3.2 inch tft lcd shield touch screen made in china

I purchased this LCD Touch along with the TFT LCD Mega Shield 2.2 shield for the Arduino Mega also from Amazon. It was easy to figure out getting the UFTF library from Rinky Dink Electronics to work. I used "UTFT myGLCD(CTE32_R2,38,39,40,41);" or "UTFT myGLCD(ILI9341_16,38,39,40,41);" and they both worked. I had a very hard time getting the actual touch function to work. The default of "URTouch myTouch(6, 5, 4, 3, 2);" for the touch library is correct on the Mega. It turned out to be a connection issue. I just reseated the board a couple of times and it worked. I recommend testing this LCD with the examples from the URTouch library. The online examples are too complicated and have too many dependencies to break. Get the basic screen and touch working first. Don"t forget to debounce the touch with a short delay. This screen is touchy which makes it fast to enter numbers for me. It worked just powered from my PC with a USB cable to the Arduino Mega. Very Easy.

※ Price Increase NotificationThe TFT glass cell makers such as Tianma,Hanstar,BOE,Innolux has reduced or stopped the production of small and medium-sized tft glass cell from August-2020 due to the low profit and focus on the size of LCD TV,Tablet PC and Smart Phone .It results the glass cell price in the market is extremely high,and the same situation happens in IC industry.We deeply regret that rapidly rising costs for glass cell and controller IC necessitate our raising the price of tft display.We have made every attempt to avoid the increase, we could accept no profit from the beginning,but the price is going up frequently ,we"re now losing a lot of money. We have no choice if we want to survive. There is no certain answer for when the price would go back to the normal.We guess it will take at least 6 months until these glass cell and semiconductor manufacturing companies recover the production schedule. (Mar-03-2021)

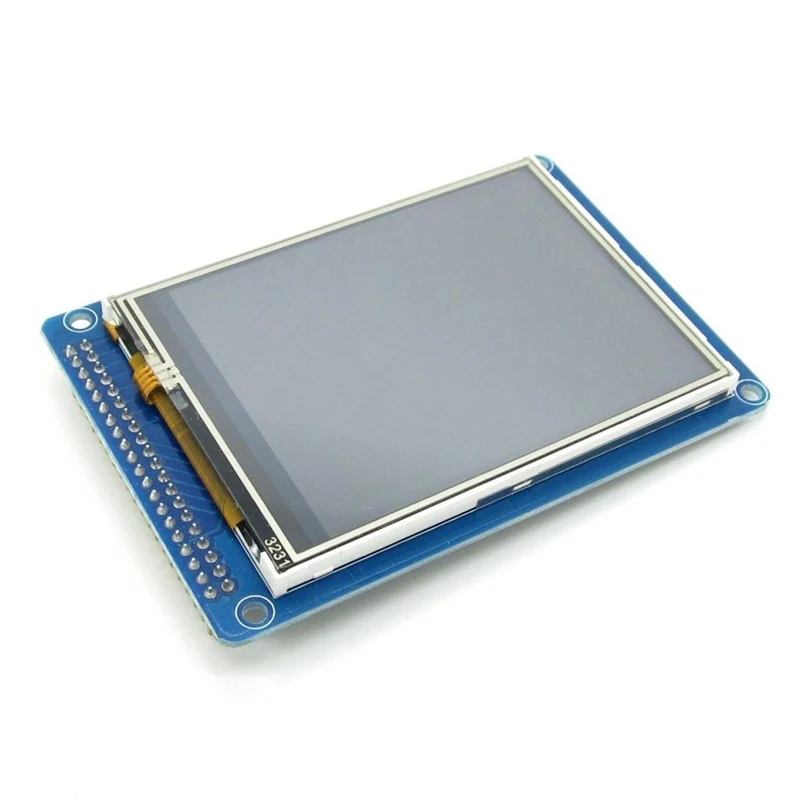

ER-TFT032-2 is 240x320 dots 3.2 " color tft lcd module display with ILI9320 controller and optional 4-wire resistive touch panel,superior display quality,super wide viewing angle and easily controlled by MCU such as 8051, PIC, AVR, ARDUINO ARM and Raspberry PI.It can be used in any embedded systems,industrial device,security and hand-held equipment which requires display in high quality and colorful image.It supports 8080 16-bit parallel interface. .FPC is soldering type,there is no need for zif connector.Lanscape mode is also available.

Fully assembled 3.2inch display with 320x240 pixels TFT LCD and a resistive touch overlay. Just plug it on top of ODROID-C1. 2x13 tall female header is already soldered on the PCB.

This is a 3.2 inch TFT t o u c h screen expansion board using standard Shield interface and it has good compatibility. It integrates a 3.2-inch t o u c h screen, I2C temperature sensor, TF card holder, level conversion circuit, and the secondary development is easy.

No! For about the price of a familiar 2x16 LCD, you get a high resolution TFT display. For as low as $4 (shipping included!), it"s possible to buy a small, sharp TFT screen that can be interfaced with an Arduino. Moreover, it can display not just text, but elaborate graphics. These have been manufactured in the tens of millions for cell phones and other gadgets and devices, and that is the reason they are so cheap now. This makes it feasible to reuse them to give our electronic projects colorful graphic displays.

There are quite a number of small cheap TFT displays available on eBay and elsewhere. But, how is it possible to determine which ones will work with an Arduino? And what then? Here is the procedure:ID the display. With luck, it will have identifying information printed on it. Otherwise, it may involve matching its appearance with a picture on Google images. Determine the display"s resolution and the driver chip.

Find out whether there is an Arduino driver available. Google is your friend here. Henning Karlsen"s UTFT library works with many displays. (http://www.rinkydinkelectronics.com/library.php?i...)

Load an example sketch into the Arduino IDE, and then upload it to the attached Arduino board with wired-up TFT display. With luck, you will see text and/or graphics.

Note that these come in two varieties, red and black. The red ones may need a bit of tweaking to format the display correctly -- see the comments in the README.md file. The TFT_ILI9163C.h file might need to be edited.

It is 5-volt friendly, since there is a 74HC450 IC on the circuit board that functions as a level shifter. These can be obtained for just a few bucks on eBay and elsewhere, for example -- $3.56 delivered from China. It uses Henning Karlsen"s UTFT library, and it does a fine job with text and graphics. Note that due to the memory requirement of UTFT, this display will work with a standard UNO only with extensive tweaking -- it would be necessary to delete pretty much all the graphics in the sketch, and just stay with text.

This one is a 2.2" (diagonal) display with 176x220 resolution and parallel interface. It has a standard ("Intel 8080") parallel interface, and works in both 8-bit and 16-bit modes. It uses the S6D0164 driver in Henning Karlsen"s UTFT library, and because of the memory requirements of same, works only with an Arduino Mega or Due. It has an SD card slot on its back

This one is a bit of an oddball. It"s a clone of the more common HY-TFT240, and it has two rows of pins, set at right angles to one another. To enable the display in 8-bit mode, only the row of pins along the narrow edge is used. The other row is for the SD card socket on the back, and for 16-bit mode. To interface with an Arduino ( Mega or Due), it uses Henning Karlsen"s UTFT library, and the driver is ILI9325C. Its resolution is 320x240 (hires!) and it incorporates both a touch screen and an SD card slot.

Having determined that a particular TFT display will work with the Arduino, it"s time to think about a more permanent solution -- constructing hard-wired and soldered plug-in boards. To make things easier, start with a blank protoshield as a base, and add sockets for the TFT displays to plug into. Each socket row will have a corresponding row next to it, with each individual hole "twinned" to the adjacent hole in the adjoining row by solder bridges, making them accessible to jumpers to connect to appropriate Arduino pins. An alternative is hard-wiring the socket pins to the Arduino pins, which is neater but limits the versatility of the board.

The key to an effective DIY shield is a neat and logical layout. Sketching the prospective shield on quadrille (graph) paper may be helpful. A multitester or continuity tester might be useful for detecting wiring and soldering errors.

In step 5, you mention that the TFT01 display can"t be used with the UTFT library on an Arduino Uno because of its memory requirements. It can - all you have to do is edit memorysaver.h and disable any display models you"re not using.

Tho I realize this is quickly becoming legacy hardware, these 8,16 bit parallel spi with 4 wire controller 3.2in Taft touch display 240x380. It has become very inexpensive with ally of back stock world wide so incorporating them into any project is easier then ever. Sorry to my question. I’m having difficulty finding wiring solution for this lcd. It is a sd1289 3.3 and 5v ,40 pin parallel 8,16 bit. I do not want to use a extra shield,hat or cape or adapter. But there’s a lot of conflicting info about required lvl shifters for this model any help or links to info would be great .. thank you. I hope I gave enough information to understand what I’m adoing

hooking up and adding a lib is no piece of cake insure the screen you buy is arduino ready and sold by a reputable shop with step by step directions...WCH0

Thanks for the wealth of knowledge! It is amazing at what is possible with items the average person can easily acquire. I hope to put some of your tips to use this winter as I would like to build sensors and other items for home automation and monitoring. Being able to have small displays around the house in addition to gathering and controlling things remotely will help the family see room conditions without going to the computer. The idea of a touchscreen control for cheap is mind blowing.

NMLCD-32240320-CTP-CLBis a colour active matrix LCD module incorporating amorphous silicon TFT (Thin Film Transistor). It is composed of a colour TFT-LCD panel, driver IC, FPC and a back light unit and with a Capacitive Touch Panel (CTP), with a Cover Lens Bezel (CLB). The module display area contains 240 x 320 pixels. This product accords with RoHS environmental criterion.

Shenzhen SLS Industrial Co.,ltd established in 2003, is a professional LCD module manufacturer and solution provider. We have 1 full-auto COG assembly line, 2 semi-auto assembly line, backlight assembly line, no dust TP bonding line and manufacturing tech support, we can provide unique, innovative and cost effective LCD module development and manufacturing. Our product range includes: middle-small size TFT LCD, industrial capacitive touch panel... Our LCD products have been widely used in communications, GPS, Equipment, electronic audio-visual, instrumentation, household appliances, PDA and other industries.

The TFT display is a kind of LCD that is connected to each pixel using a transistor and it features low current consumption, high-quality, high-resolution and backlight. This 2.8-inch full color LCD has a narrow PCB display. The resolution is 320×280 pixels and it has a four-wire SPI interface and white backlight.

A few weeks ago, I wrote this article about using a text variable as an array, either an array of strings or an array of numbers, using the covx conversion function in addition for the latter, to extract single elements with the help of the spstr function. It"s a convenient and almost a "one fits all" solution for most use cases and many of the demo projects or the sample code attached to the Nextion Sunday Blog articles made use of it, sometimes even without mentioning it explicitly since it"s almost self-explaining. Then, I got a message from a reader, writing: "... Why then didn"t you use it for the combined sine / cosine lookup table in the flicker free turbo gauge project?"105 editions of the Nextion Sunday blog in a little over two years - time to look back and forth at the same time. Was all the stuff I wrote about interesting for my readers? Is it possible at all to satisfy everybody - hobbyists, makers, and professionals - at the same time? Are people (re-)using the many many HMI demo projects and code snippets? Is anybody interested in the explanation of all the underlying basics like the algorithms for calculating square roots and trigonometric functions with Nextion"s purely integer based language? Are optimized code snippets which allow to save a few milliseconds here and there helpful to other developers?Looking through the different Nextion user groups on social networks, the Nextion user forum and a few not so official but Nextion related forums can be surprising. Sometimes, Nextion newbies ask questions or have issues although the required function is well (in a condensed manner for the experienced developer, I admit) documented on the Nextion Instruction Set page, accessible through the menu of this website. On top of that, there is for sure one of my more than 100 Sunday blog articles which deals not only with that function, but goes often even beyond the usual usage of it. Apparently, I should sometimes move away from always trying to push the limits and listen to the "back to the roots!" calls by my potential readers...Do you remember the (almost) full screen sized flicker free and ultra rapid gauge we designed in June? And this without using the built-in Gauge component? If not, it"s time to read this article first, to understand today"s improvements. The June 2022 version does its job perfectly, the needle movement is quick and smooth, and other components can be added close to the outer circle without flickering since there is no background which needs constantly to be redrawn. But there was a minor and only esthetic weak point: The needle was a 1px thin line, sometimes difficult to see. Thus, already a short time after publishing, some readers contacted me and asked if there were a way to make the needle thicker, at least 2 pixels.Recently, when playing with a ESP32 based NodeMCU 32S and especially with its WiFi configuration, I did as (I guess) everybody does: I loaded an example sketch to learn more about the Wifi library. When you set up the ESP32 as an access point, creating its own wireless network, everything is pretty straightforward. You can easily hard code the Wifi name (SSID) and the password. But what about the client mode ? Perhaps one needs to use it in different environments. And then, a hard coded network name and password are definitively not the best solution. Thus, I thought, why not use a Nextion HMI for a dynamic WiFi setup functionality?Although the Nextion MIDI I/O interface has been primarily designed as an add-on for Nextion HMI screens to transform these in fully autonomous MIDI devices as shown in previous blog posts here, it is also of great use for any Arduino based electronic music project! Many MIDI projects for Arduino suffer from a lack good hardware support. There are sophisticated code, excellent libraries and an infinity of use cases, but afterwards, things tend not to work in a rather rough environment in the studio or on stage. That"s because two resistors and a few Dupont wires on a breadboard besides the Arduino are not really an interface which could drive your Synth, Sequencer, or Drum machine over a 5m long MIDI cable.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey