tft lcd display wiki factory

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

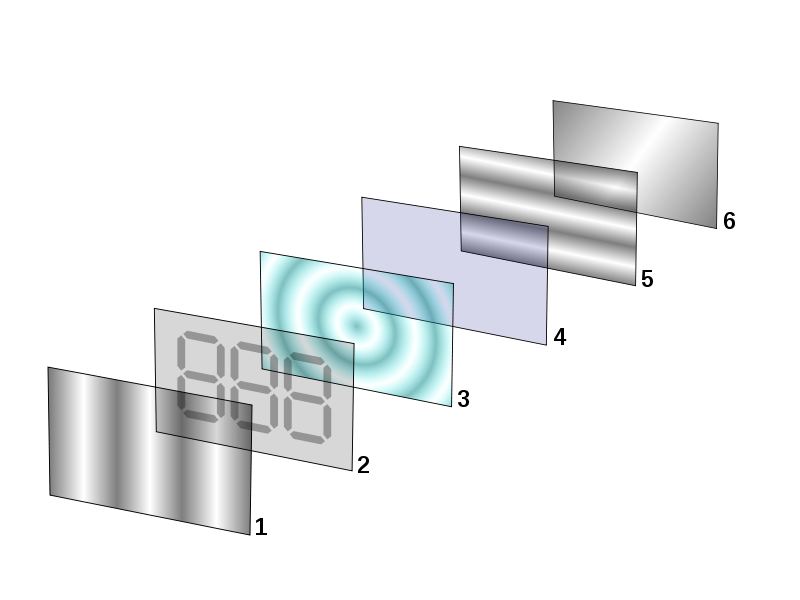

The liquid crystal displays used in calculators and other devices with similarly simple displays have direct-driven image elements, and therefore a voltage can be easily applied across just one segment of these types of displays without interfering with the other segments. This would be impractical for a large display, because it would have a large number of (color) picture elements (pixels), and thus it would require millions of connections, both top and bottom for each one of the three colors (red, green and blue) of every pixel. To avoid this issue, the pixels are addressed in rows and columns, reducing the connection count from millions down to thousands. The column and row wires attach to transistor switches, one for each pixel. The one-way current passing characteristic of the transistor prevents the charge that is being applied to each pixel from being drained between refreshes to a display"s image. Each pixel is a small capacitor with a layer of insulating liquid crystal sandwiched between transparent conductive ITO layers.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

Most TN panels can represent colors using only six bits per RGB channel, or 18 bit in total, and are unable to display the 16.7 million color shades (24-bit truecolor) that are available using 24-bit color. Instead, these panels display interpolated 24-bit color using a dithering method that combines adjacent pixels to simulate the desired shade. They can also use a form of temporal dithering called Frame Rate Control (FRC), which cycles between different shades with each new frame to simulate an intermediate shade. Such 18 bit panels with dithering are sometimes advertised as having "16.2 million colors". These color simulation methods are noticeable to many people and highly bothersome to some.gamut (often referred to as a percentage of the NTSC 1953 color gamut) are also due to backlighting technology. It is not uncommon for older displays to range from 10% to 26% of the NTSC color gamut, whereas other kind of displays, utilizing more complicated CCFL or LED phosphor formulations or RGB LED backlights, may extend past 100% of the NTSC color gamut, a difference quite perceivable by the human eye.

The transmittance of a pixel of an LCD panel typically does not change linearly with the applied voltage,sRGB standard for computer monitors requires a specific nonlinear dependence of the amount of emitted light as a function of the RGB value.

In 2004, Hydis Technologies Co., Ltd licensed its AFFS patent to Japan"s Hitachi Displays. Hitachi is using AFFS to manufacture high end panels in their product line. In 2006, Hydis also licensed its AFFS to Sanyo Epson Imaging Devices Corporation.

Less expensive PVA panels often use dithering and FRC, whereas super-PVA (S-PVA) panels all use at least 8 bits per color component and do not use color simulation methods.BRAVIA LCD TVs offer 10-bit and xvYCC color support, for example, the Bravia X4500 series. S-PVA also offers fast response times using modern RTC technologies.

A technology developed by Samsung is Super PLS, which bears similarities to IPS panels, has wider viewing angles, better image quality, increased brightness, and lower production costs. PLS technology debuted in the PC display market with the release of the Samsung S27A850 and S24A850 monitors in September 2011.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

The bare display panel will only accept a digital video signal at the resolution determined by the panel pixel matrix designed at manufacture. Some screen panels will ignore the LSB bits of the color information to present a consistent interface (8 bit -> 6 bit/color x3).

With analogue signals like VGA, the display controller also needs to perform a high speed analog to digital conversion. With digital input signals like DVI or HDMI some simple reordering of the bits is needed before feeding it to the rescaler if the input resolution doesn"t match the display panel resolution.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

Brody, T. Peter; Asars, J. A.; Dixon, G. D. (November 1973). "A 6 × 6 inch 20 lines-per-inch liquid-crystal display panel". 20 (11): 995–1001. Bibcode:1973ITED...20..995B. doi:10.1109/T-ED.1973.17780. ISSN 0018-9383.

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

Kim, Sae-Bom; Kim, Woong-Ki; Chounlamany, Vanseng; Seo, Jaehwan; Yoo, Jisu; Jo, Hun-Je; Jung, Jinho (15 August 2012). "Identification of multi-level toxicity of liquid crystal display wastewater toward Daphnia magna and Moina macrocopa". Journal of Hazardous Materials. Seoul, Korea; Laos, Lao. 227–228: 327–333. doi:10.1016/j.jhazmat.2012.05.059. PMID 22677053.

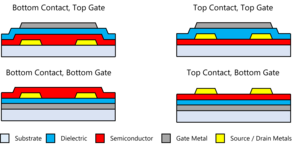

A thin-film transistor (TFT) is a special type of field-effect transistor (FET) where the transistor is thin relative to the plane of the device.substrate. A common substrate is glass, because the traditional application of TFTs is in liquid-crystal displays (LCDs). This differs from the conventional bulk metal oxide field effect transistor (MOSFET), where the semiconductor material typically is the substrate, such as a silicon wafer.

TFTs can be fabricated with a wide variety of semiconductor materials. Because it is naturally abundant and well understood, amorphous or polycrystalline silicon was historically used as the semiconductor layer. However, because of the low mobility of amorphous siliconcadmium selenide,metal oxides such as indium gallium zinc oxide (IGZO) or zinc oxide,organic semiconductors,carbon nanotubes,metal halide perovskites.

Because TFTs are grown on inert substrates, rather than on wafers, the semiconductor must be deposited in a dedicated process. A variety of techniques are used to deposit semiconductors in TFTs. These include chemical vapor deposition (CVD), atomic layer deposition (ALD), and sputtering. The semiconductor can also be deposited from solution,printing

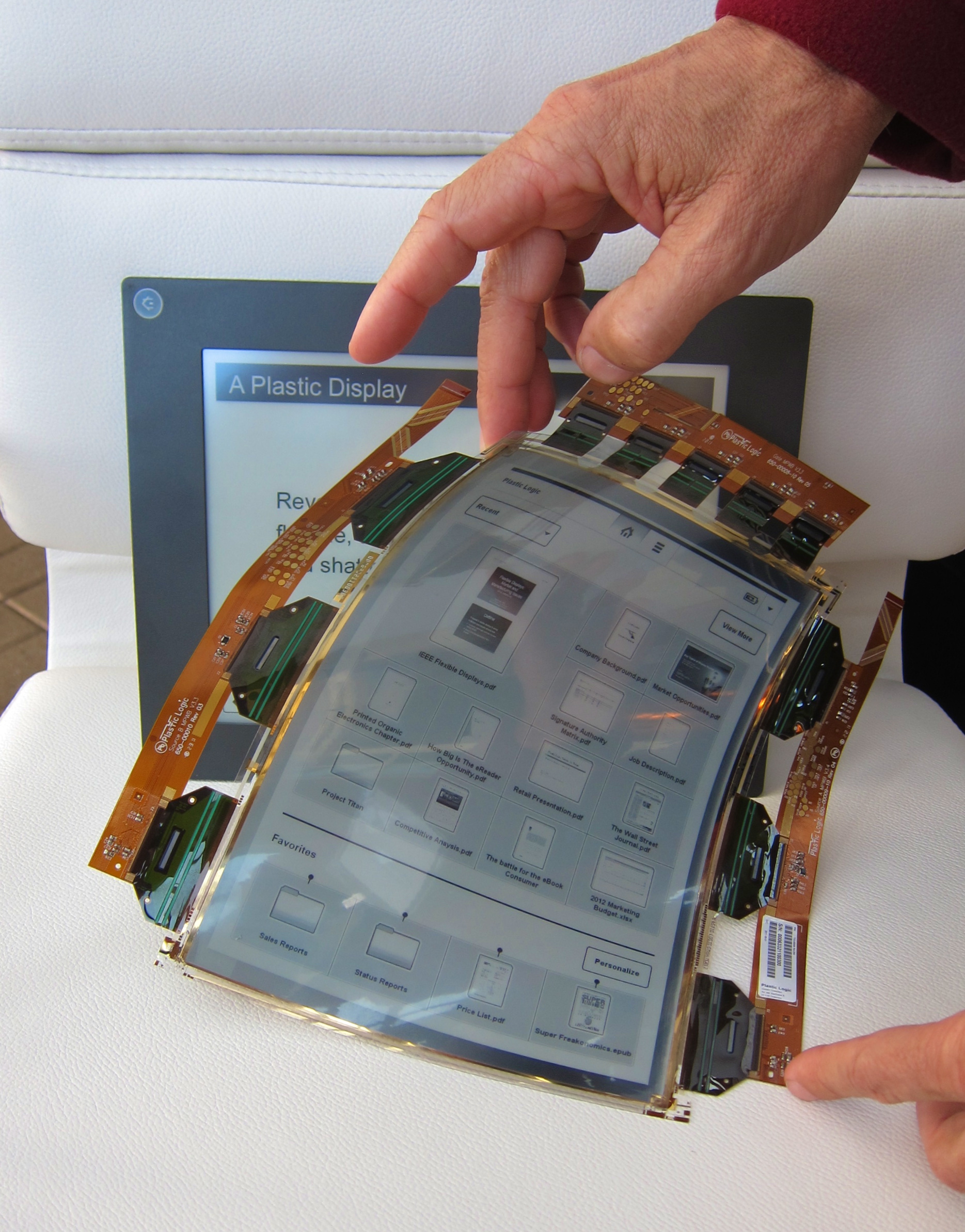

Some wide band gap semiconductors, most notable metal oxides, are optically transparent.electrodes, such as indium tin oxide (ITO), some TFT devices can be designed to be completely optically transparent.head-up displays (such as on a car windshield).The first solution-processed TTFTs, based on zinc oxide, were reported in 2003 by researchers at Oregon State University.Universidade Nova de Lisboa has produced the world"s first completely transparent TFT at room temperature.

The best known application of thin-film transistors is in TFT LCDs, an implementation of liquid-crystal display technology. Transistors are embedded within the panel itself, reducing crosstalk between pixels and improving image stability.

As of 2008LCD TVs and monitors use this technology. TFT panels are frequently used in digital radiography applications in general radiography. A TFT is used in both direct and indirect capturemedical radiography.

The most beneficial aspect of TFT technology is its use of a separate transistor for each pixel on the display. Because each transistor is small, the amount of charge needed to control it is also small. This allows for very fast re-drawing of the display.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET in which germanium monoxide was used as a gate dielectric. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. In 1966, T.P. Brody and H.E. Kunig at Westinghouse Electric fabricated indium arsenide (InAs) MOS TFTs in both depletion and enhancement modes.

The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard J. Lechner of RCA Laboratories in 1968.dynamic scattering LCD that used standard discrete MOSFETs, as TFT performance was not adequate at the time.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).electroluminescence (EL) in 1973, using CdSe.active-matrix liquid-crystal display (AM LCD) using CdSe in 1974, and then Brody coined the term "active matrix" in 1975.

A breakthrough in TFT research came with the development of the amorphous silicon (a-Si) TFT by P.G. le Comber, W.E. Spear and A. Ghaith at the University of Dundee in 1979. They reported the first functional TFT made from hydrogenated a-Si with a silicon nitride gate dielectric layer.research and development (R&D) of AM LCD panels based on a-Si TFTs in Japan.

By 1982, Pocket TVs based on AM LCD technology were developed in Japan.Fujitsu"s S. Kawai fabricated an a-Si dot-matrix display, and Canon"s Y. Okubo fabricated a-Si twisted nematic (TN) and guest-host LCD panels. In 1983, Toshiba"s K. Suzuki produced a-Si TFT arrays compatible with CMOS integrated circuits (ICs), Canon"s M. Sugata fabricated an a-Si color LCD panel, and a joint Sanyo and Sanritsu team including Mitsuhiro Yamasaki, S. Suhibuchi and Y. Sasaki fabricated a 3-inch a-SI color LCD TV.

The first commercial TFT-based AM LCD product was the 2.1-inch Epson ET-10Hitachi research team led by Akio Mimura demonstrated a low-temperature polycrystalline silicon (LTPS) process for fabricating n-channel TFTs on a silicon-on-insulator (SOI), at a relatively low temperature of 200°C.Hosiden research team led by T. Sunata in 1986 used a-Si TFTs to develop a 7-inch color AM LCD panel,Apple Computers.Sharp research team led by engineer T. Nagayasu used hydrogenated a-Si TFTs to demonstrate a 14-inch full-color LCD display,electronics industry that LCD would eventually replace cathode-ray tube (CRT) as the standard television display technology.notebook PCs.IBM Japan introduced a 12.1-inch color SVGA panel for the first commercial color laptop by IBM.

TFTs can also be made out of indium gallium zinc oxide (IGZO). TFT-LCDs with IGZO transistors first showed up in 2012, and were first manufactured by Sharp Corporation. IGZO allows for higher refresh rates and lower power consumption.polyimide substrate.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

Brody, T. Peter; Asars, J. A.; Dixon, G. D. (November 1973). "A 6 × 6 inch 20 lines-per-inch liquid-crystal display panel". 20 (11): 995–1001. Bibcode:1973ITED...20..995B. doi:10.1109/T-ED.1973.17780. ISSN 0018-9383.

Morozumi, Shinji; Oguchi, Kouichi (12 October 1982). "Current Status of LCD-TV Development in Japan". Molecular Crystals and Liquid Crystals. 94 (1–2): 43–59. doi:10.1080/00268948308084246. ISSN 0026-8941.

Mimura, Akio; Oohayashi, M.; Ohue, M.; Ohwada, J.; Hosokawa, Y. (1986). "SOI TFT"s with directly contacted ITO". IEEE Electron Device Letters. 7 (2): 134–6. Bibcode:1986IEDL....7..134M. doi:10.1109/EDL.1986.26319. ISSN 0741-3106. S2CID 36089445.

Sunata, T.; Yukawa, T.; Miyake, K.; Matsushita, Y.; Murakami, Y.; Ugai, Y.; Tamamura, J.; Aoki, S. (1986). "A large-area high-resolution active-matrix color LCD addressed by a-Si TFT"s". 33 (8): 1212–1217. Bibcode:1986ITED...33.1212S. doi:10.1109/T-ED.1986.22644. ISSN 0018-9383. S2CID 44190988.

Sunata, T.; Miyake, K.; Yasui, M.; Murakami, Y.; Ugai, Y.; Tamamura, J.; Aoki, S. (1986). "A 640 × 400 pixel active-matrix LCD using a-Si TFT"s". IEEE Transactions on Electron Devices. 33 (8): 1218–21. Bibcode:1986ITED...33.1218S. doi:10.1109/T-ED.1986.22645. ISSN 0018-9383. S2CID 6356531.

Nagayasu, T.; Oketani, T.; Hirobe, T.; Kato, H.; Mizushima, S.; Take, H.; Yano, K.; Hijikigawa, M.; Washizuka, I. (October 1988). "A 14-in.-diagonal full-color a-Si TFT LCD". Conference Record of the 1988 International Display Research Conference: 56–58. doi:10.1109/DISPL.1988.11274. S2CID 20817375.

The graphic display coordinates and the text display coordinates of the 2.2”screen are two different coordinates systems. The origin of the graphic display coordinates begin from the centre point of the screen while that of the later one begins from the top left hand side of the screen.

The following codes are just one part of the API funciotn description. For more information, please refer to ST7687S Library Introduction and Display Library Introduction.

* @The formal parameter size refers to the text size based on the font(6×8). Size is rounded to the integer greater than 0; if size is 1, the pixel points the font occupied will be 6×8. if it is 2, that will be 12×16. The text out of the screen cannot be displayed;

The function of the program: taking the centre point of the 2.2”screen as the starting point(note: the graphic display coordinates and the text display coordinates are two different coordinates, the centre point of the graphic display coordinates is (64, 64) while that of the later one is (0, 0)), display a character string ”fire” with red text background box, white font and the size of the font 2 on the screen. The formal parameter size of the function to set font size tft.setTextSize (uint8_t size) should be greater than 0 and the text out of the screen cannot be displayed.

The function of the program: use the software image2lcd.exe to extract the bitmap of one image and display it on the centre part of the 2.2”screen(note: for the reason of UNO’s internal memory, the following demo cannot be accepted on UNO since the image file is too large, but it can be displayed on ESP32. So you’d better choose small image file if you want to display it on UNO. ) The parameter selection of the software is provided below.

This is a 2.8” TFT Resistive Touchscreen Display. The module, with a resolution of 320x240, adopts ILI9341 as driver IC and SPI (4-line) communication mode. The board integrates touch chip XPT2046, which converts the touch data collected by the AD to SPI data. The module also integrates an SD card slot allowing you to easily read the full-color bitmap. There are two modes of wiring supplied, normal pin header wiring and GDI. The latter one requires to work with a main controller board with a GDI interface (e.g. FireBeetle-M0). You can use it with only one FPC line plugging in, which reduces the complexity of the wiring. Furthermore, it features high resolution, wide viewing angle, and simple wiring, which can be used in all sorts of display applications, such as, IoT controlling device, game console, desktop event notifier, touch interface, etc.

This product is Breakout module with SPI communication mode and GDI interface, which reduces the wiring complexity and makes it easy to display what was read from the SD card.

One of the things that sets us apart from other touchscreen display manufacturers is the level of customization we offer. Our product portfolio includes a wide range of TFT & Monochrome LCDs, OLED, touch sensor and glass technologies, which we can provide stand-alone or integrated into complete assemblies.

Our custom display, touch and cover lens solutions are used in a variety of end-user applications. For example, our touchscreens are used in many vehicle infotainment systems and dashboard controls. We also provide custom touch displays for popular marine applications such as watercraft navigation screens and fish finders. For consumer electronics, we manufacture custom touchscreen display solutions and smartphone screen protectors. Whether your application will be used in the great outdoors, a construction site, or a hospital operating room, we can build a custom, all-in-one solution for your needs.

Our strength as a custom display company comes from the extensive technical expertise of our engineering team. The approach our engineers take is always based on experience and data-driven decisions that help you find the right solution for your application. In addition, our extensive manufacturing capabilities enable us to deliver quick design cycles, cost-effective solutions, and high-quality products that will meet your specifications even in the harshest conditions. To learn more about what makes us the display manufacturer for your needs, get in touch with us today.

Furthermore, IBM and Lenovo branded certain types of displays under such names as Flexview, MaxBright and UltraLight TFT. See below for more information on their special characteristics.

The Flexview LCD displays used on select IBM/Lenovo models use the IPS (In-Plane Switching) technology, which provide wide viewing angles (the display can literally be seen from all angles with no color distortions and minimal loss of contrast), better contrast (making the whites brighter and the blacks darker) and richer colors overall than the regular laptop screens. In-plane switching (IPS) is an evolution of the Twisted Nematic field effect (TN) LCD technology.

The FFS (Fringe Field Switching) technology is patented by BOE-Hydis LCD manufacturing company and extends conventional IPS technology by offering even wider viewing angles (full 180 degrees are claimed) and better transmittance. The X41 Tablet for example features a Super Wide Angle FFS screen.

sRGB Mode is a method applied in some BOE-Hydis TFTs to re-map colors from the native (non-calibrated) TFT color space into a color space within a scaled down sRGB color triangle, thus with sides parallel to the sRGB color triangle. This means that the color gamut is not 72% of NTSC like normal sRGB, but it is still in the range of 45-55%. By sRGB mode one gains the benefit of a completely calibrated LCD (in sRGB terms) within the possible color gamut the color filters allow it to display.

6) Power on the Raspberry Pi and wait for a few seconds until the LCD displays normally. And the touch function can also work after the system starts.

If you are using the Buster branch system, the DSI LCD can work with Raspberry Pi directly after connecting and powering on. But if you are using the Bullseye branch system, you need to modify the config.txt as below:

It is commonly held that a team at the RCA David Sarnoff Research Center in Princeton, NJ under the leadership of George H. Heilmeier did the initial development of liquid crystal displays (LCDs), in particular of the Dynamic Scattering Mode (DSM) LCD.

In 2002, a comprehensive history of LCDsSharp Corporation, a major competitor of Casio Computer Co., and some "survivorship bias" concerning persons and institutions still engaged in LCD work, had an influence on the sources used.

As the very first Member of Technical Staff doing work on LCDs at the Brown, Boveri Research Center in Baden, Switzerland, I have recently become personally motivated to give my account of less known events that took place while I was employed by BBC from 1969 to 1980. First, some personal background:

A new facility for its research center was opened in the Stanford Industrial Park at Hillview Avenue in Palo Alto. I moved to Palo Alto and drove across the Bay Bridge to attend classes at CAL. While I was studying at Berkeley from 1966 to 1968, political student activities on the campus were in full bloom, but these were for me not more than a sideshow. At Friden I conceived a potential electronic replacement for the magnetic wire memory in the desktop electronic calculator. Transistors were relatively expensive. Therefore, using flip-flops with two transistors to store bits was not an option. I proposed a type of dynamic shift register using basically one transistor and capacitor per stage in 1967. Unlike the concept of a Bucket Brigade for analog voltages as first published by Philips researchers in 1969 and later implemented as Charge-Coupled Devices, my circuit was intended to shift digital bit information in a serial memory. This is when I learned about the US custom of writing an invention report. It made me aware of the importance of patent notebooks and filings during my later work on LCDs (see section Patents).

Luckily, I could do my thesis at work choosing a topic of interest to both the company and my research adviser Martin Graham Oral History, Martin H. Graham. This was an exemplary cooperation between university and industry already at that time! The name of my final report was A Vector Generator for CRT Displays. I got the M.Sc. degree as a straight-A student, which gave me quite a feeling of satisfaction after my initial difficulties in the US. Now the doors were open. I got job offers from Bell Labs, Murray Hill, NJ, and the Singer Librascope Division in the Bay Area, but I decided to move back to Switzerland in 1968.

In May 1969 BBC entered a formal cooperation with Hoffmann-La Roche (Roche) entitled Medical Electronics, in which various common projects were studied, such as a new mobile intensive care unit. I was asked by F. K. von Willisen to look into display technologies as part of the BBC side of the cooperation. On December 11th 1969 I gave an overview of state-of-the-art display technologies including RCA"s work on LCDs at an internal BBC symposium. At the same venue Gerhard Meier of the Fraunhofer Institute in Freiburg, Germany, explained liquid crystals in detail. This institute already had a tradition of LC research. There was an exchange of staff and knowledge between this institute and a team at the Kent State University LC Institute, where Alfred Saupe and Juergen Nehring worked at the time.

In following with the conclusions of internal reports by both sides, LCDs were established as a common research project. I became the very first person at BBC to work full time on LCDs, while Roche assigned organic chemists and hired additional physicists. Roche concentrated on the synthesis of LC substances suitable for LCDs and the physics of electrooptical effects in LC structures. BBC developed the corresponding cell technology, explored applications and driving electronics. It was a truly interdisciplinary effort. I set up a small team with a young electrical engineer and a couple of technical assistants to develop a suitable cell technology. We used a pyrolytic process to deposit metaloxyd transparent electrodes on glass substrates. The disadvantage of this approach was that edging of electrode patterns was difficult. It was exiting to work with our first LCDs exhibiting the Dynamic Scattering Mode (DSM) discovered by RCA. A common project with ROCHE called for patient monitoring to indicate crucial measurements as part of new life support equipment, so we studied bar graph displays.

We found that we needed an array of several quasi-analog bar displays side-by-side, which led us to study simple matrix displays. We certainly were among the first to study the limitations of matrix-addressed LCDs, and I disclosed some of the results at conferences later-on. In an experimental unit we connected a discrete capacitor in parallel to each LC segment and decoupled the segment with a diode from the driving electronics when not selected.TFT) and a storage capacitor at each pixel.

In the meantime Juergen Nehring, a physicist with a background in LC research, joined us in 1971. Together with him we published results for contrast enhancement in a special matrix display using a high-frequency quenching scheme.

Early on I did measurements of the electrooptic threshold voltage in LCDs. As a simple matrix LCD requires sequential addressing of rows (scanning, multiplexing) with a periodic refresh, pulsed voltages have to be applied to the segments/pixels. In 1972, I found by varying the pulse width that the threshold, measured as RMS voltage, remains nearly constant.

A major milestone was the discovery of the 90-degree Twisted Nematic field effect (TN cell) and its properties by Wolfgang Helfrich and Martin Schadt, physicists at Roche. The corresponding patent application was filed on December 4th, 1970 (see section Patents). When new LC substances were developed for TN LCDs by chemists at Roche, we demonstrated the good cooperation by publishing the result together.

I probably did the first public demonstration of a working Twisted Nematic LCD, at least in Europe, at the IEE Conference on Displays organized by the University of Loughborough, UK, in September 1971. It was a transparent, quasi-analog bar TN LCD that I put on an overhead projector to show it to the audience. By varying the voltage applied, the bar moved up and down. It aroused much interest, and a I received a question from a participant about small, noticeably inhomogeneous areas, which were later identified as domains of reverse twist.

Unfortunately the common projects with Roche came to an end as early as March 1972. Roche had bought Electro-Médicine Dassault, France, which maintained some activities that were directly competing with some of the work at BBC (not related to LCDs). Our management considered this as a breach of confidence. Thereafter Roche became a supplier of LC substances to BBC. I played a role in evaluating Roche mixtures for our displays.

Early on Georges Keller, head of the electronic components division of BBC, became interested in LCDs. He provided the support of his glass technology experts at the tube division. Since initially we used a Schiff-base LC mixture for our TN displays, we had to hermetically seal our cells with glass frit bonding along the edges at high temperatures to avoid humidity entering the cell. This prevented us from using the common technique of orienting the LC molecules by rubbing an organic layer (a surfactant) on the glass surface. We employed a vacuum-deposited layer of SiO instead, where the structure for orientation is defined by the evaporation angle. The electrodes were manufactured with a new vacuum deposition process optimized by Balzers Ltd. in the neighboring Principality of Liechtenstein.

Prototype displays were made for a joint-effort wristwatch project that we did together with Ebauches SA, the major Swiss watch movements manufacturer (now part of the Swatch Group) and Faselec, the Swiss IC subsidiary of Philips. A working quartz digital wristwatch was shown at the MUBA fair in March 1973. It contained chips made by Faselec and our 8-digit TN LCD.

Georges Keller asked me to provide the technology part for a business plan to industrially manufacture LCDs. The main customers envisioned were wristwatch manufacturers. A pilot line was set up at the BBC tube factory in Birrfeld during 1973. Top management approved the business plan and credit to construct a brand new plant in Lenzburg.

As far as I know, it was the first dedicated factory worldwide, built from scratch, measuring 39,000 square feet, exclusively to manufacture TN LCDs in volume. ILIXCO had a small-scale operation in the US (comparable to a pilot line), and Sharp of Japan started with DSM LCDs for their calculators about at the same time. BBC built an additional LCD factory of 47,000 square feet in 1978.

Nobody knew in 1973 whether the new LCDs would have a sufficient operating life expectancy. I was charged to set up and supervise accelerated tests at elevated temperatures and voltages to get some clues. As a result, we improved our cell technology. I left the research center and joined the new LCD division in the capacity of deputy head to develop applications and manage part of the activities such as custom design of new LCDs, contacts with LC substance suppliers, IC manufacturers, testing and patent matters.

During the following years a lot of effort was needed to automate manufacturing. Labor costs in Switzerland were (and still are) high. The process chosen initially was not well suited for larger substrates and low-cost manufacturing. BBC was not any more willing to finance expansion in an area not important to its basic business. Therefore, a 50/50 joint venture was set up with Philips of The Netherlands at the beginning of 1980, called Videlec AG. Philips had a strong interest in display technologies for their consumer products, in particular the potential use of LCDs in TV sets.

The Japanese officer of Oki Electric from Germany, who was with us on that day, took a bow nearly to the ground when he greeted this influential man from the center of his Keiretsu. OKI Electric was interesting for us as a partner because they had a CMOS fab in Japan and were in line to become an LSI supplier for Casio wristwatches. Casio planned to diversify into quartz watches, where similar components were needed as in electronic pocket calculators. After many discussions and the evaluation of our LCD samples, we were chosen to be the LCD supplier for the new wristwatches. On one occasion we had the honor of being invited for dinner at a typically Japanese restaurant in Tokyo by Mr. Kashio, one of the founding brothers. In 1974 our new factory for TN LCDs became operational. The Casiotron digital wristwatch with some interesting new features was released with our custom made LCD in October 1974. Not everything went smoothly. We encountered yield and delivery problems which required several trips to Tokyo to see Casio people.

Due to price pressure and the fact that customers were mainly in Asia, BBC started an LCD assembly line in Hongkong. I had to travel to HK to instruct local employees, first for final testing, then for doing custom designs.

We probably were among the first to develop backlit TN LCDs. Since LCDs do not emit light themselves, they need ambient light or a dedicated light source for viewing. Wristwatches in particular cannot be read in the dark without some form of illumination. Therefore, at our laboratory we developed a suitable backlighting scheme, taking into account the limited space available in a wristwatch with a digital liquid crystal display. Our patented solution included a thin plastic diffuser plate behind the LCD with a miniature incandescent light bulb at its side.edge-lit in present-day flatscreen LCD television sets using LEDs as light sources.

The major difference is that the backlight is continuously on during the operation of an LCD TV set, whereas in wristwatches the backlight is only used while pushing a button in order to save battery power. When enough ambient light is available, the display is used in its reflective mode. This combination is called a transflective display.

A different solution was developed for panel-mounted meters that were proposed by BBC for power and industrial control centers. Reflective TN LCDs were conceived as bargraph replacements for conventional electromechanical meters, but were difficult to read under low ambient light, as they are mounted vertically. Therefore, we used a cold-cathode fluorescent lamp (CCFL) and a diffuser to backlight our bargraph display as shown on the right-hand side of the picture. This was much easier to read than the purely reflective type on the left.

Switzerland. The Swiss authorities only examined strictly new developments in the watch and textile machine sectors. Otherwise patents were granted rather freely, but could be challenged later-on at a trial. When RCA defended their patent application with a broad claim for digital electronic wristwatches containing a battery, quartz crystal, frequency divider and LCD, I was asked by the Bulova Watch Co. to testify against this claim. We showed that, based on the disclosed information, it was not possible to make a wristwatch with an adequate temperature range on the priority date. Therefore the patent was not granted in Switzerland.

USA. In the US, the examination process was not public and the duration unpredictable until a patent was granted and published. In addition, priority could be established before the filing date, if relevant patent notebook entries or other evidence was presented by the inventor. This opportunity did not exist in Europe. A famous case was the invention of the twisted nematic, field effect LCD. Roche filed this patent application on December 4th, 1970 in Switzerland establishing thereby a priority. James Fergason followed more than four months later filing a similar patent application in the US on April 22nd, 1971. However, Fergason presented patent notebook entries, witnessed by colleagues, predating the priority date of Roche. In my opinion this gave unfair advantage to US filers.

For Roche as well as BBC (which after the merger with ASEA from Sweden in 1987 changed their name to ABB) royalty income from their LCD patents became a substantial source of income.

Working at the forefront of a new technology is exciting. I could attend many conferences, learned to make presentations and was invited to lecture on topics relating to my work on LCDs. Early recognition was evident in that I received invitations to make presentations at UC Berkeley, at the IEEE EUROCON conference and organize a panel discussion at the École Polytechnique de l"Université de Lausanne (EPUL) in 1972. During several years I gave a lecture at the Technische Akademie Esslingen near Stuttgart, Germany. As the only Swiss among many German lecturers, it was gratifying to get good ratings by participants from industry.

I left BBC in 1980 to work in the field of telecommunications. In 1983 my former colleagues from the BBC Research Center invented the Super-Twisted Nematic LCD (STN-LCD), which made it possible to have passive-matrix flat-panel displays with many pixels and reasonably high resolution for the first time.Game Boy, cellular phones, viewfinders of cameras, etc. I like to believe that this invention was a successful follow-up of our earlier focus on improving matrix addressing of LCDs. The corresponding patent brought in millions from licenses. Shortly thereafter Videlec in Lenzburg ceased operations, and the LC staff at the BBC Research Center was reduced to a skeleton.

P. J. Wild, P. U. Schulthess: "Liquid Crystal Bar Graph Displays," Conference on Displays, IEE Conference Publication no. 80, pp. 161-164, Sept. 1971.

P. J. Wild: "Matrix-addressed Liquid Crystal Projection Display," Digest of Technical Papers, International Symposium, Society for Information Display, pp. 62–63, June 1972.

Patent US3895866: "Information-bearing Devices and Projection Display Systems Therefor," filed in Switzerland on Dec. 3, 1971 (priority date), published July 22, 1975, inventors: A. de Quervain, P. Wild.

Patent US4096550: "Illuminating Arrangement for a Field-effect Liquid-crystal Display as well as Fabrication and Application of the Illuminating Arrangement," filed Oct. 15, 1976, published June 20, 1978, inventors: W. Boller, M. Donati, J. Fingerle, P. Wild.

Display technology plays a critical role in how information is conveyed. Since its commercialization in 1922 up until the late 20th century, Cathode Ray Tube (CRT) has dominated the display industry. However, new trends such as the desire for mobile electronics have increased demand for displays that rival and surpass CRTs in areas such as picture quality, size, and power consumption. One such technology that has replaced the CRTs is Liquid Crystal Display (LCD) due to their lightweight, low operating power, and compact design. LCDs allowed devices such as digital watches, cell phones, laptops, and any small screened electronics to be possible. Although LCDs were initially created for handheld and portable devices, they have expanded into areas previously monopolized by CRTs such as computer monitors and televisions. Other contenders for leadership in display technology are Organic light emitting diode(OLED) and Plasma Display.

LCD is an electronically-modulated optical device made up of any number of pixels filled with liquid crystals and arrayed in front of a light source (backlight) or reflector to produce images in color or monochrome.

An active matrix liquid crystal display (AMLCD) is a type of flat panel display, currently the overwhelming choice of notebook computer manufacturers, due to low weight, very good image quality, wide color gamut and response time.

The most common example of an active matrix display contains, besides the polarizing sheets and cells of liquid crystal, a matrix of Thin film transistor(TFT) to make a TFT-LCD. These devices store the electrical state of each pixel on the display while all the other pixels are being updated. This method provides a much brighter, sharper display than a passive matrix of the same size. An important specification for these displays is their viewing-angle.

Twisted nematicdisplays contain liquid crystal elements which twist and untwist at varying degrees to allow light to pass through. A Super-twisted nematic(STN)display is a type of monochrome passive matrix LCD.STN displays provide more contrast than TN displays by twisting the molecules from 180 to 270 degrees. Film compensated Super-twisted nematic (FSTN) is a passive matrix LCD technology that uses a film compensating layer between the STN display and rear polarizer for added sharpness and contrast. It was used in laptops.

Pie chart depicts the revenue share of major technologies in the display market in 2010, which clearly indicates that TFT LCD is the leading technology and has maximum market share(92%) of the global display market.

After growing rapidly throughout the 2000s, industry revenues declined in both 2008 and 2009. While the immediate cause of this decline was the global recession, the display industry has also entered a mature phase. With notebook PCs and desktop monitors completely penetrated by TFT-LCDs, much of the growth in recent years has come from the TV market. Despite the recession, flat-panel-TV shipments grew on the order of 30% per year in 2008 and 2009. However, this growth is leading to high penetration rates, even in formerly emerging markets, such as China, and will push the flat-panel share of the TV market past 90% in 2011. This high penetration, combined with increasing pressure on prices, will lead to slower revenue growth, particularly for TFT-LCDs.

Large Area TFT - comprises of products that have a display size of more than 10 inches. The major applications for these displays are Television, Desktop Monitor and Notebook PC. Public displays comprises of only 2% share of the large area but is a growing sector.

Small & Medium TFT- comprises of products that have a display size of less than 10 inches The major applications for these displays are mobile phones and automotive displays. Digital cameras and Digital photo frames are also promising sectors in the future.

The revenue of overall TFT LCD market had gone down in the years 2008 and 2009 due to recession. Also, the share of Large area in these 2 years have gone down, as the demand for these high priced products had gone down.

Year on Year there was an increase in shipments for all the products of large area TFT LCD. In total the revenue grew by 25% in 2010 up from 20% in 2009. After recession and a laggard growth of 11.5% in 2008, the market has picked up and the revenue is growing.

Notebook PC market also looks profitable, with a growth rate of 31.7%, but a decline from the previous year from 36.6%. The OLED technology is eating up the market share of the TFT LCD market share in this market.

Here we observe that there is technology shift that is happening. Industry has moved from CRT to LCD now. The is shift has been gradual over the time.

Display Search forecasts that the plasma TV market will start shrinking in 2009 after hitting $24 billion in 2008, while it sees LCD TV demand reaching $75 billion in 2008 and $93 billion in 2010 - a trend that will likely make companies offering both LCD and plasma lines think twice about their strategy.

Sharp has recently developed 64 inch ultra high resolution direct view LCD with “ 4k *2k” one kind of digital cinema system specification- making it world’s first.

Sharp Corp. in August started LCD production at its Kameyama No. 2 plant, the world"s first to cut panels from eighth-generation glass substrates, which can yield eight 40-inch-class panels.

With escalating demand for larger fabs of Gen 8, Gen 8.5, and Gen 10, the liquid crystal display (LCD) and organic light emitting diode (OLED) manufacturing equipment market has witnessed a growth spur. The market will continue its upward growth trajectory through 2011, with the majority of demand stemming.

Under the belief that only technological development can secure the company"s survival and progress, Dongwoo Fine- Chem has been investing aggressively in the field of R&D. The company has built its main R&D center in Poseung Industrial Park in Pyeongtaek with an investment of 10 billon won for improving the quality of such LCD materials as color resists and polarized films in addition to electronics materials such as CMP slurries and color resists of next generation. In addition, the company constructed a new R&D center next to its already existent one in Iksan. The company has invested 7 billion won for the construction of Iksan research center furnished with ultramodern equipment.

The world"s largest LCD display manufacturer TPV Technology has signed an agreement with the Chengdu Hi-tech Zone to launch its R&D and production center in Chengdu, capital of Southwest China"s Sichuan Province. The center of an investment of $90 million is expected to start operation in 2012 and will reach its full capacity in five years, with an annual output of some 6 billion yuan, said officials from the zone.

The share of LCD TVs outsourced reached a record high of 34% in Q3"10, as Sony and LGE increased their outsourcing ratio to more than 50% and 20%, respectively.

In 2011, the top three panel makers, Samsung, LG Display, and Chimei Innolux, will be aggressive with their plan to ship more than 60 million units of LCD TV panels. In total, LCD TV panel makers plan to ship more than 270 million units in 2011.

Equipment/Material Suppliers: these are the industries which supply the basic material like ICs, Chemicals, and Liquid crystal etc. They help in putting the fundamental frame in place and start the process of manufacturing. They supply the basic and essentials parts required for the LCD.

Panel Makers: Panel makers are the companies which make basic Skeleton for product. They design the panels according to the demand and requirement. They play a major role as to design the basic frame. They are the players who design the basic technology like LCD, AMOLED etc. these are the companies which do most of the R&D in the technology to improve and introduce innovations.

LCD TV in the worldwide TV market has been well placed in the developed nations. However, there is an increase in the sales of LCD TV in the emerging countries as well.

Similarly, LG display(LGD) captures 20% market share of the TV OEM and 13% share of the market"s brand share. In the TV market, backward integration has worked for both Samsung and LGD.

Even though LG display(LGD) captures 24% market share of the Desktop OEM but only 9% share of the market"s brand share (behind Dell and HP), which shows it could not leverage the benefits of backward integration like Samsung in Desktop Monitor marketspectively.

Nokia captures 36% of the mobile market, but Nokia doesn"t produce its own mobile phone LCD panels but rather outsources it from other companies that produce the same.

Major segments of the LCD display technology were found out on the basis of the revenue and the shipments of each. 5 top segments were found out: Television, Desktop Monitor, Notebook PC, Mobile Phones and Automotive monitor displays. Automotive monitors are used for in-console navigation, controls and rear-seat entertainment.

Market sizes of each of the 5 segments on the basis of revenue were found out. Also the revenue share of the Total TFT LCD market was found out in order to calculate the share of each segment in the whole industry.

In 2009, Innolux Display acquired Taiwan LCD maker TPO Displays Corp. Then, Innolux acquired another Taiwan LCD maker, Chi Mei Opto electronics Corp. And recently, Innolux Display announced the completion of its acquisition of Chi Mei Optoelectronics and TPO Displays.

The new entity is called Chimei Innolux Corp. Chimei Innolux is now a dominant player in the global TFT-LCD panel market. It sells from 1.5- to 50-inch. panels. By essentially gaining control of Chimei Innolux, Foxconn can now offer customers a one-stop shop of contract manufacturing services, including LCD production.

Hisense and Konka have set up LCD-module assembly lines with the help of CMO; TCL set up an LCD-module assembly line using know-how transmitted from Samsung.

LG Display formed an alliance with AmTRAN to set up an LCD-module and LCD-TV-set assembly line and set up a joint venture with TPV for LCD-module lines.

The new entity would overtake Sharp as the largest maker of small and mid-sized LCD panels, which are commonly found in smartphones and tablet computers.

Though the market share of TFT LCD in the display market is predicted to reduce in the future, it would still capture more than 80% of the market. This presents ample of opportunity for existing players (currently producing semiconductor devices and want to enter LCD market) to use their technological excellence to milk the LCD market.

AMOLED technology is predicted to substitute TFT LCD in applications like smart phones and tablets. Hence for a new player, who plans to invest in R&D and manufacturing to enter the LCD industry, investing in better technology is advisable.

It is not advised for small players to enter the LCD industry as it is already in the consolidation phase. Many players like Samsung, have undergone vertical integration to optimize their costs. The initial investment required to enter the LCD industry is very high. In such a scenario, for a small player, who manufactures displays or products, will find it difficult to compete with giants like Samsung, LG etc on prices.

Players who have the expertise, capital and capacity to invest in LCD market can consider entering Mobile phones and Notebook PCs market. For them to succeed in the LCD market, they can either specialize in producing LCD displays with the latest and best technology available or consider vertical integration to optimize their cost.

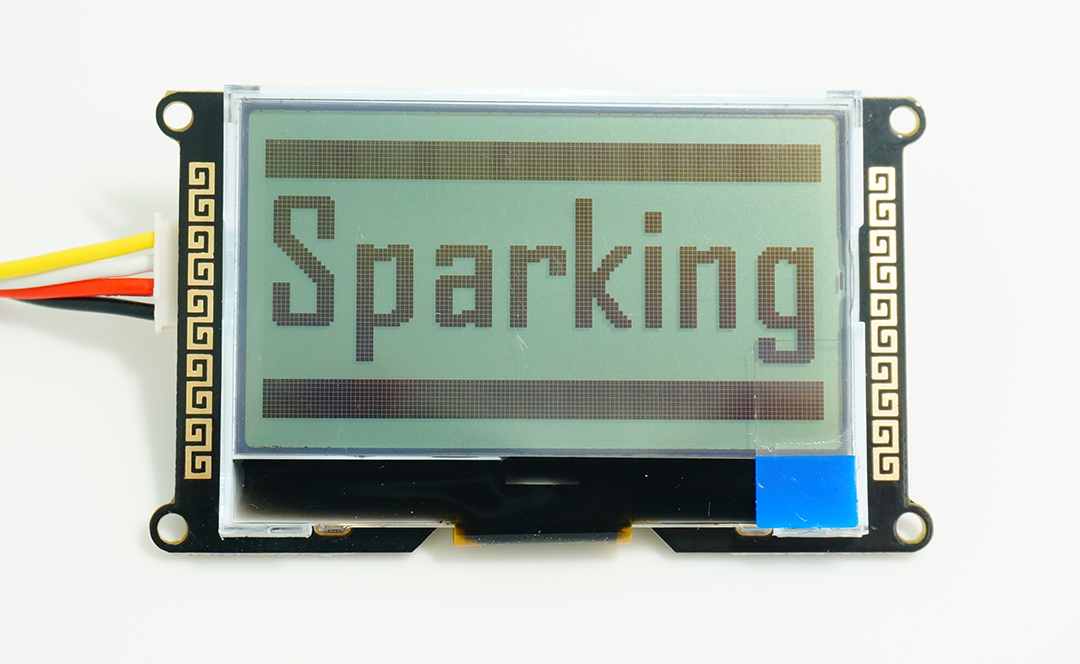

Established in 1998, Winstar Display Co., Ltd. is a reliable LCD Display Module Manufacturer and LCD Panel Supplier. Winstar has development of high-quality display module products. We operate worldwide, configure, service products, and also provide logistics support to deliver products and services competitively. We provide LCM Modules including monochrome TN/STN/FSTN LCM, COG LCD, TFT LCM / TFT panels, FSC-LCD, graphic LCM, character LCD displays, OLED display modules (PMOLED), custom LCD displays, OLED and LCD panel.

The new line of 3.5” TFT displays with IPS technology is now available! Three touchscreen options are available: capacitive, resistive, or without a touchscreen.

For over 20 years Newhaven Display has been one of the most trusted suppliers in the digital display industry. We’ve earned this reputation by providing top quality products, services, and custom design solutions to customers worldwide.

SainSmart 2.8" TFT LCD Display is a LCD touch screen module. It has 40pins interface and SD card and Flash reader design. It is a powerful and mutilfunctional module for your project.The Screen include a controller ILI9325, it"s a support 8/16bit data interface , easy to drive by many MCU like arduino families,STM32 ,AVR and 8051. It is designed with a touch controller in it . The touch IC is XPT2046 , and touch interface is included in the 40 pins breakout. It is the version of product only with touch screen and touch controller.

Voltage type: 5v or 3v voltage input voltage,input is selectable. Because TFT can only work under 3.3 V voltage, so when the input voltage VIN is 5V, need through the 3.3 V voltage regulator IC step down to 3.3V , when the input voltage of 3.3 V, you need to use the zero resistance make J2 short , is equivalent to not through the voltage regulator IC for module and power supply directly.

Dual Display: A full color: LCD transmissive mode; a low-power, sunlight-readable, reflective e-paper mode; and a transflective mode, which makes the LCD display visible in sunlight, all in One!

PixelQi is the technology behind the screen used on the One Laptop Per Child portable computer. It is also used on Sol Computers. The above 10.1" and a 7" display.

Monochrome display: High-resolution, reflective sunlight-readable monochrome mode; Color display: Standard-resolution, Quincunx-sampled, transmissive color mode;

The display-controller chip (DCON) with memory that enables the display to remain live with the processor suspended; the display and this chip are the basis of our extremely low power architecture; the display controller chip also enables deswizzling and anti-aliasing in color mode.

"Like standard back-lit LCD displays, Pixel Qi displays renders quality full-color images, full-motion video, and high screen brightness. However, in environments with high ambient light levels, the Pixel Qi Display’s reflective mode contributes to the image, allowing the backlight to be turned down or off. This unique capability delivers significant power savings, an attractive screen and a comfortable reading experience, with very high resolution in the bright sun. Because of the ability to work in the reflective mode, the backlight can be turned completely off making the display perfect for people who suffer from computer vision syndrome as it’s easy on the eyes."

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey