lcd panel price trend 2020 for sale

Prices for all TV panel sizes fluctuated and are forecast to fluctuate between 2020 and 2022. The period from March 2020 to July 2021 saw the biggest price increases, when a 65" UHD panel cost between 171 and 288 U.S. dollars. In the fourth quarter of 2021, such prices fell and are expected to drop to an even lower amount by March 2022.Read moreLCD TV panel prices worldwide from January 2020 to March 2022, by size(in U.S. dollars)Characteristic32" HD43" FHD49"/50" UHD55" UHD65" UHD------

DSCC. (January 10, 2022). LCD TV panel prices worldwide from January 2020 to March 2022, by size (in U.S. dollars) [Graph]. In Statista. Retrieved December 15, 2022, from https://www.statista.com/statistics/1288400/lcd-tv-panel-price-by-size/

DSCC. "LCD TV panel prices worldwide from January 2020 to March 2022, by size (in U.S. dollars)." Chart. January 10, 2022. Statista. Accessed December 15, 2022. https://www.statista.com/statistics/1288400/lcd-tv-panel-price-by-size/

DSCC. (2022). LCD TV panel prices worldwide from January 2020 to March 2022, by size (in U.S. dollars). Statista. Statista Inc.. Accessed: December 15, 2022. https://www.statista.com/statistics/1288400/lcd-tv-panel-price-by-size/

DSCC. "Lcd Tv Panel Prices Worldwide from January 2020 to March 2022, by Size (in U.S. Dollars)." Statista, Statista Inc., 10 Jan 2022, https://www.statista.com/statistics/1288400/lcd-tv-panel-price-by-size/

DSCC, LCD TV panel prices worldwide from January 2020 to March 2022, by size (in U.S. dollars) Statista, https://www.statista.com/statistics/1288400/lcd-tv-panel-price-by-size/ (last visited December 15, 2022)

THANK YOU FOR VISITING ENERGYTREND (HEREINAFTER REFERRED TO AS "THE WEBSITE"). THE WEBSITE, OWNED AND OPERATED BY TRENDFORCE CORP. (HEREINAFTER REFERRED TO AS "TRENDFORCE"), WILL COLLECT, HANDLE, AND USE PRIVATE USER DATA IN ACCORDANCE WITH THE PERSONAL INFORMATION PROTECTION LAW (HEREINAFTER "PERSONAL INFORMATION LAW") AND THE WEBSITE"S PRIVACY POLICY. THE WEBSITE AIMS TO RESPECT AND PROTECT ALL USERS" ONLINE PRIVACY RIGHTS. IN ORDER TO UNDERSTAND AS WELL AS PROTECT YOUR RIGHTS, PLEASE READ THE FOLLOWING TERMS CAREFULLY:

1.1. THE POLICY COVERS THE HANDLING OF THE PRIVATE INFORMATION EACH USER SHARES WITH TRENDFORCE WHILE VISITING OUR WEBSITES. IF A DIFFERENT PRIVATE POLICY HAS BEEN REFERED TO FOR SPECIFIC TRENDFORCE WEBSITES AND SERVICES, THAT POLICY WILL REPLACE OR SUPPLEMENT THE PRIVACY POLICY MENTIONED IN THIS DOCUMENT. THIS POLICY ALSO COVERS INDIVIDUALS LEGALLY RESIDING IN OR ORGANIZATIONS LEGALLY BASED IN MEMBER COUNTRIES OF THE EUROPEAN UNION (EU) AND ARE SUBJECTED TO EU GENERAL DATA PROTECTION REGULATION (GDPR) WITH REGARD TO PROVISION OF SERVICES AND PERSONAL DATA PROTECTION.

1.2. THIS POLICY IS NOT APPLICABLE TO EITHER COMPANIES OTHER THAN TRENDFORCE AND ITS SUBSIDIARIES OR PERSONNEL NOT EMPLOYED OR AUTHORIZED BY TRENDFORCE AND ITS SUBSIDIARIES.

2.4. THE WEBSITE COLLECTS TRANSACTION DATA BETWEEN YOU AND TRENDFORCE AND FROM RELEVANT BUSINESS PARTNERS. THESE INCLUDE SPECIFIC PRODUCTS AND SERVICES THAT ARE DIRECTLY OBTAINED FROM THE WEBSITE.

b. THIS WEBSITE WILL NOTIFY YOU ON MATTERS RELATED TO YOUR PERSONAL DATA BY EMAIL, OR TRENDFORCE CORP. WILL NOTIFY YOU BY OTHER MEANS (SUCH AS VIA TELEPHONE). CLIENTS ARE FULLY RESPONSIBLE FOR PROVIDING AN UPDATED, VALID, AND DELIVERABLE EMAIL ADDRESS THAT CAN RECEIVE NOTIFICATION EMAILS FROM TRENDFORCE CORP.

EXCEPT AS OTHERWISE EXPRESSEDLY PROVIDED BY GDPR OR ORDERED BY THE LAWS OF A COMPETENT JURISDICTION, CLIENTS CAN USE CUSTOMER EMAILServiceGDPR@energytrend.comTO CONTACT THIS WEBSITE TO EXERCISE THEIR RIGHTS PERTAINING TO THEIR ACCOUNT USER NAMES, ACCOUNT USER DATA, SESSION COOKIES, AND OTHER FORMS OF ACCOUNT DATA RECORDS. THESE RIGHTS INCLUDE RIGHT TO ACCESS, RIGHT TO RECTIFICATION, RIGHT TO BE FORGOTTEN/DATA ERASURE, RIGHT TO RESTRICTION OF PROCESSING, RIGHT OF DATA PORTABILITY, RIGHT TO OBJECT, AND ETC. TO EXERCISE THESE RIGHTS, A CLIENT MUST INCLUDE LEGALLY VALID AND VERIFICABLE PROOFS OF PERSONAL IDENITIFICATION ALONG WITH HIS/HER REQUEST. FURTHEMORE, THE CLIENT ISSUING THE REQUEST TO EXERCISE THESE RIGHTS MUST HAVE FUFILLED VARIOUS LEGAL OBLIGATIONS ON HIS/HER PART BEFOREHAND. AFTERWARDS, TRENDFORCE WILL FULFILL THE CLIENTS’ REQUEST/PROVIDE RESOLUTIONS WITHIN REASONABLE TIME AND EFFORT.

LCD panel prices have risen for 4 months in a row because of your home gaming? Since this year, the whole LCD panel market has smoked. Whether after the outbreak of the epidemic, LCD panel market prices rose for four months, or the panel giants in Japan and South Korea successively sold production lines, or the Chinese mainland listed companies frequently integrated acquisition, investment, and plant construction, all make the industry full of interesting.

LCD panel prices are already a fact. Since May this year, LCD panel prices have risen for four months in a row, making the whole industry chain dynamic. Why are LCD panels going up in price in a volatile 2020? The key factor lies in the imbalance between supply and demand.

For larger sizes, overseas stocks remained strong, with prices for 65 inches and 75 inches rising $10 on average to $200 and $305 respectively in September.

The price of LCDS for large-size TVs of 70 inches or more hasn’t budged much. In addition, LTPS screens and AMOLED screens used in high-end phones have seen little or no increase in price.

As for October, LCD panel price increases are expected to moderate. The data shows that in October 32 inches or 2 dollars; Gains of 39.5 to 43 inches will shrink to $3;55 inches will fall back below $10; The 65-inch gain will narrow to $5.

During the epidemic, people stayed at home and had no way to go out for entertainment. They relied on TV sets, PCS, and game consoles for entertainment. After the resumption of economic work and production, the market of traditional home appliances picked up rapidly, and LCD production capacity was quickly digested.

However, due to the shutdown of most factories lasting 1-2 months during the epidemic period, LCD panel production capacity was limited, leading to insufficient production capacity in the face of the market outbreak, which eventually led to the market shortage and price increase for 4 consecutive months.

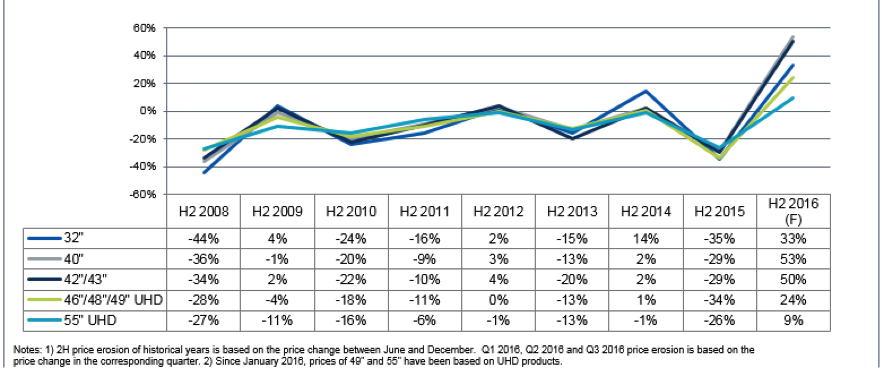

In fact, the last round of price rise of LCD panels was from 2016 to 2017, and its overall market price has continued to fall since 2018. Even in 2019, individual types have fallen below the material cost, and the whole industry has experienced a general operating loss. As a result, LCD makers have been looking for ways to improve margins since last year.

A return to a reasonable price range is the most talked about topic among panel makers in 2019, according to one practitioner. Some manufacturers for the serious loss of the product made the decision to reduce production or even stop production; Some manufacturers planned to raise the price, but due to the epidemic in 2020, the downstream demand was temporarily suppressed and the price increase was postponed. After the outbreak was contained in April, LCD prices began to rise in mid-to-late May.

This kind of price correction is in line with the law of industrial development. Only with reasonable profit space can the whole industry be stimulated to move forward.

In fact, the market price of LCD panels continued to decline in 2018-2019 because of the accelerated rise of China’s LCD industry and the influx of a large number of local manufacturers, which doubled the global LCD panel production capacity within a few years, but there was no suitable application market to absorb it. The result of excess capacity is oversupply, ultimately making LCD panel prices remain depressed.

Against this background, combined with the impact of the epidemic in 2020, the operating burden of LCD companies in Japan and South Korea has been further aggravated, and it is difficult to make profits in the production of LCD panels, so they have to announce the withdrawal of LCD business.

business in June 2022. In August, Sharp bought JDI Baishan, a plant in Ishikawa prefecture that makes liquid crystal display panels for smartphones. In early September, Samsung Display sold a majority stake in its SUZHOU LCD production plant to Starlight Electronics Technology, a unit of TCL Technology Group. LGD has not only pulled out of some of its production capacity but has announced that it will close its local production line in 2020. According to DSCC, a consultancy, the share of LCD production capacity in South Korea alone will fall from 19% to 7% between 2020 and 2021.

It is worth mentioning that in industry analysis, in view of the fact that Korean companies are good at using “dig through old bonus – selling high price – the development of new technology” the cycle of development mode, another 2020 out of the LCD production capacity, the main reason may be: taking the advantage of China’s expanding aggressively LCD manufacturers, Korean companies will own LCD panel production line hot sell, eliminating capacity liquid to extract its final value, and turning to the more profitable advantage of a new generation of display technologies, such as thinner, color display better OLED, etc. Samsung, for example, has captured more than 80% of the OLED market with its first-mover advantage.

From the perspective of production capacity, the launch of LCD tracks by major manufacturers in Japan and South Korea must reduce some production capacity in the short term, which to some extent induces market price fluctuations. In the long run, some of the Japanese and Korean LCD production capacity has been bought by Chinese manufacturers, coupled with frequent investment in recent years, the overall capacity is sure to recover as before, or even more than before. But now it will take time to expand the production layout, which more or less will cause supply imbalance, the industry needs to be cautious.

The LCD panel industry started in the United States and then gradually moved to Japan, South Korea, China, and Taiwan. At present, the proportion of production capacity in The Chinese mainland has reached 52% in 2020, and there are leading LCD panel products in China represented by BOE, Huxing Optoelectronics. Meanwhile, the production capacity layout of BOE, Huike, Huxing Optoelectronics, and other manufacturers has been basically completed, making industrial integration a necessity.

On the one hand, South Korean enterprises out of the LCD track, the domestic factory horse enclosure, plant expansion action. While LCDs may not sell as well as “upstart” flexible screens, respondents believe they are still strong enough in the traditional home appliance market to warrant continued investment. Zhao Bin, general manager of TCL Huaxing Development Center, has said publicly that the next-generation display technology will be mature in four to five years, but the commercialization of products may not take place until a decade later. “LCD will still be the mainstream in this decade,” he said.

On the other hand, there is no risk of neck jam in China’s LCD panel industry, which is generally controllable. In mainland China, there will be 21 production lines capable of producing 32-inch or larger LCD panels by 2021, accounting for about two-thirds of the global total. In terms of the proportion of production capacity, the Chinese mainland accounted for 42% of the global LCD panel in 2019, 51% this year, and will continue to climb to 63% next year.

Of course, building factories and expanding production cannot be accomplished overnight. In the process of production capacity recovery, it is predicted that there will be several price fluctuations, and the cost may be passed on to the downstream LCD panel manufacturers or consumers when the price rises greatly, which requires continuous attention.

LCD TV panel prices have stopped falling after sliding below suppliers" cash-cost levels, according to industry sources. Additionally, aggressive production cuts by panel makers also have helped bring a stop to falling prices.

According to Pan Tai-chi, general manager of the TV Business Center of Innolux, TV panel inventories at most TV vendors and channel operators have bottomed out, and correspondent TV panel prices have risen since the second half of October.

Sales dynamics for TVs and monitors with high CP (cost-performance) ratios have started gaining momentum recently as current panel prices have made high CP display products more affordable, Pan said.

It was the supply side that drove the recent price hikes instead of being pushed up by increasing demand, Pan noted, noting that the price increases will sustain for a more extended period only when demand is solid enough to soak up the output.

It is worth observing whether the sales of consumer electronics products during the forthcoming year-end shopping season in China, the US and Europe are robust enough to stir up panel demand in the first quarter of 2023, Pan commented.

Large LCD panels have seen dramatic increase in prices in the first half of 2021 due to unprecedented tight supply that was impacted by component shortages. Panel prices have been increasing for more than a year starting from mid-2020 due to strong demand both in TV and IT market.

Tight supply and extremely high panel prices have resulted in LCD TV set price increases. Softness in demand (due to higher set prices and changes in the COVID 19 situation globally) combined with supply expansion will lead to panel price reductions in 2H 2021.

An increase in demand for larger size TVs in the second half (2H) 2020 combined with component shortage (glass, driver ICs, Polarizers and other components) has pushed the market to unprecedented supply constraint and continuous panel price increase from end of Q2 2020 to 1H 2021 according to DSCC"s blog in August this year,

“Prices increased in Q2 2021 by a double-digit percentage for all sizes of TV panels, with increases ranging from 11% to 22%. Also according to the company, “Comparing our forecast for peak panel prices (in June or July 2021) with the prices in May 2020, we see trough-to-peak increases from 32% for 75” to 175% for 32”, with an average of 106%. In comparison, the average trough-to-peak increase of the 2016 to 2017 cycle was 48%, and prior cycles saw smaller increases.”

Market demand for tablets, notebooks, monitors and TVs increased in 2020 especially in the second half of the year due to the "stay at home" impact, when work from home, education from home and more focus on home entertainment pushed the demand to a higher level. With "stay at home" continuing in the first half of 2021 and UEFA European Championship soccer and Olympics in Japan, TV brands continued to see strong panel demand in that period.

Dramatic panel price increases have resulted in higher costs for TV brands reducing profitability. Brands have increased set prices for their TVs. TV brands have also focused more on larger size higher specs products for better profitability moving away from small and medium sizes, which will impact shipments volume. Lower priced brands (Tier2/3) had a difficult time acquiring enough panels to offer lower priced TVs. Panel suppliers are also giving priority to top brands with larger orders during the supply constraint. In recent quarters, the top five TV brands including Samsung, LG, and TCL, have been gaining higher market share.

Countries with better control of COVID variants such as U.S and Europe are starting to open up offices, schools and increasing travel. Demand that surged during the stay at home economy, has slowed down as consumers spend more on other things. Countries like India and Japan continue to struggle with the variant. High set prices combined with changes in the stay-home economy will impact TV demand especially in 2H2021.

While LCD TV faced extreme tight supply and panel price increases, OLED TV has made capacity expansions and cost reductions as LG Display added additional capacity in its 8.5 Gen fab in Guangzhou (increasing to 90K/m up from 60K/m). Also TV brands are more focused on expanding their OLED TV product line as the cost gap between equivalent LCD and OLED panels has reduced significantly. OLED TV is also providing higher profitability for brands. OLED TV has gained higher market share.

“While OLED TV share of all Advanced TV had declined during 2018-2020, the additional capacity from LG Display’s Guangzhou fab combined with rising LCD TV panel prices has helped OLED TV regain share in the premium category. OLED TV shipments increased by 169% Y/Y in Q2 2021, while Advanced LCD TV shipments increased by a more modest 36% Y/Y, and OLED TV share increased from 25% in Q2 2020 to 40% in Q2 2021.”

“OLED panels expected to reach 3% penetration in TV panel market in 2021 owing to persistently narrowing price gap with LCD panels. The company also reported that high-end OLED TV panels and 8K LCD TV panels showed dramatically opposed movements in 1H21, while OLED TV panel increased market shares to 2.6%, 8K LCD shares fell to a mere 0.2%”. This is because as the company reported “panel suppliers’ concerns about profit and yield maximization resulted in their relatively low willingness to manufacture these products. On the demand side, clients were also unwilling to procure these panels due to persistently high quotes from suppliers.”

“tight supply, high factory utilization rates, and high profitability are encouraging many panel makers to increase their capacities. There were already multiple Gen 8.6 and Gen 10.5 factories in China that were accelerating capacity ramp-ups in 2021 and 2022 after COVID-19 delayed them in 2020”.

Chinese panel makers are incrementally increasing the capacity of their current factories through productivity enhancements and new equipment purchased for de-bottlenecking or creating capacity expansion according to Omdia.

“Chinese panel suppliers were able to achieve a 58.3% share in the TV panel market, which was nearly 5 percentage points higher than their 1H20 market shares, thanks to their growing number of production lines. Conversely, Taiwanese suppliers saw their market share drop by 2.2 percentage points from 1H20 levels to 21.1% in 1H21… Korean suppliers experienced a decline in market shares to 14.3% while Japanese suppliers’ market shares increased to 6.3% as a result of SDP’s Gen 10.5 capacity expansion”.

BOE and CSOT (China Star) have been the top two panel suppliers for LCD TV. They are expanding their production capacity. At the same time HKC is currently increasing its production capacity (4 Gen 8.6 fabs) and is expected to enter the top three rank of TV panel suppliers for the first time with 33.7% YoY increase in TV panel shipments in 2021, according to TrendForce.

The capacity ramp-up by panel suppliers in China and their strong dominance in the TV panel market combined with higher profitability and the need for new suppliers to increase their market share will result in supply expansion in the second half of 2021.

The industry is already reporting some price reduction for TV panels. TrendForce reported in the beginning of August: 7.5% MoM decline for 55’ W UHD open cell TV panels in July. The Display Supply Chain Consultants LCD TV Panel Price Update in August 2021 confirmed LCD panel pricing peaking in June/July and starting to go down. DSCC forecasts price declines for LCD TV throughout the second half of 2021.

It seems that market has reached the end of the “up cycle” of the LCD crystal cycle ending the tight supply situation. The LCD crystal cycle generally creates a multiplier effect with each “up and down” cycle. During the “up cycle” with tight supply and panel price increases, panel buyers buy more, keep higher inventories and sometimes place orders with double bookings to ensure future supply, thereby pushing the market to an even tighter situation. In the “down cycle” when prices decline, panel buyers delay purchases and keep lower inventories to avoid holding higher cost inventory, resulting in a further reduction in demand. With the start of the down cycle, LCD TV panel prices will decline in the second half of 2021. (SD)

Robust TV demand in the US and China, combined with capacity reductions by the Korean panel makers, is leading to LCD TV panel price increases in Q3, which will improve the profitability for panel makers who rely on TV panels. We at Display Supply Chain Consultants (DSCC) are updating our data and forecast for TV panel prices for the rest of 2020 and adding a forecast for the first half of 2021, and we now expect double-digit % increases for some TV sizes in Q3 2020 compared to Q2.

The first chart shows our latest TV panel price update, with several inflection points already this year. Prices hit all-time lows in Q4 2019, but he industry saw a brief price bump in Q1 after the two Korean panel makers announced capacity cuts. That price increase was cut short by the COVID-19 pandemic, and fears of a demand slowdown, so prices in Q2 dropped back down to roughly the same levels as Q4 2019, with certain sizes hitting all-time lows and other sizes slightly higher than their Q4 2019 trough. Starting in June, we have seen another price bump, bringing prices above their recent high points of Q1 2020, to prices last seen in the summer of 2019.

We now expect prices to increase in Q3 for all sizes of TV panels except 75”, with double-digit % gains in sizes from 32” to 55”. Although we continue to expect that the long-term downward trend will resume in Q4, and that TV panel prices will hit new all-time lows in Q1 2021, the situation remains dynamic, and with the pandemic raging it seems like an eternity between now and the end of the year.

Our forecast presumes a weaker-than-normal holiday selling season in Q4, based on the idea that the surge in demand in Q2 has pulled demand forward. This view is shared by NPD’s Stephen Baker (see comments on his presentation in the DisplayWeek article in this issue), but many variables surrounding the pandemic, the global economy, and political unrest could affect the outcome. We are now projecting another panel price increase starting in Q2 2021, based on demand related to the Tokyo Olympics, if they continue to be held as currently planned.

The only exception to the Q3 price increases, as noted, are 75” panels, which are made efficiently on Gen 10.5 fabs. These largest TV panels sell at a premium price in terms of area, as shown in the next chart here. The gap in price per square meter between 75” and 65” is still very wide at $37 per square meter in August but has closed from more than $50 per square meter at the beginning of the year. The current price gap represents a 25% area price premium for 75” over 65”. Viewed another way, Gen 10.5 fabs can generate $1752 of revenue per substrate making 75” panels 6-up at August prices, compared to $1408 of revenue making 65” panels 8-up or $1350 making 43” panels 18-up. Thus the big fabs still have a generous incentive to make 75”, which will lead to continued price pressure on those larger sizes.

The bellwether 32” TV panel typically shows the fastest drops to the lowest area prices in times of oversupply, and the sharpest price increases in times of supply constraint, and we show that pattern repeating itself in Q2 and Q3. In May 2020, 32” panel prices matched their all-time lows, but these panels will get an 18% increase Q/Q in Q3, before falling again in Q4.

After the industry recognized an average TV panel price increase of 4.6% Q/Q in Q1, and a Q/Q price decline of 3.4% in Q2, we are now expecting prices to increase in Q3 2020 by an average of 9.1% Q/Q. As noted above, however, the average increase in sizes between 32” and 55” is substantially larger at 11.7%, while we expect 65” to get a 6% price increase Q/Q and 75” to see a 1% price decline. In Q4, we expect all TV panel sizes to get a price decrease, ranging from 2% to 5% depending on size, with an average of 4.5%, but this would still leave Q4 LCD TV panel prices higher than those in Q2 2020.

Our TV price index, set to 100 for prices in January 2014, has increased from its all-time low of 42.0 in May 2020 to 47.3, and we expect it to decline in Q4 to 43.0 by December. This month of August 2020 will see the first Y/Y price increase in our LCD TV price index since September 2017. Higher prices, combined with robust volumes, will surely improve the profitability picture for panel makers in the third quarter.

Large-area flat panel display prices increased by over 50% in 2020 due to increased demand from consumers, according to Omdia"s latest OLED and LCD Supply Demand & Equipment Tracker.

A combination of tight capacity for thin film transistor display screens, along with material and component supply bottlenecks, is fueling a panel shortfall, which is increasing demand further, as set manufacturers buy more panels to fulfill demand in 2021, according to a press release on the Omdia tracker results. In the second half of 2021, TFT supply/demand is forecast to trend above 10% almost reaching similar glut levels to 2019.

A string of accidents has created a historically tight glass market and caused an unusual industry average price increase of several percentage points, according to the press release. The lack of investment in polarizers and base films in 2019 caught the industry off guard when demand turned around in 2020. Aside from these three main components, many other materials are also in tight supply, which is affecting makers in different ways, supporting inflationary price trends.

"Although multiple caveats remain about how both supply and demand will trend over the coming months, the modeled glut level is a leading indicator that the next cycle is now on its way, which implies falling prices, utilization and profitability," Charles Annis, practice leader for display manufacturing, technology and cost at Omdia, said in the press release. "Industry players should consider the implications when planning business strategies for the next two years."

LCD TV panel prices reached all-time lows in August but they continue to decline in September, and we continue to forecast that the industry will have an “L-shaped” recovery in the fourth quarter. In other words, no recovery at all until 2023; the only question is how low prices will go before they flatten out. The ‘perfect storm’ of a continued oversupply, near-universally weak demand and excessive inventory throughout the supply chain has combined, and every screen size of TV panel has reached an all-time low price. Although fab utilization slowed sharply starting in July, we do not see any signal to suggest that prices can increase any time soon.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey