearness, re-radiation from other walls, buildings, ground etc., and incident wall surface properties, some simplifying measures must be taken into account. The result is that one can effectively double or triple the amount of heat flux being added into the enclosure depending on the calculation method. The calculation of the cooling load is carried out using several methods. One of these methods is the ASHRAE’s cooling load calculation methods. Normally, when calculating cooling loads, one would include a) Space heat gain, b) Space cooling load, and c) Space heat extraction rate. Space heat gain is the rate at which heat enters or is generated within the space at any given instant. This includes for the enclosure heat transferred into the conditioned space from the external walls and roof due to solar radiation, convection and temperature differential.

One normally includes instantaneous solar radiation effects and delayed effects. The delayed effects include the slow build-up of energy that the external walls accumulate as they absorb solar radiation. This happens because walls are normally thick and massive; making energy absorbed important. For LED enclosures this is not included since its walls are thin (at the most 3 cm when insulation might be added) and should not be included. Another component of heat gain is latent heat due to moisture infiltration. For sealed LED outdoor enclosures, the power electronics are kept in an airtight enclosure with negligible contribution.

where, α -absorptance of solar radiation surface, It – total solar radiation [W/m2], ho– coefficient of heat by long wave radiation and convection [W/K-m2], ε – hemispherical emittance, and ΔR a radiation correction factor [W/m2]. Figure 2 shows typical Sol-Air temperatures for various latitudes.

For roofs: ΔR =63 W/m2, for walls: ΔR = 0, for dark surfaces, α/It = 0.052, which is the maximum value for any surface. To calculate heat transfer into the conditioned space,

where U is the overall heat transfer coefficient for the wall and A is the surface area for the wall. The term, U, includes convective and radiation effects by the internal and external airflow (See AHSHRAE’s Fenestration Chapter for more details, ASHRAE, 1981, 1986) and the wind outside, in addition to conduction through the walls. The solar load calculated will be added to the equipment load to find the total cooling load. The solar load will include three surfaces that can be illuminated simultaneously, with the roof always included.

Display/signage enclosures have evolved. Typical LED system design has been the display shown in Figure 3. They typically were metal enclosures measuring 5-10 m wide, 250 mm deep and 5 m high. These enclosures could have thousands of LEDs each measuring, typically,5- 8 by 5-8 by 3 mm and dissipating an average of 1W each, all installed on the largest vertical wall. Therefore, the total amount of heat dissipation for this enclosure (including the electronics needed to control and manage the LEDs) could reach thousands of Watts. Figure 3 shows a CFD model of this enclosure using Phoenics by CHAM Ltd of the UK.

In the last few years, display outdoor enclosures are also being designed to house various display signage equipment configurations such as LED monitors with dissipating heat rates ranging from 200 to 1500 W, depending on the size and type of auxiliary equipment. These enclosures are installed in various environmental conditions, and typically the enclosures, without major structural modifications, may be fitted with fans, air conditioning or air-to-air heat exchangers as needed. Figure 4 shows at typical enclosure (CFD model).

Equipment housed in these enclosures include TV LED monitors that have been initially designed for indoor use and have been slightly hardened to be placed in a hot, dry environment without the support of an enclosure. Many manufacturers sell these monitors.

The goal of the designer is to maintain the peak temperatures in the enclosures, which are below a certain level that is normally prescribed by the electronic equipment manufacturer. Humidity levels are also of concern, but since in most enclosures, its temperatures are much higher than the air’s dew points, humidity is generally not an issue (after the transient effect of opening and closing the enclosure is eliminated). However, typically, the LED monitors are not fully outdoor rated, that is they must be protected from rain and moisture, therefore they must be installed in IP55/56/66 enclosures.

Most enclosures need to be designed to keep the system operating with slight internal overpressure. Cooling air is guided to flow into a gap between the LED screen surface and external transparent wall guided by guide-vanes, and the cooling system also must allow for air to flow to the rest of the enclosure, in addition to the flow in the LED/Wall gap. Overpressure is used to maintaining IP55 and IP66 design and a fan and filter inlet system construction allows for proper solar mitigation technology. For further solar mitigation purposes, if used, a solar shield overhang can reduce solar loading.

Finally, of paramount importance is to keep the LED surface (especially when in full solar exposure) under a maximum temperature. For the above LED monitor, this temperature is 110 C. Since, maximum solar radiation for latitudes below 35 N or S can generate surface temperatures higher than 110 C, then a typical construction would involve a gap between the outdoor facing glass plane and the LED monitor (see Figure 5).

Digital InfiniteTouch™ | All-glass multi-touch p-cap interactive touch screen with the capability to report 60,000 simultaneous touch points over the active area of display at a 300Hz refresh rate

The human cognitive ability to perceive and process data from several heterogeneous outputs and react correctly to the information is greatly enhanced with the proper representation of graphical data. Large format displays allow for the consolidation of multiple heterogeneous displays, fonts, dials, gauges, numbers, into a single homogeneous representation of situational awareness.

For example, for many years, firemen first to arrive on scene have been met with screeching fire alarms, indicator lights on a fire panel and “as built” drawings locked in a cabinet with a special key. Today they could now be greeted by a large format LCD with a 3D view of the building, smoke flow diagrams, and other information to help them understand the situation and make better decisions faster. Occupants leaving a building can also benefit from graphical mass notification information which can be tailored for the situation.

Ship systems comprised of different steam gauges and manual operations such as sticking tanks and closing valves can now be automated with their instruments consolidated on a single screen or redundant large screens, showing graphically status of fuel, water, and ballast, improving productivity and decreasing workload.

Similarities exist on industrial control systems where several CRTs or smaller LCDs are being replaced by a large LCD with clever graphics designed for human factors and perception.

The challenge of these applications is the proper integration of the COTS LCD technology to meet requirements of availability, reliability, and intended use.

Large LCD panels are coming out of the factory with brilliant colors and near perfect viewing angles using ASV (Advanced Super View) and IPS (In Plane Switching) innovations driven by consumer TV requirements. The challenge is ruggedizing a display to preserve as much of this as possible, this while shielding against objects, liquids, sunlight and EMI. These surface choices may adversely affect the optics of the panel, which can be reduced through bonding techniques to eliminate air gaps.

Depending on its intended use, mission critical displays may be required to operate in an environment subject to dust, sand, fog, chemicals, falling or spraying liquids (broken pipes, sprinklers, etc). Protection of the LCD panel involves designing an outer enclosure capable of keeping dust and liquids out while keeping the display operating in its proper temperature range.

In addition to isotropic display clearing, long-term reliability is adversely affected by running panels at or near the clearing temperature. Depending on the application, enclosures can be de signed to circulate air through filtered and louvered vents. This can prevent dust and water ingress while providing a cooling mechanism capable of keeping the panel within specified operating temperatures.

The transition of display backlights from CCFL to LED has also helped reduce the amount of energy in a panel, which has been a great benefit to thermal management. Displays that are used in direct sunlight, however, have to deal with solar gain which can add as much as 1000W /m2 to the problem on a sunny, cloudless day at high noon. The amount absorbed depends on the enclosure’s material and color, but typically blocking IR films or a laminar flow of air over the display are used to prevent the display from “blacking out”. In sub freezing environments, such as outdoor, or non temperature controlled areas, supplemental heaters may be required to prevent slow response of the LCDs due to low temperature.

The deployment of large screen LCDs in control rooms, ships, industrial areas, or public venues requires consideration of tampering, vibration, and shock. It is important to understand the nature of the vibration or shock in magnitude and frequency to which the screen may be subjected. Sources can be motors, conveyors, engines, propeller blades or even seismic events. In many industries, there are published standards, which represent shock and vibration experienced by the display in both transit and operation. Some of the component considerations when designing a display requiring ruggedization are listed in Table 3.

There are several touchscreen technologies available, each having its own set of strengths and weaknesses. It is important to understand the end use and user to choose the best solutions. For instance, using an infrared touch screen in an outdoor location at night can attract insects which can actually cause false touches if they land on the screen and break the IR light beam. Other touch screen technologies such as capacitive are sensitive to metal enclosures making them difficult choices for very rugged applications. Some of the more popular technologies and their strengths and weaknesses are listed in Table 4.

Parts within a large screen display are considered to have a large Mean Time Between Failures (MTBF) usually measured in tens of thousands of hours or higher. The first reaction is to divide this number by 8760 hours per year and feel assured your 24X7 display will last that many years before it fails. However the MTBF is just a probability of failure and is calculated during the “useful life” of a part, typically at room temperature. As a part starts to wear out, or gets used at high temperature, its reliability can decrease rapidly. Solid-state components such as ICs are thought of as lasting virtually forever, but within an LCD there are several components that, when routinely maintained or changed out, will keep the reliability at its maximum. The use of intelligent health monitoring such as temperature, brightness, fan speed or air flow to trigger maintenance events will increase overall reliability and availability.

Leveraging the performance and value of large format commercial off the shelf (COTS) displays requires careful attention and understanding of the environment and operation by the end user. Using this information to develop specific design requirements, engineering a design that meet these requirements, and finally developing test steps that validate the product meets these requirements will ensure a successful large format COTS display implementation.

BoldVu® displays deliver unparalleled visual performance in outdoor environments. With luminance ratings up to 5000 nits, their high-efficiency LED backlight and obsessively engineered optical stack achieve incredibly bright imagery in the face of intense sunlight – and will do so day-in and day-out for 10 full years. So bring on the sun, BoldVu’s got it managed.

Nothing will destroy a display faster than inadequate thermal management. CoolVu® is BoldVu’s multi-patented thermal management technology that extracts and expels heat from inside the BoldVu®, without exposing display electronics to ambient air or environmental contaminants, like dust, dirt and moisture and without the use of air filters – which means typically no periodic maintenance required. With CoolVu®, BoldVu® displays can operate in environments up to 122°F (50°C) without any degradation in visual performance.

BoldVu® displays are designed to live in a world of turbulence. ToughVu® cover glass shields delicate electronic components from the effects of adverse weather and vandalism. And with its low diffuse reflection, low haze, and anisotropy and bi-refringence qualities, ToughVu® glass ensures that digital imagery shines with brilliance and delivers maximum contrast, color accuracy, color saturation, and viewing angles.

As an added layer of intelligence, BoldVu® displays are equipped with a MEMS sensor which detects and reports on shock and impact events, so in the event of attempted vandalism, you’ll be in the know.

The world is full of spectacular color, and BoldVu® ensures that every one of them is accurately reproduced. The meticulously engineered optical stack achieves ultra-bright whites and super deep blacks so that every color in-between appears as vibrant as you could hope for. A billion colors never looked so good.

At the heart of BoldVu® is a sophisticated logic controller that receives data from electronic components within the display and autonomously optimizes parameters affecting image quality, chassis thermals, and power draw. With built-in intelligence, BoldVu® takes care of itself so you don’t have to.

With an embedded media player and a 13-megapixel camera capable of 4K video at 30fps, BoldVu® makes delivering amazing, interactive campaigns easier than ever. Output gorgeous graphics, measure audience engagement1 via the USB camera, and translate insights into more effective campaigns.

InfiniteTouch® is a next-gen PCAP touch sensor exclusively available on BoldVu® displays. Comprised of multiple layers of glass with index-matched sputter ITO conductors, containing no plastic films, InfiniteTouch® delivers high transmission, low reflection, and true tablet-like responsiveness, making it an incredible platform for delivering engaging interactive experiences.

The Internet of Things (IoT) is changing the way we live, work, and how cities and venues are able to offer digital services to the citizens and visitors they serve. As the IoT continues to grow the need for communications and data processing infrastructure grows with them.

An optional structure affixed atop BoldVu®, the Comms Cap is an additional housing for IoT and connectivity devices designed to extend functionality beyond the edges of the digital screen.

When you place a display out in the world, you never know what to expect. BoldVu® displays self-monitor and report on over 150 operating parameters and settings to the SmartVu® Portal. Via the secure web interface you can see how displays are performing, adjust what they’re doing, and troubleshoot errant behavior, all from anywhere you can access the internet.

BoldVu® LT Semi-Outdoor displays are designed for placement in areas protected from direct sun exposure, like in shopping malls and subway stations where its 850 nit operating luminance is bright but not overbearing.

BoldVu® outdoor displays are intended for deployment in areas out in the open and exposed to the elements. With a daytime operating luminance of 3500 nits BoldVu® is an excellent fit for a wide array of outdoor venues.

BoldVu® XT displays are for outdoor venues with big skies and ultra-bright sunlight like stadiums and raceways. When the sunglasses come out, the 5000 nit daytime luminance of BoldVu® XT still shines bright.

The CoolVu® thermal management system operates without air filters or coolants, requiring zero regular maintenance, while ensuring on-spec performance across temperature extremes (-40°C ~ +50°C / -40° F ~ +122° F).

With full product development, engineering, fabrication, assembly, and configuration under one roof, BoldVu® is a turnkey solution that makes deployment as easy as bolting to the ground, connecting power, and standing back in awe.

BoldVu® is built for as many components to be field replaceable as possible so in the event of part failure or vandalism, displays can be serviced in their installed position and back online with minimal downtime.

2 Intel, the Intel logo, and other Intel names and brands are the sole property of Intel Corporation or its subsidiaries in the US and/or other countries.

4 Power consumption based on full luminance with a white display field, averaged over 10 years of 24/7 use. All figures subject to change without notice.

BoldVu® displays deliver unparalleled visual performance in outdoor environments. With luminance ratings up to 5000 nits, their high-efficiency LED backlight and obsessively engineered optical stack achieve incredibly bright imagery in the face of intense sunlight – and will do so day-in and day-out for 10 full years. So bring on the sun, BoldVu’s got it managed.

Nothing will destroy a display faster than inadequate thermal management. CoolVu® is BoldVu’s multi-patented thermal management technology that extracts and expels heat from inside the BoldVu, without exposing display electronics to ambient air or environmental contaminants, like dust, dirt and moisture. With CoolVu®, BoldVu® displays can operate in environments up to 122°F (55°C) without any degradation in visual performance.

BoldVu® displays are designed to live in a world of turbulence. ToughVu® cover glass shields delicate electronic components from the effects of adverse weather and vandalism. And with its low diffuse reflection, low haze, and anisotropy and bi-refringence qualities, ToughVu® glass ensures that digital imagery shines with brilliance and delivers maximum contrast, color accuracy, color saturation, and viewing angles.

As an added layer of intelligence, BoldVu® displays are equipped with a MEMS sensor which detects and reports on shock and impact events, so in the event of attempted vandalism, you’ll be in the know.

The world is full of spectacular color, and BoldVu® ensures that every one of them is accurately reproduced. The meticulously engineered optical stack achieves ultra-bright whites and super deep blacks so that every color in-between appears as vibrant as you could hope for. A billion colors never looked so good.

At the heart of BoldVu® is a sophisticated logic controller that receives data from electronic components within the display and autonomously optimizes parameters affecting image quality, chassis thermals, and power draw. With built-in intelligence, BoldVu® takes care of itself so you don’t have to.

With an embedded media player and a 13-megapixel camera capable of 4K video at 30fps, BoldVu® makes delivering amazing, interactive campaigns easier than ever. Output gorgeous graphics, measure audience engagement1 via the USB camera, and translate insights into more effective campaigns.

InfiniteTouch® is a next-gen PCAP touch sensor exclusively available on BoldVu® displays. Comprised of multiple layers of glass with index-matched sputter ITO conductors, containing no plastic films, InfiniteTouch® delivers high transmission, low reflection, and true tablet-like responsiveness, making it an incredible platform for delivering engaging interactive experiences.

The Internet of Things (IoT) is changing the way we live, work, and how cities and venues are able to offer digital services to the citizens and visitors they serve. As the IoT continues to grow the need for communications and data processing infrastructure grows with them.

An optional structure affixed atop BoldVu®, the Comms Cap is an additional housing for IoT and connectivity devices designed to extend functionality beyond the edges of the digital screen.

When you place a display out in the world, you never know what to expect. BoldVu® displays self-monitor and report on over 150 operating parameters and settings to the SmartVu® Portal. Via the secure web interface you can see how displays are performing, adjust what they’re doing, and troubleshoot errant behavior, all from anywhere you can access the internet.

BoldVu® LT Semi-Outdoor displays are designed for placement in areas protected from direct sun exposure, like in shopping malls and subway stations where its 850 nit operating luminance is bright but not overbearing.

BoldVu® outdoor displays are intended for deployment in areas out in the open and exposed to the elements. With a daytime operating luminance of 3500 nits BoldVu® is an excellent fit for a wide array of outdoor venues.

BoldVu® XT displays are for outdoor venues with big skies and ultra-bright sunlight like stadiums and raceways. When the sunglasses come out, the 5000 nit daytime luminance of BoldVu® XT still shines bright.

The CoolVu® thermal management system operates without air filters or coolants, requiring zero regular maintenance, while ensuring on-spec performance across temperature extremes (-40°C ~ +50°C / -40° F ~ +122° F).

With full product development, engineering, fabrication, assembly, and configuration under one roof, BoldVu® is a turnkey solution that makes deployment as easy as bolting to the ground, connecting power, and standing back in awe.

BoldVu® is built for as many components to be field replaceable as possible so in the event of part failure or vandalism, displays can be serviced in their installed position and back online with minimal downtime.

2 Intel, the Intel logo, and other Intel names and brands are the sole property of Intel Corporation or its subsidiaries in the US and/or other countries.

4 Power consumption based on full luminance with a white display field, averaged over 10 years of 24/7 use. All figures subject to change without notice.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey