lcd screen damage causes supplier

Accidental Damage is any damage due to an unintentional act that is not the direct result of a manufacturing defect or failure. Accidental damage is not covered under the standard warranty of the product. Such damage is often the result of a drop or an impact on the LCD screen or any other part of the product which may render the device non-functional. Such types of damage are only covered under an Accidental Damage service offering which is an optional add-on to the basic warranty of the product. Accidental Damage must not be confused with an occasional dead or stuck pixel on the LCD panel. For more information about dead or stuck pixels, see the Dell Display Pixel Guidelines.

No, accidental damage is covered for Dell computers or monitors which are covered under the Accidental Damage Service offering for that specific product.

For more information about Dell Limited Hardware Warranty and Dell"s Accidental Damage service offering, see the Dell Warranty & Support Services page.

NOTE: Other damages may be considered customer induced if determined by Dell Technical Support, an on-site field engineer, or at the mail-in repair center.

The LCD glass on the display is manufactured to rigorous specifications and standards and will not typically crack or break on its own under normal use. In general, cracked, or broken glass is considered accidental damage and is not covered under the standard warranty.

Internal cracks typically occur due to excessive force on the screen. This can be the result of some object hitting the screen, a drop, attempting to close the lid while an object is on the keypad area, or even holding the laptop by its screen.

Spots typically occur due to an external force hitting the screen causing damage to the LCD panel"s backlight assembly. While the top layer did not crack or break, the underlying area was compressed and damaged causing this effect.

If your Dell laptop LCD panel has any accidental damage but the laptop is not covered by the Accidental Damage service offering, contact Dell Technical Support for repair options.

Dell monitors cannot be repaired by an on-site field engineer or at the mail-in repair center. If you notice any damage to the monitor, you must purchase a new monitor.

There’re more than 300 procedures to produce TFT LCD. The most advanced LCD, in which the array and cell process are highly automatic. Technically, every step in the process can lead to defects, and most of the defects have been eliminated through the development of TFT LCD technology.

Point defect is a kind of defect that some point on your screen don’t display correctly. There are mainly three situations: the point keeps displaying black or whitewhen the screen is working or the point can only display a single color.

For the first two situations, that’s because the circuit on the TFT and CF controlling that defective pixel point is shorted or broken. While the third situation is caused by damaged color pixel.

In LCD, newton’s rings may occur on screen when two glass substrate haven’t been sealed well, so that one of the glass may form a convex lens and lead to light interference.

You may notice there are some screens have uneven display, which means some white area appears in dark picture or vice versa. We call this ‘mura’, a word originated from Japanese.

Mura is very common but it doesn’t affect the screen function severely, however it still bring bad look. Hence, many high end display manufacturers have their own standards of mura, and the displays without mura are of the best quality.

Among the causes listed, thickness of the whole cell is the most critical one, and there are many factors related to that. Researches provide a lot of advice to adjust the thickness of the whole cell:

Issues with non-conforming performance, where the product no longer meets the performance specification, may be tied to a lack of quality of the components, LCD manufacturing, or in some rarer circumstance a change on the end-product that affected the LCD display.

Additionally there can be mechanical non-conformities, where there are aspects exceeding the defined tolerance as described in the specification. And in some instances, there may be variations not designated in the specification, but quite different from the original qualification units. These non-conformances are capable of affecting the fit, form, or function of the LCD display when assembled.

If your supplier has excessive component variability or possible process variability, there is the potential for a number of LCD display performance-related issues. These issues can be one-off or related to a larger batch of products manufactured together. Good serialization and traceability will help in isolating these occurrences and get to the root cause quickly.

While out-of-the-box nonconformance is typically the responsibility of the supplier, but it becomes a little more ambiguous when the non-conformance is not covered specifically by the governing specification. In this case, common sense and reasonable expectations of variation, the concept of the TEAM is considered. But at the end of the day, the LCD displays need to work in the finished product, and both parties should take the responsibility together to help get to the most efficient solution.

On the other hand, you need to be aware that performance degradation is sometimes caused by a change in another component upstream of the LCD display. Sometimes, a non-display component that is malfunctioning or is incompatible and interfaces with the display may cause the display to exhibit irregular behavior or render it inoperable altogether.

To verify this, swap displays to a fully functioning assembly and see whether the problem follows the display. If the issue does not reappear, the cause is likely a non-LCD display component.

The likelihood of damage, or the display being non-functional from the supplier’s end, is fairly low, as it is standard to test 300%, or three times throughout the process. Additionally, the final packaging itself is subject to drop testing during the initial development phase prior to mass production to ensure a damage-free trip despite your carrier’s best efforts to drop the packaging. That means the defect is likely latent or occurred during installation into the end-product.

This could be a manufacturing issue during the LCD display production or a quality issue with an upstream component that exposed a failure mode. In this case, fault may lie with the design itself, which indicates the need for a more robust design. Alternatively, a burn-in test process may be needed to expose potential defects prior to final inspection.

The final assembly process could also be a problem area. If the process is complicated, difficult to maneuver, or there are new operators involved there is a much higher probability of damage while assembling the LCD display into the end-product.

There is also the potential for misusing the product. A good example of this is using the product in an unintended environment such as extreme moisture. Impact is another unmistakable failure mode as it can manifest itself as a broken touch panel or cracked LCD glass.

Liquid crystal displays (LCDs) are the most widely used display technology. Their applications cover TV, mobile phone, appliances, automotive, smart home, industrial meters, consumer electronics, POS, marine, aerospace, military etc. LCD screen display problem can occur for several reasons.

Effect of environmental conditions on the LCD assembly. Environmental conditions include both the effects of temperature and humidity, and cyclic loading.

Effect of manufacturing process. With the development of LCD for more than 40 years and the modern manufacturing equipment, this kind if defects are getting rear.

Common failures seen in LCDs are a decrease in screen contrast, non-functioning pixels or the whole display, and broken glass. Different kinds of LCD display problem need to have different kinds of fix methods or make the decision not worthwhile to repair.

Broken glassIf you accidently drop the LCD and you find it broken on the surface but the display still works. You might just break the touch panel; you can find a repair house or find a youtube video to replace the touch panel. If you find the display not showing, especially you find the fluid leaking out. You need to reply the whole display modules.

Dim LCD displayLCD can’t emit light itself. It uses backlight. Normally, the backlight is not fully driven, you can increase the LED backlight to make a dim LCD display brighter. But if you LCD display has been used for a long time, it is possible that the LED backlight has to be the end of life (not brightness enough) if you turn on 100% backlight brightness. In that case to fix LCD screen, you have to find a way to change the backlight. For some display, it is an easy job but it can be difficult for other displays depending on the manufacturing process.

LCD has white screen – If a LCD has a white screen which means the backlight is good. Simply check your signal input sources which are the most causes. It can also be caused by the display totally damaged by ESD or excess heat, shock which make the LCD controller broken or the connection failure which has to be repaired by professionals.

Blur ImagesAs the LCD images are made of RGB pixels, the screen shouldn’t be blur like old CRT displays. If you do see blur images, they might be caused by two reasons. 1) LCD has certain response time, if you are playing games or watch fast action movies, some old LCD displays can have image delays. 2) The surface of the LCD is made of a layer of plastic film with maximum hardness of 3H. If you clean the surface often or use the wrong detergent or solvent which cause the surface damage. To fix damage on LED screen it’s need to be changed with professionals.

-If you crack LCD screens and find the liquid crystal leakage, don’t panic. Just remember that the liquid crystal materials might not be more toxic than your detergents for stove or washroom. Just wash your hands with soup throughout. Never try to play with it or even worse to taste it. The liquid of the cracked computer screen will not evaporate, no emissions worries.

-Any electronics has environment impact and can’t be used landfills. If you want to get rid of old LCD monitors or LCD TVs, give them to electronic collection stations. Let’s the professionals to handle them. They will extract some precious metals/parts and make them into something useful or at least not hazard. FYI, liquid crystal materials are retrievable.

However, if the digitizer or LCD is also damaged during a fall, that screen no longer carries value because it cannot be refurbished. Repair shops cannot sell broken LCDs to refurbishing companies; therefore, they cannot offset the cost of an LCD repair. That is why repair stores often charge a little extra if there is damage to the LCD or digitizer, to make up for that loss. Repair stores that don’t have an additional charge for an LCD repair typically inflate their glass repair price to make up for the loss from damaged LCDs. If they have one price, that means everyone is paying more to cover the cost of customers who have damaged LCDs and customers who only have cracked glass. This is why TCR separates the price of glass and LCD repairs for you! If you only have cracked glass, you only have to worry about paying to replace the cracked glass.

If your phone or tablet’s glass is shattered there will be cracks or chips on the screen itself. If it is just the glass that is damaged, the device may still function and you may be able to use it normally. If this is the case, it is likely that only the glass needs to be replaced. To prevent further damage to your device it is best to get it repaired quickly. For example, if liquids seep through the cracks it could cause permanent damage to the LCD.

Many people may continue to use their touchscreen with shattered glass and delay fixing the glass on their devices; however, if the touchscreen isn’t responsive, it could be a sign of more significant damage to the device’s digitizer which is integrated with the LCD screen.

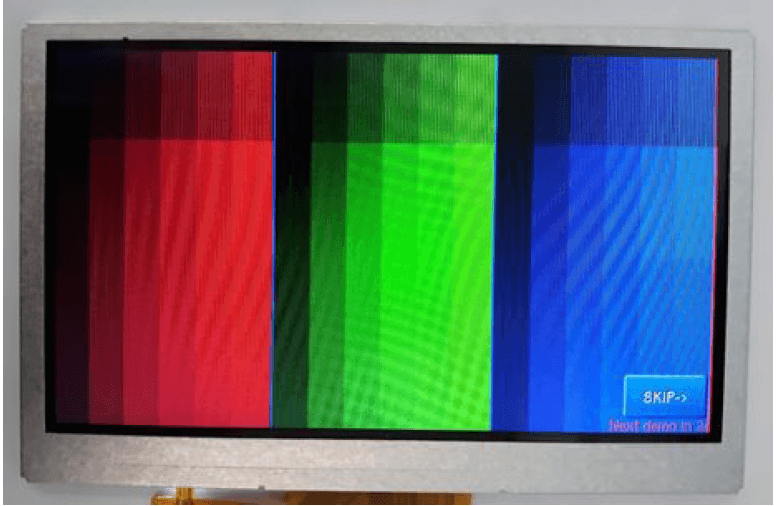

A pixelated screen can indicate LCD damage. This would look like a patch of multicolored dots, a line or lines of discoloration, or a screen with rainbow colors. For many people, these colors are an easy way to know that their LCD is broken and that they should get it repaired.

Dropping your phone isn’t the only reason you’ll end up with a pixelated screen. Over time, your screen’s LCD may break down through regular use. This happens to other devices aside from your smartphone or tablet. Pixelation can happen to TVs and computers, too. People typically decide to buy a new device when this happens. Fortunately, with an LCD repair, you can fix the device without needing to replace it.

A black screen or black spots on your smartphone or tablet is an indication of a damaged LCD. Often with a bad LCD, a phone may still turn on and make noises, but there is no clear picture. This does not necessarily mean any other part of the phone is damaged and a simple screen replacement will get it functioning again. Sometimes it can mean a battery or other internal component is damaged. It is best to have a highly qualified phone repair technician diagnose what is wrong so the appropriate repair can be made.

Fortunately, your mobile device is fixable whether you cracked the glass or damaged the LCD. Stop by or call TCR: Triangle Cellular Repair at (919) 263-2699 for a free diagnostic and quick, affordable cell phone repair in Chapel Hill and surrounding areas. We’re always happy to help!

Yes, it happens. It was 2013 when I had a phone call from BenQ, a multinational manufacturer of LCD monitors. The project manager mentioned that one kind of LCD TV screen they were currently shipping damage. BenQ team looked for a solution from us to prevent broken TV monitors when shipped because defective products are not what any good business would want to do.

It was BenQ’s biggest embarrassment. They had a factory in mainland China and every time certain models of LCD screens were produced, they would be shipped to PChome Taiwan for sale. However, the recent damage rate of the goods had been abnormally high up to nearly 20%. Taking preventive measures, such as adjustment of packaging materials or structure, etc., there is no significant effect.

The situation became increasingly serious and it’s not just that it was BenQ who noticed this problem; customers’ feedback also showed that their LCD TVs were suffering from abnormal damages when delivered to them. Without any big accidents happening during the transportation or delivery process at all – one could only imagine what was going on inside those.

And now, with excessive losses and customers’ claims, BenQ had no idea how to do and kept seeking solutions from others, finally, they notice Impact Label through others’ introductions and heard that the label can reduce damage rates by 40-60%.

We had conducted a study on what type of shock can affect the LCD screen and how much damage it entails. We first put types of indicators labels in the box of the LCD panel in order to determine how much force damage would occur during regular shipment and transit.

According to the results of the test, the impact force on the cargo’s bottom is more than the acceleration of 50G, and this impact may damage the screen.

In addition, we observed that these impacts may cause a variety of different damages to screens: scratches on protective glass; or impairing light colors by undergoing color change from long-term use so that they become grayish black patches–which will affect a customer’s viewing experience.

Something wonderful happened. When the Impact Label indicator is in place, the damage rate of products was reduced to 0%. BenQ was enthusiastic and apprehensive, and would like to try a couple more batches.

After several weeks of discussion and debate, BenQ internally decided to adopt an impact monitor to decrease the risk of transportation damage, as the ratio of cargo damage reduced from 20% to 2%. In the next, all package is written “reminder before receipt” on outside the box. Customers can reject shipment if the Impact Label is RED upon arrival.

A study shows the damage rate typically drops by 50% or more when a monitor is in place. The TV screens are rarely damaged in this case, which proves the statement.

From customers’ point of view, the indicator label provides simple reminders of a concealed damage, and the time it takes to process the damaged product after purchase.

As for sellers, the Impact Label reduces the rate of damaged goods and makes business better. More importantly, the cost derived from customer complaints is lower and provides indisputable evidence of mishandling for freight claims.

Managing damage in the supply chain has many options, redesign the package is always the first impression comes to mind, however, it’s more expensive.

In fact, change the handling environment is the fastest and most effective way to solve damaged LCD TV screens, and where Impact Label comes to play! BenQ is not the first user of impact indicators in LCD TV manufacturers. To comply with your LCD TV, our free consultant and free samples for testing are waiting for you.

If you are a business man , no doubt, avoid to the product defects can bring more benefit to you, so, how to avoid products defectives ? If you do lcd business , pls read on !

Have you ever met some problems when you got your parcel and check your lcd,(such as the touch , the show problem, etc..) when you"re complaining about the poor quality ,maybe lcd broken, if you are not professional person, you will think this is an excuse , beacuse the screen look no cracks, but inner lcd broken is one of the main causes to scarp(means can"t use anymore)

2:Posture of taking/testing lcd, the two side of lcd top place are easy to be broken(when you install or test lcd, pls hold lcd carefully , as the corner of lcd, it will easy to make the lcd inner broken and can"t working)

The inner lcd is fragile and very easy to be broken, In order to reduce broken lcd, hope you can careful when use the lcd screens, hope my text can help you know how to avoid lcd broken .

The new line of 3.5” TFT displays with IPS technology is now available! Three touchscreen options are available: capacitive, resistive, or without a touchscreen.

JUMP! ®, JUMP on Demand®, and Trade-In devices with damage will be assessed at a lower value or require a fee. See your program terms & conditions for details.

The warehouse will check the device condition when we receive it. If it’s damaged, you may receive a reduced trade-in value or be required to pay a fee on your bill statement. (Prepaid customers will have the defective device shipped back instead.)

If the device was sent for in-store pickup, a Mobile Expert will conduct a device condition check. If there"s damage, the Mobile Expert will inform you of your options.

When inspecting a screen, remove any screen protectors and cases first. Tilt the device under good lighting conditions and inspect it at multiple angles. Screen damage includes hairline cracks that are difficult to see.

Mobile devices have a Liquid Damage Indicator (LDI) to show if the device has contacted any liquids. The indicator is white when it"s new, and it turns pink or red when it contacts water.

Wearables like Apple & Samsung watches often don"t have visible LDIs. Check for moisture under the display screen, as well as corrosion, discoloration, and fuzzy growth on the charging connection.

If the device does not fully turn on and load the home screen or if it cannot stay on without being connected to a charger, it"s considered not able to turn on.

No matter how careful you are, accidents happen. Screen damage and liquid damage are not covered under the warranty, so T-Mobile can"t exchange devices with this damage. But, we don’t want you to be stuck with a broken phone, so you have two options to replace or repair your damaged device:

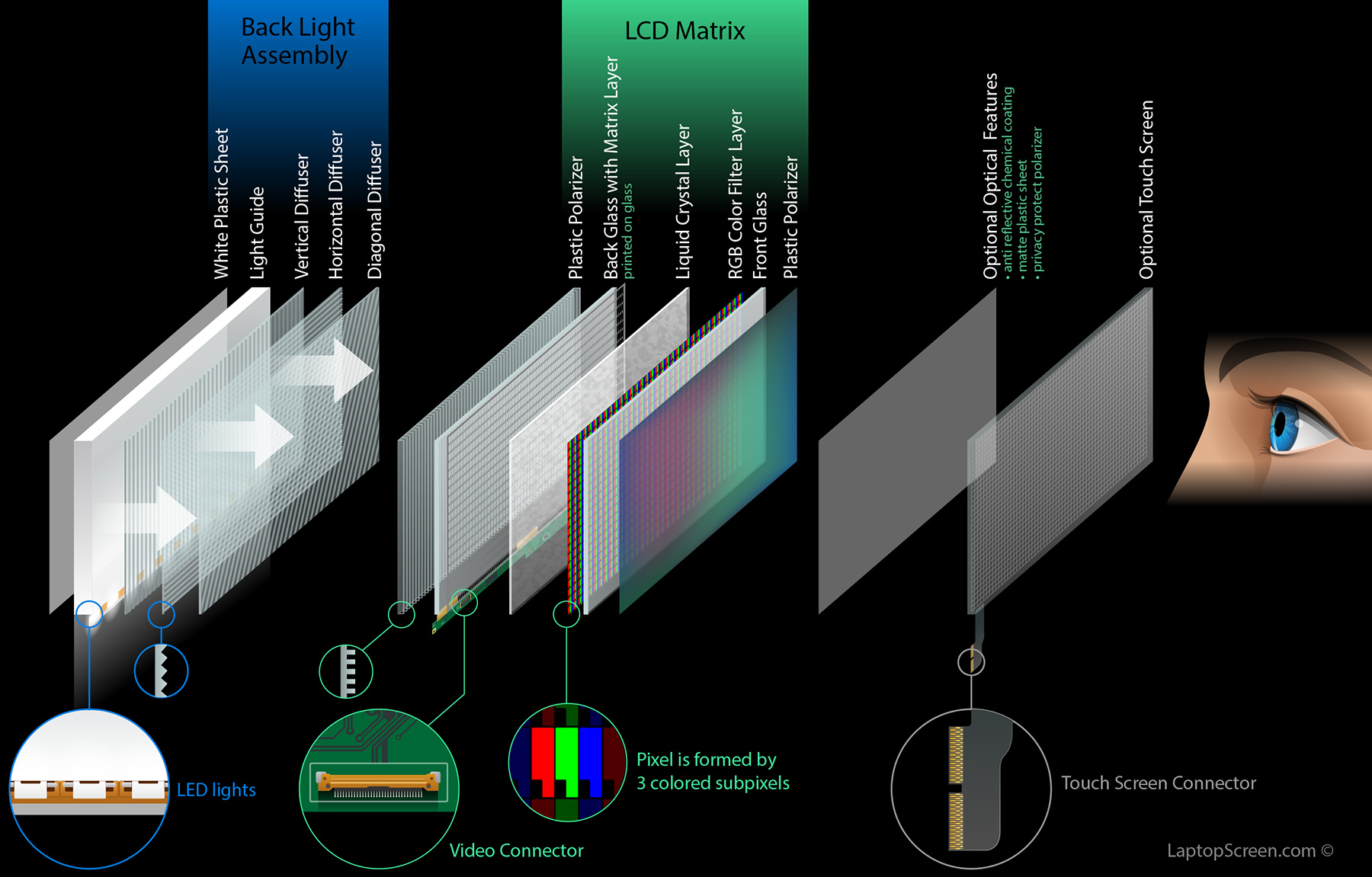

Liquid Crystal Display is a kind of screen filled with a polarizing fluid between two glass plates. This liquid is an electrically controlled fluid trapped between two transparent polarizing sheets. The polarizing axes of the two sheets are aligned perpendicular to each other. The polarizing liquid is filled in cells which have electrical contacts to permit the entry of electrical field into the cells. When an electric field is applied, the molecules in the liquid align themselves with the field, inhibiting rotation of the polarized light. As the light hits the polarizing sheet perpendicular to the direction of polarization, all the light is absorbed and the cell appears dark.

The whole display has array of segments calledPixels which may be coloured or monochrome or both. The pixels may be divided into Sub pixels of Red, Green, and Blue by additional filters as in the case of LCD TV. These pixels are arranged in front of a light source with a reflector. Each sub pixel can be controlled independently to produce thousands or millions possible colors for each pixel. The liquid crystal makes the light to pass through the other by twisting the polarization of light entering one filter. By applying a small electric charge to transparent electrodes over each pixels or sub pixels, the molecules of the liquid crystal are twisted by electrostatic forces. This reorientation of the liquid crystal makes the image.

LCD screen is too sensitive to mechanical shocks and heat , since the pressure may squeeze the fluid present in between the plates which can cause its permanent damage. Excessive heat can change the physical properties of the liquid so some part of the screen may damage and appear as black spots or segments.

The concept of liquid crystal display was first found out by Otto Lehmann in 1904. In1911, Charles Mauguin described structure and properties of Liquid Crystal. The first operational LCD was introduced in 1968 by George Heilhemer.

The Transmissive LCD is illuminated from one side and viewed from the opposite side. Activated cells appear dark and inactive cells appear bright. One disadvantage of transmissive LCD is that lamp used to illuminate the LCD consumes more power than consumed by the LCD itself.

Television LCD is the most advance technology that uses active matrix LCD. Here a matrix of Thin-film transistors (TFT) is added to the polarizing and color filters. It is used to rapidly switch the LCD’s pixels on and off. Each pixel of the LCD has its own dedicated transistor. This transistor allows each column line to access one pixel. When a row line is activated, all the column lines are connected to a row of pixels and the correct voltage is driven onto all of the column lines. The row line then is deactivated and the next row line is activated. All of the row lines are thus activated in sequence.

A very faint or dim image can be seen on the screen, with the brightness controls turned up, but the image is not bright enough to be usable. This issue is very common with CCFL (Cold Cathode Fluorescent Lamp) type screens. The majority of the time that this occurs with a CCFL, the LCD screen inverter is to blame. The inverter powers the backlight in the screen and if it malfunctions, the screen will stay dim. In the remainder of the cases, the florescent bulb may fail to light up causing the screen to stay dim even with a good working LCD inverter.

Replacing the LCD inverter is the most inexpensive place to start, but because there are many different LCD screens and LCD inverters, finding an LCD inverter that is compatible with your screen can prove to be difficult. Also, if the LCD screen turns out to be the problem, then you could waste time and money on the LCD inverter. To avoid this problem, I suggest buying a LCD screen with the compatible LCD inverter included.

For most customers, visiting a professional repair provider with certified technicians who use genuine Apple parts is the safest and most reliable way to get a repair. These providers include Apple and Apple Authorized Service Providers, and Independent Repair Providers, who have access to genuine Apple parts.* Repairs performed by untrained individuals using nongenuine parts might affect the safety of the device or functionality of the display. Apple displays are designed to fit precisely within the device. Additionally, repairs that don"t properly replace screws or cowlings might leave behind loose parts that could damage the battery, cause overheating, or result in injury.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey