tft display definition factory

The two buzzwords the tech world has been chatting about for a number of years now is IPS, (In-Plane Switching) screen technology used for liquid crystal displays or LCD’s for short, and TFT (Thin-Film-Transistor) an active matrix screen technology, which is more expensive, but a sharper image.

TFT (Thin-Film-Transistor) Liquid Crystal Display is a thin display type, where a transistor embedded into each crystal gate; these transistors are then printed on thin-transparent film. The technology was designed to improve image qualities, such as contrast and addressability.

Also designed in the late 1980’s, TFT display technologies is just another variation of LCD displays that offer greater color, contrast, and response times as opposed to available passive matrix LCD’s. One of the primary differences between IPS and TFT display technologies is the cost. IPS is more expensive than TN technology. However, there are some key differences between the two that should be noted.

Before we go into the differences, let’s talk about features of each technology. Note that we’re not talking TVs, computer, or tablets, but screens on a much smaller scale, (think 7” or smaller) which uses different rules to fit that scale. First, it’s interesting to discover that the TFT display technologies is the most common type of color display technology; more monochrome displays still out-sell color, due to lower cost and lower power consumption, however, the narrow poor visibility of TFTs in direct sunlight is their downside; but I’m getting ahead of myself here.

Brilliant color image – this is a huge advance in technology, from a Twisted Nematic (TN) display that only produced 6-bit color, to an 8-bit color display with the IPS technology

TFT display technologies have developed over the years and have become quite popular in tech circles. The features offered with this advancing technology are:Superior color display – for technology that requires it or for consumers that desire color screens

Features a longer half-life, (half-life is the amount of time in hours before the display is 50% as bright as when it was first turned on), than OLEDs and comes in varying sizes, from under an inch up to over 15 inches

Variety of displays, which can be interfaced through a variety of bus types, including 18 and 24 bit for red/green/blue, LVDS, and 8 bit and 16 bit for a CPU – many controllers allow for two or more different types of interfaces on the same TFT screen

Let me explain. As you can see, both have excellent color display and clarity; however, IPS screens offer greater color reproduction and viewing angles because of the way crystal orientation and polarizers are arranged. In a TFT screen, the structure of the crystals results in angular retardation in the light. The IPS screens thus offer less distortion properties. Other differences include power consumption and cost. With IPS screens, it takes more power (up to 15% more) than with a TFT screen. If you’re on a monitor, such as a computer screen that’s bigger than 7 inches, it will drain your battery faster than if you’re on a 3.5” screen. Regarding cost, IPS panels are more expensive to produce than TFT panels.

The color channels increase from 6 bits (TN displays) to 8 bits (IPS displays) to ensure the precision of shades per color channel, thus increasing manufacturing costs

If you want the benefits of having a Smartphone without a huge price tag, then TFT devices are your best bet. Another difference is that IPS screens have longer response times than TFT screens, so the lag output is greater. A few other key differences to be aware of are that with IPS panels, you get a bigger variety of panels, as was discussed above, with their super, advanced, and so forth developments, giving the consumer options, and IPS screens that can display 24-bit TrueColor; they also stay color-accurate and remain stable.

Now we will go over the downside of IPS screens, which we briefly touched on above, which includes a major disadvantage: cost. If you’re just looking for an average Smartphone or don’t need all the fancy coloring and clarity for LCD displays, then cost may not be a big factor; however, this is the main reason why IPS technology is beginning to come down. As with every new invention, discovery or technology, demand is everything. Another disadvantage is that colors may not always transcribe correctly or accurately, which may or may not be a deterrent. Also, high resolutions are not always readily available for personal applications. In certain circumstances, the brightness may not be enough, especially in darkness.

Steve Jobs said it best: “Design is not just what it looks like and feels like. Design is how it works.” I tend to agree with him. With TFT display technologies, less energy consumption is a big deal, especially when dealing with bigger screens, and of course less electricity means lower cost, overall. The visibility is sharper, meaning no geometric distortion, which is great for these tired, old eyes. The response time and physical design of the screens are also appealing. TFT displays can also save space and be placed virtually anywhere in an office or home, because of the brightly lit feature and crisp clear images.

Some cons of TFT screens deal with the viewing angle, which create distortion, resulting in a less-than-perfect image. Static resolution, meaning the resolution can’t be changed, may also cause a problem, but newer models seem to have tackled that issue. The accuracy of the display of colors is not perfect, specifically strong blacks and bright whites, so when printing an image, it may not display the spectrum of colors.

And there you have it. In the future, even this superb technology will change and new, more exciting technology will take its place. But until then, IPS & TFT screens are forging ahead with their own advances and improvements, so stayed tune. You don’t want to miss it.

Focus Display Solutions (www.FocusLCDs.com) offers off-the-shelf Color TFT display technologies in both TN and IPS. Many of the color modules contain built in touch panels.

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

The liquid crystal displays used in calculators and other devices with similarly simple displays have direct-driven image elements, and therefore a voltage can be easily applied across just one segment of these types of displays without interfering with the other segments. This would be impractical for a large display, because it would have a large number of (color) picture elements (pixels), and thus it would require millions of connections, both top and bottom for each one of the three colors (red, green and blue) of every pixel. To avoid this issue, the pixels are addressed in rows and columns, reducing the connection count from millions down to thousands. The column and row wires attach to transistor switches, one for each pixel. The one-way current passing characteristic of the transistor prevents the charge that is being applied to each pixel from being drained between refreshes to a display"s image. Each pixel is a small capacitor with a layer of insulating liquid crystal sandwiched between transparent conductive ITO layers.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

Most TN panels can represent colors using only six bits per RGB channel, or 18 bit in total, and are unable to display the 16.7 million color shades (24-bit truecolor) that are available using 24-bit color. Instead, these panels display interpolated 24-bit color using a dithering method that combines adjacent pixels to simulate the desired shade. They can also use a form of temporal dithering called Frame Rate Control (FRC), which cycles between different shades with each new frame to simulate an intermediate shade. Such 18 bit panels with dithering are sometimes advertised as having "16.2 million colors". These color simulation methods are noticeable to many people and highly bothersome to some.gamut (often referred to as a percentage of the NTSC 1953 color gamut) are also due to backlighting technology. It is not uncommon for older displays to range from 10% to 26% of the NTSC color gamut, whereas other kind of displays, utilizing more complicated CCFL or LED phosphor formulations or RGB LED backlights, may extend past 100% of the NTSC color gamut, a difference quite perceivable by the human eye.

In 2004, Hydis Technologies Co., Ltd licensed its AFFS patent to Japan"s Hitachi Displays. Hitachi is using AFFS to manufacture high end panels in their product line. In 2006, Hydis also licensed its AFFS to Sanyo Epson Imaging Devices Corporation.

A technology developed by Samsung is Super PLS, which bears similarities to IPS panels, has wider viewing angles, better image quality, increased brightness, and lower production costs. PLS technology debuted in the PC display market with the release of the Samsung S27A850 and S24A850 monitors in September 2011.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

The bare display panel will only accept a digital video signal at the resolution determined by the panel pixel matrix designed at manufacture. Some screen panels will ignore the LSB bits of the color information to present a consistent interface (8 bit -> 6 bit/color x3).

With analogue signals like VGA, the display controller also needs to perform a high speed analog to digital conversion. With digital input signals like DVI or HDMI some simple reordering of the bits is needed before feeding it to the rescaler if the input resolution doesn"t match the display panel resolution.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

Brody, T. Peter; Asars, J. A.; Dixon, G. D. (November 1973). "A 6 × 6 inch 20 lines-per-inch liquid-crystal display panel". 20 (11): 995–1001. Bibcode:1973ITED...20..995B. doi:10.1109/T-ED.1973.17780. ISSN 0018-9383.

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

Kim, Sae-Bom; Kim, Woong-Ki; Chounlamany, Vanseng; Seo, Jaehwan; Yoo, Jisu; Jo, Hun-Je; Jung, Jinho (15 August 2012). "Identification of multi-level toxicity of liquid crystal display wastewater toward Daphnia magna and Moina macrocopa". Journal of Hazardous Materials. Seoul, Korea; Laos, Lao. 227–228: 327–333. doi:10.1016/j.jhazmat.2012.05.059. PMID 22677053.

When compared to the ordinary LCD, TFT LCD gives very sharp and crisp picture/text with shorter response time. TFT LCD displays are used in more and more applications, giving products better visual presentation.

TFT is an abbreviation for "Thin Film Transistor". The colorTFT LCD display has transistors made up of thin films of Amorphous silicon deposited on a glass. It serves as a control valve to provide an appropriate voltage onto liquid crystals for individual sub-pixels. That is why TFT LCD display is also called Active Matrix display.

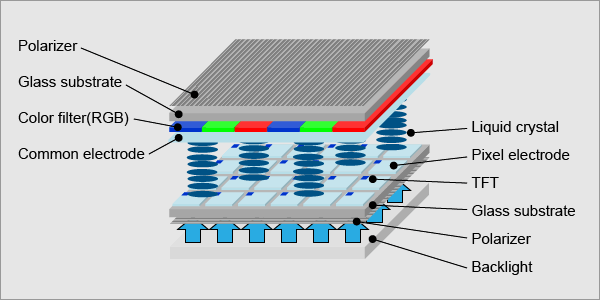

A TFT LCD has a liquid crystal layer between a glass substrate formed with TFTs and transparent pixel electrodes and another glass substrate with a color filter (RGB) and transparent counter electrodes. Each pixel in an active matrix is paired with a transistor that includes capacitor which gives each sub-pixel the ability to retain its charge, instead of requiring an electrical charge sent each time it needed to be changed. This means that TFT LCD displays are more responsive.

To understand how TFT LCD works, we first need to grasp the concept of field-effect transistor (FET). FET is a type of transistor which uses electric field to control the flow of electrical current. It is a component with three terminals: source, gate, and drain. FETs control the flow of current by the application of a voltage to the gate, which in turn alters the conductivity between the drain and source.

Using FET, we can build a circuit as below. Data Bus sends signal to FET Source, when SEL SIGNAL applies voltage to the Gate, driving voltage is then created on TFT LCD panel. A sub-pixel will be lit up. A TFT LCD display contains thousand or million of such driving circuits.

Topway started TFT LCD manufacturing more than15 years ago. We produce color TFT LCD display from 1.8 to 15+ inches with different resolutions and interfaces. Here is some more readings about how to choose the right TFT LCD.

Let us start with the basics first; refresh the knowledge about TN and LCD displays in general, later we will talk about TFTs (Thin Film Transistors), how they differ from regular monochrome LCD displays. Then we will go on to the ghosting effect, so we will not only discuss the technology behind the construction of the TFT, but also some phenomena, like the ghosting effect, or grayscale inversion, that are important to understand when using an LCD TFT display.

Next, we will look at different technologies of the TFT LCD displays like TN, IPS, VA, and of course about transmissive and transflective LCD displays, because TFT displays also can be transmissive and transflective. In the last part we will talk about backlight.

Let us start with a short review of the most basic liquid crystal cell, which is the TN (twisted nematic) display. On the picture above, we can see that the light can be transmit through the cell or blocked by the liquid crystal cell using voltage. If you want to learn more about monochrome LCD displays and the basics of LCD displays, follow this link.

What is a TFT LCD display and how it is different from a monochrome LCD display? TFT is called an active display. Active, means we have one or more transistors in every cell, in every pixel and in every subpixel. TFT stands for Thin Film Transistor, transistors that are very small and very thin and are built into the pixel, so they are not somewhere outside in a controller, but they are in the pixel itself. For example, in a 55-inch TV set, the TFT display contains millions of transistors in the pixels. We do not see them, because they are very small and hidden, if we zoom in, however, we can see them in every corner of each pixel, like on the picture below.

On the picture above we can see subpixels, that are basic RGB (Red, Green, Blue) colors and a black part, with the transistors and electronic circuits. We just need to know that we have pixels, and subpixels, and each subpixel has transistors. This makes the display active, and thus is called the TFT display. TFT displays are usually color displays, but there are also monochrome TFT displays, that are active, and have transistors, but have no colors. The colors in the TFT LCD display are typically added by color filters on each subpixel. Usually the filters are RGB, but we also have RGBW (Red, Green, Blue, White) LCD displays with added subpixels without the filter (White) to make the display brighter.

Going a little bit deeper, into the TFT cell, there is a part inside well known to us from the monochrome LCD display Riverdi University lecture. We have a cell, liquid crystal, polarizers, an ITO (Indium Tin Oxide) layer for the electrodes, and additionally an electronic circuit. Usually, the electronic circuit consists of one transistor and some capacitors to sustain the pixel state when we switch the pixel OFF and ON. In a TFT LCD display the pixels are much more complicated because apart from building the liquid crystal part, we also need to build an electronic part.

That is why TFT LCD display technologies are very expensive to manufacture. If you are familiar with electronics, you know that the transistor is a kind of switch, and it allows us to switch the pixel ON and OFF. Because it is built into the pixel itself, it can be done very quickly and be very well controlled. We can control the exact state of every pixel not only the ON and OFF states, but also all the states in between. We can switch the light of the cells ON and OFF in several steps. Usually for TFT LCD displays it will be 8-bit steps per color, so we have 256 steps of brightness for every color, and every subpixel. Because we have three subpixels, we have a 24-bit color range, that means over 16 million combinations, we can, at least theoretically, show on our TFT LCD display over 16 million distinct colors using RGB pixels.

Now that we know how the TFT LCD display works, we can now learn some practical things one of which is LCD TFT ghosting. We know how the image is created, but what happens when we have the image on the screen for a prolonged time, and how to prevent it. In LCD displays we have something called LCD ghosting. We do not see it very often, but in some displays this phenomenon still exists.

If some elements of the picture i.e., your company logo is in the same place of the screen for a long period of time, for couple of weeks, months or a year, the crystals will memorize the state and later, when we change the image, we may see some ghosting of those elements. It really depends on many conditions like temperature and even the screen image that we display on the screen for longer periods of time. When you build your application, you can use some techniques to avoid it, like very rapid contrast change and of course to avoid the positioning the same image in the same position for a longer time.

You may have seen this phenomenon already as it is common in every display technology, and even companies like Apple put information on their websites, that users may encounter this phenomenon and how to fix it. It is called image ghosting or image persistence, and even Retina displays are not free of it.

Another issue present in TFT displays, especially TN LCD displays, is grayscale inversion. This is a phenomenon that changes the colors of the screen according to the viewing angle, and it is only one-sided. When buying a TFT LCD display, first we need to check what kind of technology it is. If it is an IPS display, like the Riverdi IPS display line, then we do not need to worry about the grayscale inversion because all the viewing angles will be the same and all of them will be very high, like 80, 85, or 89 degrees. But if you buy a more common or older display technology type, like the TN (twisted nematic) display, you need to think where it will be used, because one viewing angle will be out. It may be sometimes confusing, and you need to be careful as most factories define viewing direction of the screen and mistake this with the greyscale inversion side.

On the picture above, you can see further explanation of the grayscale inversion from Wikipedia. It says that some early panels and also nowadays TN displays, have grayscale inversion not necessary up-down, but it can be any angle, you need to check in the datasheet. The reason technologies like IPS (In-Plane Switching), used in the latest Riverdi displays, or VA, were developed, was to avoid this phenomenon. Also, we do not want to brag, but the Wikipedia definition references our website.

We know already that TN (twisted nematic) displays, suffer from grayscale inversion, which means the display has one viewing side, where the image color suddenly changes. It is tricky, and you need to be careful. On the picture above there is a part of the LCD TFT specification of a TN (twisted nematic) display, that has grayscale inversion, and if we go to this table, we can see the viewing angles. They are defined at 70, 70, 60 and 70 degrees, that is the maximum viewing angle, at which the user can see the image. Normally we may think that 70 degrees is better, so we will choose left and right side to be 70 degrees, and then up and down, and if we do not know the grayscale inversion phenomena, we may put our user on the bottom side which is also 70 degrees. The viewing direction will be then like a 6 o’clock direction, so we call it a 6 o’clock display. But you need to be careful! Looking at the specification, we can see that this display was defined as a 12 o’clock display, so it is best for it to be seen from a 12 o’clock direction. But we can find that the 12 o’clock has a lower viewing angle – 60 degrees. What does it mean? It means that on this side there will be no grayscale inversion. If we go to 40, 50, 60 degrees and even a little bit more, probably we will still see the image properly. Maybe with lower contrast, but the colors will not change. If we go from the bottom, from a 6 o’clock direction where we have the grayscale inversion, after 70 degrees or lower we will see a sudden color change, and of course this is something we want to avoid.

To summarize, when you buy older technology like TN and displays, which are still very popular, and Riverdi is selling them as well, you need to be careful where you put your display. If it is a handheld device, you will see the display from the bottom, but if you put it on a wall, you will see the display from the top, so you need to define it during the design phase, because later it is usually impossible or expensive to change the direction.

We will talk now about the other TFT technologies, that allow us to have wider viewing angles and more vivid colors. The most basic technology for monochrome and TFT LCD displays is twisted nematic (TN). As we already know, this kind of displays have a problem with grayscale inversion. On one side we have a higher retardation and will not get a clear image. That is why we have other technologies like VA (Vertical Alignment), where the liquid crystal is differently organized, and another variation of the TFT technology – IPS which is In-Plane Switching. The VA and IPS LCD displays do not have a problem with the viewing angles, you can see a clear image from all sides.

Apart from the different organization of the liquid crystals, we also organize subpixels a little bit differently in a VA and IPS LCD displays. When we look closer at the TN display, we will just see the subpixels with color filters. If we look at the VA or IPS display they will have subpixels of subpixels. The subpixels are divided into smaller parts. In this way we can achieve even wider viewing angles and better colors for the user, but of course, it is more complicated and more expensive to do.

The picture above presents the TN display and grayscale inversion. For IPS or VA technology there is no such effect. The picture will be the same from all the sides we look so these technologies are popular where we need wide viewing angles, and TN is popular where we don’t need that, like in monitors. Other advantages of IPS LCD displays are they give accurate colors, and wide viewing angles. What is also important in practice, in our projects, is that the IPS LCD displays are less susceptible to mechanical force. When we apply mechanical force to the screen, and have an optically bonded touch screen, we push the display as well as squeeze the cells. When we have a TN display, every push on the cell changes the image suddenly, with the IPS LCD displays with in-plane switching, different liquid crystals organization, this effect is lesser. It is not completely removed but it is much less distinct. That is another reason IPS displays are very popular for smartphones, tablets, when we have the touchscreens usually optically bonded.

If we wanted to talk about disadvantages, there is a question mark over it, as some of them may be true, some of them do not rely on real cases, what kind of display, what kind of technology is it. Sometimes the IPS displays can have higher power consumption than others, in many cases however, not. They can be more expensive, but not necessarily. The new IPS panels can cost like TN panels, but IPS panels definitely have a longer response time. Again, it is not a rule, you can make IPS panels that are very fast, faster than TN panels, but if you want the fastest possible display, probably the TN panel will be the fastest. That is why the TN technology is still popular on the gaming market. Of course, you can find a lot of discussions on the internet, which technology is better, but it really depends on what you want to achieve.

Now, let us look at the backlight types. As we see here, on the picture above, we have four distinct types of backlight possible. The most common, 95 or 99 per cent of the TFT LCD displays on the market are the transmissive LCD display type, where we need the backlight from the back. If you remember from our Monochrome LCD Displays lecture, for transmissive LCD displays you need the backlight to be always on. If you switch the backlight off, you will not see anything. The same as for monochrome LCD displays, but less popular for TFT displays, we have the transflective LCD display type. They are not popular because usually for transflective TFT displays, the colors lack in brightness, and the displays are not very practical to use. You can see the screen, but the application is limited. Some transflective LCD displays are used by military, in applications where power consumption is paramount; where you can switch the backlight off and you agree to have lower image quality but still see the image. Power consumption and saving energy is most important in some kind of applications and you can use transflective LCD displays there. The reflective type of LCD displays are almost never used in TFT. There is one technology called Low Power Reflective Displays (LPRD) that is used in TFT but it is not popular. Lastly, we have a variation of reflective displays with frontlight, where we add frontlight to the reflective display and have the image even without external light.

Just a few words about Low Power Reflective Displays (LPRD). This kind of display uses environmental light, ambient light to reflect, and produce some colors. The colors are not perfect, not perfectly clear, but this technology is becoming increasingly popular because it allows to have color displays in battery powered applications. For example, a smartwatch would be a case for that technology, or an electrical bike or scooter, where we can not only have a standard monochrome LCD display but also a TFT LCD color display without the backlight; we can see the image even in

strong sunlight and not need backlight at all. So, this kind of TFL LCD display technology is getting more and more popular when we have outdoor LCD displays and need a low power consumption.

On the picture above, we have some examples of how transmissive and reflective LCD displays work in the sunlight. If we have a simple image, like a black and white pattern, then on a transmissive LCD display, even with 1000 candela brightness, the image probably will be lower quality than for a reflective LCD display; if we have sunlight, we have very strong light reflections on the surface of the screen. We have talked about contrast in more detail in the lecture Sunlight Readable Displays. So, reflective LCD displays are a better solution for outdoor applications than transmissive LCD displays, where you need a really strong backlight, 1000 candela or more, to be really seen outdoors.

To show you how the backlight of LCD displays is built, we took the picture above. You can see the edge backlight there, where we have LEDs here on the small PCB on the edge, and we have a diffuser that distributes the light to the whole surface of LCD screen.

In addition to the backlight, we have something that is called a frontlight. It is similar to backlight, it also uses the LEDs to put the light into it, but the frontlight needs to be transparent as we have the display behind. On the example on the picture above we can see an e-paper display. The e-paper display is also a TFT display variation, but it is not LCD (liquid crystal), it is a different technology, but the back of the display is the same and it is reflective. The example you see is the Kindle 4 eBook reader. It uses an e-paper display and a frontlight as well, so you can read eBooks even during the night.

TFT is a Thin Film Transistor, TFT refers to each LCD liquid crystal display pixels that are driven by integration in the behind of the Thin Film Transistor. Therefore, the TFT-type display has the advantages of high responsiveness, high brightness, and high contrast, and its display effect is close to that of CRT display, TFT-LCD is one of the most liquid crystal displays.TFT display is also a kind of active-matrix liquid crystal display equipment. TFT-LCD is one of the best LCD color displays, TFT-LCD has the advantages of fine and vivid image, lightweight, low power consumption, and good environmental protection performance, widely used in TV, laptop, mobile phone, monitor, medical beauty, and other equipment.

Unlike TN, TFT displays are “backlit” – the imaginary light path is not from top to bottom, as in TN, but from bottom to top. In this way, a special light tube is set on the back of the liquid crystal, and the light source shines upward through the lower polarizer. Since the upper and lower interlayer electrodes are changed into FET electrodes and common electrodes, the performance of liquid crystal molecules will also change when the FET electrode is switched on. The display purpose can be achieved through shading and light transmission, and the response time is greatly improved to about 80ms.TFT is commonly known as “true color” because it has higher contrast and richer colors than TN-LCD, and the screen updates faster.

The main feature of TFT-LCD, as opposed to TN, is one semiconductor switch per pixel. Because each pixel can be directly controlled by point pulses. Therefore, each node is relatively independent and can be controlled continuously. Such a design method not only improves the response speed of the display screen but also can accurately control the display grayscale, which is why TFT color is more realistic than DSTN.

The TFT panel is cut from a larger substrate. LCD products also have a large array of transistors to control the three primary colors, and current manufacturing technology is difficult to ensure that tens or even hundreds of millions of transistors on a large substrate are without a single problem. If there is a problem with one of the transistors, then the corresponding color of the corresponding point of the transistor will go wrong (only a certain fixed color can be displayed), and this point is commonly called “bad point”. The probability of bad spots is not fixed in position, so a substrate is likely to be wasted a lot. Generally, LCD requires that the bad point is less than 5, and some large manufacturers have narrowed the standard to 3, or even 0, which will reduce the yield rate. Some smaller manufacturers expand the bad points, which naturally reduces costs and quality, which is one reason why some manufacturers have been able to slash prices.

Although there are many manufacturers capable of producing LCDs, there are only a handful of manufacturers capable of producing TFT panels.ACER, as a well-known enterprise in the IT industry, is quite powerful. Although IT does not have the ability to produce TFT panels by itself,

The display sets the electron, the communication and the information processing technology in one body, is considered as the electron industry after the 20th-century microelectronics, the computer another important development opportunity.

With the rapid development of science and technology, a revolution is taking place in display technology. After more than 20 years of research, competition, and development, the flat-panel display has entered the role and become the mainstream of display products in the new century. There are four types of flat-panel displays with the most fierce competition:

The principle of field emission flat display is similar to that of CRT, which only has one to three electron guns and up to six. The field emission display adopts an electron gun array (electron emission micro tip array, such as diamond film tip cone), and the display with a resolution of VGA (640×480×3) needs 921,600 electron emission micro tips with uniform performance.

Glow plasma display are through small vacuum plasma discharge excitation discharge cavity light-emitting materials, luminous effect, and low power consumption is its shortcomings (only 1.2 lm/W, and lamp luminous efficiency more than 80 lm/W, 6 watts per square inch display area), but in 102 ~ 152 cm diagonal field of the large-screen display has a strong competitive advantage.

The semiconductor light-emitting diode (LED) display scheme, due to the successful development of GaN blue light-emitting diode, has won absolute control over the market of the video display with very large screens, but this kind of display is only suitable for large outdoor displays, and video display with a small and medium screen does not have its market.

Special TFT – LCD, LCD flat panel display, is the only one in the brightness, contrast, such as power, life, volume and weight of integrated performance to catch up with and surpass that of the CRT display device, it features good performance, large-scale production, a high degree of automation, low cost of raw materials, the vast development space, will quickly become the mainstream product of the new century, is one of the highlights of the 21st-century global economic growth.

TFT-LCD, which USES liquid crystal as the excellent characteristic of the light valve, divides the luminous display device into two parts, namely the light source and the control of the light source. As a light source, no matter from luminous efficiency, full color, or life, has achieved brilliant results, but also in continuous deepening. Since the invention of the LCD, the backlight has been continuously improved, from monochrome to color, from thick to thin, from side fluorescent lamps to flat fluorescent lamps. The latest achievements in light sources will provide a new backlight for LCD. With the progress of light source technology, there will be newer and better light sources and LCD applications. Is the control of the light source, the rest of the large scale integrated circuit technology and semiconductor technology transplanted, successfully developed the thin film transistor (TFT) production technology, implements the matrix addressing the control of the liquid crystal light valve, solved the LCD light valve and the controller, so that the advantages of liquid crystal display (LCD).

The TFT thin-film transistor (matrix) — which “actively” controls individual pixels on the screen — is the origin of the so-called active matrix TFT.So how exactly do images come about? The basic principle is simple: a display screen consists of a number of pixels that can emit light of any color, and controlling each pixel to display a corresponding color does the trick. In TFT LCD, backlight technology is generally adopted. In order to accurately control the color and brightness of each pixel, a switch similar to a shutter needs to be installed after each pixel. When the “shutter” is opened, light can come through, but when the “shutter” is closed, light cannot come through.

Of course, it’s not as simple technically as that. Liquid Crystal Display USES the properties of Liquid crystals (Liquid when heated and solid when cooled)

Liquid crystal displays (LCDs) are filamentous, and their molecular structure changes as the environment change, giving them different physical properties — allowing light to pass through or block it — in the case of louvers.

You know the three primary colors, so each pixel on the display needs to be made up of three similar basic components described above, which control the red, green, and blue colors respectively.

TFT color filter is divided into red, green, and blue according to the color, which is successively arranged on the glass substrate to form a group (dot pitch) corresponding to a pixel. Each monochrome filter is called a sub-pixel. That said, if a TFT display supports a maximum resolution of 1280×1024, it needs at least 1280×3×1024 sub-pixels and transistors. For a 15-inch TFT display (1024 x 768), a pixel is about 0.0188 inches.

As you know, pixels are critical to a display, and the smaller each pixel, the larger the maximum possible resolution of the display. But because of the physical limitations of transistors, the TFT is roughly 0.0117 inches (0.297mm) per pixel, so the maximum resolution for a 15-inch display is 1,280 by 1,024.[1]

TFT technology is the basis of liquid crystal (LC), inorganic and organic thin-film electroluminescence (EL and OEL) flat panel displays.TFT is a kind of film necessary for manufacturing circuits formed by sputtering and chemical deposition process on the non-single wafers such as glass or plastic substrate, and large-scale semiconductor integrated circuit (LSIC) is produced by processing of the film. Using non-single-crystal substrate can greatly reduce the cost, which is the extension of traditional LSI to large-area, multi-function, and low-cost direction.

The first generation of large-area glass substrate (300mm×400mm) TFT-LCD production line was put into production in the early 1990s. By the first half of 2000, the area of glass substrate has been expanded to 680mm×880mm), and the recent 950mm×1200mm glass substrate will also be put into operation. In principle, there is no area limit.

The 1.3-inch TFT chip used for liquid crystal projection has a resolution of one million pixels in XGA.The resolution of the SXGA (1280×1024) 16.1-inch TFT array amorphous silicon film thickness is only 50nm, and the TAB ON GLASS and SYSTEM ON GLASS technology, its IC integration, requirements for equipment and supply technology, technical difficulty than the traditional LSI.

TFT was first used as a matrix location circuit to improve the optical valve characteristics of liquid crystals. For high-resolution displays, the accurate control of object elements is realized through voltage adjustment in the range of 0-6v (its typical value is 0.2 to 4V), thus making it possible for LCD to achieve a high-quality high-resolution display.TFT-LCD is the first flat panel display in human history to surpass CRT in display quality. Now people are starting to integrate the drive IC into the glass substrate, and the whole TFT will be more powerful than traditional large-scale semiconductor integrated circuits.

Low voltage applications, low drive voltage, solid use safety, and reliability improvement; Flat, light, and thin, saving a lot of raw materials and space; Low power consumption, its power consumption is about one-tenth of the CRT display, reflective TFT-LCD is only about one percent of the CRT, saving a lot of energy; TFT-LCD products also have specifications, models, size series, variety, convenient and flexible use, maintenance, update, upgrade easy, long service life and many other characteristics. The display range covers the application range of all monitors from 1 inch to 40 inches and the large projection plane, which is a full-size display terminal; Display quality from the simplest monochrome character graphics to high resolution, high color fidelity, high brightness, high contrast, the high response speed of various specifications of video display; Display mode has direct vision type, projection type, perspective type, and reflection type.

No radiation, no flicker, no harm to the user’s health. In particular, the appearance of TFT-LCD electronic books and periodicals will bring mankind into the era of a paperless office and paperless printing, and trigger the revolution of human learning, communication, and recording civilization.

The temperature range from -20℃ to +50℃ can be used normally, and the low temperature working temperature of TFT-LCD after temperature reinforcement can reach -80 ℃. It can be used as a mobile terminal display, desktop terminal display, and large screen projection TV. It is a full-size video display terminal with excellent performance.

TFT-LCD was invented in 1960 and successfully commercialized as a notebook computer panel in 1991 after continuous improvement, thus entering the TFT-LCD generation.

Simply put, the basic structure of the TFT-LCD panel is a layer of liquid crystal sandwiched between two glass substrates. The front TFT display panel is coated with a color filter, and the back TFT display panel is coated with a thin film transistor (TFT). When a voltage is applied to the transistor, the liquid crystal turns and light passes through the liquid crystal to create a pixel on the front panel. The backlight module is responsible for providing the light source after the TFT-Array panel. Color filters give each pigment a specific color. The combination of each different color pixel gives you an image of the front of the panel.

The TFT panel is composed of millions of TFT devices and ITO (In TI Oxide, a transparent conductive metal) regions arranged like a matrix, and the so-called Array refers to the region of millions of TFT devices arranged neatly, which is the panel display area. The figure below shows the structure of a TFT pixel.

No matter how the design of TFT display board changes or how the manufacturing process is simplified, its structure must have a TFT device and control liquid crystal region (if the light source is penetration-type LCD, the control liquid crystal region is ITO; but for reflective LCD, the metal with high reflection rate is used, such as Al).

The TFT device is a switch, whose function is to control the number of electrons flowing into the ITO region. When the number of electrons flowing into the ITO region reaches the desired value, the TFT device is turned off. At this time, the entire electrons are kept in the ITO region.

The figure above shows the time changes specified at each pixel point. G1 is continuously selected to be turned on by the driver IC from T1 to TN so that the source-driven IC charges TFT pixels on G1 in the order of D1, D2, and Dn. When TN +1, gATE-driven IC is selected G2 again, and source-driven IC is selected sequentially from D1.

Many people don’t understand the differences between generations of TFT-LCD plants, but the principle is quite simple. The main difference between generations of plants is in the size of glass substrates, which are products cut from large glass substrates. Newer plants have larger glass substrates that can be cut to increase productivity and reduce costs, or to produce larger panels (such as TFT display LCD TV panels).

The TFT-LCD industry first emerged in Japan in the 1990s, when a process was designed and built in the country. The first-generation glass substrate is about 30 X 40 cm in size, about the size of a full-size magazine, and can be made into a 15-inch panel. By the time Acer Technology (which was later merged with Unioptronics to become AU Optronics) entered the industry in 1996, the technology had advanced to A 3.5 generation plant (G3.5) with glass substrate size of about 60 X 72 cm.Au Optronics has evolved to a sixth-generation factory (G6) process where the G6 glass substrate measures 150 X 185 cm, the size of a double bed. One G6 glass substrate can cut 30 15-inch panels, compared with the G3.5 which can cut 4 panels and G1 which can only cut one 15-inch panel, the production capacity of the sixth generation factory is enlarged, and the relative cost is reduced. In addition, the large size of the G6 glass substrate can be cut into large-sized panels, which can produce eight 32-inch LCD TV panels, increasing the diversity of panel applications. Therefore, the global TFT LCD manufacturers are all invested in the new generation of plant manufacturing technology.

The TRANSISTor-LCD is an acronym for thin-film TFT Display. Simply put, TFT-LCD panels can be seen as two glass substrates sandwiched between a layer of liquid crystal. The upper glass substrate is connected to a Color Filter, while the lower glass has transistors embedded in it. When the electric field changes through the transistor, the liquid crystal molecules deflect, so as to change the polarization of the light, and the polarizing film is used to determine the light and shade state of the Pixel. In addition, the upper glass is fitted to the color filter, so that each Pixel contains three colors of red, blue and green, which make up the image on the panel.

The luminescence principle is tied to the vapor electroplating organic film between the transparent anode and the metal cathode. The electron and electric hole are injected, and the energy is converted into visible light by the composite between the organic film. And can match different organic materials, emit different colors of light, to achieve the requirements of the full-color display.

The organic light display can be divided into Passive Matrix (PMOLED) and Active Matrix (AMOLED) according to the driving mode. The so-called active driven OLED(AMOLED) can be visualized in the Thin Film Transistor (TFT) as a capacitor that stores signals to provide the ability to visualize the light in a grayscale.

Although the production cost and technical barriers of passive OLED are low, it is limited by the driving mode and the resolution cannot be improved. Therefore, the application product size is limited to about 5″, and the product will be limited to the market of low resolution and small size. For high precision and large picture, the active drive is mainly used. The so-called active drive is capacitive to store the signal, so when the scanning line is swept, the pixel can still maintain its original brightness. In the case of passive drive, only the pixels selected by the scan line are lit. Therefore, in an active-drive mode, OLED does not need to be driven to very high brightness, thus achieving better life performance and high resolution.OLED combined with TFT technology can realize active driving OLED, which can meet the current display market for the smoothness of screen playback, as well as higher and higher resolution requirements, fully display the above superior characteristics of OLED.

The technology to grow The TFT on the glass substrate can be amorphous Silicon (A-SI) manufacturing process and Low-Temperature Poly-Silicon (LTPS). The biggest difference between LTPS TFT and A-SI TFT is the difference between its electrical properties and the complicated manufacturing process. LTPS TFT has a higher carrier mobility rate, which means that TFT can provide more current, but its process is complicated.A-si TFT, on the other hand, although a-Si’s carrier movement rate is not as good as LTPS’s, it has a better competitive advantage in cost due to its simple and mature process.Au Optronics is the only company in the world that has successfully combined OLED with LTPS and A-SI TFT at the same time, making it a leader in active OLED technology.

Polysilicon is a silicon-based material about 0.1 to several um in size, composed of many silicon particles. In the semiconductor manufacturing industry, polysilicon should normally be treated by Low-Pressure Chemical Vapor Deposition. If the annealing process is higher than 900C, this method is known as SPC. Solid Phase Deposition. However, this method does not work in the flat display industry because the maximum temperature of the glass is only 650C. Therefore, LTPS technology is specifically applied to the manufacture of flat displays.

The LTPS membrane is much more complex than a-SI, yet the LTPS TFT is 100 times more mobile than A-SI TFT. And CMOS program can be carried out directly on a glass substrate. Here are some of the features that p-SI has over A-SI:

2. Vehicle for OLED: High mobility means that the OLED Device can provide a large driving current, so it is more suitable for an active OLED display substrate.

The “reflective” architecture USES an external light source to display the image via a reflector, which saves electricity but is harder to see in the absence of an external light source.

Display screen is everywhere nowadays. Do you still remember the TVs or computer monitors 20 years ago? They were quadrate, huge and heavy. Now let’s look at the flat, thin and light screen in front of you, have you ever wondered why is there such a big difference?

Actually, the monitors 20 year ago were CRT (Cathode Ray Tube) displays, which requires a large space to run the inner component. And now the screen here in your presence is the LCD (Liquid Crystal Display) screen.

As mentioned above, LCD is the abbreviation of Liquid Crystal Display. It’s a new display technology making use of the optical-electrical characteristic of liquid crystal.

Liquid crystal is a state of substance that has both the characteristics of liquid and solid crystal. It don’t emit light itself, but it can let the light pass perfectly in specific direction. Meanwhile, liquid crystal molecule will rotate under the influence of a electric field, and then the light goes through it will rotate too. That said, liquid crystal can be a switch of light, which is the key in display technology.

STN LCD: STN is for Super-twisted Nematic. The liquid crystal in STN LCD rotate more angles than that in TN LCD, and have a different electrical feature, allowing STN LCD to display more information. There are many improved version of STN LCD like DSTN LCD (double layer) and CSTN LCD (color). This LCD is used in many early phones, computers and outdoor devices.

TFT LCD: TFT is for Thin Film Transistor. It’s the latest generation of LCD technology and has been applied in all the displaying scenario including electronic devices, motor cars, industrial machines, etc. When you see the word ‘transistor’, you may realize there’s integrated circuits in TFT LCD. That’s correct and the secret that TFT LCD has the advantage of high resolution and full color display.

In a simple way, we can divide TFT LCD into three parts, from bottom to top they are: light system, circuit system and light and color control system.In manufacturing process, we’ll start from inner light and color control system and then stretch out to whole module.

It’s accustomed to divide TFT LCD manufacturing process into three main part: array, cell and module. The former two steps are about the production of light and color control system, which contains TFT, CF (color filter) and LC (liquid crystal), named a cell. And the last step is the assembly of cell, circuit and light system.

Now let’s turn to the production of TFT and CF. Here is a common method called PR (photoresist) method. The whole process of PR method will be demonstrated in TFT production.

TFT (Thin Film Transistor) LCD (Liquid Crystal Display) dominates the world flat panel display market now. Thanks for its low cost, sharp colors, acceptable view angles, low power consumption, manufacturing friendly design, slim physical structure etc., it has driven CRT(Cathode-Ray Tube) VFD ( Vacuum Fluorescent Display) out of market, squeezed LED (Light Emitting Diode) displays only to large size display area. TFT LCD displays find wide applications in TV, computer monitors, medical, appliance, automotive, kiosk, POS terminals, low end mobile phones, marine, aerospace, industrial meters, smart homes, handheld devices, video game systems, projectors, consumer electronic products, advertisement etc. For more information about TFT displays, please visit our knowledge base.

What we are talking about TFT LCD, it is a LCD that uses TFT technology to improve image qualities such as addressability and contrast. A TFT LCD is an active matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven LCDs with a few segments without TFT in each pixel.

The TN type TFT LCD display is one of the oldest and lowest cost type of LCD display technology. TN TFT LCD displays have the advantages of fast response times, but its main advantages are poor color reproduction and narrow viewing angles. Colors will shift with the viewing angle. To make things worse, it has a viewing angle with gray scale inversion issue. Scientist and engineers took great effort trying to resolve the main genetic issues. Now, TN displays can look significantly better than older TN displays from decades earlier, but overall TN TFT LCD display has inferior viewing angles and poor color in comparison to other TFT LCD technologies.

IPS TFT LCD display was developed by Hitachi Ltd. in 1996 to improve on the poor viewing angle and the poor color reproduction of TN panels. Its name comes from its in-cell twist/switch difference compared with TN LCD panels.The liquid crystal molecules move parallel to the panel plane instead of perpendicular to it. This change reduces the amount of light scattering in the matrix, which gives IPS its characteristic of much improved wide viewing angles and color reproduction. But IPS TFT display has the disadvantages of lower panel transmission rate and higher production cost compared withTN type TFT displays, but these flaws can’t prevent it to be used in high end display applications which need superior color, contrast, viewing angle and crispy images.

The mono-domain VA technology is widely used for monochrome LCD displays to provide pure black background and better contrast, its uniformly alignment of the liquid crystal molecules makes the brightness changing with the viewing angle.

MVA solves this problem by causing the liquid crystal molecules to have more than one direction on a single pixel. This is done by dividing the pixel into two or four regions – called domains – and by using protrusions on the glass surfaces to pretilt the liquid crystal molecules in the different directions. In this way, the brightness of the LCD display can be made to appear uniform over a wide range of viewing angles.

In 2004, Hydis Technologies Co., Ltd licensed its AFFS patent to Japan’s Hitachi Displays. Hitachi is using AFFS to manufacture high end panels in their product line. In 2006, Hydis also licensed its AFFS to Sanyo Epson Imaging Devices Corporation. (Reference)

The AFFS is similar to the IPS in concept; both align the crystal molecules in a parallel-to-substrate manner, improving viewing angles. However, the AFFS is more advanced and can better optimize power consumption. Most notably, AFFS has high transmittance, meaning that less of the light energy is absorbed within the liquid crystal layer and more is transmitted towards the surface. IPS TFT LCDs typically have lower transmittances, hence the need for the brighter backlight. This transmittance difference is rooted in the AFFS’s compact, maximized active cell space beneath each pixel.

If you want to buy a new monitor, you might wonder what kind of display technologies I should choose. In today’s market, there are two main types of computer monitors: TFT LCD monitors & IPS monitors.

The word TFT means Thin Film Transistor. It is the technology that is used in LCD displays. We have additional resources if you would like to learn more about what is a TFT Display. This type of LCDs is also categorically referred to as an active-matrix LCD.

These LCDs can hold back some pixels while using other pixels so the LCD screen will be using a very minimum amount of energy to function (to modify the liquid crystal molecules between two electrodes). TFT LCDs have capacitors and transistors. These two elements play a key part in ensuring that the TFT display monitor functions by using a very small amount of energy while still generating vibrant, consistent images.

Industry nomenclature: TFT LCD panels or TFT screens can also be referred to as TN (Twisted Nematic) Type TFT displays or TN panels, or TN screen technology.

IPS (in-plane-switching) technology is like an improvement on the traditional TFT LCD display module in the sense that it has the same basic structure, but has more enhanced features and more widespread usability.

These LCD screens offer vibrant color, high contrast, and clear images at wide viewing angles. At a premium price. This technology is often used in high definition screens such as in gaming or entertainment.

Both TFT display and IPS display are active-matrix displays, neither can’t emit light on their own like OLED displays and have to be used with a back-light of white bright light to generate the picture. Newer panels utilize LED backlight (light-emitting diodes) to generate their light hence utilizing less power and requiring less depth by design. Neither TFT display nor IPS display can produce color, there is a layer of RGB (red, green, blue) color filter in each LCD pixels to produce the color consumers see. If you use a magnifier to inspect your monitor, you will see RGB color in each pixel. With an on/off switch and different level of brightness RGB, we can get many colors.

Winner. IPS TFT screens have around 0.3 milliseconds response time while TN TFT screens responds around 10 milliseconds which makes the latter unsuitable for gaming

Winner. the images that IPS displays create are much more pristine and original than that of the TFT screen. IPS displays do this by making the pixels function in a parallel way. Because of such placing, the pixels can reflect light in a better way, and because of that, you get a better image within the display.

As the display screen made with IPS technology is mostly wide-set, it ensures that the aspect ratio of the screen would be wider. This ensures better visibility and a more realist

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey