why a custom lcd display quotation

Some of my customers have sent me inquiries about LCD panels and asked for quote. They only gave me the information about the screen size, for example, segment LCD screen 36 x 22 mm & 57 x 22 mm & 77 x 25 mm or 128 * 32 pixel. I had to explain to them why we cannot give a quote. Here is a summary of the necessary information that we need before we can offer quotes:

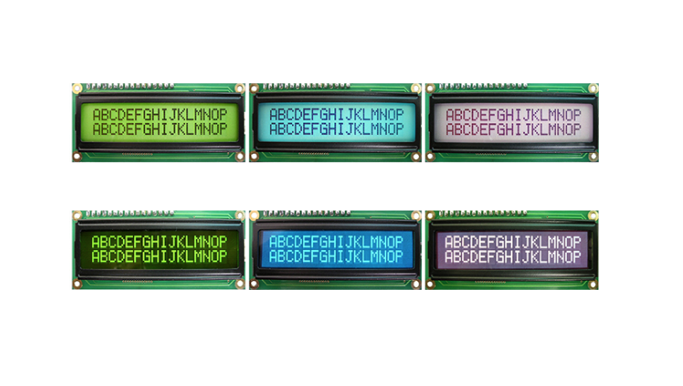

Do you only need a LCD screen or LCD module (including LCD screen, LED backlight, IC, PCB, Plastic shell)? If you only need a LCD screen, is it a segment LCD or a dot matrix LCD? We have a lot of experience in the LED and LCD industries and give the best quote.

Please give me the quantity you want before you ask me for a quote. There is definitely a difference between purchasing 100,000 and 1,000 pieces. The more you order each buy, the cheaper the unit price and shipping cost will be.

Does 36 x 22 mm & 57 x 22 mm & 77 x 25 mm mean outer dimension or view area? As for 128*32 pixel, we don’t know the size of LCD screen, so we are unable to give a quote.

I have been asked this question by my customers many times: what is your MOQ (minimum order quantity)? There are different MOQ for different sizes of LCD screens. For example: The MOQ of 36 x 22 mm segment LCD is 5000 pieces, and the MOQ of 113.5 x 62mm segment LCD is 1,000 pieces. So please tell me the size of your LCD first before you ask me for the MOQ.

Dot matrix LCD can display any graphic, so it doesn’t need it. But segment LCD does and we are going to need it for the official blueprint we are about to make.

We can make custom operating voltage according to our clients’ requirements. Typical voltage rangesfrom 2.5v to 4.5v. The most commonly used operating voltages are 3.0v, 4.5v and 5.0v.

If we make a 17 segment LCD display that adopts static drive mode, there will be 18 feet (each segment has one foot and one common foot). If it adopts a dynamic drive mode whose duty is one-third, there will be 9 feet (17/3=6 feet and 3 common feet).

Static drive mode needs more feet, so it costs a little more than dynamic drive, but the display effect of static drive is a little better. If it is a dot matrix LCD, it must adopt dynamic drive, otherwise, the feet will be too many. For example, 128 * 32 pixel LCD screen adopts static drive, it will be (128 * 32+1) 4097 feet. If the duty of 128 * 32 pixel LCD screen is 32, there will be (128 * 32/32+32) 160 feet.

As you can see from the 11 points, there is no fixed price list because of the various factors listed above. Please review the 11 points before asking for a quote. This will make everything easier for all parties concerned.

There are two points we have to emphasize:Outer Dimension and Main Application. There are the most important factors and it is necessary for us to know them. If we don’t even know the outer dimension and the main application, we don’t know where to start.

Liquid Crystal Displays or more commonly known as LCDs are one of the most common electronic components which help us interact with an equipment or a device. Most personal portable equipment and even gigantic industrial equipment utilize a custom segment display to display data. For many portable consumer electronics, a segment LCD display is one of the biggest contributors to the overall cost of the device, hence designing a custom segment display can drive the cost down while also utilizing the display area in the most optimum manner. These displays have the lowest cost per piece, low power requirements, and a low tooling fee too.

At first thought, designing a custom segment LCD might look like a Herculean task, but trust me that it is easier than it seems. In this article, we have summarised and compared the display types and available technologies which are required to construct a custom segment LCD. We have also provided a flowchart that can act as a step-by-step guide while you design your own custom LCD. We have also provided the process we followed, a require gathering sheet we used for communicating our needs to the manufacturer, and a few other data and the quotation we received from the manufacturer.

Icons: A silhouette of any shape can be placed on the glass which enhances the ability to display data. For example, a symbol of a heart can be made to denote heart rate or an icon for a low battery to show that the battery needs to be charged. Icons are counted as a single pixel or segment and can give a lot more details than similar-sized text.

LCD Bias– It denotes the number of different voltage levels used in driving the segments, static drives (explained later in this article) only have 2 voltage levels or 2 bias voltage while multiplex drives have multiple voltage levels. For example, 1/3 will have 4 bias voltages.

LCDs utilizes the light modulating properties of liquid crystals which can be observed by using polarizing filters. Polarizing filters are special materials that have their molecules aligned in the same direction. If the light waves passing through polarisers have the same orientation as the filter, then the molecules of lights are absorbed by the filter, hence reducing the intensity of light passing through it, making it visible.

In Layman’s language, when an electric current is applied to the electrodes, i.e. to the segment line and common line, it twists the Liquid Crystals w.r.t to the polarizing filter, obstructing the light in that particular area as shown in the figure below. Hence, that area becomes darker and prominent.

A custom LCD is important for maximizing the efficiency of the display area by adding custom symbols and characters. It also helps in reducing the cost and improving energy efficiency of the product. A higher number of custom symbols and specified placement of numerical and alphanumerical characters make the display more informative and readable for the user. This makes it look better than the plain old boring displays we get in the market. Furthermore, we can specify the viewing angle, contrast, and other specifications which can increase durability or give a better value for money for our intended usage. A typical Custom Segment display is shown below, we will also show you how to design and fabricate the same further in the article.

The LCD display doesn’t emit any light of its own, therefore it requires an external source of illumination or reflector to be readable in dark environments.

While designing a custom segment LCD display, we have the leverage of choosing a lot of parameters that affect the final product. From the color of the display to the illumination technique and color of illumination as well as the type of input pins. Some important considerations we need to take while designing a custom 7 segment display are - the type of display, i.e. positive or negative, illumination method, driving technique, polarising type, and connection method. All these design criteria are explained below:

Positive and negative displays can be easily distinguished by the colour of the background and characters. Some common differences between the positive and negative displays are:

So, which one should you choose? When the displays are to be used in areas with higher ambient light, we should select positive segment LCD display as it has better visibility than negative segment LCD displays without using a backlight.

As we know that LED displays don’t emit any light, hence to illuminate it and make it visible in a dark environment, we can use different methods of illumination. The most common LCD Illumination methods are compared below:

For displays that need to be used for budget-friendly devices that should be small and rugged, LED lights are preferred for the displays due to the high durability and low cost of operations. For high brightness, CCFL and Incandescent lights can be used.

A polarizer film is the most important component of an LCD display, which makes it possible to display characters by controlling the light. There are 3 types of polarizers that can be used in the LCD display, the properties and difference are given below:

If your products need to be used with a switchable backlight, then trans-reflective reflectors are best to be used for front reflectors. If the device has to be used without backlight, then we can select a reflective polarizer for the back-panel as it gives the best contrast ratio.

Displays can be categorized into two types, passive displays, and active display, passive displays are simpler to construct as they have 2 connections at each segment, the conductors comprise of an Indium Tin Oxide to create an image, whereas the active displays use thin-film transistors (TFT) arranged in a grid. The name is due to its ability to control each pixel individually.

If your displays have fewer segments, then static LCD drive is preferred as it is easier to control and cheaper to construct, and has a better contrast ratio. But let’s say that if the number of segments in the display are more than 30-40 then a multiplex LCD drive should be preferred as it has multiple common pins, hence reducing the total number of pins required to drive the display.

Choosing a connector type!!! For the prototyping phase or if you need to connect your LCD display on a Microcontroller directly, a pin type connector is the best and most economical option you have. If you need to connect your LCD display in a final product with a high volume of production which also requires to be extremely durable, but at the same time should not take up a lot of space, a Flex type LCD Connector will work best for you

LCDs have limited viewing angles and when seen from an angle they lose contrast and are difficult to be observed. The viewing angle is defined by the angles perpendicular to the center of the display towards its right, left, up, and down which are denoted by the notations 3:00, 9:00, 12:00, and 6:00 respectively. The viewing angle of LCD can be defined as the angle w.r.t. to the bias angle at which the contrast of segments is legible.

To improve the viewing angle in an LCD, a Bias is incorporated in the design which shifts the nominal viewing angle with an offset. Another technique is to increase the Voltage, it affects the bias angle, making the display crisper when viewed from a direction.

For example, the viewing angle of a TN type TFT LCD is 45-65 degrees. Extra-wide polarising film (EWP) can increase the viewing angle by 10 degrees, using an O film polariser can make the viewing angles 75 degrees but these come at a cost of reduced contrast.

Anti-glare filters are bonded with the top polarising filters using adhesive. It improves the viewability by re-directing light waves so they don’t reflect back towards the viewer thus reducing glare. Newer materials are capable of reducing the front glare by up to less than 0.3%.

LCD Control chip or LCD driver chips can be mounted on the flex cable, display, or externally on a PCB. The placement of LCD control chip can affect the cost and size of the display. The 2 most common methods of chip placement are-Chip of Board (COB)and Chip on Glass(COG) which are described below:

COG can be used as it is cheaper and makes the assembly process simpler, but if the dimensions are a constraint, then the COB is also a viable option.

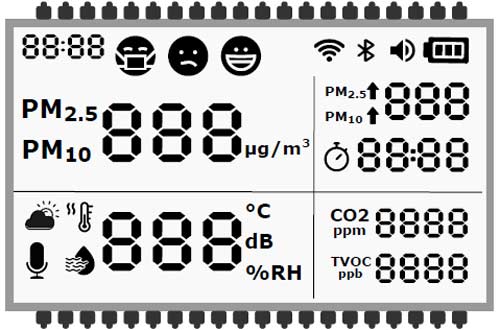

We planned to design an air quality monitoring system for which we needed a custom segment LCD panel for an air quality monitoring device. Our product needs to display the following data: 2.5-micron and 10-micron particulate matter (PM) suspended in the air; the units should be in parts per million (PPM). CO2 in the air in PPM along with total volatile organic compounds present in the air in parts per billion (PPB). To make the product more usable, we included time in 24-hour format, Temperature in ºC, Battery status, loudspeaker status, Bluetooth status, and Wi-Fi status. And for some personal touch, we also added how good the air quality in the room is by using 3 different smileys.

We realized that it was impossible to provide all these data in a generic LCD available in the market, thus decided to build a custom LCD for our project.

A step-by-step flowchart is shown below to walk you through each and every step of selecting components and getting your custom segment LCD manufactured.

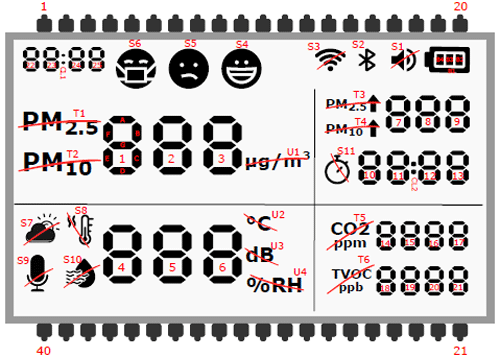

We started by listing down our requirements and drew a mock-up of the display on paper. After finalizing the placement of all the segments and icons on the prototype sketch of the display, we then decided which all icons and segments have to be kept on for the whole time and which needs to be driven. Realizing that there are too many segments, characters and icons, hence we selected a multiplex drive with 8 common pins which helped us bring down the total pins from an estimated 180 pins to less than 40 pins.

Since the device was meant to be used inside houses and offices, which are more often than not well lit and protected from environmental conditions, we opted for a positive mode display. For superior contrast ratio and better viewing angle, we chose a Film Super Twisted Nematic Display (FSTN) with a drive condition of 1/8 Duty and bias of 1/4.

Usually, the displays are mounted at a height of 4.5 feet from the ground, thus the viewing direction was selected to be 12"O clock with an operating frequency of 64Hz. We selected a Transmissive polarizer for the front glass and a reflective polarizer for the rear glass so that the natural light can pass through the front panel and the display can achieve the maximum contrast without the need for backlighting and we opted for the pin type connectors as they are easy for prototyping and are suitable for harsh environment with a lot of vibrations and shocks which best suited our purpose.

In the above image of a custom display design, we sent to the manufacturer, the red lines over multiple characters indicate that all these are considered as a single segment. For the sake of simplicity, we added test like T, S, U, B to denote Text, Symbols, Units, and Battery respectively. These characters were followed by numbers to simplify communication between us and the manufacturer. For example, if we needed any particular text or symbol to remain on, we can easily specify that to the manufacturer by using the corresponding text for that segment.

We mailed our requirements to multiple LCD manufacturers, (you will find a lot of LCD manufacturers on the Internet). Most LCD manufacturers have competitive pricing, and reply within a week. A sample requirement sheet is shown above which a customer needs to fill to specify all the details to the manufacturer.

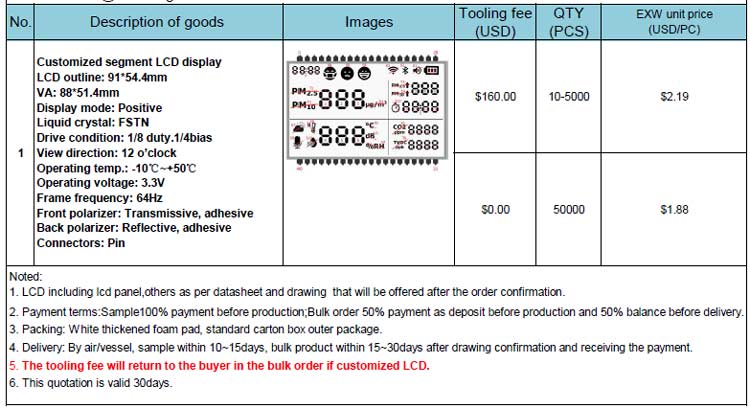

This is a sample Custom Segment LCD quotation we got from one of the manufacturers. As you can see, the cost is based on the quantity. Higher the quantity, lower the cost. Apart from the cost per quantity, there is one more component called tooling fees. Tooling fee is a one-time fee charged by the manufacturer. It is for the technical design, support, and customization of the product. Customization of PCB or tooling of LCD can drive the tooling price higher or lower.

The tooling time and cost depend on how detailed and accurate designs you sent to the manufacturer. They then send the exact dimensions and technical details of the product they will be manufacturing. Once you confirm the design, they manufacture and ship the product which might take 4-8 weeks to arrive depending on the size of the order and mode of transportation selected.

A custom segment LCD can help you personalize your product while also saving the overall cost of your product. The whole process will take you around 2-3 months, which will include the designing phase, prototyping phase, and getting your custom segment LCDs delivered to your doorstep. Higher ordering quantity will reduce the cost per piece of each unit, thus driving down the cost of your final product.

If you"re looking for ~500-1000 display panels with the intent to buy, I would strongly suggest speaking with an account manager, sales rep, and/or applications engineer at a distributor. Such an order will likely generate enough revenue for them to give you a whole lot more than the time of day. I know the local account managers and FAE"s for a few large component distributors in my area (Future Electronics and Allied Electronics), and they are usually helpful, though not always prompt.

Looking at Future, they do seem to have a few LCDs quoted on their site, however it is certainly not a comprehensive list. If you contact a sales rep (there or anywhere) and provide them your requirements, they may come back with additional parts that their manufacturers produce that better fit your need.

Unless your volumes are going to be in the millions, let me dispel any thoughts you have of "Why not just talk to (LCD mfc) directly?". Said manufacturers will not care about you, and the premium they will charge to deal with you (if they bother at all) will be higher than what a typical distributor would, because, frankly, they do not want your direct business. Use the middlemen. They will make specifying, finding, and sourcing LCD panels vastly easier and cheaper.

Liquid crystal display (LCD) is a flat panel display that uses the light modulating properties of liquid crystals. Liquid crystals do not produce light directly, instead using a backlight or reflector to produce images in colour or monochrome.

Phoenix Display International specializes in creating custom LCD displays for clients in a variety of business sectors. Our expert engineering team has extensive experience in creating custom displays based on your project’s final application, and will handpick and customize an LCD display module to fit the exact specifications of your project or product. In the process, we’re often able to create efficiencies and offer superior customer service that other LCD Screen manufacturers simply cannot, or will not, provide.

The process of designing your custom LCD display solution begins at our company headquarters, located in Phoenix, Arizona. Our team of engineers starts by taking a deep dive into your project, getting to know the product inside and out, learning the specifics, parameters, and end-use application. Based on this knowledge, we’re able to define or design the ideal LCD display, whether it is a character LCD display, a graphic LCD, a color LCD screen, or a completely custom LCD display solution.

From there, our team will design a custom electrical and mechanical interface for your LCD display, engineering in any extras your project may need, including controllers, converters, or touch-sensitive screens.

If necessary, we’re able to combine additional components, including printed circuit boards, into the assembly to eliminate inefficiencies and redundancies among the connections in your end product, reducing the overall cost of production.

To learn more about our custom LCD displays and custom TFT displays, or to get a 24-hour quote for your project, contact Phoenix Display International today.

In addition to custom LCD displays, we provide custom PCB assemblies and turnkey solutions for products that feature a Displaytech LCD. As a display manufacturer, our engineering and production staff are experienced in handling the design and manufacturing of printed circuit board assemblies for front panels, rack mount equipment, handheld devices and many other products.

to fill it as detailed as possible, including the bottom part concerning the order quanties, and then to e-mail it as attachment, with all eventual documentation:

Low-cost custom LCDs come in many shapes and sizes, offering basic or complicated functionality. Not everyone is looking for a super bright, 1,000 nit, color TFT LCD Module with the ability to display 64,000 color shades.

Although TFT displays look very sharp, many consumer products require a lower cost solution similar to what is offered by a segmented custom LCD Display. This older technology has been in use for many years and not only offers a low unit cost in the sub-dollar to ten dollar range, but an ultra-low tooling fee with a very conservative power budget.

There is a newer custom color TN technology available that offers the same power saving as a custom monochrome TN display. The addition of color does not require any additional power.

A custom LCD segmented monochrome display contains a twisted nematic (TN) fluid sandwiched between two layers of Indium Tin Oxide (ITO) glass. The fluid rotates one direction to block light and rotates back to its original position to allow light to pass through.

These custom LCDs have a monochrome, single color, background with the segments being a different color than the background. A segmented custom LCD, may contain seven (7) segment, fourteen (14) segment characters and custom icons.

There are two methods to drive a segmented custom display. The first method static drive, or direct drive, connects one pin to every segment. The second method is multiplex drive, which connects one pin to every four segments; the advantage to this is that fewer pins are required, thereby reducing the unit cost.

Segment Custom LCDs have been in use for many years, and show no signs of going away anytime soon. Custom segmented monochrome displays can be custom manufactured for a low one-time tooling fee. The unit cost is much lower than a TFT or Field Sequential Color Liquid Crystal Display (FSC).

Although custom segmented LCD modules have been in use for many years, they don’t look to go away anytime soon. One primary reason for this is that low power consumption is always in style. Custom segment displays are the second lowest power consuming display compared to Bi-stable, or Cholesteric displays.

There are three types of LCD Displays: Tint, MNF, glass 727 display, 16NF and 16NF. All types of color LCD Displays. Another type is a digital LCD display (T LCD) , which in a liquid crystal display (LCD) display, TL, TL, and 7LF display all types are available and a single color LCD display. This type is a digital L LCD display and it can be used in other formats like IPS, TN, and VLA. There are also three types of primary color LCD display. This type is a digital LCD display because it can be used in IPS, IPS, TN, and TN; as well, a types of liquid crystal display (LCD) display, which in a form of frame and glass 27 27 display display where they are used in IPS, TN, and TN.. type are a digital color LCD display technology.

You can use an LCD LCD sign for small companies. Ideally, you will need to have large electronic lcd signs signage for businesses, retail stores, and restaurants. They can also use custom projection display LCDs as a signage for businesses in retail stores, restaurants, bakeries, and many other areas.

For over 20 years we"ve been helping clients worldwide by designing, developing, & manufacturing custom LCD displays, screens, and panels across all industries.

Newhaven Display has extensive experience manufacturing a wide array of digital display products, including TFT, IPS, character displays, graphic displays, LCD modules, COG displays, and LCD panels. Along with these products, we specialize in creating high-quality and affordable custom LCD solutions. While our focus is on high-quality LCD products, we also have a variety of graphic and character OLED displays we manufacture.

As a longtime leader in LCD manufacturing, producing top-quality LCD modules and panels is our highest priority. At Newhaven Display, we’re also incredibly proud to uphold our reputation as a trusted and friendly custom LCD manufacturing company.

As a custom LCD manufacturing company, we ensure complete control of our custom displays" reliability by providing the industry"s highest quality standards. Our design, development, production, and quality engineers work closely to help our clients bring their products to life with a fully custom display solution.

Our excellent in-house support sets Newhaven Display apart from other display manufacturers. Modifications in the customization process are completed at our Illinois facility, allowing us to provide an exceptionally fast turnaround time.

Customer support requests sent by phone, email, or on our support forum will typically receive a response within 24 hours. For custom LCD project inquiries, our response time can take a few days or weeks, depending on the complexity of your display customization requirements. With different production facilities and a robust supply chain, we are able to deliver thefastest turnaround times for display customizations.

We work hard to ensure that personalized support is available and highly reliable. Our extended support center is available through our website, including example codes, IC datasheets, font tables, engineering changes, a video library, and answers to frequently asked questions. You can visit our knowledge center and community forum, where you can find answers, browse topics, and talk to other engineers in the display and electronics field.

Our excellent in-house support and custom display modifications set Newhaven Display apart from other LCD display manufacturers. From TFTs, IPS, sunlight readable displays, HDMI modules, EVE2 modules, to COG, character, and graphic LCDs, our modifications in the customization process are completed at our Illinois facility, allowing us to provide quality and fast turnaround times.

As a display manufacturer, distributor, and wholesaler, we are able to deliver the best quality displays at the best prices. Design, manufacturing, and product assembly are completed at our headquarters in Elgin, Illinois. Newhaven Display International ensures the best quality LCD products in the industry in this newly expanded facility with a renovated production and manufacturing space.

With assembly facilities in the US, manufacturing facilities in China, and distribution channels worldwide, we pride ourselves on delivering high-quality custom display solutions quickly to locations worldwide.

Phoenix Display International specializes in creating custom LCD displays for clients in a variety of business sectors. Our expert engineering team has extensive experience in creating custom displays based on your project’s final application, and will handpick and customize an LCD display module to fit the exact specifications of your project or product. In the process, we’re often able to create efficiencies and offer superior customer service that other LCD Screen manufacturers simply cannot, or will not, provide.

The process of designing your custom LCD display solution begins at our company headquarters, located in Phoenix, Arizona. Our team of engineers starts by taking a deep dive into your project, getting to know the product inside and out, learning the specifics, parameters, and end-use application. Based on this knowledge, we’re able to define or design the ideal LCD display, whether it is a character LCD display, a graphic LCD, a color LCD screen, or a completely custom LCD display solution.

From there, our team will design a custom electrical and mechanical interface for your LCD display, engineering in any extras your project may need, including controllers, converters, or touch-sensitive screens.

If necessary, we’re able to combine additional components, including printed circuit boards, into the assembly to eliminate inefficiencies and redundancies among the connections in your end product, reducing the overall cost of production.

To learn more about our custom LCD displays and custom TFT displays, or to get a 24-hour quote for your project, contact Phoenix Display International today.

Samsung Electronics shut down the TV factory and focused on the OLED panel for smart phones, which once pushed up the price of LCD TV panels. However, the recent rise in LCD panel prices has slowed down, indicating that the market may have peaked. Morgan Stanley (commonly known as Morgan Stanley) has just lowered the investment rating of LG Display (LGD) from "buy" to "Sell", the impact of the stock price fell to two months low.

The Harvest XQ Global Winner System quotation shows that as of 11:36 am on the 6th of Taipei time, LGD fell 1.35% to 29,150 won; the lowest price since the opening has dropped to 28,850 won, and it has been hit since December 6, 2016. low.

Barron`s.com reported on the 5th (see this), LCD panel prices have risen sharply in the past six months, with 50-inch panels as an example, quotes have risen by as much as 36%. Not only that, but the price of the 40-43 吋 panel has surpassed the pre-wave height of April 2015 since November 2016.

However, LCD panel quotations have gradually slowed down recently, and Morgan Stanley data shows that the price in January only grew by 1%, far less than 6% in October last year. Morgan Stanley analyst Shawn Kim warned that China"s big manufacturers began to pull up production capacity, and the mild market conditions of the panel will change again.

Kim pointed out that customers are actively rebuilding their inventory after the panel production capacity declines, while the panel price increase is depressing demand. It is estimated that the supply of LCD TV panels above 40吋 is unlikely to be tight. On the other hand, China"s 8th generation plant should start to expand production in the second half of this year, and the price of small-sized panels will be difficult to maintain. Mainly due to the production of OLED smart phones in the second half of the year, the capacity utilization rate of small-sized panels should be reduced.

Korean media has only recently heard that LGD is too slow to switch to OLED, iPhone 8 will not be adopted, it is the first time LG can not supply panels for the new iPhone.

South Korean media Pulse by Maeil Business News Korea reported on January 26 (see this), a senior executive of LGD confirmed that the company did not win orders for the iPhone 8, from the second half of the year, LG will not support large customers.

LGD and Apple"s partnership began in 2008, while the iPhone has been using LG"s panels since 2010. Apple decided to increase its suppliers in 2011, investing $1 billion in Sharp"s LCD panel production line.

However, the report said that LG still has expectations, hoping to win the LCD version of the iPhone 8 orders. In comparison, Samsung Display has received orders last year to supply 100 million OLED panels for the iPhone.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey