life of lcd display factory

How long will your LED display last? In nearly every industry, from retail businesses to concert halls to corporate centers, decision makers need to evaluate the return on investment (ROI) of their LED signage. In most cases, potential buyers go straight to the obvious place: the LED manufacturer’s spec sheet. The industry standard for LED lifespan is 100,000 hours, or about 10 years, and most people assume that’s how long their display will last. But it’s not quite that simple.

The 100,000-hour figure assumes that every diode will be running at full brightness, consistently — which, on an LED screen, is virtually never the case. The lifespan figure can also be misleading because it indicates when a diode degrades to half-brightness, not completely dark. Many other variables affect an LED display’s lifespan; you can’t rely solely on the number on the diode spec sheet.

“The reality is, your screen can often last significantly longer than 100,000 hours,” says Kevin Izatt, a senior product manager in Samsung’s Display division. “We’ve had displays that have been up for 15-plus years with more than adequate brightness. Because the diode is actually only one factor in the lifespan of your LED display.”

The biggest contributor to diode degradation is heat. As you increase a diode’s brightness, it produces more heat. Your display’s physical environment also contributes to the temperature of the diodes, especially for outdoor displays.

The quality of your display’s power supply — and how hard it drives the diodes — can have a significant impact on your screen’s lifespan. The other components being powered, such as fans and electrical components, have their own lifespans as well, which are also impacted by the power supply.

“Fans are mechanical; they break down,” explains Izatt. “And similar to your computer, the electrical components don’t last forever. Together, these factors all contribute to the lifespan of an LED display. Looking at just the diode lifespan doesn’t give you the complete story — almost always, another part will go out first.”

“Something like airflow is very important,” says Izatt. “You need a screen that has good cooling, and a design that allows heat to flow out of the back through vents.”

It’s easy to see why: The circuit boards powering the display release heat, and that heat needs to go somewhere. Without a strong design, thermal stress will degrade the life of the display, except for the highest-quality parts — optimal conditions notwithstanding.

“Lots of variations on the color and brightness you use will impact the life of the diode,” explains Izatt. “For instance, black doesn’t use any of the diodes at all. And if your content is using lots of gray, that’s a much lower power output than white.”

That’s not to say you should hold back on displaying rich, vibrant colors — after all, that’s what LED does best. But it does factor into your product’s life expectancy.

To help businesses transition from LCD to longer-lasting LED signage, Samsung has launched a trade-in program. Samsung will come on site to remove your existing display and provide a discount on a new LED bundle kit.

Traded-in LCD displays that are still operating will be refurbished and resold, and your business will receive a cash rebate. Nonworking displays will be recycled and their parts reused.

You can’t rely on the number on the diode spec sheet; the lifespan of your LED display depends on many more factors. “Overall quality has a tremendous impact on the life of the display that diode specs just don’t take into account,” says Izatt. Your best bet is to look at the purchase holistically and invest in a top-tier product.

As you plan your LED signage rollout — or an upgrade — learn how to configure and tailor your screens’ real-time messaging with an integrated CMS in thisfree guide. And if you haven’t decided what kind of display is best suited to your current project, compare all ofSamsung’s LED displays.

Perhaps you’ve wondered how long a digital display lasts. It’s a great question. One quick search on Google will tell you that an LCD panel has a lifespan of about 60,000 hours, which is equivalent to almost seven years.

Of course, LCDs aren’t the only kind of displays. You also have LED, OLED, QLED, ELD, PDP, and MicroLED, plus many other variations. Obviously, that 7-year estimation will not apply across the board. For the sake of ease, let’s just focus on some of the common types of displays that most of us are familiar with.

Here’s some LCD alphabet soup: There are LED LCD displays, CFFL LCD displays, LED displays, and more. With all these acronyms, it can get a bit confusing. What"s important to note is whether or not the display uses an LCD panel, and how the LCD panel is illuminated. You can read more about thedifferences between types of LCD and LED signage, but these are the most common types:

LCD displaysgenerate images and colors via a Liquid Crystal Display (LCD) panel, which is not self-emitting and requires an external light source to illuminate the image, typically an LED backlight. Their full name "LED-backlit LCD display" is commonly shortened to "LED displays", which is why they"re often confused with the true LED displays we"ve identified above.

Unfortunately, LED backlights used in LCD displays burn out over time. If used at high or maximum brightness, which is necessary for outdoor applications,an LED backlight will last between 40,000 to 60,000 hours. Or, about 4.5 to 7 years.

OLED stands for Organic Light Emitting Diode. OLED displays differ from common LCD displays in that their pixels are self-illuminating. In other words, there is no LED backlight required to illuminate the the display image; everything occurs within the OLED pixels themselves. According to onearticle from the US Department of Energy,OLED screens have a life expectancy of about 40,000 hours at 25% brightness, and 10,000 hours at full brightness. That equates to about 1 to 4.5 years, which is a much shorter (albeit, brilliant) lifetime than an LCD display.

Perhaps you noticed that the acronym QLED closely resembles the acronym OLED. This is not accidental. QLED is basically Samsung’s original design built to compete with OLED technology. However, the two are not the same. QLED stands for Quantum Light Emitting Diode. While QLED is similar to a regular LED design, it in fact differs by using nanoparticles called “Quantum dots” to achieve its unique brightness and color. Samsung approximates that the lifespan ofQLED panels are likely to last 7-10 years. After that, a user is likely to notice traces of degradation.

MicroLED is an emerging display technology, consisting of small LEDs in tiny arrays within each pixel. This technology goes beyond the offerings of the formerly frontrunning OLEDs, with much darker blacks and more radiant contrast levels. And, unlike OLEDs, MicroLEDs are not organic. They are not as subject to burn-in, and thus, have a longer lifespan than OLEDs. However, they are significantly more expensive - so much, in fact, that they aren’t considered a viable option for the majority of consumers.According to Samsung, the lifespan of its MicroLED panels should last about 100,000 hours, or, roughly 11 years.

PDP stands for Plasma Display Panel, and it refers to displays that use small cells full of plasma. The atoms within the plasma emit light upon being charged by electricity. While PDP is generally considered to offer better colors than LCDs, they consume a lot more power and usually cannot be battery-operated.The average lifespan of the newest generation of PDPs is approximated to be 100,000 hours, or 11 years of continual use.

In some ways,reflective LCD panelsoperate similarly to other LCDs, only they have one key difference - they do not require a backlight. Instead, they rely on ambient light (or sunlight) in order to produce images. This opens the door to some groundbreaking possibilities. The first (and most appreciable) is low power consumption. Reflective displays use up to 95% less energy. Not bad - especially in a world that is continually looking for new ways to go green. Take into consideration the financial implications of this. Lower power means less money spent on operating costs.

Being that reflective displays do not require a backlight (a component that is particularly subject to degradation), and since they do not generate as much heat, it is safe to say that the lifespan of these displays should far exceed that of backlit LCD panels (which was 7 years at the high end). However, being that thisinnovative technologyis relatively new, its actual lifespan is therefore more difficult to estimate -- simply because it has yet to be reached.

There are also a few challenges that can affect reflective displays. For one, they rely on ambient light. On a nice sunny day, these displays perform beautifully and can be easily seen in even the brightest of conditions. This performance wanes as the available ambient light decreases. And, since they do not generate light of their own, they are not designed to be viewed under nighttime or extremely low light conditions (without additional lighting features). In short, their images are visible to the degree that ambient light is present. However, in light of this, side light (and front light) options are being explored.

One company at the front lines of this research isAzumo. Azumo has created a light guide that laminates to the front of a display. It requires 90% less energy than the backlight of a traditional LCD display. This greatly improves the problem of low light visibility otherwise encountered, and keeps reflective displays in the same low energy consumption ballpark. One issue, however, is that Azumo currently only offers its light guides for smaller-sized units. If you happen to want this feature applied to a display that is over 10” diagonally, then you’re still on the search for a solution.

Other “pioneer companies” are at the frontier of this research as well, and many are already innovating new solutions to increase the viability of reflective technology - both in their low light visibility and in the screen sizes they are available in. Due to the huge potential offered by reflective technology, it is fair to assume that we will see even greater enhancements to it in the very near future.

One other factor to consider regarding reflective technology is its cost. That reflective layer is more costly to manufacture than many of the backlights it replaces, creating a seemingly greater upfront cost for those who are interested in investing in energy-efficient signage. However, these initial price points are quickly justified as buyers will recognize the significantly lower operating costs and increased longevity (not even including replacement costs of other “expired” displays) that comes with their purchase of reflective display signage. If a backlit LCD panel only lasts 7 years, for example, you’ll have paid for that LCD twice in the period of ten years. A very valid question arises… is that “cheaper” backlight really cheaper? Probably not. It only feels that way at first.

Sun Vision Displayis working hard to create reflective display solutions for the digital signage world. We are currently offering them in 32" and 43" diagonal sizes, with a 55” size in development. These displays are built formany environments. We are thrilled to be bringing such innovative solutions to the market.

If you have any questions, or if you would like to talk to a representative about how our solutions might work for you, please don’t hesitate to contact us. Simply scroll down to the bottom of the page to our form, and we’ll get back to you in a timely manner. We look forward to the possibility ofworking with you!

Early flat-screen TVs, especially plasmas, were notorious for their limited lifespan. This has improved dramatically with the latest technology, however. You can rest assured that any new TV you buy now should last you until you decide to change it.

A screen"s lifespan is measured as "half life", which is the time it takes for the internal lamp to fade to half its original brightness. Your old CRT set has an average half life of around 25,000 hours, but the latest flat screens claim to last up to twice as long.

LCDs are said to have a slightly longer lifespan to plasmas, but the difference is not particularly significant. Plasma"s half life ranges between 30,000 to 50,000 hours, while LCD offers around 60,000 hours.

In real terms, if you watch the TV for an average of 4-6 hours a day, then a screen with a half life of 30,000 hours will last you over 16 years -- by which time we"ll probably all be watching holograms!

It"s possible to change the lamp for both plasmas and LCDs, but not all manufacturers offer this service and the cost is usually greater than the expense of simply buying a new TV.

There are several technical problems that can afflict flat screens during their lifespan, including dead pixels, backlights and, in plasmas, screen burn -- where a lasting image leaves an imprint on the screen. But manufacturers don"t usually offer repairs and it"s best to find a screen with a good guarantee.

Equally important to extending the lifespan of a flat-screen TV is finding a model with a future-proof specification. This includes features such as integrated Freeview, high-definition compatibility and multiple HDMI connections.

Sony claims the model you mentioned, the KDL-40W2000, has a half life of around 60,000 hours -- more than enough in this day and age. The screen also features a future-proof specification and comes with a free three-year warranty from good suppliers.

Responsible for performing installations and repairs (motors, starters, fuses, electrical power to machine etc.) for industrial equipment and machines in order to support the achievement of Nelson-Miller’s business goals and objectives:

• Provide electrical emergency/unscheduled diagnostics, repairs of production equipment during production and performs scheduled electrical maintenance repairs of production equipment during machine service.

Much has been made of the longevity of LCD displays, at least compared to plasma monitors. The conventional wisdom is that LCD televisions last longer than their plasma TV counterparts, which is true. The problem is, a lot of people extrapolate from this that either (a) LCD displays last forever or (b) LCD monitors suffer no picture "wear" over time. Neither of these suppositions is correct.

Flat-panel LCD screen displays have a lifespan approaching 60,000 hours. The lifespan of an LCD display is generally longer than that of similar-sized plasma displays. Some manufacturers even claim that their LCDs can last upwards of 80,000 hours when used continuously under controlled conditions (e.g., in a room with "standard" lighting conditions and 77° temperatures throughout). Just how realistic such claims are is debatable. After all, whose living room has no windows and remains at a perfectly comfortable 77 degrees year-round?

In any case, the pictures on LCD displays will show some "wear" because they are generated by powerful lamps, which, like any lighting appliance, will dim over time and with use. The picture you see will dim ever so slightly as the lamp itself dims.

Therefore, the most important thing to consider when it comes to the lifespan of your LCD TV is the actual lifespan of the light source in your LCD. LCD TVs last as long as their lightsources do. So, the lightsource in your LCD monitor is the critical component of your LCD display unit.

The quality of your lightsource is particularly important for maintaining a proper white balance on your TV. As these florescent bulbs age, colors can become unbalanced, which could result in too much red, for example, in your picture. So, it pays to buy name-brand displays. You will definitely pay more for better LCD display brands like Sharp, Toshiba, JVC, or Sony than you will for cheap Chinese or Korean variety knock-offs, but you"ll get a backlighting bulb of higher quality and, in the end, a TV whose colors will stay truer longer.

To ensure the integrity of your lightsource for the duration of your LCD display"s lifespan, you will definitely want to adjust the CONTRAST setting of your LCD TV. Too high of a CONTRAST level will prematurely age your lightsource because it will have to work harder to maintain such light intensities. Your best bet is to keep your CONTRAST set appropriately for the conditions under which your view your LCD display. Higher light levels require slightly higher CONTRAST levels, while lower ambient light levels demand less CONTRAST.

You will also want to pay attention to the warranty for this particular feature, since it can be shorter than for the display as a whole. This means you might have to buy a whole new LCD monitor because the coverage on its backlight has expired. Moreover, some bulbs can be replaced, while others are built in to the unit itself. You should definitely do some research on the backlighting system, how it"s configured, and how it"s warranted.

Note: Sharp is currently the only manufacturer that makes LCD displays whose lamps can be changed out. This is definitely something to consider, given that LCD monitors dim as their lightsources do, so being able to replace its lamp will restore your picture to "like new" levels.

LCD is a very popular display technology used by many monitor manufacturers. As a matter of fact, you might be reading this article on a device with LCD technology. And you know that every monitor would come with an estimated lifespan. But what about LCD monitors? Do they have an estimated lifespan?

To answer all of your questions regarding this topic, we have written this post. In this post, we will share how long do LCD monitors last. We will share the estimated lifespan of other display technologies as well. In addition, we will try to share some tips to extend the average lifespan of your particular monitors.

LCD or Liquid Crystal Display is a technology that is found on flat-screen monitors. Typically, the estimated lifespan of an LCD monitor is 30,000 hours to 60,000 hours. That means if you will be using the monitor for 8 hours every day, you will be able to go for 10 to 20 years. Remember, this is an estimation. We cannot tell the exact lifespan of any particular monitor.

This type of monitor does not have a long lifespan. For the record, it has an estimated lifespan of 25,000 to 30,000 hours. This means you can expect 8 to 10 years of lifespan if you are using it 8 hours per day.

LED or Light Emitting Diode is a newer technology. You might already be using an LED display on your phone or monitor. They tend to be very bright and color accurate.

Also, they are a bit pricey compared to the previously mentioned display types. Reportedly, LED monitors can last for up to 50,000 hours. That means it can go up to 17 years if you are using your monitor for 8 hours per day.

OLED is a different type of display panel technology. And, this is also very new and expensive technology. Still, OLED or Organic Light-emitting Diode monitors are known for color accuracy and high brightness and contrast.

However, if you use screensavers or don’t overuse your monitor, an OLED monitor can go a long way. Reportedly, an OLED monitor can have a lifespan of up to 100,000 hours. Theoretically, you can expect an average lifespan of 8 to 15 years from your OLED monitor.

At this point, you are aware of the average lifespan of different types of monitors. But how would you know if your monitor is defective or not? There are a few ways you can be sure about that. So, let’s talk about it…

Of course, if you see that the display is behaving erratically, then it is a sign of defective monitors. In that case, your monitor would turn on or off from time to time automatically. The source of the problem could be a faulty power adapter. Also, the physical buttons on the monitor could be damaged as well.

Have you recently noticed any ghosting on your monitor? It means that you will see a ghost-like appearance on the monitor of a graphic that was showing while the monitor was on. It could also occur when you are playing resource-hungry games with a low-end GPU.

The dead pixel issue is related to the hardware. So it is not possible to fix it without replacing the monitor. Normally, some new monitors even can have dead pixels. It is the absence of pixels on the monitor. For some monitors, there could be only one dead pixel. However, for others, there could be multiple dead pixels.

Last but not least, your monitor can show random issues all of a sudden. You could notice that your monitor’s display has turned blue or greenish. Also, you could see that your monitor is flashing automatically from time to time.

In addition, you could also notice a burning smell if the monitor is defective. In the case of CRT monitors, you might hear a random popping sound when it became damaged. And of course, if you see that your monitor is not turning on anymore, you can be sure that it is already damaged.

Now, whatever the problem on your monitor is, you should contact a professional for this. And if your monitor still has the warranty, then you should send it to the warranty as fast as possible. Most monitor issues can be solved by repairing.

There are many ways you can take care of your monitors. And, if you want to extend the estimated lifespan of your monitor, you should follow some instructions. Let’s talk about them…

Normally, your monitor should come with a power adapter. That adapter should be able to withstand a wide range of voltage. That way, if there is a sudden spike in the electricity flow in your home, your monitor will be protected.

Normally, you will find air vents at the back or bottom of the monitor. When you are running a monitor for a long time, it will get hot. To prevent heat buildup, those air vents are there.

If you are living in an area where load-shedding is a regular occurrence, you should opt for a UPS. That way, your monitor will not be turned off suddenly.

So now you know how long does LCD monitors last. At the same time, you also know this information for other types of display technology. To be honest, most monitors come with a very high estimated lifespan. Still, it is not possible that every monitor will last that long.

LCD display screens are everywhere. You probably own one or more devices with an LCD display screen at home and at work. This includes your TV, computer monitor, watches, clocks, smartphones, and even calculators.

But have you ever wondered about how your LCD display screen works, its lifespan, components, and how it holds up to other emerging display technologies today?

Knowing all these things about your LCD display lets you appreciate your screen all the more. Caring for your device becomes easier when you’re armed with this knowledge.

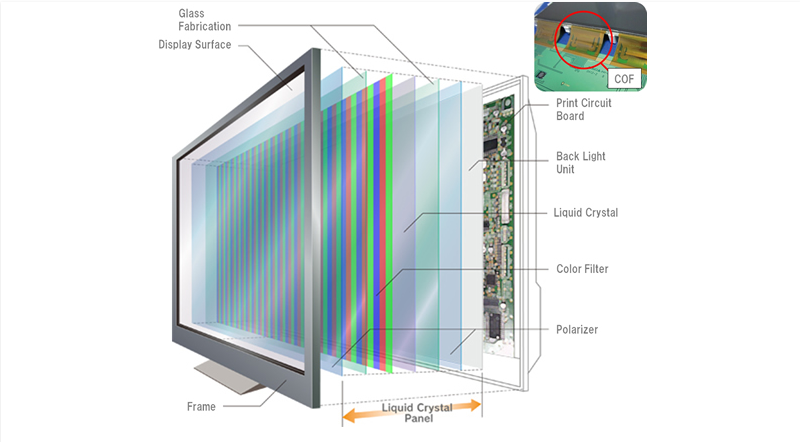

LCD display screens make use of Liquid Crystal Display technology. The screen is embedded with liquid crystals, a substance that has properties in between a conventional liquid and a solid crystal. Liquid crystals can flow, but their molecules carry a crystal-like solid orientation.

Liquid crystals are responsible for producing an image flashed onto the LCD screen. They don’t emit light, though. Backlights are used to illuminate these crystals.

A display screen is made up of several tiny color blocks called pixels. The term is a portmanteau of “picture” and “element”, denoting pixels as little elements making up an entire screen picture. A screen is typically made up of millions of pixels.

Every pixel on the display screen is made up of red, blue, and green light. These lights can be quickly turned on or off to create an overall moving picture or image.

Now, in LCD displays, pixels are regulated by using liquid crystals for rotating polarized light. Polarized light denotes light waves with vibrations occurring in a single plane. In LCDs, this is achieved by using polarized layers.

Each pixel has polarizing filters on both its front and back. Tiny nematic (twisted) liquid crystals are placed in between these filters. The liquid crystals can be switched on or off electronically through tiny electronic transistors.

When the liquid crystal is turned off, electricity controlled by the transistor stops flowing. The pixel is then turned on, brightening up due to the 90-degree twisting of the nematic liquid crystal. This allows light to pass through both polarizing filters on the pixel, illuminating the pixel by letting light pass through.

When the liquid crystal is turned on, electricity flows through the nematic liquid crystals. They completely straighten out from their twisted state. The polarizing filter in front of the liquid crystal blocks out the light, resulting in the pixel turning off and becoming dark.

A single LCD contains millions of pixels, nematic liquid crystals, polarizing filters, and transistors. They all work together to create images on the screen.

Most LCD monitors have a lifespan ranging from 30,000 to 60,000 hours. That’s equivalent to 5-7 years using the monitor for 24 hours per day. It could also translate to 10-20 years with running the monitor for 8 hours a day, 5 days a week.

The backlight’s life expectancy is the biggest factor in determining the LCD display lifespan. It’s because liquid crystals do not give off light from themselves. The liquid crystals depend on the backlight for illuminating them. Hence, the LCD screen wears off when the backlights dim as it reaches its maximum lifespan.

The backlight serves as the illuminator of the entire LCD display device. Without a backlight, the LCD device remains darkened and hard to use. Backlights are installed directly behind the LCD panel to lighten up the display.

Simple devices such as pocket calculators don’t use a backlight for their LCD screens. Users rely on natural light to see the numbers displayed on such calculators. However, the majority of modern LCD screens such as televisions, computer monitors, smartphones, aviation screen panels, outdoor signages, and medical monitoring devices use backlights as their internal light source.

This type of backlight is the most popular and widely-used light source for LCDs today. Light-emitting diodes are semiconductors that emit light once electric current flows into it. Particles carrying the electric current are called electrons holes. These combine with electrons in the semiconductor, releasing photons (light particles).

Band separations called bandgaps determine the photons’ energy. Furthermore, the photon’s energy dictates which color the LED emits, depending on the emitted light’s wavelength. Various kinds of semiconductors and their corresponding varying bandgaps create different light colors.

Edge-Lit White LED (EL-WLED)– One or more LED rows are placed on the screen’s edge. A special light diffuser is used to scatter the light evenly across the entire display screen. Computer monitors, laptops, notebooks, and even HDTVs are now lit in this way.

White LED (WLED)– The LCD panel’s rear side is lit up with several white-colored LEDs. A diffuser is set in front of the LEDs to help evenly smooth out the light throughout the screen. Some computer monitors and large-screen LCD TVs use this LED technology.

Red-Green-Blue LED (RGB LED)– This technology works like WLED. The difference is that it uses red, green, and blue LED combination lights instead of white lights. Better picture quality and higher color gamut are its advantages over WLED and EL-WLED.

ELP uses electroluminescent materials such as colored phosphors instead of heat to create light. This material is placed in between two conductor layers. The material emits light as a result of an electric current flowing through it. ELPs are mostly used in small LCD screens.

CCFL backlight uses a cold cathode fluorescent lamp as its main light source. This lamp consists of a cathode that isn’t heated electrically by a filament, hence the connotation “cold”. A diffuser is placed in front of the CCFL lamp to evenly distribute light across the entire screen.

The cathodes used in CCFL produce light by creating a non-heated thermionic emission of electrons. This is accomplished by using discharges in mercury vapor to create an ultraviolet light. This light, in turn, creates a fluorescent coating inside the lamp, resulting in visible light.

Computer monitors and TV screens predominantly used CCFLs for backlights. However, modern manufacturers opt for LED technology instead of CCFL for their devices’ backlights.

HCFL backlights have filaments that need to be heated to excite mercury atoms, cause the current to flow, and ultimately emit light. HCFLs are often used in LCD equipment such as medical devices, custom task-oriented lamps, scanners, and outdoor LCD signs.

Liquid crystals are the heart of an LCD display. This unique substance flows like a liquid but retains many characteristics of solid crystals. They have long and cylindrical-shaped molecules that can twist when changes in molecular orientation happen.

Different liquid crystal families are used in LCD displays. One requirement of such liquids is to exhibit mutual attraction. Also, the molecules in the liquid crystal need to be anisotropic. This means that the liquid crystal molecules have that average structural order along a molecular axis.

Liquid crystals are often sandwiched in between the color filters and the polarizers. They twist and straighten in response to electrical currents applied to them. The movement of liquid crystals controls whether polarized light will pass through the filters or not.

The nematic phase is characterized by the crystal molecules freely moving around the liquid. However, these molecules point themselves to one direction only, making it unique from pure liquid molecules. Nematic liquid crystals are the most common liquid used in LCD screens.

Color filters are found in between the liquid crystals. These filters determine whether the pixel shows red, green, or blue colors when activated. The filters work by independently controlling the pixel’s red, green, and blue sub-pixels. With this, the LCD screen can reproduce all possible colors found in the color space.

The color filters aren’t active elements, though. It’s the liquid crystal molecules that control the light passing through the filters. The color filters simply determine the color the pixel shows based on how much light is passing through them, as determined by the applied electric voltage and the movement of the liquid crystal molecules.

An LCD cell is made up of two polarizing filters. They enclose the LCD display and color filters. One polarizing filter is located in front of the backlight and is horizontal in orientation. The other one is found just beneath the pixel in front and is vertical in orientation. Polarizing filters are typically made of transparent crystals or glass substrates.

The role of polarizing filters is to control which light patterns can pass through the LCD screen. Without these filters, visual images generated by the LCD panel will have a poor contrast ratio and an inferior quality image.

Meanwhile, if the LCD display is arranged in a straightened way, the horizontal light waves that came from the first polarizing filter will be blocked from entering the vertical polarizing filter. The pixel is then turned off and no light illuminates it.

The two polarizing filters need to be vertical and horizontal in orientation, respectively. If the filters are oriented in the same way (ie; both horizontal or both vertical) will block all the light passing through, displaying nothing on the screen.

TFTs are responsible for providing electrical voltage to the LCD display. Each screen pixel has a corresponding transistor, enabling the pixels to easily be controlled in unison through changes in electrical current.

Using TFTs requires less charge and less power to operate the LCD display screen successfully. TFT use also leads to sharper images because each pixel has its own transistor controlling it. The charge given to a certain pixel can be actively maintained even if the screen is refreshed to display another image.

That’s all the basic information you need to know about LCD display screens. Now, you know how an LCD screen works, its possible lifespan, its components, and how it compares to other display technologies.

Armed with this information, you can better appreciate and take care of your LCD display devices. And in case you’re planning to add display devices to your business, the information you’ve learned will help you make educated choices regarding the display technologies you’ll utilize.

The overall display market – a $120 billion industry, is primarily driven by smartphone displays and TVs, and new production capacity continues to be added to serve these segments. As a result of their very different requirements, these two display applications typically use different display backplane and frontplane technologies. Therefore they require different factories for manufacturing, not only because of their size difference, but also because of the different requirements for pixel size and resolution, refresh rate, viewing angle and lifetime.

Much of this additional LCD capacity is a result of a wave of ‘Generation 10’ display fabs currently under construction or planning. There are around five of these planned at present, each costing in the range of $5-$6 billion to build. These huge factories will use sheets of glass over 3m x 3m in size, which will be cut into multiple large screen TVs, monitors, and digital signs.

With each Gen 10 line adding around 10 million square meters of display capacity once online, there is expected to be significant oversupply, resulting in squeezed margins as TV prices are cut. Their arrival will therefore unavoidably have an effect on the existing and earlier generations of fabs which will struggle to compete if making the same display specification as the new lines.

Owners of Gen 7/8 fabs will already be considering their long term options for these fabs: are there new markets that can be reached using the existing display technology in the fab? If not, can the factory be converted to manufacture differentiated display types to avoid competition? The second question may even lead to innovations that allow these lines to be used for applications beyond displays such as large area sensor arrays.

What goes around comes around: The same Gen 8 lines under question today were the cause of similar disruption when they themselves were built: causing Gen 4 and below fabs to be repurposed or sold. Today most operating Gen 4/5 fabs have moved away from manufacturing vanilla consumer LCDs to focus on higher margin applications such as such as automotive and industrial displays, flexible displays, X-ray sensor backplanes and other kinds of large area sensor arrays.

FlexEnable’s Organic LCD (OLCD) technology has been designed not only to create new market opportunities and sales avenues for display makers, but also to fit into these factories with little or no Capex requirement. It doesn’t require any special equipment and takes advantage of already established LCD supply chain, meaning it’s the lowest cost flexible display technology today. Whilst the first OLCDs in production will be small- and medium-sized, the same approach can be applied to Gen 7/8 lines for TVs, digital signage and monitors.

OLCD has no compromise in optical performance compared to glass LCD, but is built onto plastic films, opening up new product applications and use cases. Its thinness, lightness and robustness combined with its high brightness, long lifetime and scalability make it ideal for small and large area display applications.

Fifty years ago, a pair of physicists in a Swiss laboratory began untangling a mystery that had been intriguing a handful of other scientists for several years.

Here was their conundrum: Could miniscule electrical jolts unwind the spiral molecular structure of a new substance known as “liquid crystal,” causing the crystals to block light, then re-twist them and allow light to pass through again?

The physicists – Dr. Martin Schadt and Dr. Wolfgang Helfrich – placed the liquid crystal between two plastic surfaces carrying a grid of transparent electrodes. In so doing, they discovered they could create individual picture elements, or “pixels,” which could be used to form shapes.

They filed a Swiss patent for the idea on Dec. 4, 1970. Though it attracted scant attention at the time, the milestone now stands as the birthdate of the liquid crystal display (LCD) – the technological platform which has transformed consumer electronics and presented a brilliant new way to view the world.

Early LCD developers took a few years to figure out that specialty glass, not plastic, was the best stable substrate for the delicate LCD circuitry and the color backplane component. Once they did, they turned increasingly to Corning to supply them with extraordinarily stable, flat, fusion-formed glass, able to preserve the critical properties of the liquid crystal and withstand high processing temperatures.

And LCDs rapidly transformed from “passive matrix” models, mostly used in pocket calculators and digital watches, to “active matrix” LCDs in which each sub-pixel was controlled with an isolated thin-film transistor. AMLCDs enabled wide viewing angles; brilliant, fast-moving images; and high-resolution images that had never been possible before.

Corning Incorporated was a critical player in this development, and eventually became the world’s leading supplier of LCD glass substrates. And Corning® EAGLE XG® Glass, the world’s first LCD substrate with no arsenic or other heavy metals, went on to exceed sales of 25 billion square feet, making it one of the most successful products in Corning’s history.

When you look at a display device – your phone, your TV, your smartwatch, the screen in your car – what do you see? You see the image. A bright, vivid image on surfaces of all shapes and sizes. Flat, curved, flexible, thinner than ever before.

When you stop and think about what goes into displaying one of these amazing images, you might recognize most are protected by a glass cover. You might even be familiar with display types like LCD or OLED. Yet for many, the recognition stops there. You may see the image on the surface, but rarely think about what creates that image, how it achieves life-like, vibrant color, and the journey it makes to reach our eyes.

If we look deeper, beyond the surface and the cover glass of our devices, we would find one or more layers of ultra-thin, technical glass make such images possible. Each layer with a different purpose, all working together to deliver the beautiful, thin displays we use each and every day. Combined, these layers form what we at Corning call the “glass stack.”

It’s worth looking at the individual layers of the glass stack, since each layer is the result of breakthroughs in glass science, optical physics, and state of the art manufacturing. At the top of the stack, we have the protective cover glass of a mobile device that most consumers have heard of – Corning Gorilla Glass. This cover glass protects and maintains the appearance of the display, and also supports the use of front-facing cameras and various sensors. Often, the rear side of such devices is covered with a similar protective glass, which also allows for wireless charging.

A layer deeper, beneath the surface of the glass cover, are the substrates that serve very specific functions depending on the type of display being created.

Though each layer of the glass stack is formed with the same fusion manufacturing process, the compositions of the glass are different – allowing for different properties and benefits. LCD and OLED displays, whether on mobile devices with glass cover and back or otherwise, utilize different super-thin layers of glass specific to their applications:

Glass substrate with ITO electrodes. The shapes of these electrodes will determine the shapes that will appear when the LCD is switched ON. Vertical ridges etched on the surface are smooth.

A liquid-crystal display (LCD) is a flat-panel display or other electronically modulated optical device that uses the light-modulating properties of liquid crystals combined with polarizers. Liquid crystals do not emit light directlybacklight or reflector to produce images in color or monochrome.seven-segment displays, as in a digital clock, are all good examples of devices with these displays. They use the same basic technology, except that arbitrary images are made from a matrix of small pixels, while other displays have larger elements. LCDs can either be normally on (positive) or off (negative), depending on the polarizer arrangement. For example, a character positive LCD with a backlight will have black lettering on a background that is the color of the backlight, and a character negative LCD will have a black background with the letters being of the same color as the backlight. Optical filters are added to white on blue LCDs to give them their characteristic appearance.

LCDs are used in a wide range of applications, including LCD televisions, computer monitors, instrument panels, aircraft cockpit displays, and indoor and outdoor signage. Small LCD screens are common in LCD projectors and portable consumer devices such as digital cameras, watches, digital clocks, calculators, and mobile telephones, including smartphones. LCD screens are also used on consumer electronics products such as DVD players, video game devices and clocks. LCD screens have replaced heavy, bulky cathode-ray tube (CRT) displays in nearly all applications. LCD screens are available in a wider range of screen sizes than CRT and plasma displays, with LCD screens available in sizes ranging from tiny digital watches to very large television receivers. LCDs are slowly being replaced by OLEDs, which can be easily made into different shapes, and have a lower response time, wider color gamut, virtually infinite color contrast and viewing angles, lower weight for a given display size and a slimmer profile (because OLEDs use a single glass or plastic panel whereas LCDs use two glass panels; the thickness of the panels increases with size but the increase is more noticeable on LCDs) and potentially lower power consumption (as the display is only "on" where needed and there is no backlight). OLEDs, however, are more expensive for a given display size due to the very expensive electroluminescent materials or phosphors that they use. Also due to the use of phosphors, OLEDs suffer from screen burn-in and there is currently no way to recycle OLED displays, whereas LCD panels can be recycled, although the technology required to recycle LCDs is not yet widespread. Attempts to maintain the competitiveness of LCDs are quantum dot displays, marketed as SUHD, QLED or Triluminos, which are displays with blue LED backlighting and a Quantum-dot enhancement film (QDEF) that converts part of the blue light into red and green, offering similar performance to an OLED display at a lower price, but the quantum dot layer that gives these displays their characteristics can not yet be recycled.

Since LCD screens do not use phosphors, they rarely suffer image burn-in when a static image is displayed on a screen for a long time, e.g., the table frame for an airline flight schedule on an indoor sign. LCDs are, however, susceptible to image persistence.battery-powered electronic equipment more efficiently than a CRT can be. By 2008, annual sales of televisions with LCD screens exceeded sales of CRT units worldwide, and the CRT became obsolete for most purposes.

Each pixel of an LCD typically consists of a layer of molecules aligned between two transparent electrodes, often made of Indium-Tin oxide (ITO) and two polarizing filters (parallel and perpendicular polarizers), the axes of transmission of which are (in most of the cases) perpendicular to each other. Without the liquid crystal between the polarizing filters, light passing through the first filter would be blocked by the second (crossed) polarizer. Before an electric field is applied, the orientation of the liquid-crystal molecules is determined by the alignment at the surfaces of electrodes. In a twisted nematic (TN) device, the surface alignment directions at the two electrodes are perpendicular to each other, and so the molecules arrange themselves in a helical structure, or twist. This induces the rotation of the polarization of the incident light, and the device appears gray. If the applied voltage is large enough, the liquid crystal molecules in the center of the layer are almost completely untwisted and the polarization of the incident light is not rotated as it passes through the liquid crystal layer. This light will then be mainly polarized perpendicular to the second filter, and thus be blocked and the pixel will appear black. By controlling the voltage applied across the liquid crystal layer in each pixel, light can be allowed to pass through in varying amounts thus constituting different levels of gray.

The chemical formula of the liquid crystals used in LCDs may vary. Formulas may be patented.Sharp Corporation. The patent that covered that specific mixture expired.

Most color LCD systems use the same technique, with color filters used to generate red, green, and blue subpixels. The LCD color filters are made with a photolithography process on large glass sheets that are later glued with other glass sheets containing a TFT array, spacers and liquid crystal, creating several color LCDs that are then cut from one another and laminated with polarizer sheets. Red, green, blue and black photoresists (resists) are used. All resists contain a finely ground powdered pigment, with particles being just 40 nanometers across. The black resist is the first to be applied; this will create a black grid (known in the industry as a black matrix) that will separate red, green and blue subpixels from one another, increasing contrast ratios and preventing light from leaking from one subpixel onto other surrounding subpixels.Super-twisted nematic LCD, where the variable twist between tighter-spaced plates causes a varying double refraction birefringence, thus changing the hue.

LCD in a Texas Instruments calculator with top polarizer removed from device and placed on top, such that the top and bottom polarizers are perpendicular. As a result, the colors are inverted.

The optical effect of a TN device in the voltage-on state is far less dependent on variations in the device thickness than that in the voltage-off state. Because of this, TN displays with low information content and no backlighting are usually operated between crossed polarizers such that they appear bright with no voltage (the eye is much more sensitive to variations in the dark state than the bright state). As most of 2010-era LCDs are used in television sets, monitors and smartphones, they have high-resolution matrix arrays of pixels to display arbitrary images using backlighting with a dark background. When no image is displayed, different arrangements are used. For this purpose, TN LCDs are operated between parallel polarizers, whereas IPS LCDs feature crossed polarizers. In many applications IPS LCDs have replaced TN LCDs, particularly in smartphones. Both the liquid crystal material and the alignment layer material contain ionic compounds. If an electric field of one particular polarity is applied for a long period of time, this ionic material is attracted to the surfaces and degrades the device performance. This is avoided either by applying an alternating current or by reversing the polarity of the electric field as the device is addressed (the response of the liquid crystal layer is identical, regardless of the polarity of the applied field).

Displays for a small number of individual digits or fixed symbols (as in digital watches and pocket calculators) can be implemented with independent electrodes for each segment.alphanumeric or variable graphics displays are usually implemented with pixels arranged as a matrix consisting of electrically connected rows on one side of the LC layer and columns on the other side, which makes it possible to address each pixel at the intersections. The general method of matrix addressing consists of sequentially addressing one side of the matrix, for example by selecting the rows one-by-one and applying the picture information on the other side at the columns row-by-row. For details on the various matrix addressing schemes see passive-matrix and active-matrix addressed LCDs.

LCDs, along with OLED displays, are manufactured in cleanrooms borrowing techniques from semiconductor manufacturing and using large sheets of glass whose size has increased over time. Several displays are manufactured at the same time, and then cut from the sheet of glass, also known as the mother glass or LCD glass substrate. The increase in size allows more displays or larger displays to be made, just like with increasing wafer sizes in semiconductor manufacturing. The glass sizes are as follows:

Until Gen 8, manufacturers would not agree on a single mother glass size and as a result, different manufacturers would use slightly different glass sizes for the same generation. Some manufacturers have adopted Gen 8.6 mother glass sheets which are only slightly larger than Gen 8.5, allowing for more 50 and 58 inch LCDs to be made per mother glass, specially 58 inch LCDs, in which case 6 can be produced on a Gen 8.6 mother glass vs only 3 on a Gen 8.5 mother glass, significantly reducing waste.AGC Inc., Corning Inc., and Nippon Electric Glass.

The origins and the complex history of liquid-crystal displays from the perspective of an insider during the early days were described by Joseph A. Castellano in Liquid Gold: The Story of Liquid Crystal Displays and the Creation of an Industry.IEEE History Center.Peter J. Wild, can be found at the Engineering and Technology History Wiki.

In 1888,Friedrich Reinitzer (1858–1927) discovered the liquid crystalline nature of cholesterol extracted from carrots (that is, two melting points and generation of colors) and published his findings at a meeting of the Vienna Chemical Society on May 3, 1888 (F. Reinitzer: Beiträge zur Kenntniss des Cholesterins, Monatshefte für Chemie (Wien) 9, 421–441 (1888)).Otto Lehmann published his work "Flüssige Kristalle" (Liquid Crystals). In 1911, Charles Mauguin first experimented with liquid crystals confined between plates in thin layers.

In 1922, Georges Friedel described the structure and properties of liquid crystals and classified them in three types (nematics, smectics and cholesterics). In 1927, Vsevolod Frederiks devised the electrically switched light valve, called the Fréedericksz transition, the essential effect of all LCD technology. In 1936, the Marconi Wireless Telegraph company patented the first practical application of the technology, "The Liquid Crystal Light Valve". In 1962, the first major English language publication Molecular Structure and Properties of Liquid Crystals was published by Dr. George W. Gray.RCA found that liquid crystals had some interesting electro-optic characteristics and he realized an electro-optical effect by generating stripe-patterns in a thin layer of liquid crystal material by the application of a voltage. This effect is based on an electro-hydrodynamic instability forming what are now called "Williams domains" inside the liquid crystal.

In 1964, George H. Heilmeier, then working at the RCA laboratories on the effect discovered by Williams achieved the switching of colors by field-induced realignment of dichroic dyes in a homeotropically oriented liquid crystal. Practical problems with this new electro-optical effect made Heilmeier continue to work on scattering effects in liquid crystals and finally the achievement of the first operational liquid-crystal display based on what he called the George H. Heilmeier was inducted in the National Inventors Hall of FameIEEE Milestone.

In the late 1960s, pioneering work on liquid crystals was undertaken by the UK"s Royal Radar Establishment at Malvern, England. The team at RRE supported ongoing work by George William Gray and his team at the University of Hull who ultimately discovered the cyanobiphenyl liquid crystals, which had correct stability and temperature properties for application in LCDs.

The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968.dynamic scattering mode (DSM) LCD that used standard discrete MOSFETs.

On December 4, 1970, the twisted nematic field effect (TN) in liquid crystals was filed for patent by Hoffmann-LaRoche in Switzerland, (Swiss patent No. 532 261) with Wolfgang Helfrich and Martin Schadt (then working for the Central Research Laboratories) listed as inventors.Brown, Boveri & Cie, its joint venture partner at that time, which produced TN displays for wristwatches and other applications during the 1970s for the international markets including the Japanese electronics industry, which soon produced the first digital quartz wristwatches with TN-LCDs and numerous other products. James Fergason, while working with Sardari Arora and Alfred Saupe at Kent State University Liquid Crystal Institute, filed an identical patent in the United States on April 22, 1971.ILIXCO (now LXD Incorporated), produced LCDs based on the TN-effect, which soon superseded the poor-quality DSM types due to improvements of lower operating voltages and lower power consumption. Tetsuro Hama and Izuhiko Nishimura of Seiko received a US patent dated February 1971, for an electronic wristwatch incorporating a TN-LCD.

In 1972, the concept of the active-matrix thin-film transistor (TFT) liquid-crystal display panel was prototyped in the United States by T. Peter Brody"s team at Westinghouse, in Pittsburgh, Pennsylvania.Westinghouse Research Laboratories demonstrated the first thin-film-transistor liquid-crystal display (TFT LCD).high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.active-matrix liquid-crystal display (AM LCD) in 1974, and then Brody coined the term "active matrix" in 1975.

In 1972 North American Rockwell Microelectronics Corp introduced the use of DSM LCDs for calculators for marketing by Lloyds Electronics Inc, though these required an internal light source for illumination.Sharp Corporation followed with DSM LCDs for pocket-sized calculators in 1973Seiko and its first 6-digit TN-LCD quartz wristwatch, and Casio"s "Casiotron". Color LCDs based on Guest-Host interaction were invented by a team at RCA in 1968.TFT LCDs similar to the prototypes developed by a Westinghouse team in 1972 were patented in 1976 by a team at Sharp consisting of Fumiaki Funada, Masataka Matsuura, and Tomio Wada,

In 1983, researchers at Brown, Boveri & Cie (BBC) Research Center, Switzerland, invented the passive matrix-addressed LCDs. H. Amstutz et al. were listed as inventors in the corresponding patent applications filed in Switzerland on July 7, 1983, and October 28, 1983. Patents were granted in Switzerland CH 665491, Europe EP 0131216,

The first color LCD televisions were developed as handheld televisions in Japan. In 1980, Hattori Seiko"s R&D group began development on color LCD pocket televisions.Seiko Epson released the first LCD television, the Epson TV Watch, a wristwatch equipped with a small active-matrix LCD television.dot matrix TN-LCD in 1983.Citizen Watch,TFT LCD.computer monitors and LCD televisions.3LCD projection technology in the 1980s, and licensed it for use in projectors in 1988.compact, full-color LCD projector.

In 1990, under different titles, inventors conceived electro optical effects as alternatives to twisted nematic field effect LCDs (TN- and STN- LCDs). One approach was to use interdigital electrodes on one glass substrate only to produce an electric field essentially parallel to the glass substrates.Germany by Guenter Baur et al. and patented in various countries.Hitachi work out various practical details of the IPS technology to interconnect the thin-film transistor array as a matrix and to avoid undesirable stray fields in between pixels.

Hitachi also improved the viewing angle dependence further by optimizing the shape of the electrodes (Super IPS). NEC and Hitachi become early manufacturers of active-matrix addressed LCDs based on the IPS technology. This is a milestone for implementing large-screen LCDs having acceptable visual performance for flat-panel computer monitors and television screens. In 1996, Samsung developed the optical patterning technique that enables multi-domain LCD. Multi-domain and In Plane Switching subsequently remain the dominant LCD designs through 2006.South Korea and Taiwan,

In 2007 the image quality of LCD televisions surpassed the image quality of cathode-ray-tube-based (CRT) TVs.LCD TVs were projected to account 50% of the 200 million TVs to be shipped globally in 2006, according to Displaybank.Toshiba announced 2560 × 1600 pixels on a 6.1-inch (155 mm) LCD panel, suitable for use in a tablet computer,transparent and flexible, but they cannot emit light without a backlight like OLED and microLED, which are other technologies that can also be made flexible and transparent.

In 2016, Panasonic developed IPS LCDs with a contrast ratio of 1,000,000:1, rivaling OLEDs. This technology was later put into mass production as dual layer, dual panel or LMCL (Light Modulating Cell Layer) LCDs. The technology uses 2 liquid crystal layers instead of one, and may be used along with a mini-LED backlight and quantum dot sheets.

Since LCDs produce no light of their own, they require external light to produce a visible image.backlight. Active-matrix LCDs are almost always backlit.Transflective LCDs combine the features of a backlit transmissive display and a reflective display.

CCFL: The LCD panel is lit either by two cold cathode fluorescent lamps placed at opposite edges of the display or an array of parallel CCFLs behind larger displays. A diffuser (made of PMMA acrylic plastic, also known as a wave or light guide/guiding plateinverter to convert whatever DC voltage the device uses (usually 5 or 12 V) to ≈1000 V needed to light a CCFL.

EL-WLED: The LCD panel is lit by a row of white LEDs placed at one or more edges of the screen. A light diffuser (light guide plate, LGP) is then used to spread the light evenly across the whole display, similarly to edge-lit CCFL LCD backlights. The diffuser is made out of either PMMA plastic or special glass, PMMA is used in most cases because it is rugged, while special glass is used when the thickness of the LCD is of primary concern, because it doesn"t expand as much when heated or exposed to moisture, which allows LCDs to be just 5mm thick. Quantum dots may be placed on top of the diffuser as a quantum dot enhancement film (QDEF, in which case they need a layer to be protected from heat and humidity) or on the color filter of the LCD, replacing the resists that are normally used.

WLED array: The LCD panel is lit by a full array of white LEDs placed behind a diffuser behind the panel. LCDs that use this implementation will usually have the ability to dim or completely turn off the LEDs in the dark areas of the image being displayed, effectively increasing the contrast ratio of the display. The precision with which this can be done will depend on the number of dimming zones of the display. The more dimming zones, the more precise the dimming, with less obvious blooming artifacts which are visible as dark grey patches surrounded by the unlit areas of the LCD. As of 2012, this design gets most of its use from upscale, larger-screen LCD televisions.

RGB-LED array: Similar to the WLED array, except the panel is lit by a full array of RGB LEDs. While displays lit with white LEDs usually have a poorer color gamut than CCFL lit displays, panels lit with RGB LEDs have very wide color gamuts. This implementation is most popular on professional graphics editing LCDs. As of 2012, LCDs in this category usually cost more than $1000. As of 2016 the cost of this category has drastically reduced and such LCD televisions obtained same price levels as the former 28" (71 cm) CRT based categories.

Monochrome LEDs: such as red, green, yellow or blue LEDs are used in the small passive monochrome LCDs typically used in clocks, watches and small appliances.

Mini-LED: Backlighting with Mini-LEDs can support over a thousand of Full-area Local Area Dimming (FLAD) zones. This allows deeper blacks and higher contrast ratio.MicroLED.)

Today, most LCD screens are being designed with an LED backlight instead of the traditional CCFL backlight, while that backlight is dynamically controlled with the video information (dynamic backlight control). The combination with the dynamic backlight control, invented by Philips researchers Douglas Stanton, Martinus Stroomer and Adrianus de Vaan, simultaneously increases the dynamic range of the display system (also marketed as HDR, high dynamic range television or FLAD, full-area local area dimming).

The LCD backlight systems are made highly efficient by applying optical films such as prismatic structure (prism sheet) to gain the light into the desired viewer directions and reflective polarizing films that recycle the polarized light that was formerly absorbed by the first polarizer of the LCD (invented by Philips researchers Adrianus de Vaan and Paulus Schaareman),

Due to the LCD layer that generates the desired high resolution images at flashing video speeds using very low power electronics in combination with LED based backlight technologies, LCD technology has become the dominant display technology for products such as televisions, desktop monitors, notebooks, tablets, smartphones and mobile phones. Although competing OLED technology is pushed to the market, such OLED displays do not feature the HDR capabilities like LCDs in combination with 2D LED backlight technologies have, reason why the annual market of such LCD-based products is still growing faster (in volume) than OLED-based products while the efficiency of LCDs (and products like p

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey