1602 lcd module tutorial pricelist

ERM1602DNS-3 is 16 characters wide,2 rows character lcd module,SPLC780C controller (Industry-standard HD44780 compatible controller),6800 4/8-bit parallel interface,single led backlight with white color included can be dimmed easily with a resistor or PWM,ffstn-lcd negative black,white text on the black color,high contrast,wide operating temperature range,wide view angle,rohs compliant,built in character set supports English/Japanese text, see the SPLC780C datasheet for the full character set. It"s optional for pin header connection,5V or 3.3V power supply and I2C adapter board for arduino.

Of course, we wouldn"t just leave you with a datasheet and a "good luck!".For 8051 microcontroller user,we prepared the detailed tutorial such as interfacing, demo code and Development Kit at the bottom of this page.

Do you want your Arduino projects to display status messages or sensor readings? Then these LCD displays can be a perfect fit. They are extremely common and fast way to add a readable interface to your project.

This tutorial will help you get up and running with not only 16×2 Character LCD, but any Character LCD (16×4, 16×1, 20×4 etc.) that is based on Hitachi’s LCD Controller Chip – HD44780.

True to their name, these LCDs are ideal for displaying only text/characters. A 16×2 character LCD, for example, has an LED backlight and can display 32 ASCII characters in two rows of 16 characters each.

The good news is that all of these displays are ‘swappable’, which means if you build your project with one you can just unplug it and use another size/color LCD of your choice. Your code will have to change a bit but at least the wiring remains the same!

Vo (LCD Contrast) controls the contrast and brightness of the LCD. Using a simple voltage divider with a potentiometer, we can make fine adjustments to the contrast.

RS (Register Select) pin is set to LOW when sending commands to the LCD (such as setting the cursor to a specific location, clearing the display, etc.) and HIGH when sending data to the LCD. Basically this pin is used to separate the command from the data.

R/W (Read/Write) pin allows you to read data from the LCD or write data to the LCD. Since we are only using this LCD as an output device, we are going to set this pin LOW. This forces it into WRITE mode.

E (Enable) pin is used to enable the display. When this pin is set to LOW, the LCD does not care what is happening on the R/W, RS, and data bus lines. When this pin is set to HIGH, the LCD processes the incoming data.

Now we will power the LCD. The LCD has two separate power connections; One for the LCD (pin 1 and pin 2) and the other for the LCD backlight (pin 15 and pin 16). Connect pins 1 and 16 of the LCD to GND and 2 and 15 to 5V.

Most LCDs have a built-in series resistor for the LED backlight. You’ll find this near pin 15 on the back of the LCD. If your LCD does not include such a resistor or you are not sure if your LCD has one, you will need to add one between 5V and pin 15. It is safe to use a 220 ohm resistor, although a value this high may make the backlight a bit dim. For better results you can check the datasheet for maximum backlight current and select a suitable resistor value.

Next we will make the connection for pin 3 on the LCD which controls the contrast and brightness of the display. To adjust the contrast we will connect a 10K potentiometer between 5V and GND and connect the potentiometer’s center pin (wiper) to pin 3 on the LCD.

That’s it. Now turn on the Arduino. You will see the backlight lit up. Now as you turn the knob on the potentiometer, you will start to see the first row of rectangles. If that happens, Congratulations! Your LCD is working fine.

Let’s finish connecting the LCD to the Arduino. We have already made the connections to power the LCD, now all we have to do is make the necessary connections for communication.

We know that there are 8 data pins that carry data to the display. However, HD44780 based LCDs are designed in such a way that we can communicate with the LCD using only 4 data pins (4-bit mode) instead of 8 (8-bit mode). This saves us 4 pins!

The sketch begins by including the LiquidCrystal library. The Arduino community has a library called LiquidCrystal which makes programming of LCD modules less difficult. You can find more information about the library on Arduino’s official website.

First we create a LiquidCrystal object. This object uses 6 parameters and specifies which Arduino pins are connected to the LCD’s RS, EN, and four data pins.

In the ‘setup’ we call two functions. The first function is begin(). It is used to specify the dimensions (number of columns and rows) of the display. If you are using a 16×2 character LCD, pass the 16 and 2; If you’re using a 20×4 LCD, pass 20 and 4. You got the point!

After that we set the cursor position to the second row by calling the function setCursor(). The cursor position specifies the location where you want the new text to be displayed on the LCD. The upper left corner is assumed to be col=0, row=0.

There are some useful functions you can use with LiquidCrystal objects. Some of them are listed below:lcd.home() function is used to position the cursor in the upper-left of the LCD without clearing the display.

lcd.scrollDisplayRight() function scrolls the contents of the display one space to the right. If you want the text to scroll continuously, you have to use this function inside a for loop.

lcd.scrollDisplayLeft() function scrolls the contents of the display one space to the left. Similar to above function, use this inside a for loop for continuous scrolling.

If you find the characters on the display dull and boring, you can create your own custom characters (glyphs) and symbols for your LCD. They are extremely useful when you want to display a character that is not part of the standard ASCII character set.

As discussed earlier in this tutorial a character is made up of a 5×8 pixel matrix, so you need to define your custom character within that matrix. You can use the createChar() function to define a character.

CGROM is used to store all permanent fonts that are displayed using their ASCII codes. For example, if we send 0x41 to the LCD, the letter ‘A’ will be printed on the display.

CGRAM is another memory used to store user defined characters. This RAM is limited to 64 bytes. For a 5×8 pixel based LCD, only 8 user-defined characters can be stored in CGRAM. And for 5×10 pixel based LCD only 4 user-defined characters can be stored.

In this tutorial, we will display the custom characters on an LCD 16×2. Liquid crystal display (LCDs) offer a convenient and inexpensive way to provide a user interface for a project.

By far the most popular LCD used is the text panel based on the Hitachi HD44780 chip. This displays two or four lines of text, with 16 or 20 characters per line (32 and 40 character versions are also available, but usually at much higher prices).

We want to define and display custom characters or symbols (glyphs) that we have created. The symbols we want to display are not predefined in the LCD character memory.

A library for driving text LCD displays is provided with Arduino, and you can print text on your LCD easily as on the serial monitor because of LCD and serial share the same underlying print function.

To display custom characters on LCD, we must first know about the LCD dot matrix means pixels in LCD. There are 5 pixels in rows and 8 pixels in columns means every character is a combination of 5*8 dots.

Each big number is built from six of these glyphs, three forming the upper half of the big digit and three forming the lower half. BiDigitsTop and bigDigitsBot are arrays defining which custom glyph is used for the top and bottom rows on the LCD screen.

![]()

A few weeks ago, we examined the features of ESP32 module and built a simple hello world program to get ourselves familiar with the board. Today, we will continue our exploration of the ESP32 on a higher level as we will look at how to interface a 16×2 LCD with it.

Displays provide a fantastic way of providing feedback to users of any project and with the 16×2 LCD being one of the most popular displays among makers, and engineers, its probably the right way to start our exploration. For today’s tutorial, we will use an I2C based 16×2 LCD display because of the easy wiring it requires. It uses only four pins unlike the other versions of the display that requires at least 7 pins connected to the microcontroller board.

ESP32 comes in a module form, just like its predecessor, the ESP-12e, as a breakout board is usually needed to use the module. Thus when it’s going to be used in applications without a custom PCB, it is easier to use one of the development boards based on it. For today’s tutorial, we will use the DOIT ESP32 DevKit V1 which is one of the most popular ESP32 development boards.

The schematics for this project is relatively simple since we are connecting just the LCD to the DOIT Devkit v1. Since we are using I2C for communication, we will connect the pins of the LCD to the I2C pins of the DevKit. Connect the components as shown below.

Due to the power requirements of the LCD, it may not be bright enough when connected to the 3.3v pin of the ESP32. If that is the case, connect the VCC pin of the LCD to the Vin Pin of the ESP32 so it can draw power directly from the connected power source.

At this point, it is important to note that a special setup is required to enable you to use the Arduino IDE to program ESP32 based boards. We covered this in the introduction to ESP32 tutorial published a few weeks go. So, be sure to check it out.

To be able to easily write the code to interact with the I2C LCD display, we will use the I2C LCD library. The Library possesses functions and commands that make addressing the LCD easy. Download the I2C LCD library from the link attached and install on the Arduino IDE by simply extracting it into the Arduino’s library folder.

Before writing the code for the project, it’s important for us to know the I2C address of the LCD as we will be unable to talk to the display without it.

While some of the LCDs come with the address indicated on it or provided by the seller, in cases where this is not available, you can determine the address by using a simple sketch that sniffs the I2C line to detect what devices are connected alongside their address. This sketch is also a good way to test the correctness of your wiring or to determine if the LCD is working properly.

If you keep getting “no devices found”, it might help to take a look at the connections to be sure you didn’t mix things up and you could also go ahead and try 0x27 as the I2C address. This is a common address for most I2C LCD modules from China.

Our task for today’s tutorial is to display both static and scrolling text on the LCD, and to achieve that, we will use the I2C LCD library to reduce the amount of code we need to write. We will write two separate sketches; one to displaystatic textsand the other to display both static and scrolling text.

To start with the sketch for static text display, we start the code by including the library to be used for it, which in this case, is the I2C LCD library.

Next, we create an instance of the I2C LCD library class with the address of the display, the number of columns the display has (16 in this case), and the number of rows (2 in this case) as arguments.

With that done, we proceed to the void setup() function. Here we initialize the display and issue the command to turn the backlight on as it might be off by default depending on the LCD.

Next is the void loop() function. The idea behind the code for the loop is simple, we start by setting the cursor to the column and row of the display where we want the text to start from, and we proceed to display the text using the lcd.print() function. To allow the text to stay on the screen for a while (so its visible) before the loop is reloaded, we delay the code execution for 1000ms.

For the scrolling text, we will use some code developed by Rui Santos of RandomNerdTutorials.com. This code allows the display of static text on the first row and scrolling text on the second row of the display at the same time.

Next, we create an instance of the I2C LCD library class with the address of the display, the number of columns the display has (16 in this case), and the number of rows (2 in this case) as arguments.

Next, we create the function to display scrolling text. The function accepts four arguments; the row on which to display the scrolling text, the text to be displayed, the delay time between the shifting of characters, and the number of columns of the LCD.

That’s it for today’s tutorial guys. Thanks for following this tutorial. This cheap LCD display provides a nice way of providing visual feedback for your project and even though the size of the screen and the quality of the display is limited, with the scrolling function you can increase the amount of text/characters that can be displayed.

If you have the control board of other brands, it is also equipped with the RJ11 6P6C interface but has different internal line sequence, can’t be used compatibly with our sensor/module.

Adding a display to Raspberry PI Pico allows getting real time information from connected devices without using a computer from USB port. I2C LCD displays (with PCF8574 backpack) are one of best solution to keep wiring simple

I2C LCD displays are common LCD displays, usually composed of 16 columns x 2 rows blocks, but also different configurations can be found. Differently from simple LCD displays, they include a small panel soldered in its backside, including chips able to reduce their connection wires. The I2C LCD display usually has a PCF8574 chip, which is a device able to convert I2C serial communication into parallel connections.

To connect an I2C LCD Display with your Raspberry PI Pico, you just need to wire the Vcc and GND PINs from display to VSYS and a GND PINs of RPI Pico, then SDA and SCL PINs from the I2C Display to a couple of SDA and SCL PINs from Raspberry PI Pico, belonging to the same I2C bus, as shown in the picture on the following wiring diagram chapter.

A working solution uses the dhylands-python_lcd module including a generic API to interface to LCD displays. But this class implements commands to be sent to the LCD without caring about how to send them. The reason is that there are many different backpacks and every solution can be implemented in many different ways. The ones created with a PCF8574 use I2C as communication protocol, in this case, you need a sort of driver able to send commands via I2C. This function is implemented with a second module from T-622 user, also available from T-622 GitHub page.

Prepare cabling according to the previous paragraph. Connect RPI Pico to Thonny (you can refer to my tutorial about First steps with Raspberry PI Pico).

Before going into the usage explanation, you have to be sure that your LCD’s I2C address is correct. This is a unique address shared between I2C devices to make them able to talk on the same shared wire. This is usually a hexadecimal value and all devices connected to your RPI Pico can be scanned by copy-paste of the following code in your Thonny shell (you can copy all lines together):

As I2C LCD with PCF8574 backpack use PCF8574 chip for I2C communication, you will probably get its default address (0x27). But if your project includes more PCF8574-based chips, then you will need to identify the LCD one between those that will be shown. In case of missing devices, please check your cabling.

Starting to use your LCD device, you can run a generic test with the T-622 test script, which I have pre-configured for 16×2 LCDs using I2C0 channel (ports GP0 and GP1 according to my wiring diagram). This modified script can be get from my download area (use the following link: i2c_lcd_test). Save this file in your Raspberry PI Pico root folder or in your computer and open it with Thonny IDE.

If you will see nothing, please check your cabling. Another common issue with I2C LCD display is getting a clean screen which is only powering on and off. This means that your connection is correct and everything is working, you have only to adjust your LCD contrast by rotating the screw positioned in your LCD backside, which controls a potentiometer managing contrast:

The LCD API used has a flexible feature allowing users to display also complex icons inside a single cell. Some special characters are already available and depend on your LCD ROM (Read Only Memory, space not visible to the user). You can use these chars with “lcd.putchar(chr())” function.

The first 8 characters (from 0 to 7) character-generator RAM. This means that you can define and design any icon you want to display by identifying pixels to be put on/off for each char block, made of 8 rows and 5 columns of pixels. Each row A good description of how to define a generic icon is explained in https://github.com/dhylands/python_lcd.

You can use the generated code with “lcd.custom_char()” command. An example usage is built in my pico_i2c_lcd script. Download and open it in your Thonny IDE.

The LCD can be connected in the 4 bit as well as 8 bit mode. In the 4 bit mode we have to use only the 4 data pins while in the 8 bit mode we will have to use all the 8 data pins. You can do almost everything in the 4 bit mode, so in this example we are going to connect it in the 4 bit mode.

As we all know, though LCD and some other displays greatly enrich the man-machine interaction, they share a common weakness. When they are connected to a controller, multiple IOs will be occupied of the controller which has no so many outer ports. Also it restricts other functions of the controller. Therefore, LCD1602 with an I2C bus is developed to solve the problem.

I2C bus is a type of serial bus invented by PHLIPS. It is a high performance serial bus which has bus ruling and high or low speed device synchronization function required by multiple-host system. The blue potentiometer on the I2C LCD1602 (see the figure below) is used to adjust the backlight for better display. I²C uses only two bidirectional open-drain lines, Serial Data Line (SDA) and Serial Clock Line (SCL), pulled up with resistors. Typical voltages used are +5 V or +3.3 V although systems with other voltages are permitted.

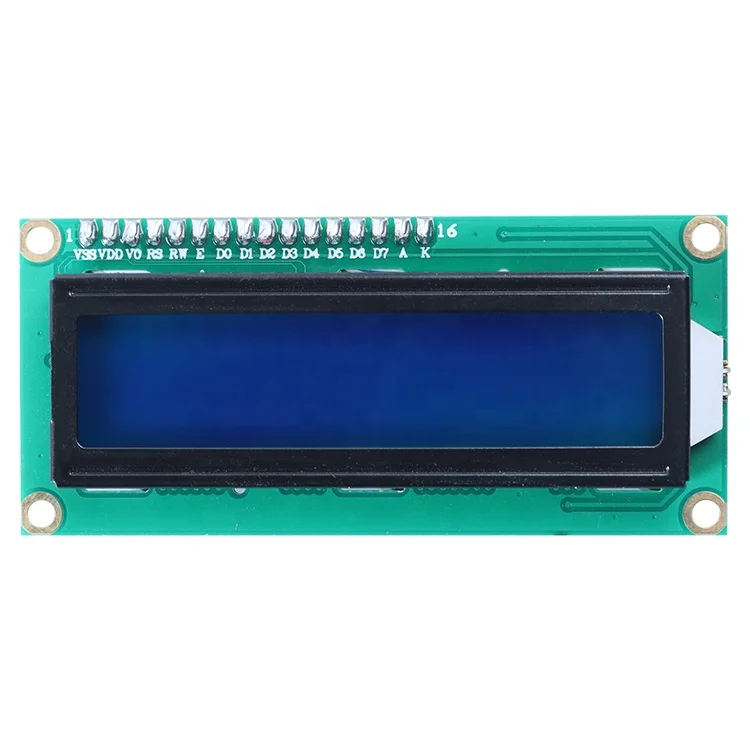

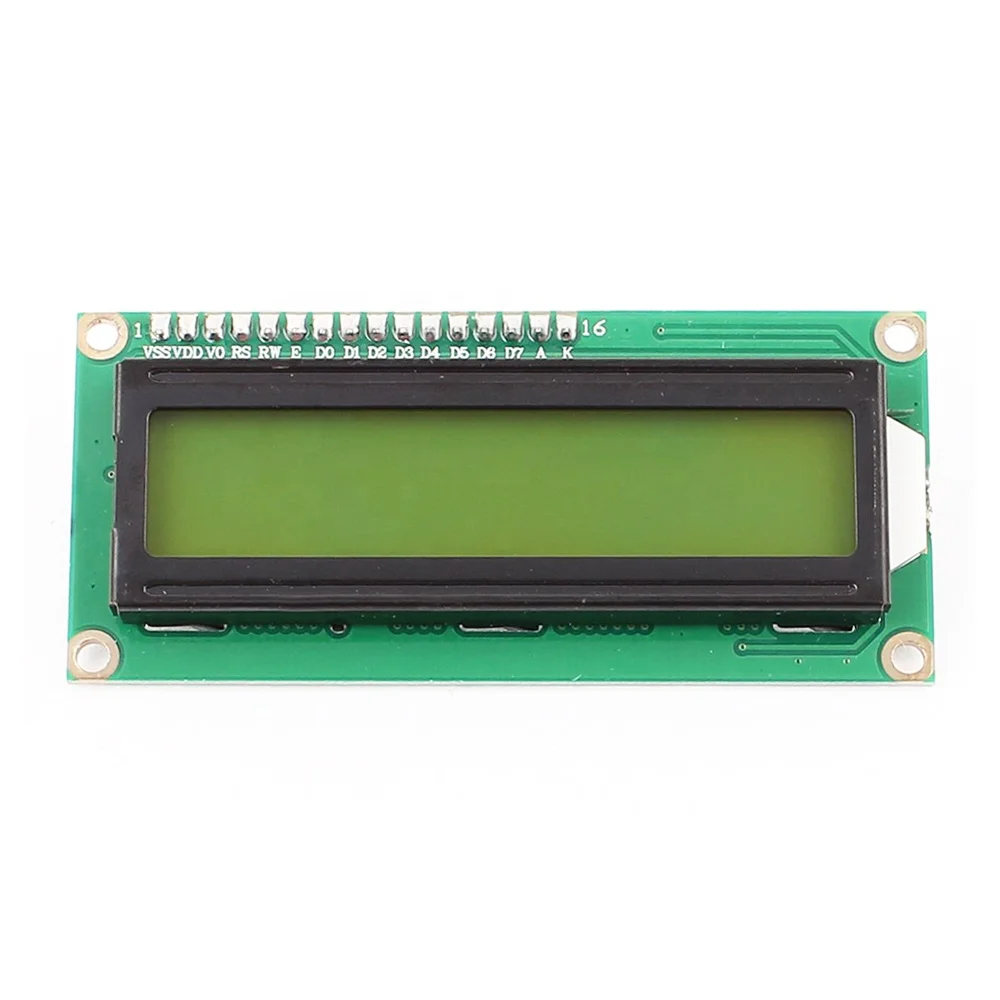

16×2 LCD is named so because; it has 16 Columns and 2 Rows. There are a lot of combinations available like, 8×1, 8×2, 10×2, 16×1, etc. But the most used one is the 16*2 LCD, hence we are using it here.

All the above mentioned LCD display will have 16 Pins and the programming approach is also the same and hence the choice is left to you. Below is the Pinout and Pin Description of 16x2 LCD Module:

These black circles consist of an interface IC and its associated components to help us use this LCD with the MCU. Because our LCD is a 16*2 Dot matrix LCD and so it will have (16*2=32) 32 characters in total and each character will be made of 5*8 Pixel Dots. A Single character with all its Pixels enabled is shown in the below picture.

So Now, we know that each character has (5*8=40) 40 Pixels and for 32 Characters we will have (32*40) 1280 Pixels. Further, the LCD should also be instructed about the Position of the Pixels.

It will be a hectic task to handle everything with the help of MCU, hence an Interface IC like HD44780 is used, which is mounted on LCD Module itself. The function of this IC is to get the Commands and Data from the MCU and process them to display meaningful information onto our LCD Screen.

The LCD can work in two different modes, namely the 4-bit mode and the 8-bit mode. In 4 bit mode we send the data nibble by nibble, first upper nibble and then lower nibble. For those of you who don’t know what a nibble is: a nibble is a group of four bits, so the lower four bits (D0-D3) of a byte form the lower nibble while the upper four bits (D4-D7) of a byte form the higher nibble. This enables us to send 8 bit data.

As said, the LCD itself consists of an Interface IC. The MCU can either read or write to this interface IC. Most of the times we will be just writing to the IC, since reading will make it more complex and such scenarios are very rare. Information like position of cursor, status completion interrupts etc. can be read if required, but it is out of the scope of this tutorial.

The Interface IC present in most of the LCD is HD44780U,in order to program our LCD we should learn the complete datasheet of the IC. The datasheet is given here.

There are some preset commands instructions in LCD, which we need to send to LCD through some microcontroller. Some important command instructions are given below:

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey