tft lcd frame buffer quotation

I"m talking about some nxp mcu like lpc1788 with the lcd controller integrated into the chip so you don"t need to use an external lcd controller. The models you are listing don"t have the lcd controller integrated,.

The main advantage of having it external is that the lcd controller has got its own memory for the frame buffer and it"s easing the load on the cpu because once you load the data it will keep refreshing the screen without calling the cpu and it doesn"t use the cpu ram memory.

In the other case if the lcd controller is integrated in the mcu you can do some nice "tricks" like using a colour look up table or palette so that your graphics takes less memory and because the framebuffer is in your internal memory it is even easier to manipulate.

Also consider that in case of lcd controller not integrated in the panel (so by using the one integrated in the mcu or another one on board as a separate chip) you can exchange panel quite easily so you are not tied to a single manufacturer as long on the lcd side you find the same interface like the 24 bit or the 18 bit.

Now, I"m considering the case of an lcd panel of 640x480 and 8 bit per colour which leads us to 640x480x8 = 2457600 bit / 8 = 307200 / 1024 = 300 KByte of ram needed for the framebuffer.

The integrated lcd controller has got a dma which will take care of transferring the data from external ram used for the frambuffer to the lcd controller which will then translate it and send to lcd but the problem is that the external bus and also the internal bus of the mcu(difficult to draw this here :-) ) is then shared by the lcd controller, which keeps accessing the memory to continuously refresh the screen, and the mcu which is fetching instructions or variables.

Because the internal bus gives priority to the mcu it means that probably you will see tearing effect on the lcd like reported by some people on the nxp question and answer (pasting the link here takes you to the general support page and not to the answer I found) because the mcu gain priority when accessing bus and memory and lcd refresh is delayed.

In the answer I found on Nxp support, they say you can actually change priority so that lcd screen has an higher priority then the cpu, problem is that in doing so the cpu and then your software will be slowed down by the lcd controller continuously refreshing and accessing memories.

The STM32 LTDC has a peripheral called LTDC LCD TFT Display Controllerwhichprovides a digital parallel interface(DPI) for a variety of LCD and TFT panels. It sends RGB data in parallel to the display and generates signals for horizontal and vertical synchronization (HSYNC, VSYNC), as well as pixel clock (PCLK) and not data enable (DE) signals:

The LTDC has two layers which can be configured, enabled and disabled independently, each with its own FIFO buffer. Layer order is fixed and layer2 is alway on top of layer1. Layer can be enabled writing the LEN Layer Enable bit in the LTDC_LxCR Layer x Control Register. Each layer gets its data from a framebuffer in memory and the start address is written in LTDC_LxCFBAR Layer x Color Frame Buffer Address Register. The frame buffer contains the display frame data in one of eight configurable pixel format: LTDC_LxPFCR Layer x Pixel Format Configuration Registeris configured to choose the pixel format used to store data into the frame buffer. The available pixel formats are:

The frame buffer has a configurable line length (in bytes) in the LTDC_LxCFBLR Layer x Color Frame Buffer Length Register and a configurable total number of lines in the LTDC_LxCFBLNR Layer x Color Frame Buffer Line Number Register. It also has a configurable line pitch, which indicates the distance in bytes between the start of a line and the beginning of the next line, also configured in the LTDC_LxCFBLRregister, and expressed in bytes. These parameters are used by the LTDC to fetch data from the frame buffer to the layer FIFO. If set to less byte than needed, a FIFO underrun interrupt will trigger (if enabled), if set to more bytes than required the rest of the data loaded into the layer’s FIFO is discarded.

Line length parameter is the number of bytes in a line plus three (so the total line length is number of pixels * bits per pixel + 3). These parameters, together with the layer windowing settings, are useful if we want to display part of an image contained in the frame buffer, as I’ll show later.

In this example I use the display on the STM32F429-Discovery board, which is driven by the ILI9341 display controller. The ILI9341 can drive a QVGA (Quarter VGA) 240×320 262,144 colors LCD display. The controller can be configured via SPI (or parallel interface, depending on the panel settings) to use a digital parallel 18 bit RGB interface (since only 6 lines per color channel are wired on the board to the LTDC). Since the display pixel format is less than 8 bit per channel (RGB666 in this case), the RGB display data lines are connected to the most significant bits of the LTDC controller RGB data lines:

Before enabling the LTDC we must configure the clock system. The LTDC uses a specific clock LCD_CLOCK to generate the pixel clock signal and it must be configured and enabled during the system initialization phase:

To display an image we must convert an image file to an array (possibly a const one, so it can be stored in flash memory) of bytes. To do this I used LCD image converter, a simple but powerful application that can convert a file to a variety of different pixel formats:

Once the image is converted to a byte array the generated header file is included and the array address can be used as the frame buffer starting address in the LTDC_LxCFBAR register. Layer window parameters are configured according to the image size (240 x 320, I rotated the image to fit the display in portrait mode).

Now I’m just showing 100 x 100 pixels of the layer 1 image so I configured the color buffer line length as 100 and the color buffer number of lines as 100. The line pitch value indicates that a framebuffer line is still 240 * 3 bytes long so the controller knows how to fetch bytes from the frame buffer correctly. I also moved the start of the window adding an offset of 50 pixels and 50 scan lines. The default background color is used where the layer isn’t used (the layer background color is a solid green):

Using two layers and playing with the layer window size and position allows to create simple animations by simply moving the layer window around the frame:

Shadow configuration registers are reloaded each vertical blanking period (after the last line has been drawn) and the code waits for the next frame by polling the VSYNCS flag of the LTDC_CDSR Current Display Status Register, whose bits contain the state of the synchronization signals (high if they’re asserted, no matter the polarity configured). Running the code we get a nice smooth animation:

Double buffer is used when we want the code to write on a frame buffer while another buffer is being read by the LTDC. This avoids corrupting the data being displayed on the screen. The buffers are switched during the vertical blanking period using polling or interrupts.

figure n: while the code writes to the back buffer the LTDC fetches data from the front (active) buffer. Famebuffers are switched during vertical blanking period.

In this example the framebuffers have a RGB888 color depth and for a 240×320 display that makes 225 KiB of memory for each buffer (3 bytes per pixel x 240 x 320 pixels) so they must be stored in external SRAM (the STM32F429I-DISCOVERY has a 64Mbit external SRAM so we’re good). The FMC Flexible Memory Controller has to be initialized and the address of the two frame buffers has to be configured. Drawing on the framebuffer is a matter of writing the right bytes in order to change the color. Once all pixels are drawn (bytes are written) the buffers are switched and the code can draw the next frame:

Now as soon as a frame is done with, calling LTDC_switch_framebuffer() waits for the vertical synchronization period and swaps the buffers. If the code is faster than the display refresh rate (70Hz in our case) it waits for the LTDC to complete drawing the frame.

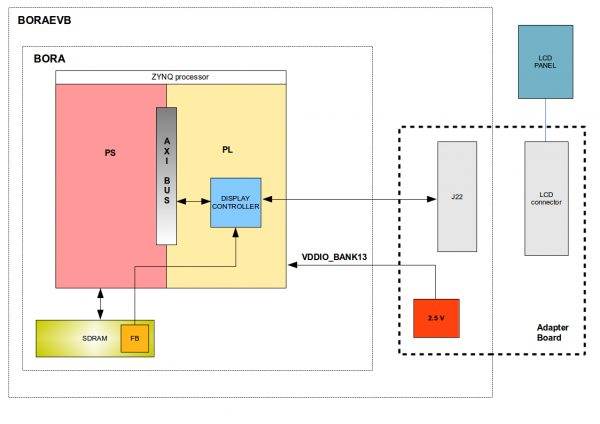

This application note describes the interfacing of Ampire AM-800480STMQW-TA1 display to BoraEVB and BoraXEVB. Main characteristics of this 7" TFT LCD panel are:

In case of BoraXEVB, no adapter board is needed. LCD panel is directly connected to J26 connector where PL bank 13"s signals implementing LVDS interface are routed (see page 14 of the schematics). I/O voltage of bank 13 is set to 2.5V by configuring JP25 as shown in the following table.

To implement frame buffer, a portion of main SDRAM is used. This area is allocated at runtime by linux frame buffer driver. Even if LCD is 18 bpp, each pixel is represented by 32-bit word in memory. In fact each pixel is in RGB666 format, so for each colour only the six most significant bits of the frame buffer RGB888 are used to drive the display.

(*) This signal is used to control backlight. It is usually driven by a PWM signal whose duty cycle is proportional to backlight intensity. For the sake of simplicity, in this project this signal is driven by a GPIO, thus only two intensity levels are supported (0% and 100%). This is a CMOS 2.5V level signal. Make sure that voltage levels of this signal are compatible with LCD backlight input.

(*) This signal is used to control backlight. It is usually driven by a PWM signal whose duty cycle is proportional to backlight intensity. For the sake of simplicity, in this project this signal is driven by a GPIO, thus only two intensity levels are supported (0% and 100%). This is a CMOS 2.5V level signal. Make sure that voltage levels of this signal are compatible with LCD backlight input.

Once the kernel has completed boot, frame buffer can be accessed from user space applications via /dev/fb0 device file (for more details please refer to https://www.kernel.org/doc/Documentation/fb/framebuffer.txt).

An LCD (Liquid Crystal Display) is a standard display device for hand-held embedded systems. Today, color TFT (Thin-Film Transistor) LCDs are common even in cost-effective equipments. An LCD display system is composed of an LCD panel, a frame buffer memory, an LCD and frame buffer controller, and a backlight inverter and lamp. All of them are heavy power consumers, and their portion becomes much more dominant when running interactive applications. This is because interactive applications are often triggered by human inputs and thus result in a lot of slack time in the CPU and memory system, which can be effectively used for dynamic power management. In this paper, we introduce low-power LCD display schemes as a system-level approach. We accurately characterize the energy consumption at the component level and minimize energy consumption of each component without appreciable display quality degradation. We develop several techniques such as variable-duty-ratio refresh, dynamic-color-depth control and backlight luminance dimming with brightness compensation or contrast enhancement.

If the display has no internal frame buffer, then the frame buffer has to be in local memory, which is expensive in terms of memory consumption, but the tradeoff is that the local memory is fast to read as well as write, and in particular is a LOT faster in random access patterns (at least compared to the interfaces typical for these sorts of displays that DO have internal frame buffers). That speed makes it a lot simpler to do more complicated graphics, because it"s easier to update arbitrary sections of the screen. Having internal memory also allows for DMA, and in fact some parts like the STM32F7/H7 family have DMA engines specifically designed to support graphical interfaces, to reduce CPU overhead. If you have enough memory to double buffer, then there"s a bonus advantage that you can swap the entire image at once and get nice crisp updates with no tearing. However this sort of thing locks you into higher performance MCUs that can support the attendant memory and interface speed requirements (not to mention pin counts).

When the frame buffer is in the display, by contrast, you generally have a much more limited rate at which you can write any changes to the screen, because not only is the interface data rate lower but typically you have to transfer commands before writing or reading, which means that random accesses are particularly expensive. This isn"t such a problem for simple character/glyph/fill types of screens because those work well with writes to rectangular areas, which allows for more efficient bulk writes to the display. Doing anything that involves partial transparency within a rectangular area, even something like a circle drawn on a background color, or text drawn over something other than a basic background color, is more complicated. That sort of thing kind of needs a local frame buffer, which gets back to needing a bunch of memory. Transferring the whole buffer to the display would still be expensive, especially on a particularly slow interface, and can result in visible tearing, so it can be beneficial to have all of the display module track the "dirty" areas of the frame buffer and then only write those areas when it"s time to update the display. I"ve done this on OLED displays where the display only allows page-wide writes, the interface is slow, and the memory requirement is low, it"s not that hard and has a significant performance improvement. Below a certain display size the frame buffer can be a reasonable tradeoff for not having to keep track of what logical objects are supposed to be on the screen anyway, and it can greatly simplify the rest of the graphics software.

So you kind of have to do the math on how fast you need to be able to update the display and how long it will take to do various size writes to the display and see how that fits in your application requirements. A full write to a 256x256x16bit display at 21Mbps ends up taking ~52ms (a little longer due to overhead, possible framing requirements, etc). If that"s acceptable, and you can spare 128kB for a frame buffer, then it would be pretty easy to do arbitrary redraws in the local buffer and just kick off a DMA transaction when you"re ready. If that"s not fast enough, you can track the areas that are changed and only rewrite those. If you don"t have the memory for a frame buffer, then you"re going to need to compensate with some extra computational complexity or simplify your graphics.

This, given the 320kB (+change) on a 746NG gives some elbow room also for double buffering, but using the internal RAM controller is no problem, if you get the Disco.

INT070ATFT and INT070ATFT-TS are embedded display driver boards based on the Displaytech 7 inch 800 x 480 RGB resolution TFT display module. This embedded driver board includes a 7" standard or resistive touchscreen display. Mounted on the embedded board is the Solomon Systech SSD1963 LCD controller that supports common RAM-less LCD drivers and offers the following features and benefits:

SSD1963 (among others) includes a (rather) deep frame buffer (sram) which holds the pixel data which is then continually sent to the TFT screen. (that"s refreshed)

Now the frame buffer is written to by the MCU. And may be read from - as well. And - each/every time that the display image is to be changed - the frame buffer must again be written. (thus the earlier "once" statement must be extended...)

There"s another data path w/in the frame buffer (in addition to MCU < -- > Frame Buffer.) And that"s (Frame Buffer -- > TFT.) This path sees a continuous "flow" of data - which must occur rapidly enough to prevent image flicker. There"s a rule of thumb - the more pixels, the greater the color depth, the higher the desired update rate - the higher must be the frame buffer to TFT data transfer rate.

Our group has used this SSD Controller (among many others). It has a limitation in that it "tops out" - and may not support "latest/greatest" TFT panels. (especially those of size) Beyond this - pcb design must employ proper HF layout rules and the many SSD Registers must be fully understood & correctly (and sequentially) loaded. Great attention to detail (at least during prototyping) is required. (i.e. not a "first nor second" project...)

The display industry in general appears to be moving to COF or COB Controllers (see below) which eliminate the need for the "dual interconnect" demands which SSD (and it"s ilk) demand. Those dual interconnects consist of wide bus interface between MCU & SSD - and then from SSD to TFT. Those newer TFTs eliminate the TFT Controller to TFT Display connection burden - thus provide substantial - Size AND Cost savings...

Hi guys, welcome to today’s tutorial. Today, we will look on how to use the 1.8″ ST7735 colored TFT display with Arduino. The past few tutorials have been focused on how to use the Nokia 5110 LCD display extensively but there will be a time when we will need to use a colored display or something bigger with additional features, that’s where the 1.8″ ST7735 TFT display comes in.

The ST7735 TFT display is a 1.8″ display with a resolution of 128×160 pixels and can display a wide range of colors ( full 18-bit color, 262,144 shades!). The display uses the SPI protocol for communication and has its own pixel-addressable frame buffer which means it can be used with all kinds of microcontroller and you only need 4 i/o pins. To complement the display, it also comes with an SD card slot on which colored bitmaps can be loaded and easily displayed on the screen.

Due to variation in display pin out from different manufacturers and for clarity, the pin connection between the Arduino and the TFT display is mapped out below:

We will use two libraries from Adafruit to help us easily communicate with the LCD. The libraries include the Adafruit GFX library which can be downloaded here and the Adafruit ST7735 Library which can be downloaded here.

We will use two example sketches to demonstrate the use of the ST7735 TFT display. The first example is the lightweight TFT Display text example sketch from the Adafruit TFT examples. It can be accessed by going to examples -> TFT -> Arduino -> TFTDisplaytext. This example displays the analog value of pin A0 on the display. It is one of the easiest examples that can be used to demonstrate the ability of this display.

The first thing, as usual, is to include the libraries to be used after which we declare the pins on the Arduino to which our LCD pins are connected to. We also make a slight change to the code setting reset pin as pin 8 and DC pin as pin 9 to match our schematics.

Next, we create an object of the library with the pins to which the LCD is connected on the Arduino as parameters. There are two options for this, feel free to choose the most preferred.

I"m trying to interface an STM32F1 with LCD using the FSMC. I was trying to do double buffer animation, and copy the frame buffer array to the LCD-Buffer. The thing is when writing a blocking code like the following, it will consume a the CPU a lot of waiting cycles, due to the interface,..etc. Is there another idea or a work around ?

I tried to write a small FSM with a simple counter that is used in the super-loop main, that keeps increment, until you get to the end of the frame buffer, then you stop copying, but it seems that operation is so fast that the LCD controller can handle.

Direct accessible frame buffer means the frame buffer is accessible directly via data- and address bus. For that case the driver GUIDRV_Lin could be used. This driver supports all display controllers with linear video memory accessible via direct interface. The driver does only manage the content of the video memory. It is independent of the register interface of the display controller and can be used for managing each linear mapped video memory.

Whereas the direct interface accesses the video memory directly by the address bus of the CPU, the indirect interface requires a more complex communication with the display controller to get access to the video memory. On LCD controller side that interface is often called "MPU" interface. It normally consists of a set of control- and data lines. on emWin side this requires a few simple communication routines. These are getting called for writing and reading operations to/from the LCD controller.

The following table lists the currently available run-time configurable drivers developed for the current interface of emWin:Display driverSupported display controllers / PurposeSupported bits/pixelGUIDRV_BitPlainsThis driver can be used for solutions without display controller. It manages separate bitplains for each color bit. Initially it has been developed to support a solution for an R32C/111 which drives a TFT display without display controller. It can be used for each solution which requires the color bits in separate plains.1 - 8

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey